SIHGA PICK User manual

Instruction for load attechment PICK

Original

Product name:Pick

Product group: Load attachment

Drawing number: B-00223

Serial numbers: ……………………………………………….

Year of Manufacture: .............……..

SIHGA®PICK

2 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

Contents

1 Foreword............................................................................................................................3

2 Safety information..............................................................................................................4

2.1 General safety information...........................................................................................4

2.2 Prerequisites for use ....................................................................................................4

3 Correct use.........................................................................................................................4

3.1 Lifting process ..............................................................................................................4

3.2 Lifting gear....................................................................................................................5

3.3 Wood..............................................................................................................................5

3.4 Drill hole........................................................................................................................5

3.5 Cross laminated timber................................................................................................5

3.6 Solid wood / glue laminated timber .............................................................................5

3.7 Storage........................................................................................................................ ..5

3.8 Accessories...................................................................................................................5

4 Incorrect use ......................................................................................................................6

5 Information about use........................................................................................................6

5.1 Cross laminated timber edge distances.......................................................................6

5.2 Solid wood edge distances............................................................................................6

5.3 Load specifications .......................................................................................................7

6 Using the Pick ..................................................................................................................30

6.1 Attaching.................................................................................................................................30

6.2 Loosening ...............................................................................................................................30

7 Tests.................................................................................................................................31

7.1 Testing before initial commissioning..........................................................................31

7.2 Testing before starting work.......................................................................................31

7.3 Testing / Maintenance.................................................................................................31

8 Annex ...............................................................................................................................32

8.1 Declaration of conformity ...........................................................................................32

8.2 Component name / Spare parts list ...........................................................................33

8.3 Delivery condition........................................................................................................33

8.4 Pick Safty Inspection ..................................................................................................34

8.5 Maintenance log..........................................................................................................36

www.sihga.com Operating Instruction Pick 3

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

1 Foreword

Dear Customer,

You have chosen a Pick, many thanks for your trust in us.

With your new Pick you have chosen a load attachment with proven engineering for numerous applications.

These operating instructions must be carefully read by all users before the first commissioning so that you

get to know your Pick quickly and comprehensively. In this document you will find all the information about

the application, expert checking and maintenance. Your care helps to prevent dangers, reduces repair costs

and down times and increases the reliability and life of the product. If you have any questions or problems

with your Pick, please contact us at SIHGA®GmbH.

These operating instructions are part of the Pick, always keep them close by or store them in the system

case.

In addition to the operating instructions and any accident prevention regulations operating in the country of

use, the acknowledged standards for safe and professional work must also be observed. National statutory

conditions shall have priority over the information provided in these operating instructions.

Producing and forwarding these operating instructions to third parties is only permitted with our consent.

We hope you enjoy the advantages of your Pick.

Yours sincerely,

Your specialist for fastening technology in wood construction SIHGA®GmbH

4 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

2 Safety information

The following safety information must be observed in all cases:

2.1 General safety information

a) The maximum load-bearing capacities stated take safety factors into account according to EN 13155:2009.

b) All persons, who work with the Pick, must know and observe the safety information in the operating

instructions.

c) The manufacturer is not liable for damage arising from non-compliance with the instructions.

d) The Pick has been designed in accordance with the recognised technical safety regulations. However, in

the event of non-compliance with the operating and safety instructions during use, dangers can arise,

which may lead to irreversible injuries or death.

e) If possible, perform a listening test during the lifting process. If there are „cracking noises“, the load must

immediately be placed on the floor and must no longer be raised.

f) Every time a load is lifted, perform a sight inspection as to whether the Pick has a force-locking

connection with the component or has slipped out.

g) With regard to the risk of injury, safety gloves and PSE must be used according to the occupational health

and safety requirements.

h) Warranty and liability claims due to personal injury or material damage are excluded in the event of the

operating instructions being disregarded.

2.2 Prerequisites for use

a) For an appropriate test before first use (Section 7.1)

b) For correct use (Section 3)

c) Use of authorised expert personnel

d) For the specified angles and loads (according to Section 5)

e) For fault-free Pick

f) For successful tests (Section 7.2 and 7.3)

g) Up to 20,000 load changes

3 Correct use

The load attachment exclusively serves the lifting of glue laminated, cross laminated and solid timber carriers (hereinafter referred

to as components) made from spruce, fir, pine and larch. Timber with very strong resin content, such as pine and larch, and grain-cut

attached walls may only be lifted at an angle of ≥ 5° to the drill hole axis and with multiple lines. Only one component may be raised per

lift. The correct use is specified below.

3.1 Lifting process

a) The duration of the lifting process may not be more than a reasonable period for the loading and unloading

process.

b) Use of the Pick and manipulation of the load may be performed exclusively by trained and qualified expert

personnel.

c) Before lifting a component, always ensure that there are no tools or other loose parts on the component.

d) The lifted goods must always be transported slowly and carefully.

e) The load-bearing capacity stated on the device is the maximum load that may be attached. However,

depending on the application, the maximum load must correspond to the load chart in Section 5.3. The

angle of the loading direction in the respective applications must be observed.

f) Standing under a suspended load is not permitted.

g) The user may only start to move a load when they are convinced that the load has been attached correctly.

h) When hanging the Pick, the user must ensure that the Pick can be operated such that the user is not at

risk either from the device itself or from the carrier or the load.

i) The Pick can work in an ambient temperature between –10°C and +80°C. For work under extreme

conditions, the manufacturer should be consulted.

j) The Pick must not come into contact with salt or chlorine.

k) If longer components are transported, the use of two or four Picks is recommended in order to prevent

pendulum movements.

l) The accident prevention and safety requirements for the Pick of the respective country where the Pick is

www.sihga.com Operating Instruction Pick 5

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

used must be observed.

m) Do not leave loads in a raised or tightened condition beyond the period of the manipulation procedure.

n) The combination of several Picks is only permitted on one surface of the component.

o) In the event of malfunctions, the Pick must immediately be switched off.

3.2 Lifting gear

a) Only suitable lifting gear may be used.

3.3 Wood

a) The component to be lifted may have a wood moisture content of 10 to 20%.

b) The component must be free from cracks and loose knots in in a radius of 25 cm around the drill hole.

c) For components with a supporting effect when installed, the drill holes must be arranged according to

statics and if necessary must be omitted.

3.4 Drill hole

a) The drill hole must have a diameter of 50 mm -0,0/+1,0 mm tolerance and a depth of at least 70 mm.

b) The drill hole must be clean and protected against weathering influences such as frost, rain and snow.

c) The drill hole must not have any coating, paints or greases.

d) The Pick must be countersunk to the stop of the base ring in the drill hole.The downside of the base ring must rest on

the entire surface.

e) The drill hole must not be used for lifting more than six times.

f) The drill hole axis must always be aligned less than 90° to the surface of the component.

g) The drill hole may only be drilled by a qualified person. The quality of the drill hole must be checked before lifting.

h) The drill hole needs to have appropriate quality otherwise the hole needs to be drilled again on site.

3.5 Cross laminated timber

a) The edge distances according to Section 5.1 must be observed.

b) For grain-cut drill holes in cross laminate timber panels, the end-grain proportion must be max. 40 mm.

3.6 Solid wood / Glue laminated timber

a) The axis of a drill hole in solid wood must not be less than 90° to the direction of grain.

b) The material thickness of the component to be lifted must not be less than 6 cm.

c) The carrier width must not be less than 8 cm.

3.7 Storage

a) To prevent corrosion, the Pick must exclusively be stored dry.

b) If the Pick is exposed to moisture, it must be ensured that the Pick is dried as quickly as possible. In

particular, the inner mechanics must be checked.

c) The Pick must be stored at all times so that damage to the Pick and injuries to persons are prevented.

(Use of the supplied system case is recommended).

d) The Pick must be protected from dirt.

