Silicon Graphics GDM-4011P User manual

SERVICE MANUAL

CHASSIS

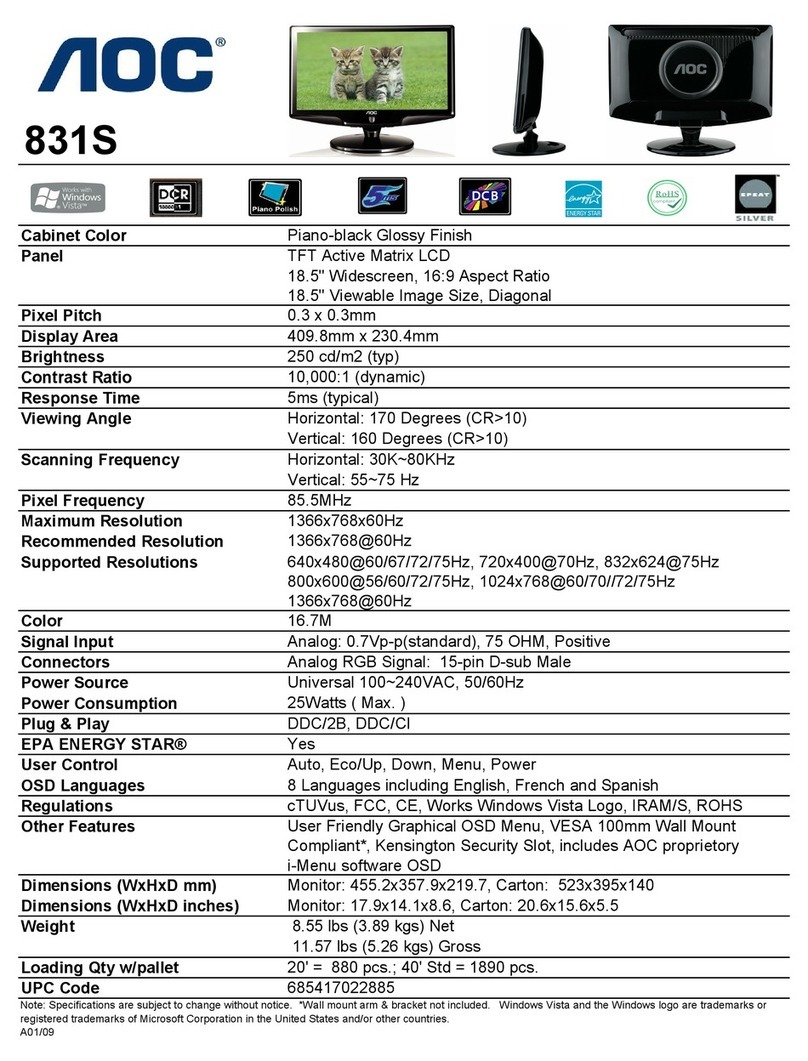

SPECIFICATIONS

N.Hemisphere Model

S.Hemisphere Model

No. SCC-L03B-A

GDM-4011P

COLOR GRAPHIC DISPLAY

N3

Picture tube 0.31 mm phosphor trio pitch

20 inches measured diagonally

90-degree deflection

Viewable image size Approx. 387 ×292 mm (w/h)

(15

1

/

4

×11

1

/

2

inches)

19.0” viewing image

Resolution Horizontal: Max. 1600 dots

Vertical: Max. 1200 lines

Standard image area Approx. 373 ×280 mm (w/h)

(14

3

/

4

×11

1

/

8

inches)

or

Approx. 350 ×280 mm (w/h)

(13

7

/

8

×11

1

/

8

inches)

Deflection frequency Horizontal: 30 to 96 kHz

Vertical: 48 to 160 Hz

AC input voltage/current

100 to 240 V, 50 – 60 Hz, 1.7 – 1.2 A

Power consumption Max. 150 W

Dimensions 472 ×490 ×500 mm (w/h/d)

(18

5

/

8

×19

3

/

8

×19

3

/

4

inches)

Mass Approx. 28 kg (61 lb 7 oz)

Design and specifications are subject to change without

notice.

REVISED

http://www.Datasheet4U.com

GDM-4011P

– 2 –

POWER SAVING FUNCTION

This monitor is capable of three states of reduced power consumption. By sensing the absence of video signals and one or both sync signals

coming from the host computer, it will reduce power consumption as follows.

Power consumption state

1 Normal operation

2 Standby (1st state)

3 Suspend (2nd state)

4 Active-off (3rd state)

5 Power-off

upower indicator

Green on

Green and orange alternate

Green and orange alternate

Orange on

Off

Recovery time

–

Approx. 1 sec.

Approx. 3 sec.

Approx. 15 sec.

–

Power consumption

≤140 W

≤100 W

≤15 W

≤5 W

0 W

DIAGNOSIS

Failre

+B failure

Horizontal / Vertical Deflection failure,

Thermal protector

ABL protector

HV failure

Aging / Self Test

Power LED

Yellow →Off

(0.5 sec) (0.5 sec)

Yellow →Off

(1.5 sec) (0.5 sec)

Yellow →Off

(0.5 sec) (1.5 sec)

Yellow →Off →Yellow →Off

(0.25 sec) (0.5 sec) (0.25 sec) (1.25 sec)

Yellow →Off →Green →Off

(0.5 sec) (0.5 sec) (0.5 sec) (0.5 sec)

Aging Mode (Video Aging) : During Power Save, press “MENU” key for longer than 2 second.

Self Test (OSD Color Bar) : During Power Save, press “CONTRAST” + (b) key for longer than 2 second.

Reliability Check Mode : During Power Save, press “CONTRAST” – (B) key for longer than 2 second.

TIMING SPECIFICATION

MODE

MODE AT PRODUCTION MODE 1 MODE 2 MODE 3 MODE 4 MODE 5 MODE 6 MODE 7 MODE 8 MODE 9 MODE 10

RESOLUTION 1280 X 1024 1280 X 1024 1280 X 1024 1280 X 1024 1280 X 1024 1024 X 768 1024 X 768 1920 X 1035 1600 X 1200 1280 X 492

CLOCK 135.000 MHz 129.250 MHz 107.250 MHz 89.571 MHz 140.250 MHz 78.750 MHz 63.546 MHz 159.923 MHz 156.200 MHz 107.250 MHz

— HORIZONTAL —

H-FREQ 79.976 kHz 76.935 kHz 63.839 kHz 53.316 kHz 81.922 kHz 60.023 kHz 48.732 kHz 65.009 kHz 74.808 kHz 63.839 kHz

usec usec usec usec usec usec usec usec usec usec

H. TOTAL 12.504 12.998 15.664 18.756 12.207 16.660 20.521 15.382 13.367 15.664

H. BLK 3.022 3.095 3.730 4.466 3.080 3.657 4.406 3.377 3.124 3.730

H. FP 0.119 0.248 0.373 0.357 0.228 0.203 1.133 0.275 0.282 0.373

H. SYNC 1.067 1.083 1.119 1.340 1.255 1.219 1.196 0.825 0.768 1.119

H. BP 1.837 1.764 2.238 2.769 1.597 2.235 2.077 2.276 2.074 2.238

H. ACTIV 9.481 9.903 11.935 14.290 9.127 13.003 16.114 12.006 10.243 11.935

— VERTICAL —

V. FREQ(HZ) 75.025 Hz 72.239 Hz 59.943 Hz 50.062 Hz 75.924 Hz 75.029 Hz 59.940 Hz 60.194 Hz 59.847 Hz 119.999 Hz

lines lines lines lines lines lines lines lines lines lines

V. TOTAL 1066 1065 1065 1065 1079 800 813 1080 1250 532

V. BLK 42 41 41 41 55 32 45 45 50 40

V. FP 1333313353

V. SYNC 3 3 3 3 3 3 3 10 6 3

V. BP 38 35 35 35 49 28 39 32 39 34

V. ACTIV 1024 1024 1024 1024 1024 768 768 1035 1200 492

— SYNC —

INT(G) NO YES YES YES YES NO YES YES YES YES

EXT(H/V)/POLARITY YES P/P NO NO NO NO YES P/P NO NO NO NO

EXT(CS) /POLARITY NO NO NO NO NO NO NO NO NO NO

INT/NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT NON INT

97. 7.17 VER.

