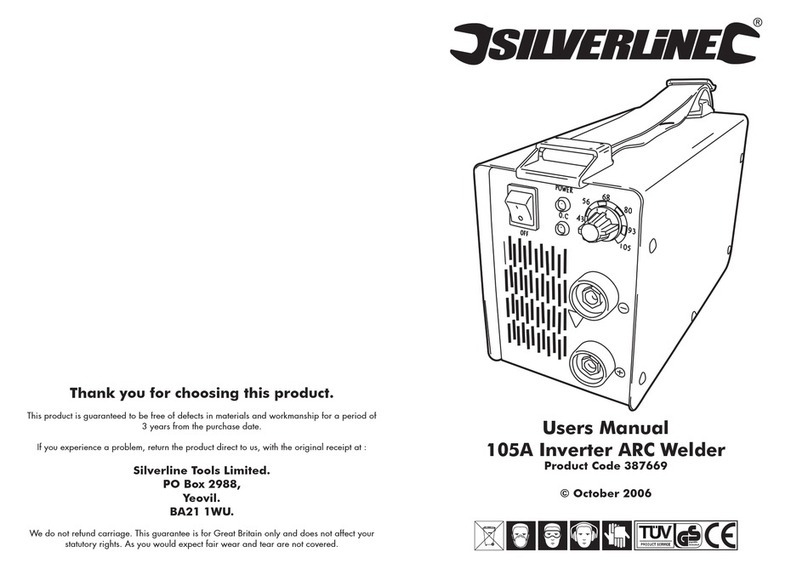

1. Temperature indicator

2. On/off switch

3. Magnetic shunt

4. Earth clamp

5. Electrode holder

6. Handle

7. Graduated welding amperage scale

SPECIFICATION

Voltage 230V

Frequency 50Hz

No load voltage 48V

Current range 55-160A

Input capacity 6.5kW

ADDITIONAL SAFETY INSTRUCTIONS

Do not operate the welder in a confined space.

The welder is required to operate in a good air space to aid

cooling.

Keep work area clean and provide the correct working

conditions.

•Arc welding produces sparks and high temperature fused

metal projectiles and fumes.

• Remove all flammable substances and materials from the

work surface.

• Provide adequate ventilation of facilities where welding

takes place.

• Do not weld on containers or pipes that hold or have held

flammable liquid or gaseous combustibles or on materials

cleaned with chlorinated solvents or on varnished surfaces.

•Cluttered areas invite injuries. Make sure the area is clear of

obstacles, which could cause accidents.

Always wear protective equipment.

Personal protective clothing must be worn, use adequate

electrical insulation with regard to the electrode, the work

piece and any earthed metal parts in the vicinity. This is

achieved by wearing gloves, shoes, head coverings (such as

the face mask provided) and clothing designed for this

purpose and using insulating platforms and mats.

Rated duty cycle 10%

Class of insulation H

Electrode size range 2-4.0mm

Fuse 16A

Mains plug Earthed

•Before carrying out maintenance on the welder ensure that

it is disconnected from the power supply.

• You must ensure that a qualified person carries out repairs

and maintenance of electrical opponents.

• When the welder is not in use, turn it off at the mains. Live

electrodes present a hazard, as they can arc against the

earthed metal.

•Before using the welder, check every time that the cable

connections are fully tightened and that there are no broken

parts.

• Keep welding cables, the electrode holder and the earth

clamp in good condition. Poor contact through the welding

circuit caused by defective cables and clamps can be

dangerous and produces poor fields.

Introduction

Carefully read and understand this manual and any label

attached to the tool before use. Keep these instructions with the

product for future reference. Ensure all persons who use and

service this product are acquainted with this manual.

Electrical Safety Information

• The wires in this product are coloured:

Blue Neutral (N)

Brown Live (L)

Green & Yellow Earth (E)

• As the colours may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows.

• The wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured black, the

wire which is coloured brown must be connected to the terminal

which is marked L or coloured red.

• This appliance must be protected by a suitable fuse.

• To prevent fire or shock hazard, do not expose this product to

rain/water or moisture. There are no user serviceable parts

inside except those referred to in this manual. Always refer

servicing to qualified service personnel. Never remove any part

of the casing unless qualified to do so; this unit contains

dangerous voltages.

• Use of a residual current device (RCD) will reduce the risk of

electric shock.