3.8 Accessories

a) The supplied shackle DIN EN 13889 (bow shackle with eye bolts) may only be replaced by an equivalent.

The minimum load-bearing capacity of the load attachment must never be undercut. The threaded

securing bolt must be used.

b) It is recommended that the supplied auger is used for the precise creation of the drill hole.

6 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

4 Incorrect use

a) The load-bearing capacity of the load attachment must not be exceeded.

b) No changes may be made to the Pick or its technical documentation.

c) The use of the Pick to transport persons is prohibited.

d) When transporting the load, pendulum movements and collisions with barriers must be avoided.

e) Do not let the Pick fall.

5 Information about use

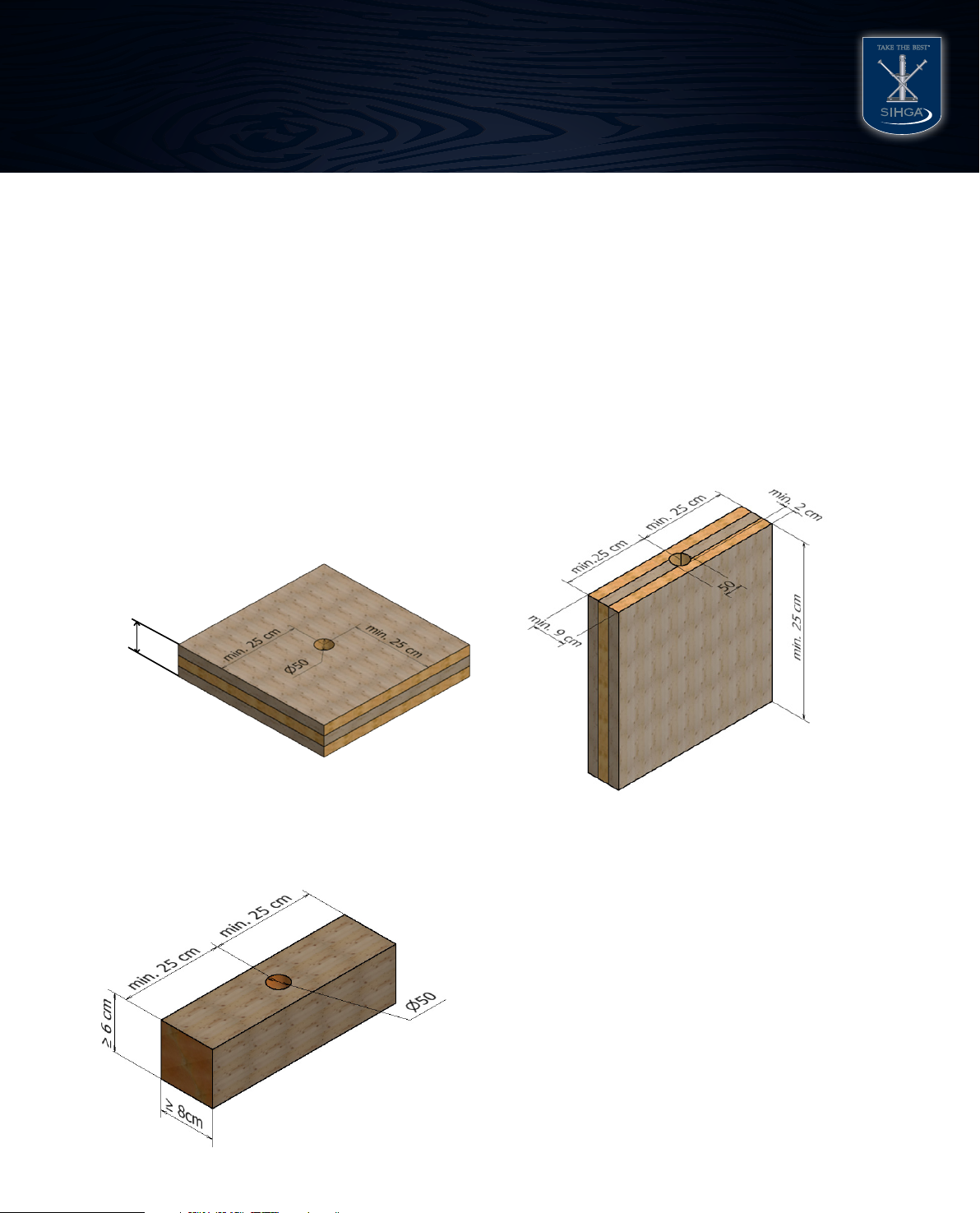

5.1 Cross laminated timber edge distances

5.2 Solid timber edge distances

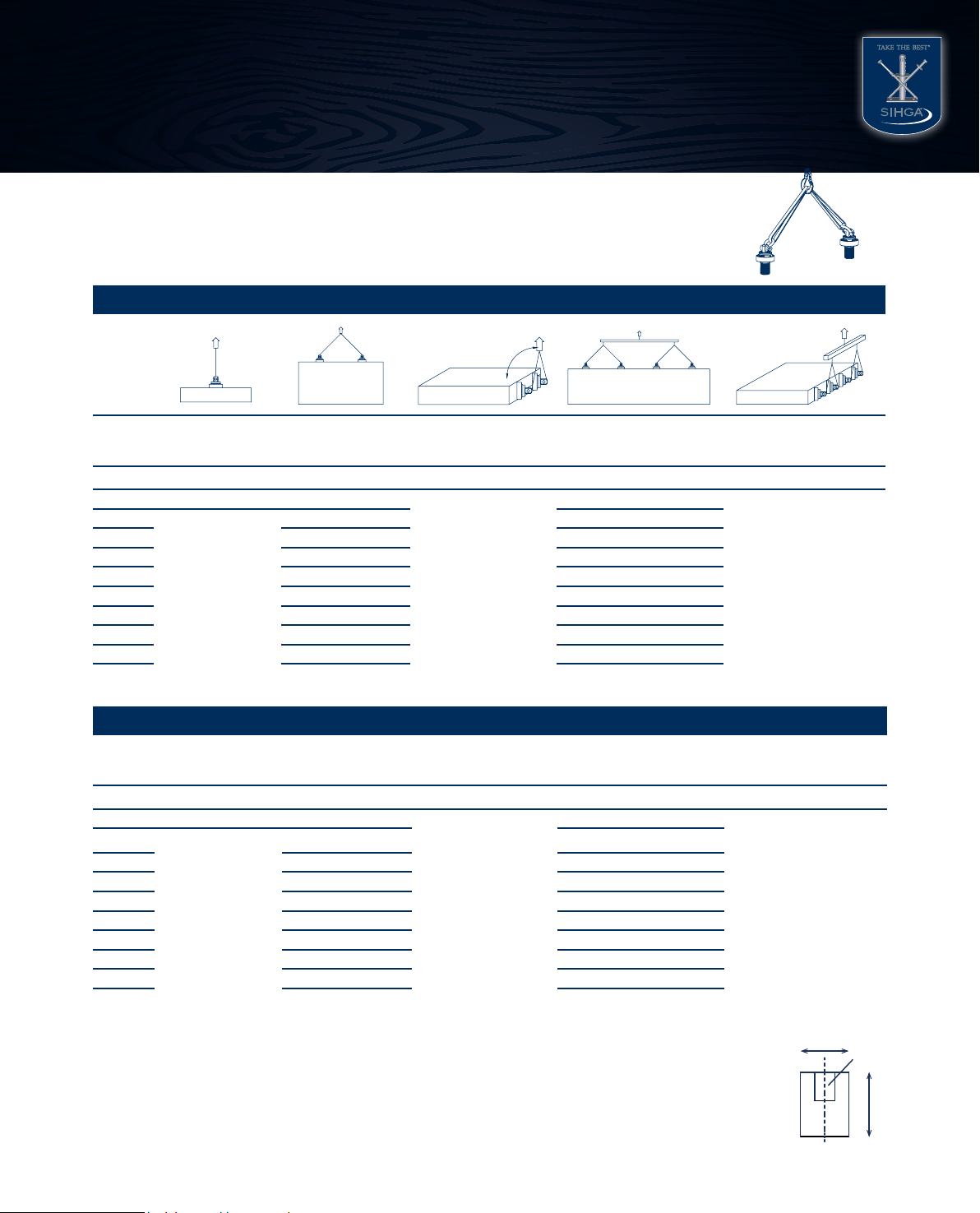

Horizontal Manipulation of cross laminated

timber

Vertical Manipulation of cross laminated

timber

Horizontal Manipulation of glue laminated and solid timber

min. 9cm for lower layer in visual quality

min 7 cm for concealed lower layer

www.sihga.com Operating Instruction Pick 7

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

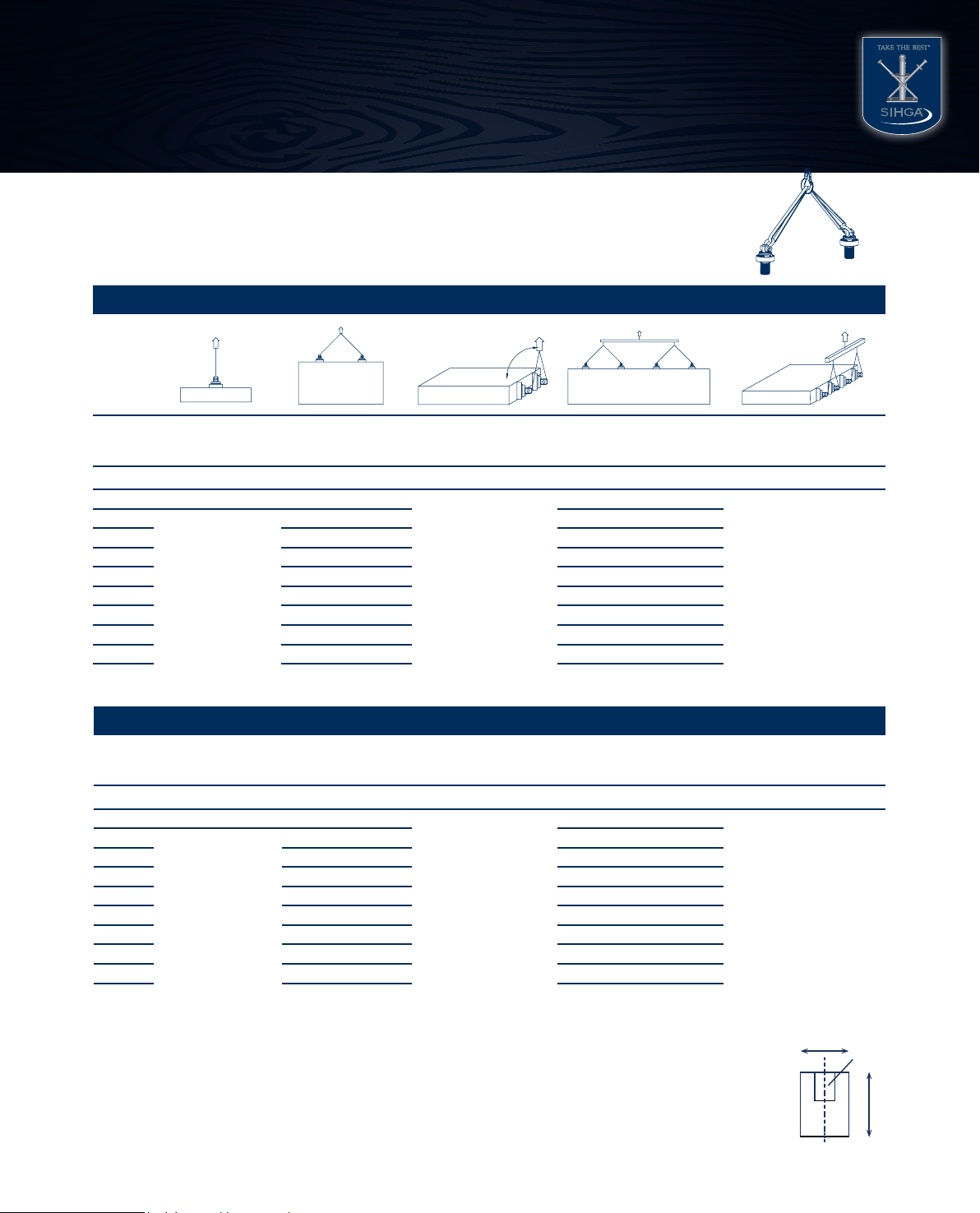

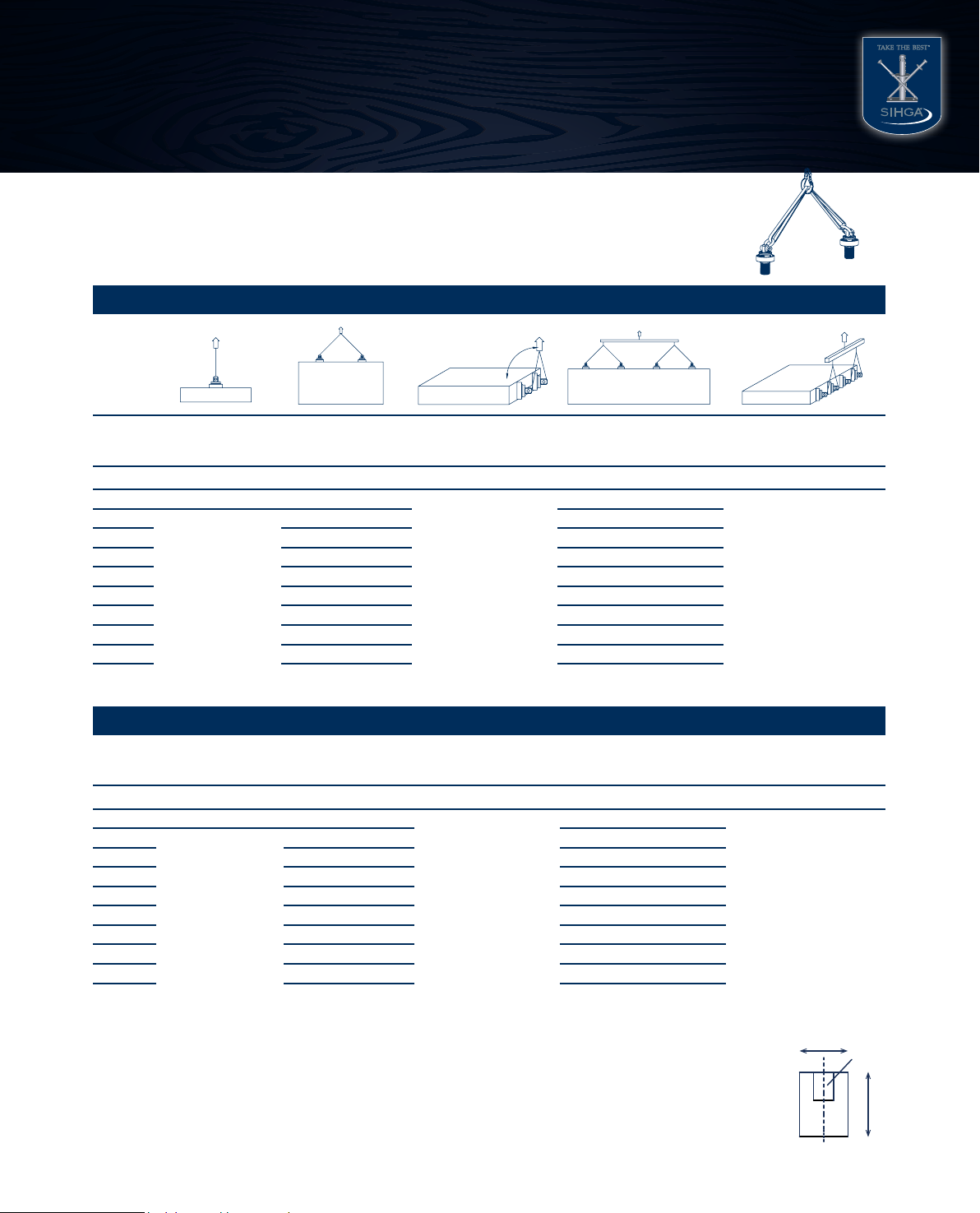

5.3 Load specifications

load specification for framework walls ≥ 8/6 head plate [min.b x h x l = 8 x 6 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 506 1012

