72

The boiler must be installed in a fixed loca-

tion and only by specialized and qualified

firms in compliance with all instructions

contained in this manual. Furthermore,

the installation must be in accordance with

current standards and regulations.

2.1 INSTALLATION

– Boilers can be installed in all domestic

environments without any whatsoever

limit in terms of location and comburent

air supply.

– These boilers can also be installed in

partially covered areas, as per EN 15502,

with a maximum ambient temperature

of 60°C and a minimum ambient tempe-

rature of -5°C. It is generally advisable

to install the boilers below weathered

roofs, on the balcony or in a protected

niche, to protect them from exposure to

weathering agents (rain, hail and snow).

All boilers provide a standard antifreeze

function.

2.1.1 Anti-freeze function

The boilers are equipped with anti-freeze

function which activates the pumps and

the burner when the temperature of the

water contained inside the appliance drops

to below 6°C. The anti-freeze function is

ensured, however, only if:

- the boiler is correctly connected to the

gas and electricity supply circuits;

- the boiler is constantly fed;

- the boiler ignition is not blocked;

- the essential components of the boiler

are all in working order.

In these conditions the boiler is protected

against frost down to an environmental

temperature of -5°C.

ATTENTION: In the case of installation

in a place where the temperature drops

below 0°C, the connection pipes must be

protected.

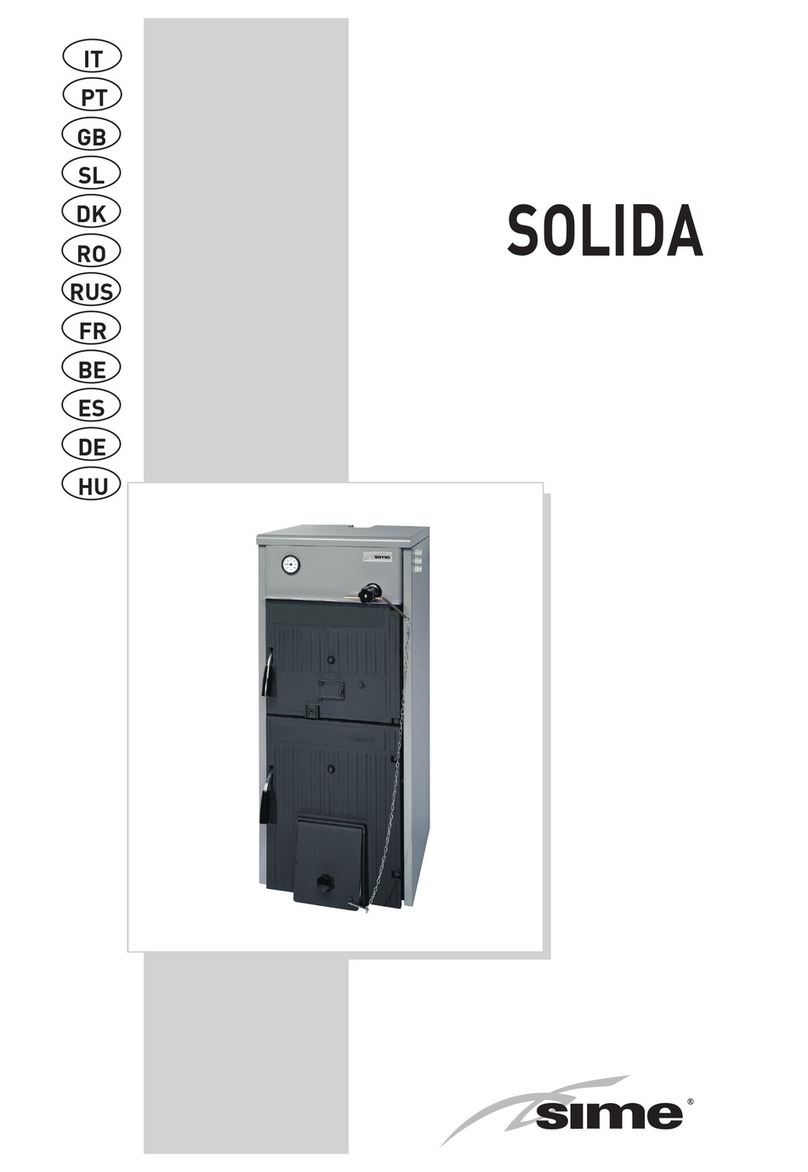

2.2 BOILER SUPPORT BRACKET

For the mounting of the support bracket of

the boiler, which is supplied, observe the

following instructions (fig. 4):

– Fix the bracket to the wall with appro-

priate dowels.

– Check with a spirit level that it is per-

fectly in horizontal plane.

– To fix the boiler with the lives put in evi-

dence in figure.

2.2.1 Complementary accessories

To simplify connections to the hydraulic and

gas supplies, it is also possible to use the

following accessories:

– Mounting plate, code 8081217

– Kit with bends, code 8075423

– Kit with faucets, code 8091833

– Antifreeze heaters kit -15°C, code

8089805

– Mixed area kit ZONA MIX, code 8092234.

For detailed information on the assembly

of fittings, see the instructions contained

in the box.

2.2.2 Flow regulator (fig. 5)

In entrance of the D.H.W. a regolator of

color capacity is installed brown for the

vers. “25/55 ErP” and blue for the vers.

“30/55 ErP”; the regolator is inserted in a

bag to equipment of the boiler.

2.3 CONNECTING UP SYSTEM

To protect the heat system from damaging

corrosion, incrustation or deposits, before

installation it is extremely important to

clean the system using suitable products

such as, for example, Sentinel X300 (new

systems), X400 and X800 (old systems) or

Fernox Cleaner F3. Complete instructions

are provided with the products but, for fur-

ther information, you may directly contact

SENTINEL PERFORMANCE SOLUTIONS

LTD or FERNOX COOKSON ELECTRONICS.

For long-term protection agains corrosion

and deposits, the use of inhibitors such as

Sentinel X100 or Fernox Protector F1 is

recommended after cleaning the system.

It is important to check the concentration

of the inhibitor after each system modifica-

tion and during maintenance following the

manufacturer’s instructions (specific tests

are available at your dealer).

The safety valve drain must be connected to

a collection funnel to collect any discharge

during interventions. If the heating system

is on a higher floor than the boiler, install

the on/off taps supplied in kit optional on

the heating system delivery/return pipes.

WARNING: Failure to clean the heat

system or add an adequate inhibitor inva-

lidates the device’s warranty.

Gas connections must be made in accor-

dance with current standards and regula-

tions. When dimensioning gas pipes from

the meter to the module, both capacity

volume (consumption) in m

3

/h and gas

density must be taken into account.

The sections of the piping making up the

system must be such as to guarantee

a supply of gas sufficient to cover the

maximum demand, limiting pressure loss

between the gas meter and any apparatus

being used to not greater than:

– 1.0 mbar for family II gases (natural gas);

– 2.0 mbar for family III gases (butane or

propane).

An adhesive data plate is sticked inside the

front panel; it contains all the technical data

identifying the boiler and the type of gas for

which the boiler is arranged.

2.3.1 Connection of condensation

water trap

The drip board and its water trap must be

connected to a civil drain through a pipe

with a slope of at least 5 mm per metre

to ensure drainage of condensation water.

The plastic pipes normally used for civil

drains are the only type of pipe which is

appropriate for conveying condensation to

the building’s sewer pipes.

2.3.2 Filter on the gas pipe

The gas valve is supplied ex factory with an

inlet filter, which, however, is not adequate

to entrap all the impurities in the gas or in

2 INSTALLATION

Fig. 4

Fig. 5