Silverline FLOW-IN PRO User manual

FLOW-IN PRO USER MANUAL

EN

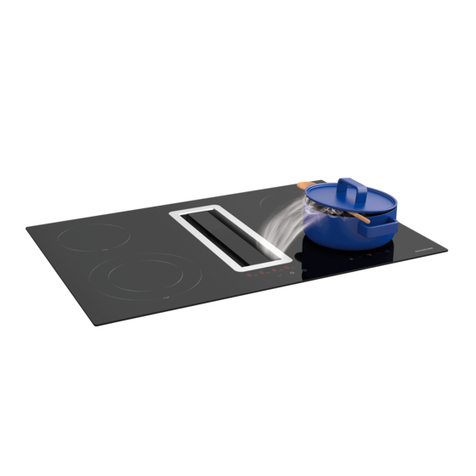

MODELS

IM7110

PE905 FIP

1, en_US

Jilmas Group Nordic ApS Eli Christensens Vej 90, 7430 Ikast Denmark

Telephone: +45 70104014

Fax: +45 70131389

E-mail: [email protected]

Internet: www.silverline.dk

11.02.2021FLOW-IN PRO USER MANUAL EN2

Table of contents

1 PREFACE............................................................................. 4

2 Warnings.............................................................................. 5

3 TECHNICAL DATA............................................................... 8

4 PRODUCT PERSPECTIVES................................................ 9

5 PRODUCT OVERVIEW...................................................... 10

6 Control Panel..................................................................... 11

6.1 Symbols...................................................................... 12

6.2 Segment Screens....................................................... 13

6.3 Stove Hood Usage Type............................................. 13

7 Active carbon filter replacement..................................... 15

8 CLEANING AND PREVENTIVE MAINTENANCE............. 17

8.1 Cleaning of the metal oil filter and water tank............. 17

9 Induction Cooking System Working Principles............. 20

9.1 Cookware.................................................................... 20

10 Packing.............................................................................. 24

11 Installation and Assembly ............................................... 25

12 Assembly .......................................................................... 28

13 Connection Scheme ........................................................ 33

14 USE OF PRODUCT............................................................ 34

14.1 Hood Panel .............................................................. 34

14.1.1 Automatic ventilation ............................................. 35

14.1.2 Timer...................................................................... 35

14.1.3 Metal Oil filter......................................................... 37

14.1.4 Active Carbon filter ............................................... 37

14.1.5 Starting the countdown of the active carbon filter.. 37

14.1.6 Stopping the countdown of the active carbon filter 37

14.1.7 Metal oil filter and active carbon filter.................... 38

14.2 Stove panel............................................................... 38

14.2.1 3 level temperature mode...................................... 39

14.2.2 Child lock .............................................................. 39

14.2.3 Power boost cooking mode selection ................... 40

14.2.4 Bridge selection .................................................... 40

14.2.5 Timer ..................................................................... 41

15 Power Levels..................................................................... 43

16 Process plate..................................................................... 44

17 Accessories and Spare Parts.......................................... 45

17.1 Accessory................................................................. 45

18 AUTHORIZED SERVICE.................................................... 50

Table of contents

11.02.2021 FLOW-IN PRO USER MANUAL EN 3

1 PREFACE

Follow the step-by-step instructions in this manual.

The manufacturer accepts no responsibility for any negativity,

damage or fire that may occur in the appliance as a result of not

following the instructions given in this manual. The appliance is

intended for domestic use only for cooking food and aspiration of

fumes from said cooking. Use for other purposes is not permitted

(eg. Heating the environment). The manufacturer accepts no

responsibility for improper use or incorrect setting of commands.