693

not permitted

1386

5 939 1879

10 867 1733

15 794 1588

20 721 1443

25 649 1297

30 576 1152

35 503 1007

40 431 861

45 358 716

90°

load specification for framework walls ≥ 10/6 head plate [min.b x h x l = 10 x 6 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 623 1246

693

not permitted

1386

5 1210 2420

10 1174 2349

15 1139 2277

20 1103 2206

25 1067 2134

30 1031 2063

35 996 1991

40 960 1920

45 924 1848

traverse sling

= 0° = 45°

*Highly resinous timber like pine and larch or walls, mounted at the front side, may only be lifted at an angle of ≥ 5° to the borehole axis and with 2

attachment points.

The minimum distance to the surface layer while fastening plates at the front face is min. 2 cm.

The minimum distance between each attachment point equals 50 cm.

The minimum distance between attachment points and beam and plate edge may not be smaller than 25 cm.

Attention: the distance of the posts at framework walls ist not permitted to be larger than 62,5 cm.

The operator is responsible for sufficient power transfer from head plate to posts. SIHGA takes on no liability.

max. = total weight /2 max. = total weight/2

b

h

drill hole

8 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

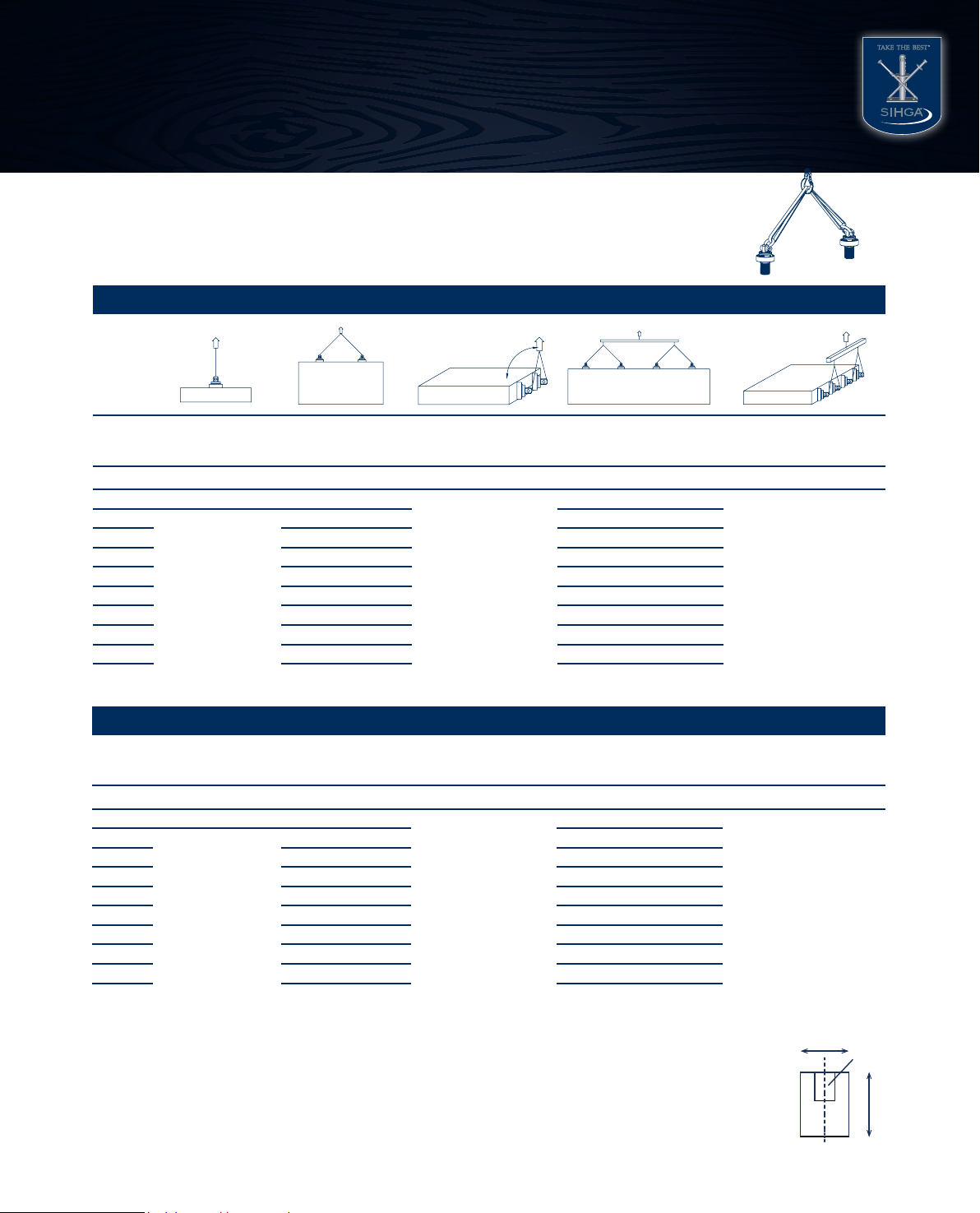

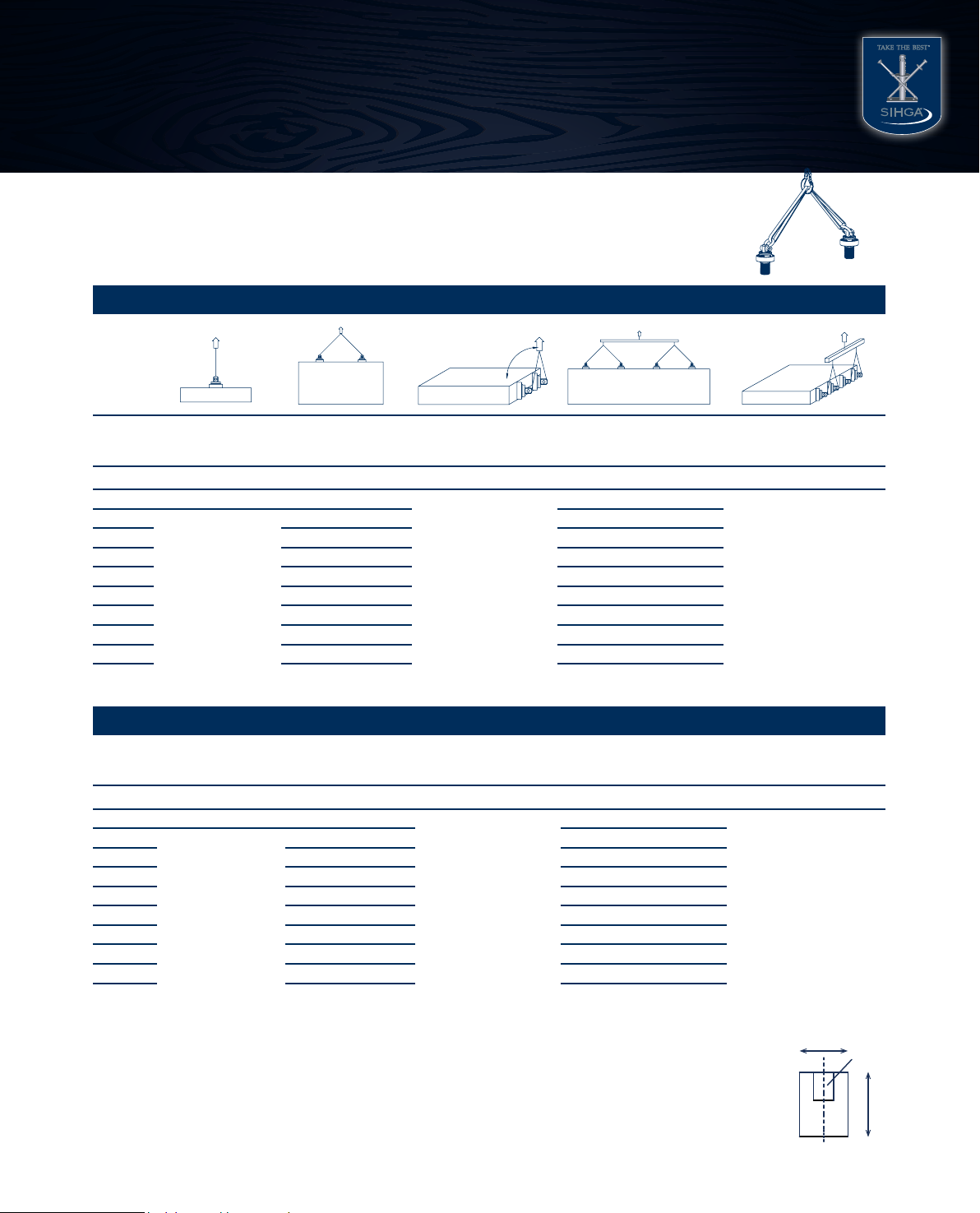

load specification for framework walls ≥ 14/6 head plate [min.b x h x l = 14 x 6 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 900 1800

947

not permitted

1894

5 1752 3504

10 1704 3409

15 1657 3313

20 1609 3218

25 1561 3122

30 1513 3027

35 1466 2931

40 1418 2836

45 1370 2740

90°

load specification for framework walls ≥ 10/8 head plate [min.b x h x l = 10 x 8 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 660 1320

960

not permitted

1920

5 1278 2556

10 1236 2472

15 1194 2388

