Sime Dewy 30 HE FS User manual

Other manuals for Dewy 30 HE FS

1

This manual suits for next models

1

Other Sime Boiler manuals

Sime

Sime MURELLE.HT 25 T Manual

Sime

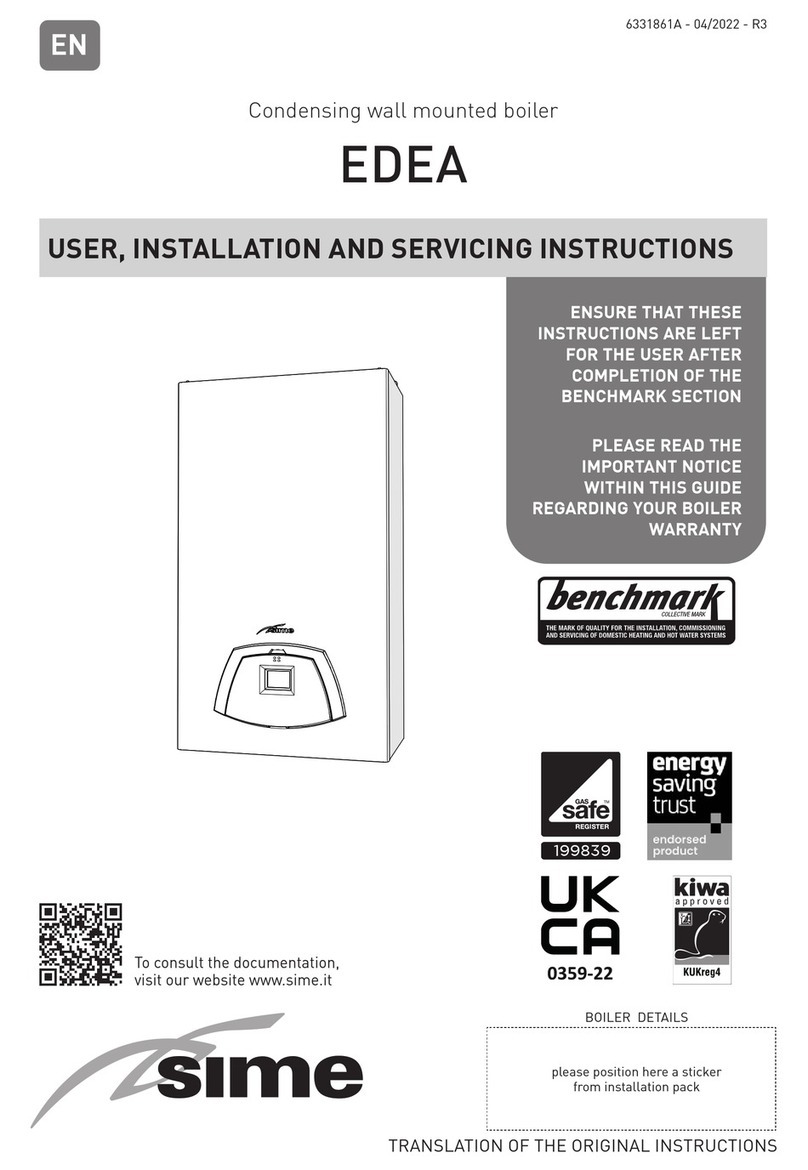

Sime EDEA Manual

Sime

Sime RS MK II Guide

Sime

Sime LOGO OF TS Series User manual

Sime

Sime MURELLE HE 70 R ErP Manual

Sime

Sime Solo/Duetto OF-BF User manual

Sime

Sime SOLO ErP Series User manual

Sime

Sime AQUA 25 INOX BF TS User manual

Sime

Sime PLANET 25/60 BF User manual

Sime

Sime BRAVA ONE BF Manual

Sime

Sime MURELLE EQUIPE 100 BOX ErP Manual

Sime

Sime RMG 70 P User manual

Sime

Sime MURELLE HM 25 ErP User manual

Sime

Sime Ecomfort User manual

Sime

Sime MURELLE HE 25-55 ErP User manual

Sime

Sime Rondo OF TS Series User manual

Sime

Sime ESTELLE B4 INOX ErP BE Manual

Sime

Sime MURELLE HE 50 R E User manual

Sime

Sime RX 19 TP Operating and maintenance manual

Sime

Sime SUPERIOR Ci EI Assembly Instructions

Popular Boiler manuals by other brands

Riello

Riello Condexa Pro2 EVO Series installation instructions

Wunda

Wunda E09 installation guide

Worcester

Worcester HEATSLAVE 9.24 RSF Installation and maintenance instructions

Immergas

Immergas VICTRIX ZEUS 20 manual

Ariston

Ariston ALTEAS ONE Training manual

MHG Heating

MHG Heating ProCon MCS 320 Installation and operating manual

Ideal Boilers

Ideal Boilers Procombi Exclusive 24 Installation & servicing instructions

LOCO COOKERS

LOCO COOKERS LCBR90KD Owner's manual and assembly instructions

Viessmann

Viessmann VITODENS operating instructions

Baxi

Baxi Luna 310 Fi User instructions

Harsco Industrial

Harsco Industrial SC-1500 owner's manual

Biasi

Biasi Advance Plus 25C Service manual

Buderus

Buderus Logano plus GB312 Installation and service instructions

Worcester

Worcester 27i System Compact Installation, commissioning and servicing instructions

Froling

Froling T4 24-150 installation instructions

Lochinvar

Lochinvar Knight 51 - 106 Service manual

Dover

Dover unified brands Groen NGB/3E Operator's manual

Freestyle

Freestyle 80 manual