GDM-4011P

– 3 –

SAFETY CHECK-OUT

(US Model only)

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-sol-

dered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly tran-

sistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specified values.

Make sure your instruments are accurate; be suspicious of

your HV meter if sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized”

knobs, screws, and all other exposed metal parts for AC

Leakage. Check leakage as described below.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indica-

tion is 0.75 V, so analog meters must have an accurate low-

voltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOMs that are suitable. Nearly all

battery operated digital multimeters that have a 2 V AC

range are suitable. (See Fig. A)

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN

WHICH THE DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

¡

ON THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS

AND IN THE PARTS LIST ARE CRITICAL FOR SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL FOR SAFE OPERATION ARE IDENTIFIED

IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED

OR IMPROPER OPERATION IS SUSPECTED.

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA

BOBINE DE DEMAGNETISATION EST ENLEVÉE.

ATTENTION AUX COMPOSANTS RELATIFS À LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET

UNE MARQUE ¡SONT CRITIQUES POUR LA

SÉCURITÉ. NE LES REMPLACER QUE PAR UNE PIÈCE

PORTANT LE NUMÉRO SPECIFIÉ. LES RÉGLAGES DE

CIRCUIT DONT L’IMPORTANCE EST CRITIQUE POUR

LA SÉCURITÉ DU FONCTIONNEMENT SONT

IDENTIFIÉS DANS LE PRÉSENT MANUEL. SUIVRE CES

PROCÉDURES LORS DE CHAQUE REMPLACEMENTDE

COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS

FONCTIONNE-MENT EST SUSPECTÉ.

CAUTION ON DAS (ECS) CONNECTOR

•The connector for DAS (ECS) adjustment is provided inside

the cover shown below. Be careful with an electrical shock

when connecting the connector with the power supplied. Also,

return the removed cover to the home position.

1.5 k

W

0.15 µF AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

use these instruments.

2. A battery-operated AC milliammeter. The Data Precision

245 digital multimeter is suitable for this job.

Rear side

GDM-4011P

– 4 –

TABLE OF CONTENTS

Section Title Page

1. GENERAL................................................................ 1-1

2. DISASSEMBLY

2-1. Cabinet Removal .............................................. 2-1

2-2. D Board Removal ............................................. 2-1

2-3. G Board Removal ............................................. 2-2

2-4. A Board Removal ............................................. 2-2

2-5. I/O Terminal Board Assy Removal ................. 2-3

2-6. Service Position ................................................. 2-3

2-7. H and J Boards Removal................................... 2-4

2-8. Picture Tube Removal ...................................... 2-4

3. SAFETY RELATED ADJUSTMENT.......... 3-1

4. ADJUSTMENTS ................................................... 4-1

5. DIAGRAMS

5-1. Block Diagrams ................................................. 5-1

5-2. Frame Shcematic Diagram................................ 5-7

5-3. Circuit Boards Location .................................... 5-9

5-4. Schematic Diagrams and Printed Wiring Boards 5-9

(1) Schematic Diagrams of G, H and J Boards ..... 5-10

(2) Schematic Diagram of D Board ....................... 5-13

(3) Schematic Diagram of A Board ....................... 5-23

5-5. Semiconductors ................................................ 5-26

6. EXPLODED VIEWS

6-1. Chassis .............................................................. 6-1

6-2. Picture Tube ..................................................... 6-2

6-3. Packing Materials ............................................. 6-3

7. ELECTRICAL PARTS LIST ......................... 7-1

SECTION 1

GENERAL

The operating instructions mentioned here are partial abstracts

from the Operating Instruction Manual. The page numbers of

the Operating Instruction Manual remain as in the manual.

8

Customizing Your Monitor

Introducing the On-screen

Display System

Most adjustments are made using the MENU OSD.

MENUOSD

Press the button to display the MENU OSD.

This MENU OSD contains links to the other OSDs described

below.

1COLOR

Displays the COLOR OSD for adjusting the color

temperature.

2CENTER

Displays the CENTER OSD for adjusting the centering

of the picture.

3SCREEN

Displays the SCREEN OSD for adjustingthe vertical and

horizontal convergence, etc.

4ZOOM

Displays the ZOOM OSD for enlarging and reducing

the picture.

5OPTION

Displays the OPTION OSD for adjusting the OSD

position and degauss the screen, etc.

6SIZE

Displays the SIZE OSD for adjusting the picture size.

7LANG

Displays the LANGUAGE OSD for selecting the

language.

8GEOM

Displays the GEOMETRY OSD for adjusting the picture

rotation and pincushion, etc.

9EXIT

Closes the MENU OSD.

MENU

EXIT

CENTER

SIZE

GEOM

COLOR

LANG

ZOOM

SCREEN

OPTION

OK

MENU

Horizontal

Frequency* Vertical

Frequency*

Beforeadjusting

• Connect the monitor and the computer, and turn them on.

• Select “ LANG” in the MENU OSD, then select

“ENGLISH” (English) (see page 15).

Customizing Your Monitor

BRIGHTNESS/CONTRAST

26 26

80.0kHz/ 75Hz

Adjusting the Picture Brightness

and Contrast

Once the setting is adjusted , it will be stored in memory for

all input signals received.

1

Press the ¨(brightness) ./>or >(contrast) ?//

buttons.

The BRIGHTNESS/CONTRAST OSD appears.

2

Forbrightnessadjustment

Press the ¨./>buttons.

>. . . for more brightness

.. . . for less brightness

Forcontrastadjustment

Press the >?//buttons.

/. . . for more contrast

?. . . for less contrast

The OSD automatically disappears after about 3 seconds.

To reset, press the ?(reset) button while the OSD is on.

The brightness and contrast are both reset to the factory

settings.

* The horizontal and vertical frequencies for the received input

signal appear in the BRIGHTNESS/CONTRAST OSD.

5

Getting Started

Getting Started

F

EN

D

ES

I

Identifying Parts and Controls

See the pages in parentheses for further details.

Front

1?(reset) button (page 16)

Resets the adjustments to the factory settings.

2(auto sizing and centering) button

(page 6)

Automatically adjusts the size and centering of the

images.

3¨(brightness) (./>) buttons (pages 7 –

16)

Adjust the picture brightness.

Function as the (./>) buttons when adjusting other

items.

4(menu) button (pages 7 -16)

Displays the MENU OSD.

5>(contrast) (?//) buttons (pages 7 – 16,

20)

Adjust the contrast.

Function as the (?//)buttons when adjusting other

items.

6u(power) switch and indicator (pages 17,

20)

Turns the monitor on or off.

The indicator lights up in green when the monitor is

turned on, and lights up in orange when the monitor is

in power saving mode.

Rear

8AC IN connector

Provides AC power to the monitor.

9Video input 2 connector (13W3)

Inputs RGB video signals (0.714 Vp-p, positive) and

SYNC signals.

A1:Red

A2:Green

A3:Blue

Note

If you use a computer or video board of high output level (about 1.0

Vp-p), you may not be able ot obtain the optimum display. In such

case, try decreasing the picture contrast, or use a computer or video

board with a lower output level.

!º Video input 1 connector (HD15)

Inputs RGB video signals (0.714 Vp-p, positive) and

SYNC signals.

* Display Data Channel (DDC) Standard of VESA

Pin No.

1

2

3

4

5

6

7

Signal

Red

Green

(Composite

Sync on Green)

Blue

ID (Ground)

DDC Ground*

Red Ground

Green Ground

Signal

Blue Ground

DDC + 5V*

Ground

ID (Ground)

Bi-Directional

Data (SDA)*

H. Sync

V. Sync

Data Clock(SCL)*

Pin No.