20 1152 2304

25 1110 2220

30 1068 2136

35 1026 2052

40 984 1968

45 942 1884

= 0° = 45°

traverse sling

*Highly resinous timber like pine and larch or walls, mounted at the front side, may only be lifted at an angle of ≥ 5° to the borehole axis and with 2

attachment points.

The minimum distance to the surface layer while fastening plates at the front face is min. 2 cm.

The minimum distance between each attachment point equals 50 cm.

The minimum distance between attachment points and beam and plate edge may not be smaller than 25 cm.

Attention: the distance of the posts at framework walls ist not permitted to be larger than 62,5 cm.

The operator is responsible for sufficient power transfer from head plate to posts. SIHGA takes on no liability.

max. = total weight /2 max. = total weight/2

b

h

drill hole

www.sihga.com Operating Instruction Pick 9

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

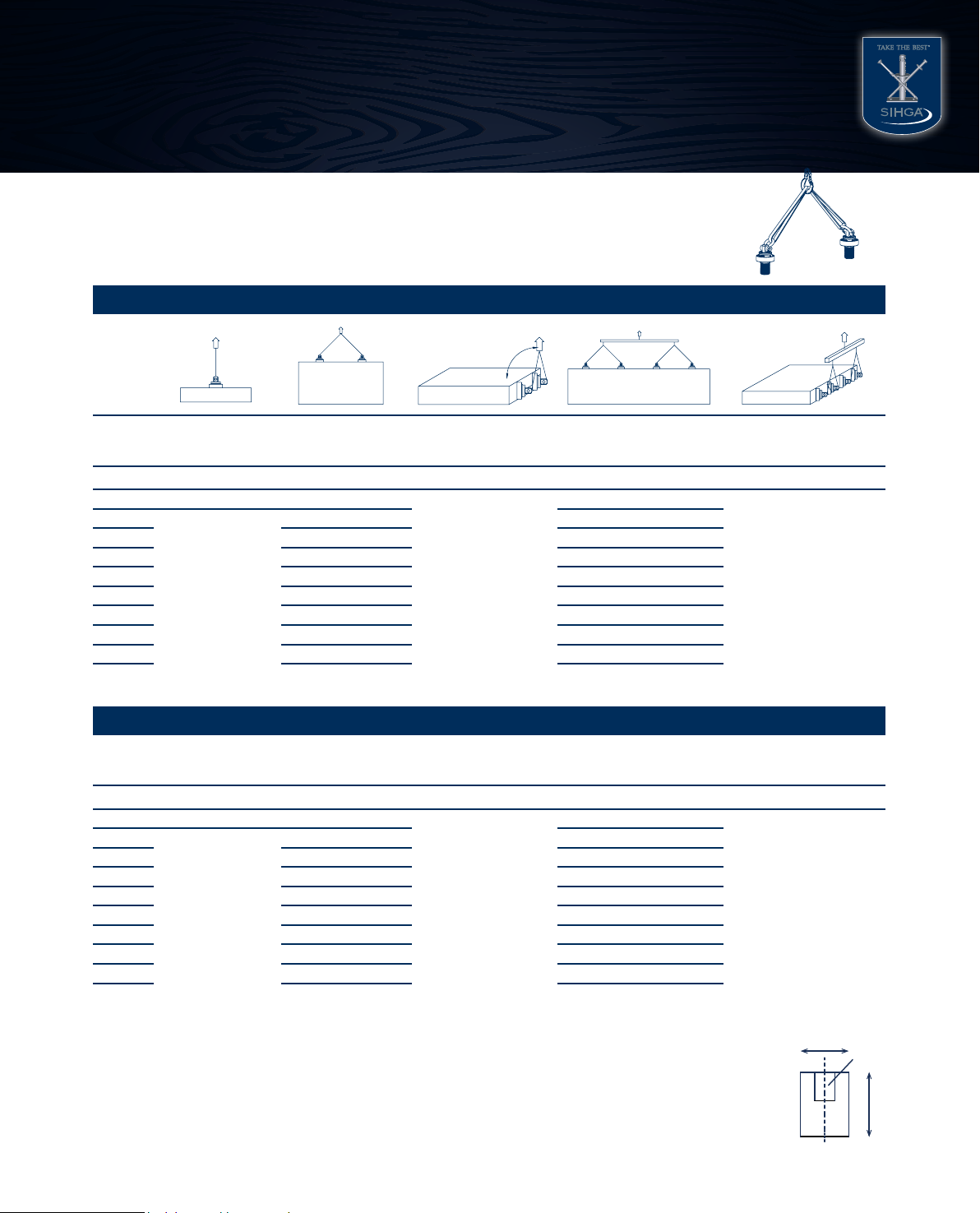

load specification for framework walls ≥ 14/8 head plate [min.b x h x l = 14 x 8 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 900 1800

1500

not permitted

3000

5 1752 3504

10 1704 3409

15 1657 3313

20 1609 3218

25 1561 3122

30 1513 3027

35 1466 2931

40 1418 2836

45 1370 2740

load specification for framework walls ≥ 8/10 head plate [min.b x h x l = 8 x 10 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total wight] [kg total wight] [kg total wight] [kg total wight] [kg total wight]

0 660 1320

827

not permitted

1654

5 1280 2559

10 1239 2478

15 1199 2397

20 1158 2316

25 1118 2236

30 1077 2155

35 1037 2074

40 996 1993

45 956 1912

90°

= 0° = 45°

traverse sling

*Highly resinous timber like pine and larch or walls, mounted at the front side, may only be lifted at an angle of ≥ 5° to the borehole axis and with 2

attachment points.

