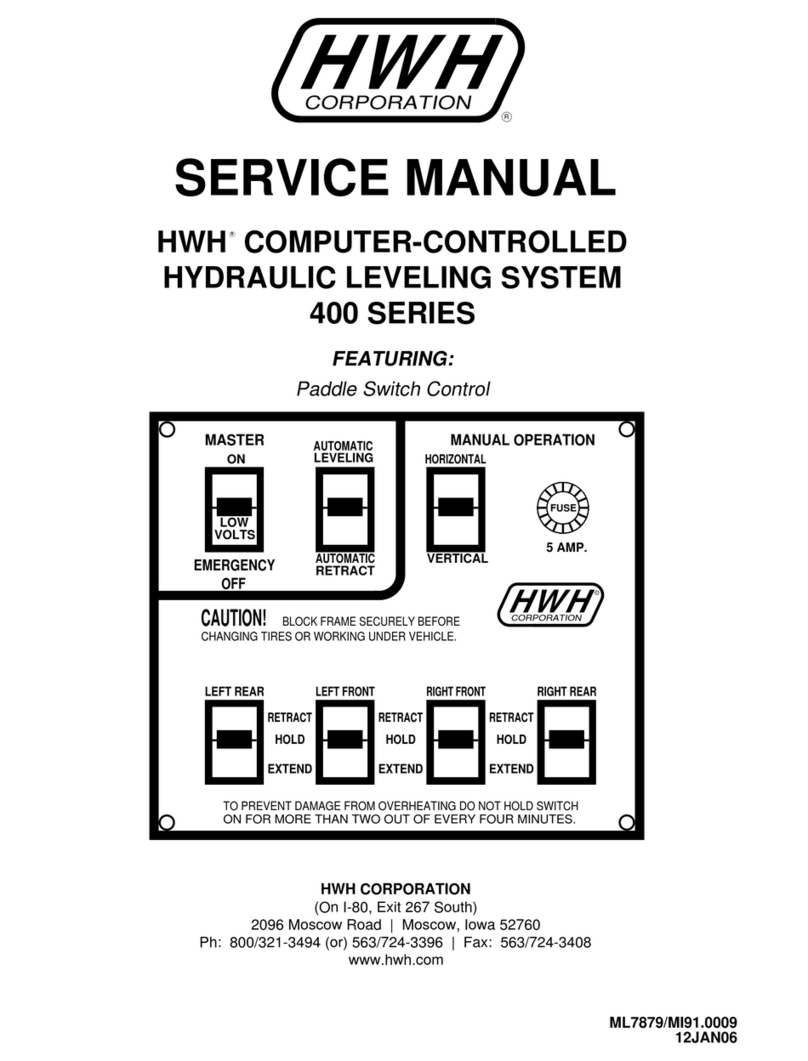

OPERATION PROCEDURES

LEVELING PROCEDURE

1. Place gear selector in the park position apply the park brake.

3. Push the rocker switch in jack control plate to "LEVEL".

4. Swing each jack to the vertical position by pushing each

control lever to "EXTEND". The respective red "WARNING" light

will light as soon as the jack swings vertical. Check that all

jacks have swung to the vertical position.

6. A lit yellow "LEVEL" light indicates that corner of the vehicle

is low. Extend jacks as needed to put out all the yellow lights.

7. After the vehicle is level, the jacks not used for leveling may be

extended until they touch the ground. This provides additional

stability against wind and activity in the vehicle.

8. Turn off the rocker switch on the leveling system panel.

9. Turn off the ignition switch.

or whenever the vehicle is used, to keep the system in good

operating condition.

Park with the front of the vehicle facing downhill if possible.

Care must be taken not to raise the rear of the vehicle too high

or the vehicle may roll forward or backward off the jacks. If

parking on soft ground or asphalt paving, wood blocks or

pads should be placed under the jacks.

SITE SELECTION

LEVELING TIPS: Two jacks maybe operated at the same time,

if desired. Operation of both side jacks at the same time often

provides a smoother lift while reducing stress on the vehicle

and jacks. If for example, a right front and a right rear yellow

"LEVEL" light is on, operate the right rear jack or the right

front and right rear jacks together. Right to left leveling is usu-

ally best accomplished using a rear jack or a front and rear

jack together. If a substantial amount of leveling is required,

it is often best to operate two jacks at the same time, leveling

If the ground is too uneven the jacks may not have enough

stroke to level the vehicle. The vehicle may have to be moved.

Remember that if the rear of the vehicle is lifted too high the

vehicle may roll forward or backward off the jacks.

side to side first.