8

9

10

11

12

13

14

15

5 4 3 2 1678910 111213

1415

A1 A2 A3

(13W3)(HD15)

1-1

9

Getting Started

F

EN

D

ES

I

Customizing Your Monitor

Navigating the MENU on-screen display

Select a link using the ¨./>and >?//buttons in the

MENU OSD.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select a link.

The selected link turns yellow.

3

Press the button.

The selected OSD appears.

If no buttons are pressed, the MENU OSD automatically

disappears after about 10 seconds.

To close the MENU OSD, select “EXIT” and press the

button.

Adjusting the on-screen display settings

Select an item using the ¨./>buttons and adjust or select

the setting of that item using the >?//buttons.

To select an item, press the ¨.or >button.

The ”mark goes to the selected item and the item turns

yellow.

To adjust or set an item, press the >?or /button.

When adjusting an item, the bar length and the figure

increase or decrease.

When setting an item, the pmark turns green.

Using the CENTER On-screen

Display

The CENTER settings allow you to adjust the centering of

the picture.

Once the setting is adjusted, it will be stored in memory for

the current input signal.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

CENTER,”and press the buttonagain.

The CENTER OSD appears.

3

For horizontal adjustment

Press the >?//buttons.

/. . . to move the picture right

?. . . to move the picture left

Forverticaladjustment

Press the ¨./>buttons.

>. . . to move the picture up

.. . . to move the picture down

The OSD automatically disappears after about 30 seconds.

To close the OSD, press the button again.

To reset, press the ?(reset) button while the OSD is on.

The horizontal and vertical centerings are both reset to the

factory settings.

CENTER

26

73

10

Customizing Your Monitor

Using the SIZE On-screen Display

The SIZE settings allow you to adjust the size of the picture.

Once the setting is adjusted, it will be stored in memory for

the current input signal.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

SIZE,” and press the button again.

The SIZE OSD appears.

3

For horizontal adjustment

Press the >?//buttons.

/. . . to increase picture size

?. . . to decrease picture size

Forverticaladjustment

Press the ¨./>buttons.

>. . . to increase picture size

.. . . to decrease picture size

The OSD automatically disappears after about 30 seconds.

To close the OSD, press the button again.

To reset, press the ?(reset) button while the OSD is on.

The horizontal and vertical sizes are both reset to the factory

settings.

SIZE

26

73

Using the GEOM (Geometry) On-

screen Display

The GEOM(geometry) settings allow you to adjust the

shape and orientation of the picture.

Once the rotation is adjusted, it will be stored in memory for

all input signals received. All other adjustments will be

stored in memory for the current input signal.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

GEOM,” and press the button again.

The GEOMETRY OSD appears.

3

Press the ¨./>buttons to select the item you want

to adjust.

Select

ROTATION

PINCUSHION

PIN BALANCE

KEYSTONE

KEY BALANCE

To

adjust the picture rotation

adjust the picture sides

adjust the picture side balance

adjust the picture width

adjust the picture shape balance

ROTATION

GEOMETRY

26

1-2

11

Getting Started

F

EN

D

ES

I

Customizing Your Monitor

4

Press the >?//buttons to adjust the settings.

The OSD automatically disappears after about 30 seconds.

To close the OSD, press the button again.

To reset, press the ?(reset) button while the OSD is on.

The selected item is reset to the factory setting.

For

ROTATION

PINCUSHION

PIN BALANCE

KEYSTONE

KEY BALANCE

Press

/. . . to rotate the picture clockwise

?. . . to rotate the picture counterclockwise

/. . . to expand the picture sides

?. . . to contract the picture sides

/. . . to move the picture sides to the right

?. . . to move the picture sides to the left

/. . . to increase the picture width at the

top

?. . . to decrease the picture width at the

top

/. . . to move the top of the picture to

the right

?. . . to move the top of the picture to

the left

Using the ZOOM On-screen

Display

The ZOOM settings allow you to enlarge or reduce the

picture.

Once the setting is adjusted, it will be stored in memory for

the current input signal.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

ZOOM,” and press the button again.

The ZOOM OSD appears.

3

Press the >?//buttons to adjust the picture zoom.

/. . . to enlarge the picture

?. . . to reduce the picture

The OSD automatically disappears after about 30 seconds.

To close the OSD, press the button again.

To reset, press the ?(reset) button while the OSD is on.

Note

The picture zoom adjustment will stop as soon as either the

horizontal or vertical size reaches its maximum or minimum value.

ZOOM

73V 26H

12

Customizing Your Monitor

Using the COLOR On-screen

Display

You can change the monitor’s color temperature. For

example, you can change the colors of a picture on the

screen to match the actual colors of the printed picture.

Once the setting is adjusted, it will be stored in memory for

all input signals received.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

COLOR,” and press the button again.

The COLOR OSD appears.

3

Press the >?//buttons to select the color

temperature.

There are three color temperature modes in the OSD.

The preset adjustments are:

5000K, 6500K, 9300K

Fine tunig the color temperature

Press the ¨./>buttons to select R (red), G (green), or B

(blue) and adjust by pressing the >?//buttons.

The “5000K,” “6500K” or “9300K” disappears and the

new color settings are memorized for each of the three

color modes.

The color temperature modes change as follows:

5000Kn1, 6500Kn2, 9300Kn3

The OSD automatically disappears after about 30 seconds.

To close the OSD, press the button again.

To reset, press the ?(reset) button while the OSD is on.

The selected color temperature is reset to the factory

settings.

5000K 6500K 9300K

G

COLOR

50

R50

B50

1 6500K 9300K

G

COLOR

50

R76

B50

Using the SCREEN On-screen

Display

Adjust convergence settings to eliminate red or blue

shadows that may appear around objects on the screen.

Adjust the CANCEL MOIRE function to eliminate wavy or

elliptical lines that may appear on the screen.

Once CANCEL MOIRE is adjusted, it will be stored in

memory for the current input signal. All other adjustments

will be stored in memory for all input signals received.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

SCREEN,”and pressthe button again.

The SCREEN OSD appears.

3

Press the ¨./>buttons to select the item you want

to adjust.

Select

H CONVERGENCE

V CONVERGENCE

TOP

V CONVER TOP

BOT

V CONVER BOTTOM

CANCEL MOIRE

ADJ *

MOIRE ADJUST

To

adjust the horizontal convergence

adjust the vertical convergence

adjust the screen’s upper vertical

convergence

adjust the screen’s lower vertical

convergence

eliminate elliptical or wavy lines on

the screen

adjust the degree of moire

cancellation

* CANCEL MOIRE must be “ON” for “ ADJ (MOIRE

ADJUST)” to appear on the screen.

SCREEN

TOP

BOT

H CONVERGENCE

26

1-3

13

Getting Started

Customizing Your Monitor

F

EN

ES

C

4

Press the >?//buttons to adjust the settings.

The OSD automatically disappears after about 30 seconds.

To close the OSD, press the button again.

To reset, press the ?(reset) button while the OSD is on.

The selected item is reset to the factory setting.

For

H CONVERGENCE

V CONVERGENCE

TOP

V CONVER TOP

BOT

V CONVER BOTTOM

CANCEL MOIRE

ADJ

MOIRE ADJUST

Press

/. . . to shift red shadows to the right

and blue shadows to the left

?. . . to shift red shadows to the left

and blue shadows to the right

/. . . to shift red shadows up and blue

shadows down

?. . . to shift red shadows down and

blue shadows up

/. . . to shift red shadows up and blue

shadows down

?. . . to shift red shadows down and

blue shadows up

/. . . to shift red shadows up and blue

shadows down

?. . . to shift red shadows down and

blue shadows up

/. . . to turn CANCEL MOIRE “ON”

?. . . to turn CANCEL MOIRE “OFF”

/. . . to increase the moire cancellation

effect

?. . . to decrease the moire cancellation

effect

ON

OFF

ON

OFF

50

0

Using the OPTION On-screen

Display

The OPTION OSD allows you to manually degauss the

screen and adjust settings such as the OSD position and

power saving delay time. It also allows you to lock the

controls.