The minimum distance to the surface layer while fastening plates at the front face is min. 2 cm.

The minimum distance between each attachment point equals 50 cm.

The minimum distance between attachment points and beam and plate edge may not be smaller than 25 cm.

Attention: the distance of the posts at framework walls ist not permitted to be larger than 62,5 cm.

The operator is responsible for sufficient power transfer from head plate to posts. SIHGA takes on no liability.

max. = total weight /2 max. = total weight/2

b

h

drill hole

10 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

*Highly resinous timber like pine and larch or walls, mounted at the front side, may only be lifted at an angle of ≥ 5° to the borehole axis and with 2

attachment points.

The minimum distance to the surface layer while fastening plates at the front face is min. 2 cm.

The minimum distance between each attachment point equals 50 cm.

The minimum distance between attachment points and beam and plate edge may not be smaller than 25 cm.

Attention: the distance of the posts at framework walls ist not permitted to be larger than 62,5 cm.

The operator is responsible for sufficient power transfer from head plate to posts. SIHGA takes on no liability.

load specification for framework walls ≥ 10/10 head plate [min.b x h x l = 10 x 10 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 827 1654

947

not permitted

1894

5 1580 3160

10 1506 3013

15 1433 2865

20 1359 2718

25 1285 2570

30 1211 2423

35 1138 2275

40 1064 2128

45 990 1980

load specification for framework walls ≥ 12/10 head plate [min.b x h x l = 12 x 10 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total wight] [kg total wight] [kg total wight] [kg total wight] [kg total wight]

0 870 1740

1160

not permitted

2320

5 1657 3313

10 1573 3147

15 1490 2980

20 1407 2813

25 1323 2647

30 1240 2480

35 1157 2313

40 1073 2147

45 990 1980

90°

= 0° = 45°

traverse sling

max. = total weight /2 max. = total weight/2

b

h

drill hole

www.sihga.com Operating Instruction Pick 11

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

load specification for framework walls ≥ 14/10 head plate [min.b x h x l = 14 x 10 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 870 1740

1547

not permitted

3094

5 1685 3370

10 1630 3260

15 1575 3149

20 1520 3039

25 1464 2929

30 1409 2819

35 1354 2708

40 1299 2598

45 1244 2488

90°

load specification for framework walls ≥ 14/20 head plate [min.b x h x l = 14 x 20 x 50]

angle° 1 attachment

point* 2 attachment points 2 attachment points

slewing

2 x 2 attachemtent points

with traverse sling and

spreader

2 x 2 attachment points

slewing with traverse

sling and spreader

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 1250 2500

1547

not permitted

3094

5 2374 4749

10 2249 4498

15 2123 4247

20 1998 3996

25 1872 3744

30 1747 3493

35 1621 3242

40 1496 2991

45 1370 2740

= 0° = 45°

traverse sling

*Highly resinous timber like pine and larch or walls, mounted at the front side, may only be lifted at an angle of ≥ 5° to the borehole axis and with 2

attachment points.

The minimum distance to the surface layer while fastening plates at the front face is min. 2 cm.

The minimum distance between each attachment point equals 50 cm.

The minimum distance between attachment points and beam and plate edge may not be smaller than 25 cm.

Attention: the distance of the posts at framework walls ist not permitted to be larger than 62,5 cm.

The operator is responsible for sufficient power transfer from head plate to posts. SIHGA takes on no liability.

max. = total weight /2 max. = total weight/2

b

h

drill hole

12 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

Load table for poles ø = min. 16 cm l = min. 50 cm rod

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 887 1774

-

not permitted

-

5 1675 3350

10 1576 3152

15 1477 2953

20 1378 2755

25 1278 2557

30 1179 2359

35 1080 2160

40 981 1962

45 882 1764

*Highly resinous timber like pine and larch, or frontally mounted walls, may only be lifted at an angle of ≥ 5° to the borehole axis, and using multiple

attachment points.

The minimum distance to the surface layer of the top layer while mounting at the front face of the plywood board is min. 2 cm

The minimum distance between each attachment point equals 50 cm

The minimum distance between attachment points and beam and plate edge may not be less than 25 cm

Caution: The axis-to-centre distance between the vertical members for timber-framed walls cannot be more than 62.5 cm.

The operator is responsible for sufficient force transfer from the upper beam (plate) to the vertical members, SIHGA®does not accept liability for this.

b

h

Bohrloch

90°

Load table for Pollmeier S beech wood grain side ≥ 8/12 [min.w x h x l = 8 x 12 x 50] rod

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 1250 2500

-

not permitted

-

5 2405 4811

10 2311 4621

15 2216 4432

20 2121 4243

25 2027 4053

30 1932 3864

35 1837 3675

40 1743 3485

45 1648 3296

= 0° = 45° max = total weight/2 max = total weight/2

traverse sling

www.sihga.com Operating Instruction Pick 13

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

Load table for Kerto®S joint side ≥ 7.5/12 [min.w x h x l = 7.5 x 12 x 50] rod

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 713 1426

-

not permitted

-

5 1376 2752

10 1326 2652

15 1276 2552

20 1226 2452

25 1176 2352

30 1126 2252

35 1076 2152

40 1026 2052

45 976 1952

*Highly resinous timber like pine and larch, or frontally mounted walls, may only be lifted at an angle of ≥ 5° to the borehole axis, and using multiple

attachment points.

The minimum distance to the surface layer of the top layer while mounting at the front face of the plywood board is min. 2 cm

The minimum distance between each attachment point equals 50 cm

The minimum distance between attachment points and beam and plate edge may not be less than 25 cm

Caution: The axis-to-centre distance between the vertical members for timber-framed walls cannot be more than 62.5 cm.

The operator is responsible for sufficient force transfer from the upper beam (plate) to the vertical members, SIHGA®does not accept liability for this.