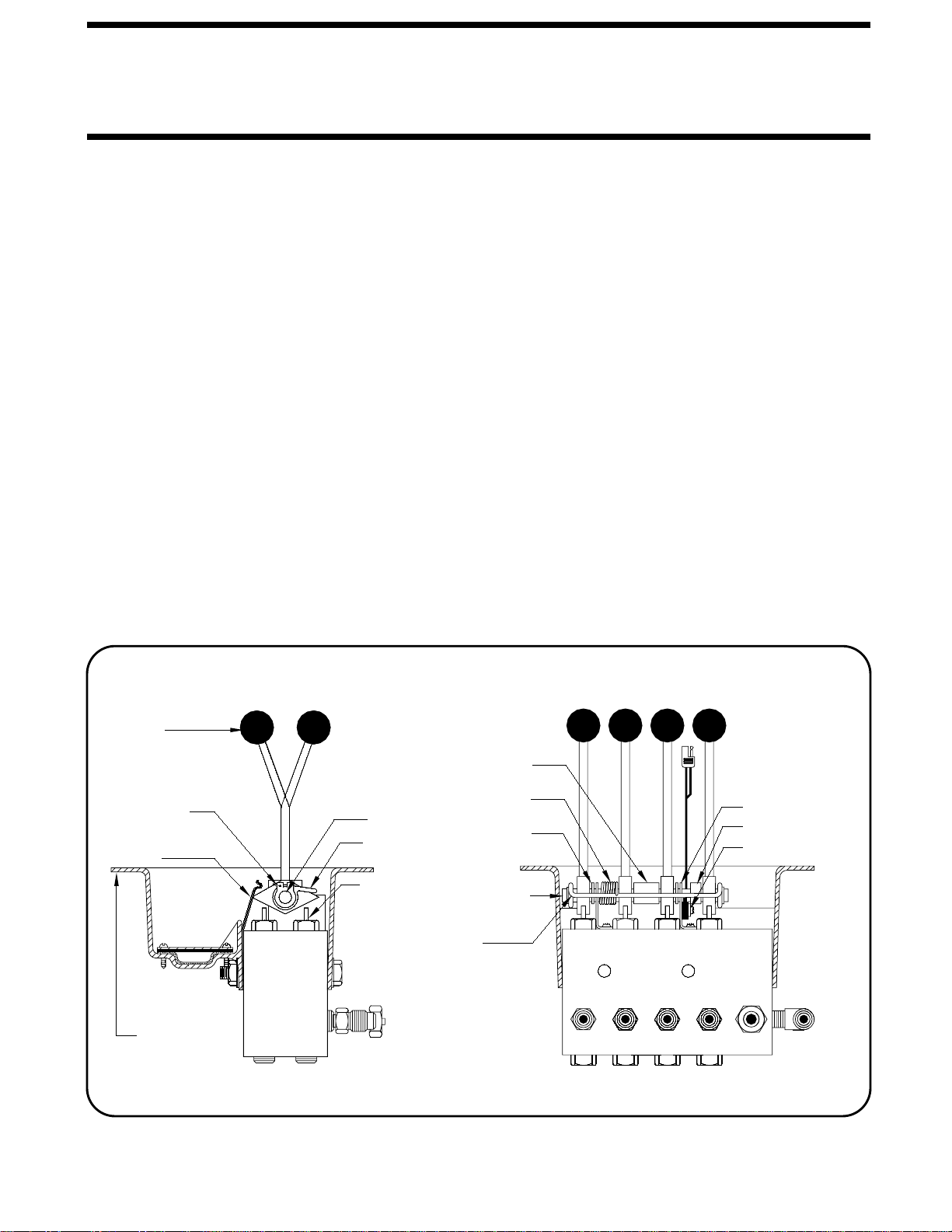

ROOM EXTENSION PROCEDURES

read this section carefully.

If the vehicle is equipped with kick-down jacks, the wheels MUST

be blocked securely. Do NOT operate any room extension

until the leveling and stabilizing procedure is complete. Do

If the vehicle is equipped with a room extension

IMPORTANT:

NOT retract the leveling system until all room extensions are

retracted. NEVER operate the leveling system when any

Refer to the vehicle owner’s manual for proper operation of

room extensions are extended.

room extensions.

IMPORTANT: Do not use a room extension support when the

vehicle is supported by the leveling system.

Block tires securely.

2. Turn ignition switch to "ON" or "ACCESSORY". The vehicle

engine must be off. Running the engine during or after leveling

may inflate the air suspension, lifting the vehicle out of level.

5. Push and hold the rocker switch to the "DUMP" position

until the air is completely exhausted from the vehicle suspension

system.

IMPORTANT:

Overheating and excessive current draw will

result if control levers are partially operated toward "EXTEND"

for an extended period of time.

NOTE:

The leveling system should be cycled once a month

MP35.1028

09MAY97