Degaussing the screen

The monitor screen is automatically degaussed

(demagnetized) when the power is turned on.

You can also manually degauss the monitor.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

OPTION,” and press the button again.

The OPTION OSD appears.

3

Press the ¨./>buttons to select “ (MANUAL

DEGAUSS).”

4

Press the >/button.

The screen is degaussed for about 2 seconds.

If you need to degauss the screen a second time, wait for at

least 20 minutes before repeating the steps above.

The OPTION OSD automatically disappears after about 30

seconds.

To close the OSD, press the button again.

ON

MANUAL DEGAUSS

UNLOCK

1 MIN

OPTION

ZZ...

14

Customizing Your Monitor

Setting the power saving delay time

You can set the delay time before the monitor enters the

power saving mode. See page 17 for more information on

this monitor’s power saving capabilities.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

OPTION,” and press the button again.

The OPTION OSD appears.

3

Pressthe¨./>buttons to select “

ZZ...

(PWRSAVE

DELAY).”

4

Press the >?//buttons to select the desired time.

When PWR SAVE DELAY is set to “OFF,” the monitor

does not go into power saving mode.

The OPTION OSD automatically disappears after about 30

seconds.

To close the OSD, press the button again.

To reset, press the ?(reset) button while the OSD is on.

ON

MANUAL DEGAUSS

UNLOCK

1 MIN

OPTION

ZZ...

Changing the on-screen display position

You can change the OSD position (for example, when you

want to adjust the picture behind the OSD).

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

OPTION,” and press the button again.

The OPTION OSD appears.

3

Press the ¨./>buttons to select “ (OSD H

POSITION)”or“ (OSDVPOSITION).”

Select “ (OSD H POSITION)” to adjust the horizontal

position.

Select “ (OSD V POSITION)” to adjust the vertical

position.

4

Press the >?//buttons to move the OSD to the

desiredposition.

The OPTION OSD automatically disappears after about 30

seconds.

To close the OSD, press the button again.

To reset, press the ?(reset) button while the OSD is on.

ON

MANUAL DEGAUSS

UNLOCK

1 MIN

OPTION

ZZ...

ZZ...

OSD H POSITION

UNLOCK

1 MIN

OPTION

ZZ...

OSD V POSITION

UNLOCK

OPTION

1

ZZ...

PWR SAVE DELAY

OPTION

5 SEC

60 MIN 1 MIN

OFF

1

1-4

15

Getting Started

F

EN

D

ES

I

Customizing Your Monitor

Locking the controls

The control lock function disables all of the buttons on the

front panel except the u(power) switch and the button.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

OPTION,” and press the button again.

The OPTION OSD appears.

3

Pressthe ¨./>buttonsto select “ (CONTROL

LOCK.)”

4

Pressthe >?//buttons toselect “LOCK.”

The OPTION OSD automatically disappears after about 30

seconds.

To close the OSD, press the button again.

Once you select “LOCK,” you cannot select any items

except “EXIT” and ” OPTION” in the MENU OSD.

If you press any button other than the u(power) switch and

the button, the mark appears on the screen.

To cancel the control lock

Repeat steps 1 through 3 above and press the >?//

buttons to select “UNLOCK.”

ON

MANUAL DEGAUSS

UNLOCK

1 MIN

OPTION

ZZ...

Using the LANG (Language) On-

screen Display

English, French, German, Spanish and Japanese versions of

the OSDs are available.

1

Press the button.

The MENU OSD appears.

2

Press the ¨./>and >?//buttons to select “

LANG,” and press the button again.

The LANGUAGE OSD appears.

3

Press the ¨./>buttons to select the desired

language.

ENGLISH: English, FRANÇAIS: French,

DEUTSCH: German, ESPAÑOL: Spanish,

or : Japanese.

The OSD automatically disappears after about 30 seconds.

To close the OSD, press the button again.

To reset to English, press the ?(reset) button while the

OSD is on.

ENGLISH

FRANÇAIS

DEUTSCH

ESPAÑOL

LANGUAGE

ZZ...

CONTROL LOCK

OPTION

UNLOCK LOCK

1

16

Technical Features

Mode

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Resolution

(dots×lines)

640 ×480

640 ×480

640 ×480

640 ×480

720 ×400

800 ×600

800 ×600

800 ×600

1024 ×768

1024 ×768

1024 ×768

1024 ×768

1152 ×864

1280 ×960

1280 ×960

1280 ×1024

1280 ×1024

1280 ×1024

1600 ×1200

1600 ×1200

1600 ×1200

1600 ×1200

1280 ×1024

1024 ×768

1920 ×1035

1600 ×1200

1280 ×492

Horizontal

Frequency

31.5 kHz

37.5 kHz

43.3 kHz

31.5 kHz

37.9 kHz

37.9 kHz

46.9 kHz

53.7 kHz

48.4 kHz

56.5 kHz

60.0 kHz

68.7 kHz

67.5 kHz

60.0 kHz

85.9 kHz

64.0 kHz

80.0 kHz

91.1 kHz

75.0 kHz

81.3 kHz

87.5 kHz

93.8 kHz

53.3 kHz

48.7 kHz

65.0 kHz

74.8 kHz

63.8 kHz

Vertical

Frequency

60 Hz

75 Hz

85 Hz

70 Hz

85 Hz

60 Hz

75 Hz

85 Hz

60 Hz

70 Hz

75 Hz

85 Hz

75 Hz

60 Hz

85 Hz

60 Hz

75 Hz

85 Hz

60 Hz

65 Hz

70 Hz

75 Hz

50 Hz

60 Hz

60 Hz

60 Hz

120 Hz

Technical Features

Customizing Your Monitor

Resetting the Adjustments

Resetting an adjustment item

1

Press the , ¨./>and >?//buttons to select

the OSD containing the item you want to reset.

2

Press the ¨./>buttons to select the item you want

to reset.

3

Press the ?(reset) button.

Resetting all of the adjustment data for

the current input signal

When there is no OSD displayed, press the ?(reset)

button.

All of the adjustments data for the current input signal is

reset to the factory settings.

Note that adjustment data not affected by changes in input

signal (OSD language, OSD position, input signal selection,

power saving delay time and the control lock function) is

not reset to the factory settings.

Resetting all of the adjustment data for all

input signals

Press and hold the ?(reset) button for more than two

seconds.

All of the adjustment data, including the brightness and

contrast, is reset to the factory settings.

Preset Modes

Factory adjusted Timing Modes

Mode

1

2

3

4

Resolution

(dots×lines)

1280 ×1024

1280 ×1024

1280 ×1024

1280 ×1024

Horizontal

Frequency

80.0 kHz

76.9 kHz

63.8 kHz

81.9 kHz

Vertical

Frequency

75 Hz

72 Hz

60 Hz

76 Hz

Data Loaded Timing Modes

1-5

18

Additional Information

Warning Messages

If there is something wrong with the input signal, one of the

following messages appears.

The message disappears after about 30 seconds.

Additional Information

1The input signal condition

“OUTOF SCAN RANGE”indicates that the input signal

is not supported by the monitor’s specifications.

“NO INPUT SIGNAL” indicates that no signal is input, or

the input signal from the selected input connector is not

received.

2The selected input connector

Indicates which input connector is receiving the wrong

signal. If there is something wrong with the signal from

both input connectors, “1” (HD15) and “2” (13W3) are

displayed alternately.

To solve these problems, see “Troubleshooting” below.

Troubleshooting

This section may help you isolate the cause of a problem and as a result, eliminate the need to contact technical support.