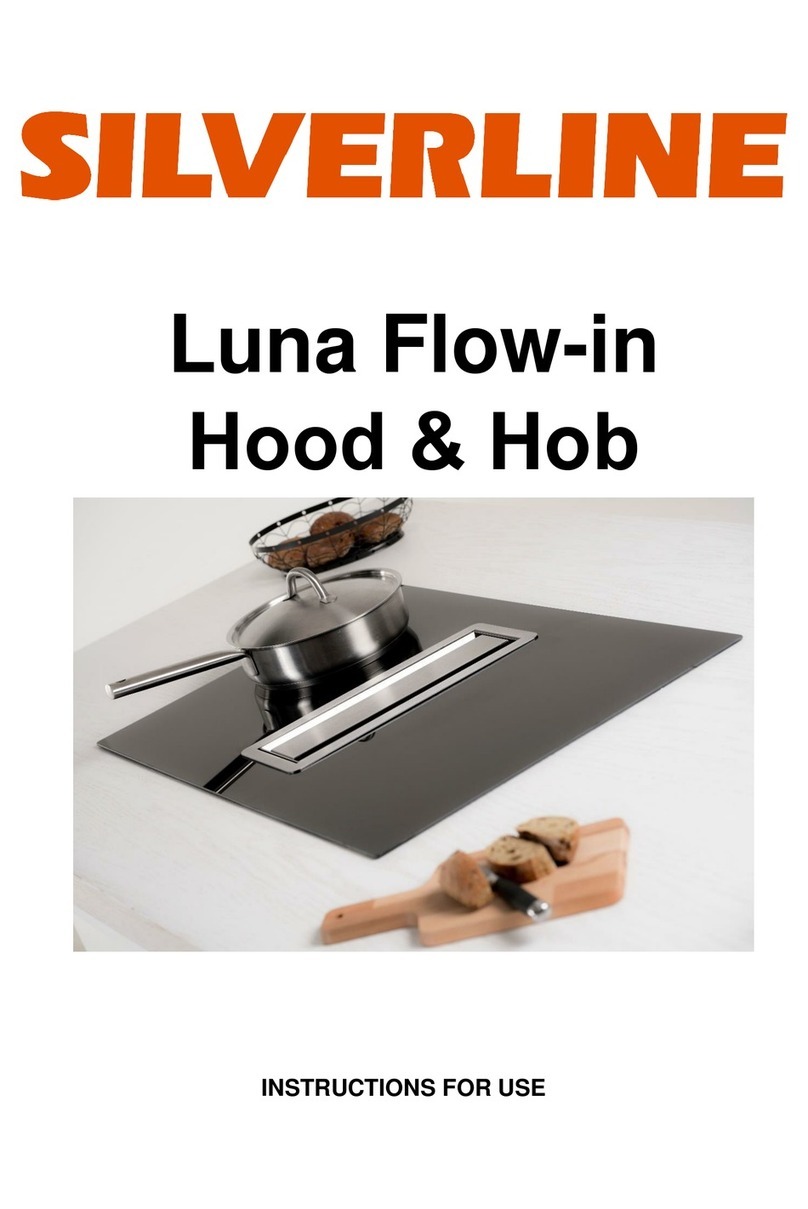

The appearance of the product may differ from

those depicted in the images in this booklet,

but the instructions for use, maintenance and

installation remain the same.

It is important to keep this user manual for future reference at any

time. Make sure that this user manual is not separated from the

product during the sale, lending or transfer of the product.

nRead the instructions carefully: It contains very important infor-

mation regarding installation, usage and safety.

nDo not perform electrical repairs on the product.

nCheck whether all the components are usable before installing

the appliance. Otherwise contact the manufacturer and do not

continue installing.

nMake sure of the product’s integrity before installing. Otherwise

contact the manufacturer and do not continue installing.

PREFACE

11.02.2021FLOW-IN PRO USER MANUAL EN4

2 Warnings

CAUTION!

Strictly follow the instructions specified on this

manual.

Before starting any installation procedure, the appliance must be

disconnected from the mains.

The installation or maintenance of the appliance must be carried

out by a qualified technician in accordance with the manufacturer's

instructions and in compliance with the local regulations in force on

safety.

In case of damage due to incorrect connection, the appliance will

be out of warranty.

Do not repair or replace any part of the appliance, unless it is spe-

cifically stated in the user manual.

CAUTION!

The appliance is not suitable for use in sockets

without grounding.

The power cable must be long enough to allow the appliance to be

connected to the mains.

In order for the installation to comply with the current safety regula-

tions, a standard-compliant switch is required, which ensures com-

plete disconnection of the network under overvoltage category con-

ditions.

Do not use multiple sockets or extensions.

After completing the installation, the user should no longer be able

to access the electrical components.

The areas touched during use are hot. Keep children away from

the appliance and under supervision.

The appliance can be used by children under 8 years of age, per-

sons with limited physical, mental and emotional abilities, and per-

sons with incomplete experience or knowledge only if they are

under the supervision of a responsible person or have been

informed about the safe use of the appliance and the dangers that

may occur.

Cleaning and maintenance should not be done by children without

supervision.

Before using the induction stove, people with pacemakers and

active implants should check whether their appliance is compatible

with the appliance. It is not possible to guarantee that 100% of the

appliances on the market will fulfil the electromagnetic compatibility

criteria in force and will not cause interference that will jeopardize

the correct operation of the appliance. It is also possible that

people wearing other appliances such as hearing aids may experi-

ence some discomfort.

Warnings

11.02.2021 FLOW-IN PRO USER MANUAL EN 5

Do not touch the heater parts of the appliance during and after use.

Avoid contact with cloth or other flammable materials before all

components of the stove are sufficiently cooled.

Overheated greases and oils can easily catch fire. When cooking

food rich in oil, keep it under supervision.

Do not place metal items such as knives, forks, spoons and lids on

the stove as there is a possibility of overheating.

Do not use a steam cleaner.

Surface damage, discolouration and stains due to unsuitable deter-

gent. Use only detergent suitable for this type of stove.

Discolouration due to surface damage and pot friction. Lift and

carry pots and pans, do not push.