b

h

Bohrloch

90°

Load table for Kerto®S joint side ≥ 9/12 [min.w x h x l = 9 x 12 x 50] rod

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 813 1626

-

not permitted

-

5 1566 3132

10 1506 3013

15 1447 2893

20 1387 2774

25 1327 2654

30 1267 2535

35 1208 2415

40 1148 2296

45 1088 2176

= 0° = 45° max = total weight/2 max = total weight/2

traverse sling

14 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

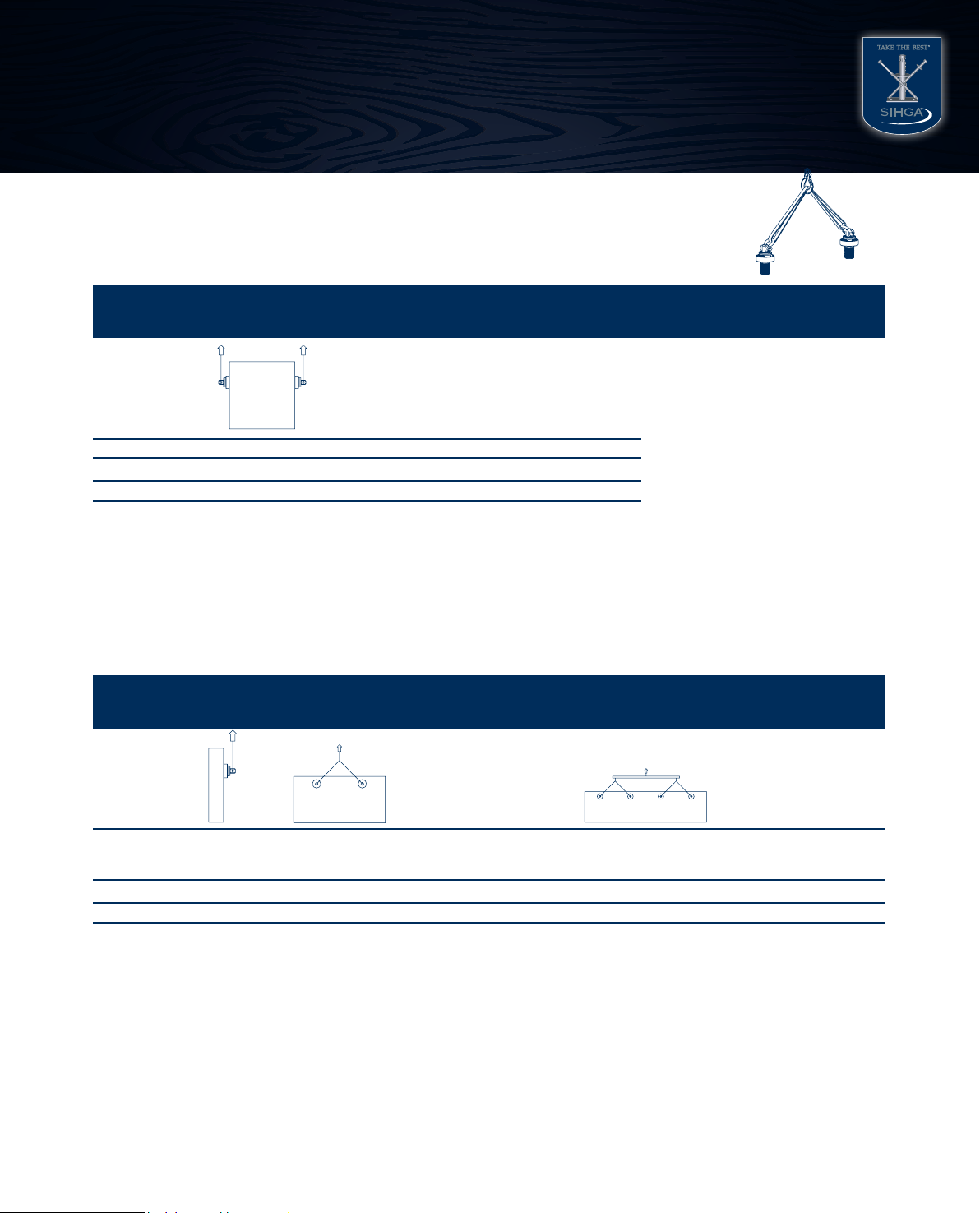

Load table for frontal wood attachment (only GLH) ≥10/10 [min.w x h x l = 10 x 10 x 50]

Angle ° 1 attachment point* 2 attachment point lifting 2 attachment points,

uprighting

2 attachment points, lifting

at less than 90°

[kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 not permitted not permitted

427 213

5 840

10 766

15 692

20 617

25 543

30 469

35 395

40 320

45 246

*Highly resinous timber like pine and larch, or frontally mounted walls, may only be lifted at an angle of ≥ 5° to the borehole axis, and using multiple

attachment points.

The minimum distance to the surface layer of the top layer while mounting at the front face of the plywood board is min. 2 cm

The minimum distance between each attachment point equals 50 cm

The minimum distance between attachment points and beam and plate edge may not be less than 25 cm

b

h

Bohrloch

90°

Load table for frontal wood attachment (only GLH) ≥ 16/16 [min.w x h x l = 16 x 16 x 50]

Angle ° 1 attachment point* 2 attachment point lifting 2 attachment points,

uprighting

2 attachment points, lifting

at less than 90°

[kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 not permitted not permitted

1427 713

5 1460

10 1343

15 1226

20 1109

25 992

30 875

35 758

40 641

45 524

= 0° = 45° max = total weight/2 = 90°

traverse sling

www.sihga.com Operating Instruction Pick 15

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

Load table for cross laminated timber boards wall panels laterally to the front surface,

fastened 15 cm from the edge [min.w x l x d = 50 x 50 x 9]

Angle ° 2 attachment point lifting 2 attachment points, uprighting

[kg total weight] [kg total weight]

90 660 660

= 90°

*Highly resinous timber like pine and larch, or frontally mounted walls, may only be lifted at an angle of ≥ 5° to the borehole axis, and using multiple

attachment points.

The minimum distance to the surface layer of the top layer while mounting at the front face of the plywood board is min. 2 cm

The minimum distance between each attachment point equals 50 cm

The minimum distance between attachment points and beam and plate edge may not be less than 25 cm

Load table for cross laminated timber boards wall panels laterally to the surface,

fastened 15 cm from the edge [min.w x l x d = 50 x 50 x 9]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

90 577 1154 1154 2308 2308

= 90°

traverse sling

16 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

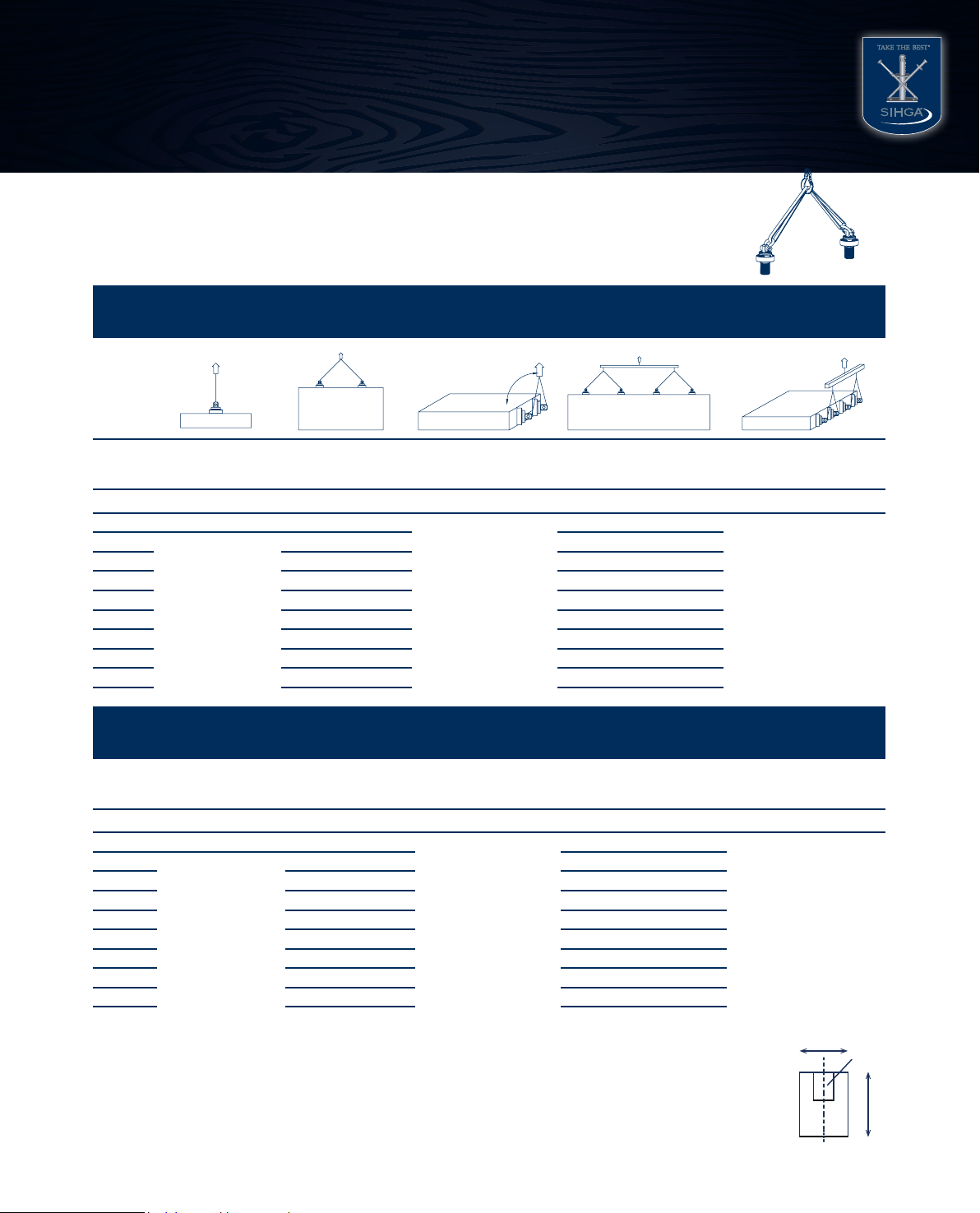

Load table for timber-framed walls ≥ 10/4.5 upper threshold [min.w x h x l = 10 x 4.5 x 50]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 250 500

500

not permitted

1000

5 500 1000

10 500 1000

15 500 1000

20 500 1000

25 500 1000

30 500 1000

35 500 1000

40 500 1000

45 500 1000

*Highly resinous timber like pine and larch, or frontally mounted walls, may only be lifted at an angle of ≥ 5° to the borehole axis, and using multiple

attachment points.