Symptom Check these items

No picture

If the uindicator is not lit

If the “NO INPUT SIGNAL”

message appears on the

screen, or if the uindicator is

either orange or alternating

green and orange

If the “OUT OF SCAN

RANGE” message appears on

the screen

If no message is displayed

and the uindicator is green

or flashing orange

Pictureisscrambled

Color is not uniform

• Check that the power cord is properly connected.

• Check that the u(power) switch is in the “on” position.

• Try pressing any key on the computer keyboard.

• Check that your computer power switch is in the “on” position.

• Check that the input select setting is correct.

• Check that the video signal cable is properly connected and all plugs are firmly seated

in their sockets.

• Ensure that no pins are bent or pushed in the HD15 or 13W3 video input connector.

• Check that the video frequency range is within that specified for the monitor.

(Horizontal: 30 – 96 kHz, Vertical: 48 – 160 Hz)

Refer to your computer’s instruction manual to adjust the video frequency range.

• If you are using a video signal cable adapter, check that it is correct.

• See “Self-diagnosis Function” (page 20).

• Check your graphics board manual for the proper monitor setting.

• Check this manual and confirm that the graphics mode and the frequency you are

trying to operate at is supported. Even if the frequency is within the proper range,

some video boards may have a sync pulse that is too narrow for the monitor to sync

correctly.

• Degauss the monitor (page 13).

If you place equipment which generates a magnetic field, such as a loudspeaker, near

the monitor, or you change the direction of the monitor, color may lose uniformity.

The degauss function demagnetizes the metal frame of the CRT to obtain a neutral

field for uniform color reproduction. If a second degauss cycle is needed, allow a

minimum interval of 20 minutes for the best result.

INFORMATION

OUT OF SCAN RANGE

INPUT : 1

19

Getting Started

F

EN

D

ES

I

Additional Information

Symptom Check these items

You cannot adjust the

monitor with the buttons on

the front panel

White does not look white

Screenimageisnotcentered

or sized properly

Edges of the image are

curved

White lines show red or blue

shadowsatedges

Pictureis fuzzy

Picturebounces or haswavy

oscillations

Pictureisflickering

Picture appears to be

ghosting

Wavy or elliptical (moire)

pattern is visible

Two fine horizontal lines

(wires) are visible

Hum is heard right after the

power is turned on

• If the control lock function is set to on, set it to off using the OPTION OSD (page 15).

• Adjust the color temperature (page 12).

• Adjust the size or centering (pages 9 – 10).

• Some video modes do not fill the screen to the edges. This problem tends to occur with

certain video boards.

• Adjust the geometry (pages 10 – 11).

• Adjust the convergence (pages 12 – 13).

• Adjust the contrast and brightness (page 8).

• Degauss the monitor (page 13).

If you place equipment which generates a magnetic field, such as a loudspeaker, near

the monitor, or you change the direction of the monitor, color may lose uniformity.

The degauss function demagnetizes the metal frame of the CRT to obtain a neutral

field for uniform color reproduction. If a second degauss cycle is needed, allow a

minimum interval of 20 minutes for the best result.

• If red or blue shadows appear along the edges of images, adjust the convergence

(pages 12 – 13).

• If the moire is cancelled, the picture may become fuzzy. Decrease the moire

cancellation effect (pages 12 – 13).

• Isolate and eliminate any potential sources of electric or magnetic fields. Common

causes for this symptom are electric fans, fluorescent lighting or laser printers.

• If you have another monitor close to this monitor, increase the distance between them

to reduce the interference.

• Try plugging the monitor into a different AC outlet, preferably on a different circuit.

• Try the monitor on a different computer in a different room.

• Set the refresh rate on the computer to obtain the best possible picture by referring to

the computer’s manual.

• Eliminate the use of video cable extensions and/or video switch boxes if this symptom

occurs. Excessive cable length or a weak connection can produce this symptom.

• Cancel the moire (pages 12 – 13).

The moire may be modified depending on the connected computer.

• Due to the relationship between resolution, monitor dot pitch and the pitch of some

image patterns, certain screen backgrounds sometimes show moire. Change your

desktop pattern.

• These wires stabilize the vertically striped aperture grille (page 17). This aperture grille

allows more light to pass through to the screen giving the Trinitron CRT more color

and brightness.

• When the power is turned on, the auto-degauss cycle is activated. While the auto-

degauss cycle is activated (2 seconds), a hum may be heard. The same hum is heard

when the monitor is manually degaussed. This is not a malfunction.

1-6

GDM-4011P

SECTION 2

DISASSEMBLY

2-1. CABINET REMOVAL

2-2. D BOARD REMOVAL

Top cover

Three screws

(+ BVTT 4 x 8)

Six screws

(+ BVTT 4 x 8)

Video shield

4

5

6

7

Two screw covers

Cabinet

3

Four screws

(+ BVTP 4 x 16)

2

1

Two screws

(+ BVTT 4 x 8)

Four screws

(+ BVTP 3 x 10)

D board

Screw

(+ P 3.5 x 20)

Open the D block in the direction

of the arrow . and remove of

the arrow .

Two hooks

1

2

3 4

5

A

B

A

B

2-1

GDM-4011P

2-3. G BOARD REMOVAL

2-4. A BOARD REMOVAL

Two screws

(+ BVTT 4 x 8)

Three hooks

Two screws

(+BVTP 3 x 10)

G shield

G board

Open the G block in the direction

of the arrow . and remove of

the arrow .

A

B

Two printed circuit board holders

B

2

3

4

5

6

7

A

Screw

(Ext tooth washer M4)

1

A borad

Two screws

(+BVTT 4 x 8)

1

2

2-2

GDM-4011P

2-5. I/O TERMINAL BOARD ASSY REMOVAL

2-6. SERVICE POSITION

2-3

Three screws

(+ BVTT 3 x 8)

1

I/O terminal board assy

2

CN511 CN401

CN402

D board (Refer to 2-2.)

Rear shield

D,G boards

A board (Refer to 2-4.)

G board

(Refer to 2-3.)

CAUTION : SHORT

If the claw is hooked,

opening and closing

the board is impossible.

Do not try to do it by force.

If the claw is hooked,

opening and closing

the board is impossible.

Do not try to do it by force.

GDM-4011P

2-7. H AND J BOARDS REMOVAL

2-8. PICTURE TUBE REMOVAL

Four screws

(Tapping screw 5)

CN801

H board Two screws

(+ BVWHTP 3 x 12)

Bezel

5

6

7

8

Hook (20)

2

Screw

(+ BVTP 4 x 16)

1

Hook (20)

4

Screw

(+ BVTP 4 x 16)

3

Claw

9

J board

10

CN891

Claw

Claw

Two claws

Open the D block

(Refer to 2-2.)

CN3 (DY)

CN6 (DY)

2P (NA)

Two screws

(+ BVTT 4 x 8)

A board

Open the G block

(Refer to 2-3.)

Neck assy

Deflection yoke

Picture tube

Three connectors

1

2

3

4

5

6

7

8

Anode cap

9

2-4

GDM-4011P

• INSTALLED POSITION OF THE ANODE-CAP

•Install the anode cap as shown a figure.

3When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in the

direction of the arrow c.

• HOW TO HANDLE AN ANODE-CAP

1Don’t hurt the surface of anode-caps with shartp shaped material!

2Don’t press the rubber hardly not to hurt inside of anode-caps!

A material fitting called as shatter-hook terminal is built in the

rubber.

3Don’t turn the foot of rubber over hardly!

The shatter-hook terminal will stick out or hurt the rubber.

a

b

c

Anode Button

• REMOVAL OF ANODE-CAP

NOTE: Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or carbon painted on the CRT, after

removing the anode.

• REMOVING PROCEDURES

1Turn up one side of the rubber cap in

the direction indicated by the arrow a.2Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b.

Anode cap

Purse lock

Deflection yoke

Top cover

TOP VIEW

2-5

GDM-4011P SECTION 3

SAFETY RELATED ADJUSTMENT

When replacing or repairing the shown below table, the

following operational checks must be performed as a

safety precaution against X-rays emissions from the unit.

a) HV Regulator Circuit Check

1) Confirm that the voltage of the pin 2of CN901 on D

board is within the voltage range shown below.

Standard: 9.00±0.068 VDC

b) HV Protector Circuit Check

1) Confirm that the HV protector circuit works and TV

Raster disappears when apply the voltage as shown

below between pin 3of CN901 on D board and

GND using an external DC power supply.

Check Condition: Less than 31.30 VDC

c) Beam Current Protector Circuit Check-1

1) Measure HV voltage and record that value.

2) Shorted between pin 1and pin 4of CN901 on D

board.

3) Connect to the Constant Current Jig (A) between pin

1of CN901 on D board and GND, confirm that the

Beam Current Protector Circuit works and HV go

down more than 1.50 kV from the value of (1).

Check Condition: 1.50 mA

d) Beam Current Protector Circuit Check-2

1) Connect to the Constant Current Jig (B) between pin

1of CN901 on D board and GND, confirm that the

Beam Current Protector Circuit works and TV Raster

disappears.

Check Condition: 1.57 mA

e) Voltage of 3rd winding of FBT

1) Confirm that the voltage of pin 3of CN901 on D

board is within the voltage range shown below.

Standard: more than 23.30 VDC

Check Condition

Input voltage : 100~120 VAC

Input signal : White Cross Hatch at 96 kHz

Beam control : BRT and CONT →Minimum

B+ voltage : 177~183 VDC

HV Regulator

Circuit Check

HV Protector

Circuit Check

Beam Current

Protector Circuit

Check

Part Replaced (])

D Board IC901, T902

• Mounted D board

D Board Q590, Q591, D916,

D935, C924, R597,

R598, R940, R980,

T902

• Mounted D board

G Board PH680, Q680, Q683,

D680, R680, R686,

R687, R688, R689

• Mounted G board

D Board IC901, D904, D907,

D908, R011, R908,

R909, R921, R925,

R926, R929, R930,

T902

• Mounted D board

3-1

GDM-4011P

SECTION 4

ADJUSTMENTS

•Landing Rough Adjustment

1. Enter the full white signal. (or the full black dots signal).

2. Adjust the contrast to the maximum.

3. Make the screen monogreen.

4. Adjust the brightness is easy to see with the G2 resistor.

5. Reverse the DY, and adjust coarsely the purity magnet so

that a green raster positions in the center of screen.

6. Moving the DY forward, adjust so that an entire screen be-

comes monogreen.

7. Adjust the tilt of DY, and fix lightly with a clamp.

•Landing Fine Adjustment

1. Put the set inside the Helmholtz coil.

2. Input the single green signal and set the CONT control to

MAX.

Note: Set to Σ 1k=200 µA with the signal green signal, and after

aging for about 30 minutes, adjust so that it is exactly this

value.

3. Demagnetize the metal part of the chassis with the hand de-

gausser and coil degausser, and the CRT surface with the

hand degausser.

Input AC 230V to AC IN, turn on and off the power to per-

form auto degaussing. (Perform auto degaussing by setting

“MONCONREG2”=152. Return to the original value after

use.)

Demagnetize the CRT surface with the hand degausser

again.

Note:

(1) Adjust in s non-magnetic field. BV=45uT.

(2) If adjusting in a magnetic fields, add the shift from the non-

magnetic field in your estimation.

4. Attach the wobbling coil to the designated part of the CRT

neck.

5. Attach the sensor of the landing adjustment unit on the CRT

surface.

6. Adjust the DY position and purity, and the DY tilt, and land-

ing of the center and 4 corners with the landing checker.

<Specification>

Adjust the green of corners 1 to 4, and center 6 to ±5 µm, and red

and blue to within ±7 µm of green, and the difference between

red and blue to within ±10 µm.

Adjust the green of 5 and 7 to within ±10 µm, and red and blue to

within ±7 µm of green, and the difference between red and blue

to within ±10 µm.

(Set each corner to 1st frame of the crosshatch.)

7. For the up/down and left/right swing, swing the DY and in-

sert a wedge so that the up and down pins are equal at the top

and bottom and the horizontal trapezoid is equal at the left

and right. Insert the wedge firmly so that the DY does not

shake.

8. Check the landing of each corner, and if they do not satisfy

the specification, paste a Disk-Mg onto the funnel and ad-

just.

Note:

(1) Do not paste more than 2 magnets to one corner.

(2) Paste within 80 to 100 mm from the DY on the diagonal line

of the magnet.

(3) If using the magnet, be sure to demagnetize with the hand

degausser and check.

9. Remove the sensor and wobbling coil.

10. Switch the signal to R.G.B., and check that each color is

pure.

11. Check that the DY is not tilting, and fix the purity Mg with a

white pen.

1 2

43

6

7

5

4-1

GDM-4011P

Connect the communication cable of the computer to the connector located on the D board on the monitor. Run the service software and

then follow the instruction.

•Convergence Specification

•Convergence Rough Adjustment

(1) Receive an image of the white crosshatch signals (white

lines on black).

(2) Place the protrusions of the 6-fold poles magnet attached to

the CRT neck upon each other.

(3) Make rough adjustment of the H direction convergence by

using H. STAT VR (left side of the video block).

(4) Make a rough adjustment of the V direction convergence by

using “V. STAT”.

*Set so that the protruding

parts of the 2 magnet rings

agree with each other.

RGB

R

G

B

XBV XCV

B

R

BR

RR

B

B

R

BBR

H. AMP H. TILT (TCH) YBH

YCH

R B

R B

•White Balance Adjustment Specification

(1) 9300K

x = 0.283 ± 0.005

y = 0.298 ± 0.005

(All White)

(2) 6500K

x = 0.313 ± 0.005

y = 0.329 ± 0.005

(All White)

(3) 5000K

x = 0.346 ± 0.005

y = 0.359 ± 0.005

(All White)

•Vertical and Horizontal Position and Size

Specification

•Focus adjustment

Adjust the focus volume 1 and 2 for the optimum focus.

MODE

fH

60 kHz

fH <

60 kHz

B

A

Zone

A zone

B zone

C zone

A zone

B zone

C zone

N. Hemisphere

0.24 mm

0.24 mm

0.32 mm

0.24 mm

0.32 mm

0.36 mm

V

H

C

Phospher edge

S. Hemisphere

0.28 mm

0.28 mm

0.36 mm

0.28 mm

0.36 mm

0.40 mm

B

a

a 2.8 mm

b 2.8 mm

a

b

b

A

MODE

A

B

1-5, 10

350 mm

280 mm

6, 7, 9

373 mm

280 mm

8

373 mm

201 mm

FBT

1 (V)

2 (H)

IBM AT Computer

as a Jig

1-690-391-21

1A-1500-819-A

Interface Unit

2

*The parts above ( ) are necessary for DAS adjustment.

13

D-sub

(9 Pin [female]) mini Din

(8Pin) 4 Pin

3-702-691-01

Connector Attachment

3

To BUS CONNECTOR

4 Pin 4 Pin

H.STAT

Magnet

Protrusions

60°

Fig. 1

Fig. 3

Fig. 2

TLYYCH YBH APH

TLH

XCV

XBV

4-2

5-1 5-2 5-3 5-4

SECTION 5

DIAGRAMS

5-1. BLOCK DIAGRAMS

4

1

1

3

6.3A

THP601

F601

T601

RY602

CN604

CN603

AC L

AC N

DGC

DGC

RELAY

DRIVE

Q690

RELAY

DRIVE

TH601 D610

RY601

VCC SW

Q615

DGC

BOOST

CONV OUT

Q610

REG SW

Q641,Q642

Q640

41

7

5

4

+80V

CN671

T640

D670

D672

T641

Q683

POWER SW

Q680-Q682

1

3

5

6

9

+80V

+15V

STBY 8V

HEATER(+)

CN672

9

+15V

-15V

11

1

3

2

H CENT H

H CENT L

H CENT N

IO

IC660

REG SW

T660

IC690

HEATER

REG

CN673

POWER SW

HEATER SW

DGC SW

PH680

PS674

G

(POWER SUPPLY)

B

A

4

2

3

1

AC INLET

Q660

IC630

C611

+180V SHUNT REG

R674

R675

1

2

3

J

(POWER SW)

AC L OUT

NC

AC L IN

1

2

3

AC L OUT

NC

AC L IN

CN605CN891

S891

POWER

2

3

1

4

56

34

D663

AC SENCE

DRIVE

I SENCE

V SENCE

OVP

VCC

LATCH

LATCH OUT

S GND

P GND

G

IC610

CHOPPER

CONT

10

8

7

5

3

6

2

1

11

9

SRT

D611L610

16

1

2

4

3

7

5

STBY 8V

C

+180V

+180V

+180V

I

VC

O

G

D691

45

D664

D665

D662

D678

4

3

1

2

7

6

1

2

3

4

5

CONT OUT

C647 PRT

SOFT START

D671

D673

D674

D682

4

3

1

2

5

6

7

8

9

10

11

12

D677

H

(USER CONTROL)

POWER

D810

LED DRIVE

Q811

LED DRIVE

Q810

3

4

5

LED 0

LED 1

KEY-DET

CN801

D

S810 S808 S806 S805 S804 S803 S802

RESET ASC BRT- BRT+ MENU CONT- CONT+

B-SS9011<NH.>-B/D-P3

PIT

8

4

3

1

4

3

1

2

3

4

5

6

7

5

4

3

11

9

8

6

4

3

2

1

ROTATION(-)

ROTATION(+)

CN509

+15V

IC701

CURRENT AMP

9

13

11

1

8

12

10

2

IC013

VS1

CS1

VS2

CS2

DMP CLK

DMP DO

DMP DI

DMP ID

39

38

46

7

45

9

11

10

12

6

41

43

42

44

33

IC007

CLP OUT

CBLK OUT

SONG

VIDEO

INPUT_SEL

CLK

DO

DI

ID

FBPIN

HS/CS1

VS1

HS/CS2

VS2

TILT

CN506

CLP

C.BLK

GREEN

VIDEO

HTIM

VIDEO OUT

VS OUT

HS OUT

VDF

HCENT

H SHAPE BAL

V SHAPE

VDC

V CONV

MOIRE

H SHAPE

H SIZE

2

8

48

47

28

32

29

19

26

27

34

30

31

DMP CLK

DMP DO

DMP DI

DMP ID

9

16

10

60

65

21

22

24

17

79

CN503

ASC_SW

MOSI

CLK

DAC_SEL

OSD_SEL

HFLB

VRET

20

19

CN505

RXD

TXD

7

2

1

6

3

5

IC009

12

13

LED0

LED1

KEY DET

CN501

EEP SDA

EEP SCL

IC004

EEP ROM

5

6

25

26

V CLK

SDA

SCL

V CLK

SDA

SCL

IC012

ROM

IC002

ROM

30

31

32

33

7

7

5

6

5

6

CN511

C.SYNC_1

V.SYNC_1

C.SYNC_2

V.SYNC_2

DDC_SDA_1

DDC_SCL_1

DDC_SDA_2

DDC_SCL_2

CPU

IC001

CS1

VS1

CS2

VS2

DDC_SDA_1

DDC_SCL_1

DDC_SDA_2

DDC_SCL_2

KEY_DET

EEP_SDA

EEP_SCL

LED0

LED1

TXD

RXD

ASC SW

OSD_SEL

DAC SEL

HFBP

VRET

DMP_CLK

DMP_DO

DMP_DI

DMP_ID

INPUT SEL

66

59

29

28

41

63,64

4

9

10

7

28

14

AFC1

SDA

SCL

HSYNC

PWM RFE

DF OUT

HVD OUT

HD OUT

FBP

PMW OUT

IC010

SYNC PROCESS

17

24

25

19

23

6

572

31

IC505

H DRIVE

Q504-Q506

PIN DRIVE

Q501-Q503

PROT DET

DGC

HTR SW

POWER SW

99

98

96

CK

RESET

8

3

IC005

WDT

85

86

87

88

89

90

82

83

X001

HV_PROT

V SHAPE

VDC

VRET

1

2

3

4

DGC

POWER

HTR_SW

STBY 8V

CN504

IO

IC006

5V REG

STBY5V

PS504

RY501

S1

S2

S3

S4

S5

T501

HDT

H OUT

Q508

PS501

T502

HOC

Q003

H DF OUT

V DF OUT

Q707,Q708

4

2

3

1

HV ADJ

IK DET

X RAY DET

1ST IK PROT

CN901

IC901

HV CONTROL

1

19

7

HV DRIVE

Q901,Q904,Q905

Q701,Q703-Q706

HV OUT

Q909

T901

HRC

HV REG SW

Q908

PS901

Q902

12

15

8

HV_PROT

ABL_DET

HV_DET

T902

FBT

HV

FV1

FV2

TO PICTURE TUBE

5

4

3

IC702

V OUT

7

2

5

1

IC703

H CENT

CONTROL

Q511

H CENT

H SHAPBAL

2

2

1

-VIN

+VIN

VEE

OUT

VCC

4

5

3

IC502

H CENT OUT

D

(U-COM,DEFLECTION)

3

2

1

9

11

7

5

4

+80V

-15V

+15V

HCENT H

HCENT N

HCENT L

CN502

1KV

CN507

I

OI

O

IC008

IC003

9V REG

9V REG

+80V

-15V

+15V

9V-1

9V-2

PS503

PS502

3

2

V.DY C

V.DY H

H.DY C

CN508

DPU

Q005

43

77

78

38

93

WDT

RESET

ABL DET

HV DET

S0

S1

S2

S3

S4

S5

+B DET

HPLL

IIC SDA

IIC SCL

HS

VS

ASC

T503

HST

T504

HCC

T701

DFT

1

A

V.DY

H.DY

H.DY C

H.DY H

H.DY H

PIN AMP

Q517

PIN OUT

Q507

S CAP

CHANGE

RELAY

DRIVE

Q509

7

10

E

D

INPUT_SW

BKGP

6

2

G

1

2

3

4

F

ROTATION

COIL

NTC

V.STAT(+)

V.STAT(-)

C

H

HOST+5V_1

HOST+5V_2

HOST+5V_1

HOST+5V_2

4

3

39

36

BKGP OUT

VRET

7

6

4

3

8

9

2

1

OUT2

V.S2

OUT1

V.S1

-VIN2

+VIN2

+VIN1

-VIN1

+180V

AFC2

Q004,007

27

AFC2

H PHASE

SOFT STR

18

TH.DET

Q512,TH501

95

TH_DET

PROT DET

Q591

Q590

1

2

6

5

HV

14

15

18

17

FV1

FV2

16

11

D935

25

ERR IN HD IN

ERR REF VREG9

PWM OUT

BTC IN

+180V

2

5

11

7

+5V

+180V

52

D512

+180V

5

2

3

5

1

2

H SIZEFB

IC501

S0

G5

G4

G3

D5

D4

D3

G1,G2 D1,D2

L503

HLC

L504

HLC

Q510

5

4

3

-VIN

+VIN OUT

+180V

+180V

4

5

8

9

4MHz

B-SS9011<NH.>-B/D-P2

100

XTALO

XTALI

S CAP

CHANGE

Q522

SOFT

START

Q001

5-6 5-7 5-8

5-5

5-2. FRAME SCHEMATIC DIAGRAM

1

2

3

4

5

6

7

CN402

CN401

CN403

CN407

R IN 2

G IN 2

B IN 2

INPUT SW

GREEN

CLP

C.BLK

VIDEO

R IN 1

G IN 1

B IN 1

ASC_SW

OSD_SEL

MOSI

CLK

DAC_SEL

HFBP

VRET

54321

10 9876

15 14 13 12 11

HD15

1

3

6

1

3

5

6

4

1

3

8

2

IC401

R_IN2

G_IN2

B_IN2

R_IN1

G_IN1

B_IN1

SW

G.SYNC

R_OUT

G_OUT

B_OUT

MOSI

CLK

HFLB

SS

VFLB

MOSI

CLK

HFBP

OSD_SEL

7

5

2

16

13

11

19

25

27

30

35

5

6

7

8

22

IC404

OSD

R

G

B

FBKG

17

12

3

23

14

9

1

26

28

27

26

25

24

R_IN

G_IN

B_IN

R_OSD

G_OSD

B_OSD

OSD_BLK

CLP

BLK

IC402

R_DRV

G_DRV

B_DRV

MAIN CONT

OSD CONT

R_OUT

G_OUT

B_OUT

37

42

51

18

13

4

27

25

52

DAC_SEL

CLK

MOSI

R_IN

G_IN

B_IN

R_OUT

G_OUT

B_OUT

1

CN1

KR

KG

KB

HEATER(+)

5

3

7

KR

KG

KB

HEATER(+)

CN2

HEATER(+)

+15V

STBY 8V

CN405

CN406

Q404

A(VIDEO AMP,RGB OUT)

BRT

Q101

Q201

Q301

IC403

RGB OUT

IC410

D/A CONVERTER

R_DRV

G_DRV

B_DRV

BRT

CONT

OSDCONT

LD

CLK

MOSI

R_CUTOFF

G_CUTOFF

B_CUTOFF

6

7

8

9

12

13

15

16

17

3

4

5

5

3

1

7

V901

PICTURE TUBE

FV1 FV2 HV

TO FBT

G2

B

9

1

3

5

6

1

1KV

IC406

12V REG

IC408

5V REG

OI

OI

+12V

+5V

+80V+80V

G.SYNC

Q401-Q403

VIDEO OUT

Q405 Q406,Q410

R_CUTOFF

G_CUTOFF

B_CUTOFF

Q105,106

Q205,Q206

Q305,Q306

E

G

F

BKGP

A3 A2 A1

12345

678910

13W3

H.STAT

H

+180V

VRET

RGB PRE-AMPRGB SWITCH

G2 CONTROL

IC409(1/3)

IC409(2/3)

IC409(3/3)

IC405(2/2)

IC405(1/2)

G2

H.STAT

19

2

H.STAT

CONTROL

Q411

11

7

1

13

5

3

RV401

H.STAT

+180V

B-SS9011<NH.>-B/D-P1

1

2

3

1

2

3

4

5

1

2

3

4

5

1

2

3

1

2

3

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

1

2

3

4

5

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

1

H

KBKG

KRG1

G2

GM

G4

RCV

HV

1

2

1

2

1

2

3

4

1

2

3

4

5

6

7

8

9

1

2

1

2

1

2

3

4

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

1

2

3

41

1

2

3

4

5

6

7

8

CN406

CN405

CN605

CN604CN603

CN504 CN673

CN1

CN402

CN401

CN891

CN403

CN407

CN2

CN671

CN502

CN801

CN503

CN508

CN509

CN511 CN505 CN506 CN507

CN901

CN672

CN602

CN501

CN607

CN902

HD15

2P

WHT

:VH

8P

WHT-L

:S-MICRO

3P

3P

WHT

:VH

4P

WHT

:VH

5P

WHT

:S-MICRO

5P

WHT

:S-MICRO

7P

WHT-L

:S-MICRO

6P

WHT-L

:S-MICRO

3P

WHT

:VH

8P

WHT-L

:S-MICRO

7P

WHT-L

:S-MICRO

11P

WHT

:S-MICRO

11P

WHT

:S-MICRO

9P

:XA

7P

WHT

:S-MICRO

9P

WHT

:VH

4P

WHT

:S-MICRO

11P

WHT

:S-MICRO

4P

WHT

8P

WHT-L

:S-MICRO

2P

WHT

:VH

5P

WHT

:S-MICRO

9P

WHT

:S-MICRO

1P

8P

YEL

:S-MICRO

1P

1P

1

2345

678910 11

12131415

1KV

NC

GND

TXD

RXD

C.SYNC_1

V.SYNC_1

C.SYNC_2

V.SYNC_2

GND

FV1

FV2

LED0

LED1

H.DY H

H.DY H

NC

NC

H.DY C

H.DY C

V.DY H

GND

V.STAT+

V.STST-

V.STAT+

IK DET

HV ADJ

DGC

NC

NC

DGC

AC N

NC

AC L

FBT

CONNECTOR PANEL

TO ECS

DGC AC INLET

H.DY

NTC

HV

X RAY DET

V.STAT-

SUB ROT +

SUB ROT -

V.DY

V.DY

V.DY C

H.CENTER.H

H.CENTER.N

H.CENTER.L

+180V

+180V

+80V

GND

+15V

GND

-15V

GND

H.CENTER.H

H.CENTER.N

H.CENTER.L

+180V

+180V

+80V

GND

+15V

GND

-15V

GND

AC L OUT

NC

AC L IN

AC L OUT

NC

AC L IN

POWER SW

GND

C BLOCK

STBY+5V

STBY+5V

KEY_DET

D GND

STBY+8V STBY+8V

DGUS SW

POWER SW

HEATER SW

DGUS SW

POWER SW

HEATER SW

1ST IK PROT

DDC_SDA_2

HOST+5V_2

DDC_SCL_2

ROTATION

R IN 2

R_GND2

G IN 2

G_GND2

B IN 2

B_GND2

R IN 1

R_GND1

G IN 1

G_GND1

B IN 1

B_GND1

CLP

GREEN

GND

GND

VIDEO

1KV

NC

FV1

FV2

INPUT_SW

+180V

+80V

GND

+15V

GND

HEATER+

NC

KB

GND

KG

GND

KR

GND

GND

HEATER+

G2 GND

HSTAT

G2 GND

HSTAT

HFLB

VRET

C.BLK

STBY+8V

NC

OSD_SEL

MOSI

CLK

DAC_SEL

NC

NC

+180V

+80V

GND

+15V

GND

HEATER+

STBY+8V

NC

NCNC

MOSI

CLK

DAC_SEL

HFLB

VRET

CLP

GREEN

GND

GND

VIDEO

INPUT_SW

C.BLK

ROTATION+

ROTATION-

(CRT SHIELD)

KB

GND

KG

GND

KR

GND

GND

HEATER+

GND

NC

DDC_SDA_1

HOST+5V_1

DDC_SCL_1

NC

GND

15V

ENV_TEMP

LED0

LED1

STBY+5V

KEY_DET

D GND

15V

ENV_TEMP

GND

GND

BKGP

OSD_SEL

ASC_SW

ASC_SW

GND

(POWER SW)

JG

(POWER SUPPLY)

A

VIDEO AMP,

RGB OUT

H

(USER CONTROL)

D

(U-COM,DEFLECTION)

A3 A2

A1

54321

10 9876

BG R

13W3

B-SS8481<NH.>-KESSENZU

Table of contents

Other Silicon Graphics Monitor manuals

Silicon Graphics

Silicon Graphics 1600SW User manual

Silicon Graphics

Silicon Graphics GDM-5011P User manual

Silicon Graphics

Silicon Graphics GDM-5411 User manual

Silicon Graphics

Silicon Graphics F181 User manual

Silicon Graphics

Silicon Graphics Reality Center User manual

Silicon Graphics

Silicon Graphics Presenter 1280 User manual

Silicon Graphics

Silicon Graphics F180 User manual

Silicon Graphics

Silicon Graphics Presenter User manual

Silicon Graphics

Silicon Graphics GDM-FW9011 User manual

Silicon Graphics

Silicon Graphics GDM-5411 User manual