If the surface is cracked, turn off the appliance to avoid possible

electric shock.

The appliance is not suitable for operation via an external timer or

a separate remote control system.

Unsupervised cooking on an oil stove can be dangerous and cause

a fire.

The cooking process should always be monitored.

NEVER try to extinguish the fire with water. On the contrary, turn

off the stove immediately and smother the flames using a fireproof

lid or a cover.

Do not put any objects on the stove.

Before connecting the appliance to the electricity network, check

the information plate at the bottom of the stove to make sure that

the electrical voltage and power values are compatible with the

network and the connection cable is suitable. In case of doubt,

contact a qualified electrical expert.

Important:

After use, turn off the stove using the control and do not rely on the

pan sensor.

To prevent liquids from overflowing, reduce heat input when boiling

or heating liquids.

When your appliance is in operation and there is a

water overflow or a wet cloth is placed, your appli-

ance shuts down to protect itself. To restart your

appliance, you must unplug the power cord and

plug it in again.

Do not leave an empty pot or pan on the heater components or

without a container.

After completing the cooking process, turn off the relevant section.

Warnings

11.02.2021FLOW-IN PRO USER MANUAL EN6

Using a high power function such as a booster is not suitable for

heating some liquids such as cooking oil. High temperature can be

dangerous. In these cases, it is recommended to use a lower

heating power.

The containers should be placed directly on the stove and cen-

tered. There should be no other objects between the pot and the

stove.

When there is high heat, the appliance automatically reduces the

power level of the cooking areas.

Before any cleaning or maintenance, disconnect the product from

the mains by unplugging or by turning off the cabinet's main switch.

Wear work gloves for all installation and maintenance operations.

The inside and outside of the appliance should be cleaned fre-

quently (AT LEAST ONCE A MONTH). Also, follow what is clearly

stated in the maintenance instructions.

Failure to comply with standards regarding the cleaning of the

appliance and the cleaning and replacement of the filters creates

the risk of fire.

Frying should be done under control to prevent the overheated oil

from catching fire.

When the stove is in operation, accessible parts of

the hood become hot.

CAUTION!

Do not connect the appliance to the power grid

until the installation is completely complete.

In terms of safety measures and technical measures to be adopted

for smoke evacuation, strictly comply with the stated facts in the

regulations of the local competent authorities.

Warnings

11.02.2021 FLOW-IN PRO USER MANUAL EN 7

3 TECHNICAL DATA

Flow-in Pro Product Features

Supply voltage 220-240 V(~) 50/60 Hz - 380-415 V(~) 2N(~) 50/60

Hz

Frequency 50/60 Hz

Max. power consumption 7360 W

Fuse protection / power source 2x16 A /1x32 A

Product dimensions (width/depth/height) 780x520x210

STOVE

Power levels 1-9 P

Front cooking area cooking pot size 190mm

Front cooking area power value 2000 W / 2800 W

Rear cooking area cooking pot size 190mm

Rear cooking area power value 1500 W / 2000 W

Stove power efficiency_EN 60350-2

1st cooking area power consumption 172.25 (Wh/kg)

2nd cooking area power consumption 175.79 (Wh/kg)

3rd cooking area power consumption 174.01 (Wh/kg)

4th cooking area power consumption 173.61 (Wh/kg)

Power efficiency value 173.92 (Wh/kg)

Oil filter

Oil capacity 60 hours

Oil filter service life 2 years

TECHNICAL DATA

11.02.2021FLOW-IN PRO USER MANUAL EN8

4 PRODUCT PERSPECTIVES

520

140,5

R5

319

126

195

482

145

512

152 58

210

780

740

480

363 20

210

453

520

06

Fig. 1: Flow-in Pro üstten / önden / yandan görünümü

PRODUCT PERSPECTIVES

11.02.2021 FLOW-IN PRO USER MANUAL EN 9

5 PRODUCT OVERVIEW

1

2

3

4

5

6

7

8

9

10

Fig. 2

1- Decorative Lid

2 - Oil Filter

3 - Carbon Filter Cover

4 - Carbon Filter (Optional)

5 - Oil filter Bed

6 - Control Panel

7 - Water Tank

8 - Elbow (Optional)

9- Fladkanal

10- Flexi pipe

PRODUCT OVERVIEW

11.02.2021FLOW-IN PRO USER MANUAL EN10

This manual suits for next models

1

Table of contents

Other Silverline Hob manuals

Silverline

Silverline AS 5443 X01 User manual

Silverline

Silverline PEK1000 Manual

Silverline

Silverline PIK 80 S User manual

Silverline

Silverline CS 5222 User manual

Silverline

Silverline PEI3084 Manual

Silverline

Silverline FLAK 810 ESK User manual

Silverline

Silverline FLHK 800 ESK Product guide

Silverline

Silverline RS5322B01 User manual

Silverline

Silverline PEK1001 User manual

Silverline

Silverline AS 5255 User manual