NEVER CONNECT THE BROWN OR BLUE WIRE TO THE

EARTH PIN OF THE 13 AMP PLUG. IF IN DOUBT CONSULT A

QUALIFIED ELECTRICIAN

General Safety Instructions

Even when used as prescribed it is not possible to eliminate all

residual risk factors. Use with caution.

Keep guards in position

•Always keep guards in position, in good working order, correctly

adjusted and aligned. Never attempt to use a power tool

without any guard supplied with it.

Remove adjusting keys

• Always check to see that keys and adjusting wrenches are

removed from power tool before turning on.

Clean work area

•Accidents occur where benches and work areas are cluttered or

dirty, floors must be kept clear, avoid working where the floor is

slippery.

Dangerous environment

• Do not use power tools in damp or wet conditions, or expose

them to rain. Provide adequate surrounding work space and

keep area well lit. Do not use power tools where there is a risk

of explosion or fire from combustible material, flammable

liquids, flammable gases or dust of an explosive nature. When

using power tools avoid contact with any earthed items such as

pipes, radiators, cookers, refrigerators, metal baths and taps.

Children & Pets

• Children and pets should always be kept at a safe distance

from your work. Make your workshop child-proof. Lock tool

away where children can't get access to them. Remove

batteries from cordless tools.

Use the correct power tool

•Don't force, or attempt to use a power tool for a purpose it was

not designed for. Do not use a small tool to do the job of a

heavy duty tool.

Wear correct clothing and footwear.

• Don't wear loose clothing, neckties or jewellery or other items

which may get caught in moving parts. Wear non-slip footwear,

cover or tie back long hair. Use safety footwear if necessary.

Protect your head

• Wear safety goggles at all times, every day glasses are not

sufficient for eye protection, as lenses are not impact resistant

and could shatter. Use an approved face or dust mask when

operation creates dust. Ensure dust extraction equipment is

functioning and correctly used. Hearing protection should be

used if the sound intensity level for the operator could exceed

85dB(A). Use a hard hat where there is a risk of falling objects

or striking your head on low level obstructions.

Protect yourself from vibration.

• Hand held power tools may produce vibration. Vibration can

cause disease. Gloves to keep the operator warm and dry and

therefore maintain good blood circulation in the fingers may

help. This tool has not been designed for extended or industrial

operation.

Secure work

• Always secure work. Where practical use a clamp or vice, it will

allow you to use both hands to operate your power tool.

Keep your balance

• Don't over reach, keep proper footing at all times to ensure

correct balance.

Maintain your power tool

• Keep your power tool in good working order, keep tools sharp

and clean for best and safest performance. Ensure ventilation

holes are kept clean and unrestricted at all times.

Always disconnect.

• Before changing tools, always ensure they are disconnected

from the power source.

Accessories

• The use of any attachment or accessory other than those

mentioned in this manual could result in damage or injury. The

use of improper accessories could be dangerous.

Never stand on your power tool

• Standing on your power tool or its stand could cause serious

injury if the tool is tipped or if the cutting tool is accidentally

contacted. Do not store materials above or near the tool so that

it is necessary to stand on the tool or its stand to reach them.

Switch off before connecting.

•Ensure the power tool is switched off before connecting to the

power source.If the power tool stops unexpectedly turn the

power switch to off.

Do not abuse the power cord.

•Be sure your cable/extension cable is properly wired and in

good condition. Always replace a damaged cable/extension

cable or have it repaired by a qualified person before using it.

Never yank or pull the cable to disconnect it from the power

socket. Never carry your power tool by it’s cable. Keep the

cable away from damp, heat, oil, solvents, and sharp edges.

Check for damaged or missing parts.

• Before each use check if any part of the power tool is damaged

or missing, check carefully that it will operate properly and

perform its intended function. Check alignment of moving parts

for binding. Any guard or other part that is damaged should be

correctly repaired or replaced. Do not use if the power switch

does not turn the power on and off. Check any other condition

that may affect the safety of the power tool. DO NOT USE IF

DEFECTIVE.

Direction of feed

•Feed work into a blade or cutter against the direction of rotation

of the blade or cutter only.

Don't leave the tool running unattended

• Always wait until your power tool has come to a complete stop

before leaving it and then disconnect from power source.

Product Familiarisation

Arc Welder

5

2

3

1

67

4