The minimum distance to the surface layer of the top layer while mounting at the front face of the plywood board is min. 2 cm

The minimum distance between each attachment point equals 50 cm

The minimum distance between attachment points and beam and plate edge may not be less than 25 cm

Caution: The axis-to-centre distance between the vertical members for timber-framed walls cannot be more than 62.5 cm.

The operator is responsible for sufficient force transfer from the upper beam (plate) to the vertical members, SIHGA®does not accept liability for this.

b

h

Bohrloch

90°

Load table for timber-framed walls ≥ 12/4.5 upper threshold [min.w x h x l = 12 x 4.5 x 50]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 487 974

720

not permitted

1440

5 931 1861

10 887 1775

15 844 1688

20 801 1601

25 757 1515

30 714 1428

35 671 1341

40 627 1255

45 584 1168

= 0° = 45° max = total weight/2 max = total weight/2

traverse sling

www.sihga.com Operating Instruction Pick 17

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

Load table for timber-framed walls ≥ 16/4.5 upper threshold [min.w x h x l = 16 x 4.5 x 50]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 500 1000

1000

not permitted

2000

5 958 1915

10 915 1830

15 873 1745

20 830 1660

25 788 1576

30 745 1491

35 703 1406

40 660 1321

45 618 1236

*Highly resinous timber like pine and larch, or frontally mounted walls, may only be lifted at an angle of ≥ 5° to the borehole axis, and using multiple

attachment points.

The minimum distance to the surface layer of the top layer while mounting at the front face of the plywood board is min. 2 cm

The minimum distance between each attachment point equals 50 cm

The minimum distance between attachment points and beam and plate edge may not be less than 25 cm

Caution: The axis-to-centre distance between the vertical members for timber-framed walls cannot be more than 62.5 cm.

The operator is responsible for sufficient force transfer from the upper beam (plate) to the vertical members, SIHGA®does not accept liability for this.

b

h

Bohrloch

90°

Load table for timber-framed walls ≥ 8/3.9 upper threshold Kerto®Q

[min.w x h x l = 8 x 3.9 x 50]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 160 320

320

not permitted

608

5 304 608

10 288 575

15 271 543

20 255 510

25 239 478

30 223 445

35 206 413

40 190 380

45 174 348

= 0° = 45°

traverse sling

18 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

Load table for timber-framed walls ≥ 12/3.9 upper threshold Kerto®Q

[min.w x h x l = 12 x 3.9 x 50]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 300 600

600

not permitted

1143

5 572 1143

10 543 1086

15 515 1029

20 486 972

25 458 916

30 429 859

35 401 802

40 372 745

45 344 688

*Highly resinous timber like pine and larch, or frontally mounted walls, may only be lifted at an angle of ≥ 5° to the borehole axis, and using multiple

attachment points.

The minimum distance to the surface layer of the top layer while mounting at the front face of the plywood board is min. 2 cm

The minimum distance between each attachment point equals 50 cm

The minimum distance between attachment points and beam and plate edge may not be less than 25 cm

Caution: The axis-to-centre distance between the vertical members for timber-framed walls cannot be more than 62.5 cm.

The operator is responsible for sufficient force transfer from the upper beam (plate) to the vertical members, SIHGA®does not accept liability for this.

b

h

Bohrloch

90°

Load table for timber-framed walls ≥ 16/3.9 upper threshold Kerto®Q

[min.w x h x l = 16 x 3.9 x 50]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 300 600

600

not permitted

1188

5 594 1188

10 588 1176

15 582 1164

20 576 1152

25 570 1140

30 564 1128

35 558 1116

40 552 1104

45 546 1092

= 0° = 45° max = total weight/2 max = total weight/2

traverse sling

www.sihga.com Operating Instruction Pick 19

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

Load table for timber-framed walls ≥ 8/5.7 upper threshold Kerto®Q

[min.w x h x l = 8 x 5.7 x 50]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 260 520

520

not permitted

1015

5 507 1015

10 495 989

15 482 964

20 469 939

25 457 913

30 444 888

35 431 863

40 419 837

45 406 812

*Highly resinous timber like pine and larch, or frontally mounted walls, may only be lifted at an angle of ≥ 5° to the borehole axis, and using multiple

attachment points.

The minimum distance to the surface layer of the top layer while mounting at the front face of the plywood board is min. 2 cm

The minimum distance between each attachment point equals 50 cm

The minimum distance between attachment points and beam and plate edge may not be less than 25 cm

Caution: The axis-to-centre distance between the vertical members for timber-framed walls cannot be more than 62.5 cm.

The operator is responsible for sufficient force transfer from the upper beam (plate) to the vertical members, SIHGA®does not accept liability for this.

b

h

Bohrloch

90°

Load table for timber-framed walls ≥ 12/5.7 upper threshold Kerto®Q

[min.w x h x l = 12 x 5.7 x 50]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 490 980

980

not permitted

1904

5 952 1904

10 924 1849

15 897 1793

20 869 1738

25 841 1682

30 813 1627

35 786 1571

40 758 1516

45 730 1460

= 0° = 45° max = total weight/2 max = total weight/2

traverse sling

20 Operating Instruction Pick www.sihga.com

SIHGA®GmbH I Gewerbepark Kleinreith 4

•A- 4694 Ohlsdorf bei Gmunden

•Tel +43 7612-74370-0

•Fax +43 7612-74370-10

•E-Mail [email protected]

SECURITY IN WOOD CONSTRUCTION GUARANTEES EXTRAORDINARY RESULTS

www.sihga.com

traverse sling

Load table for timber-framed walls ≥ 16/5.7 upper threshold Kerto®Q

[min.w x h x l = 16 x 5.7 x 50]

Angle ° 1 attachment

point*

2 attachment point

lifting

2 attachment points,

uprighting

2 x 2 attachment points

using belt and crossbeam

2 x 2 attachment points,

uprighting using belt and

crossbeam

[kg total weight] [kg total weight] [kg total weight] [kg total weight] [kg total weight]

0 750 1500

1500

not permitted

2880

5 1440 2880

10 1380 2761

15 1321 2641

20 1261 2522

25 1201 2402

30 1141 2283

35 1082 2163

40 1022 2044

45 962 1924

*Highly resinous timber like pine and larch, or frontally mounted walls, may only be lifted at an angle of ≥ 5° to the borehole axis, and using multiple

attachment points.

The minimum distance to the surface layer of the top layer while mounting at the front face of the plywood board is min. 2 cm

The minimum distance between each attachment point equals 50 cm

The minimum distance between attachment points and beam and plate edge may not be less than 25 cm

Caution: The axis-to-centre distance between the vertical members for timber-framed walls cannot be more than 62.5 cm.

The operator is responsible for sufficient force transfer from the upper beam (plate) to the vertical members, SIHGA®does not accept liability for this.

b

h

Bohrloch

90°

= 0° = 45° max = total weight/2 max = total weight/2

Table of contents

Other SIHGA Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual