Sime 021 User manual

Chillers and Inverter Air/Water heat pumps with axial fan

Controller Manual

Model

021 - 026 - 028 - 032

Fonderie SIME S.p.A. 6332364 – 02/2022 – R01

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

This manual has been created for informative purpose. The company declines any responsibility for the results of any projecting or any installation based on the explanations and/or on the

technical specifications provided in this manual. It is besides forbidden the reproduction under any form of the texts and of the figures contained in this manual.

"This manual is a translation from the official italian language version. For reasons of environmental respect the Company will not provide the hard copy in the original language which could

be directly requested or downloaded from the Company website at any time. In case of any dispute, the original language manual will be the trusted one".

Air/water inverter chillers and heat pumps with axial fans

2

01 07-2021 MS AB Update cap. 24

00 01-2021 EM AR First emission

Rev Date Compiled Approved Note

Code Serie

MCO01040101001.01 Chillers and Inverter Air/Water heat pumps with axial fan

3

Air/water inverter chillers and heat pumps with axial fans

Sommario

1.PURPOSE AND CONTENT OF THE MANUAL....................................................................... 6

1.1 HOW TO KEEP THE MANUAL....................................................................................... 6

1.2 GRAPHIC SYMBOLS USED IN THE MANUAL................................................................. 6

2. PERMITTED USE................................................................................................................. 6

3. GENERAL SAFETY GUIDELINES........................................................................................... 6

3.1 PERSONAL PROTECTIVE EQUIPMENT .......................................................................... 7

3.2 WORKERS' HEALTH AND SAFETY ................................................................................. 7

3.3 SAFETY SIGNALS .......................................................................................................... 7

3.4 REFRIGERANT SAFETY DATA SHEET ............................................................................. 7

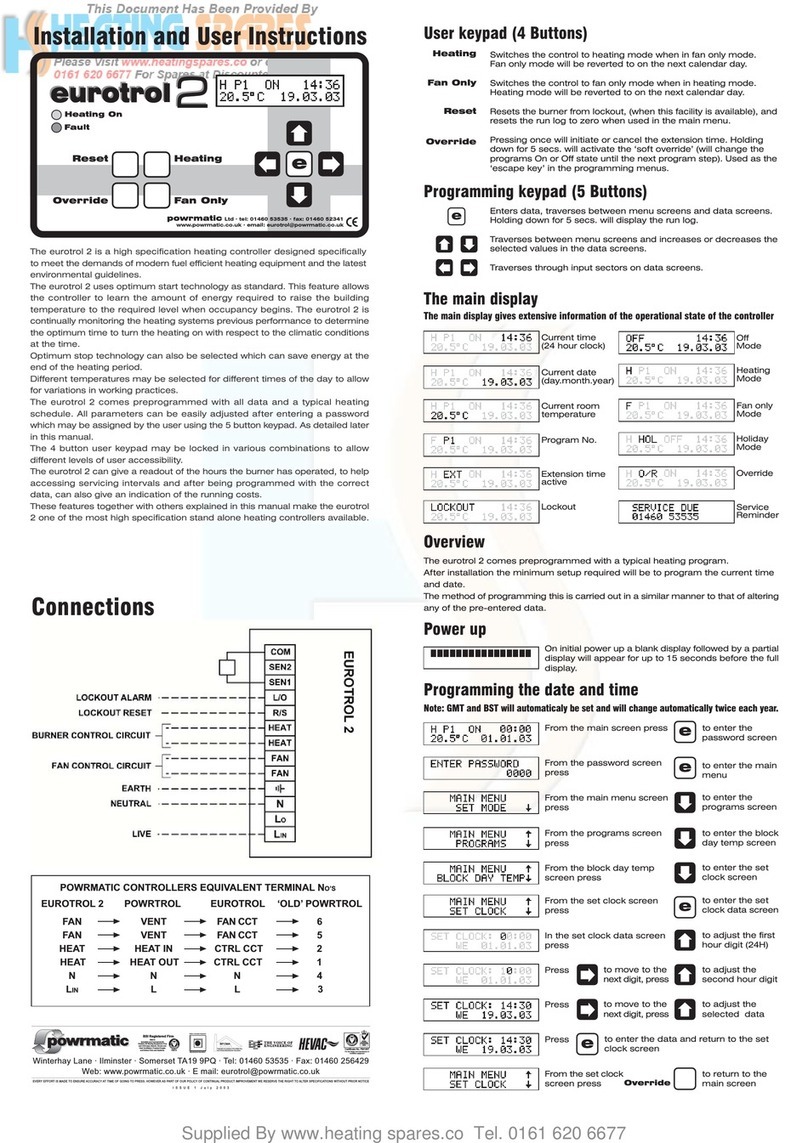

4. USER INTERFACE - CONTROLLER ....................................................................................... 7

4.1 DISPLAY........................................................................................................................ 8

4.1.1 KEYS.......................................................................................................................... 8

4.1.2 LED............................................................................................................................ 8

4.2 MENU .......................................................................................................................... 9

4.3 SETPOINT MENU [Set]................................................................................................. 9

4.4 PASSWORD MENU [PSS].............................................................................................. 9

4.5 ALARMS MENU [Err].................................................................................................... 9

4.6 PROBES MENU [tP]...................................................................................................... 9

4.7 DIGITAL INPUTS MENU [Id]........................................................................................ 10

4.8 PARAMETERS MENU [Par] ......................................................................................... 10

4.9 OPERATING HOURS MENU [oHr]............................................................................... 10

4.10 LOG MENU [HiSt]..................................................................................................... 10

4.11 FIRWARE VERSION MENU [Fir]................................................................................ 10

4.12 USB MENU[USB]...................................................................................................... 10

4.12.1 FIRMWARE UPDATE [UPdF].................................................................................. 10

4.12.2 PARAMETERS UPDATE [UPPA] .............................................................................. 10

5. SYSTEM RESOURCES........................................................................................................ 11

6. EDITING DYNAMIC SET-POINT ......................................................................................... 11

7. SET-POINT MODIFICATION FROM ANALOGUE INPUT ..................................................... 12

8. CIRCULATOR .................................................................................................................... 12

8.1 CONTINUOUS OPERATION......................................................................................... 13

8.2 OPERATION ON CALL BY TEMPERATURE CONTROLLER ............................................. 13

8.3 OPERATING ON CALL BY TEMPERATURE CONTROLLER WITH PERIODIC ACTIVATION13

8.4 OPERATION WITH INTEGRATION RESISTOR ACTIVE ..................................................13

8.5 ANTIFREEZE HYDRAULIC PUMP OPERATION ............................................................. 13

8.5.1 PROPORTIONAL REGULATION ................................................................................ 13

8.6 SYSTEM VENTING ...................................................................................................... 14

9. COMPRESSOR ON/OFF LOGIC ......................................................................................... 14

9.1 REGULATION IN COOLING MODE.............................................................................. 14

9.2 REGULATION IN HEAT MODE..................................................................................... 15

10.FAN ................................................................................................................................ 15

10.1 SILENCED VENTILATION........................................................................................... 15

11.COMPRESSOR CRANKCASE RESISTENCE........................................................................ 15

12.ENABLING DOMESTIC HOT WATER PRODUCTION......................................................... 15

Air/water inverter chillers and heat pumps with axial fans

4

12.1.1 MEMORISING THE PROBE IN HEATING MODE ..................................................... 16

12.1.2 HEATING MODE ON DHW STORAGE TANK ........................................................... 16

12.1.3 INSUFFICIENT HEAT EXCHANGE IN A DHW SYSTEM............................................. 16

13.REMOTE FUNCTION....................................................................................................... 16

13.1 ON/OFF.................................................................................................................... 16

13.2 SUMMER/WINTER MODE CHANGE......................................................................... 17

13.3 DHW CALL FROM DIGITAL INPUT ............................................................................ 17

13.4 SYSTEM WATER REMOTE PROBE ............................................................................. 17

14.DEFROSTING CYCLE ....................................................................................................... 17

15.DOUBLE SET-POINT........................................................................................................ 17

16.MINIMUM HZ FUNCTIONS ............................................................................................ 18

17.MAXIMUM HZ FUNCTIONS ........................................................................................... 18

18.AUXILIARY RESISTANCES................................................................................................ 18

18.1 SYSTEM RESISTANCE................................................................................................ 18

18.2 SANITARY RESISTANCE............................................................................................. 18

18.3 INDIVIDUAL SYSTEM/HEALTH INTEGRATION RESISTENCE....................................... 19

18.4 INTEGRATION RESISTANCE SELECTION MODE......................................................... 19

18.5 CIRCULATOR MANAGEMENT WITH ACTIVE RESISTANCE.........................................19

18.6 BOILER ENABLING ................................................................................................... 19

18.7 LOGIC OF INTEGRATION HEATERS AND/OR BOILER IN JOINT OPERATION OR IN SUB-

STITUTION OF THE HEAT PUMP COMPRESSOR .................................................................. 19

18.8 OPERATION HEAT PUMP MODE .............................................................................. 20

18.9 JOINT OPERATION (I BRACKET)................................................................................ 20

18.10 JOINT OPERATION (II BRACKET)............................................................................. 20

18.11 OPERATION IN SUBSTITUTION............................................................................... 20

18.12 OPERATING BANDS ............................................................................................... 21

18.13 AUXILIARY SYSTEMS OFFSET MANAGEMENT........................................................ 23

19.ANTIFREEZE PROTECTION RESISTANCES (IF KA ACCESSORY IS PRESENT)......................24

20.PARTIAL RECOVERY WITH DESUPERHEATER (IF DS ACCESSORY IS PRESENT)................24

21.LOGICS THAT CAN BE ACTIVATED WITH GI MODULE - SYSTEM MANAGEMENT (ACCESSO-

RY) ...................................................................................................................................... 24

22.PERMITTED CONFIGURATION TABLES ........................................................................... 24

23.ALARMS......................................................................................................................... 28

23.1 [E006] FLOW SWITCH .............................................................................................. 28

23.2 [E018] HIGH TEMPERATURE .................................................................................... 28

23.3 [E005] ANTIFREEZE.................................................................................................. 28

23.4 [E611÷E681] PROBE ALARMS OR PRESSOSTAT........................................................ 28

23.5 [E691÷E701] TRANSDUCER ALARMS....................................................................... 29

23.6 [E801] INVERTER TIMEOUT ..................................................................................... 29

23.7 [E851 ÷E971] INVERTER ALARMS ............................................................................ 29

23.8 [E00] REMOTE ON/OFF SIGNALLING ....................................................................... 29

23.9 [E001] HIGH PRESSURE............................................................................................ 29

23.10 [E002] LOW PRESSURE .......................................................................................... 29

23.11 [E008] DRIVER LIMITATION.................................................................................... 29

23.12 [E041] 4-WAY VALVE.............................................................................................. 29

5

Air/water inverter chillers and heat pumps with axial fans

23.13 LACK OF VOLTAGE.................................................................................................. 29

23.14 UTILITIES BLOCK ALARM TABLE ............................................................................. 29

24.MODBUS VARIABLES ..................................................................................................... 30

Air/water inverter chillers and heat pumps with axial fans

6

1. PURPOSE AND CONTENT OF THE MANUAL

The purpose of the control manual for i-32 MIDI units is to provide the essenal informaon necessary for the correct use of all the funcons

of the machine, in parcular, it provides the essenal informaon for the setup of unit control. The informaons contained in this manual are

wrien for the installer and for the user who uses the machine: the user, even if he does not have specic informaon, will nd in these pages

the indicaons that will allow him to use it eecvely. It is reccomended that the user carefully follows the instrucons given in this manual,

especially the safety instrucons and roune maintenance. The manual describes the machine at the me it was commercialised; the Company

reserves the right to make changes and tecnological improvements to the product and it is not obliged to update manual of previous versions.

Besides, the Company declines all responsability for any errors contained in the manual, if due to prinng or transcripon errors. Be sure to use

the manual, in case of updates or doubts contact the company.

HOW TO KEEP THE MANUAL

The manual has to always be kept together with the unit it refers to. It has to be stored in a safe place, protected from dust and moisture and

easily accessible to the operator who must consult it any me he is in doubt on how to operate the equipment. Any updates sent to the customer

must be kept in an aachment to this manual. The company is available to give any detailed informaon about this manual and to give informa-

on regarding the use and the maintenance of the units.

GRAPHIC SYMBOLS USED IN THE MANUAL

2. PERMITTED USE

• The company excludes all contractual and extra-contractual liability for damage caused to persons, animals or things, due to installaon,

adjustment and maintenance errors, improper use or paral or supercial reading of the informaon contained in this manual.

• These units are built for the heang and/or cooling of water. Any other use not expressaly authorised by the manufacturer is considered

improper and therefore not allowed.

• Modicaon of the operang logic and/or control parameters must be executed by experienced and qualied personnel. Access to the

electrical panel and the connecon of external devices are only permied to qualied personnel.

• This appliance is intended to be used by experienced or trained operators in shops, light industry and on farms, or for commercial use by

non-experted personnel.

• The appliance may be used by children at least 8 years old and by persons with reduced physical, sensory or mental capabilies or without

experience or the necessary knowledge as long as they are supervised or aer they themselves have received instrucons on the safe use

of the appliance and understand the relevant dangers. Children must not play with the appliance. The cleaning and maintenance which the

user is expected to carry out on the unit cannot be done by children without supervision.

• Direct interacon with the unit by personnel with electrically controlled medical devices, such as pacemakers, is prohibited, because it may

cause harmful interference. It is reccomended to mantein an appropriate distance from the installaon site of the unit, as indicated by the

medical system used.

3. GENERAL SAFETY GUIDELINES

Before starng any type of operaon on the unit, every user and operator must have perfect knowledge of operaon of the machine and of its

controls and have read all of the informaon in this manual and in the user-installer manual.

7

Air/water inverter chillers and heat pumps with axial fans

IS PROHIBITED:

Unauthorised access to the electrical panel.

To touch the systems if not autorised to do so.

To step on, sit down on and/or place any type of object on the appliance.

To spary or pour water directly on the appliance.

To touch the appliance when barefoot or part of the body are wet or damp.

-

lease the manufacturer from any civil or criminal responsibility.

CAUTION:

set contact the company.

personnel.

-

trical power.

PERSONAL PROTECTIVE EQUIPMENT

Refer to the user-installer manual included with the unit.

WORKERS' HEALTH AND SAFETY

Refer to the user-installer manual included with the unit.

SAFETY SIGNALS

Refer to the user-installer manual included with the unit.

REFRIGERANT SAFETY DATA SHEET

Refer to the user-installer manual included with the unit.

4.

The unit has a 4-digit display with integrated keypad, the main funcons and menu navigaon are described below. Normally, if the unit is

switched on, the display shows the water outlet temperature in degrees Celsius or the alarm code, if acve.

Air/water inverter chillers and heat pumps with axial fans

8

DISPLAY

KEYS

Select the operang mode and manually reset any alarms.

Each me you press the key you have the following sequence:

OFF -> COOL -> COOL+SAN* -> HEAT -> HEAT+SAN* -> OFF (*= if sanitary is enabled)

During parameter seg has the funcon of the back key.

Allows to enter the selected menu to view the sub-folders or to set a value (e.g. summer, winter and domesc set-points or various

parameters).

UP key allows to move to a higher menu or to increase the parameter value.

DOWN key allows to move to a lower menu or to decrease the parameter value.

LED

Cooling mode LED: is on if COOL or COOL+SAN mode is selected.

Heang mode LED: is on if HEAT or HEAT+SAN mode is selected.

Pump Led: is on if the pump is acve.

Alarm Led: is on if there are acve alarms.

Defrosng Led: ashes to enter defrosng mode, it is on when defrosng is in progress.

Compressor Led: ashes if the compressor is starng up, it is on if the compressor is acve.

Sanitary led: ashes if sanitary producon is in progress, it is on if COOL+SAN or HEAT+SAN mode is selected and sanitary produc-

on is not in progress.

Led KA resistors: is on if the anfreeze resistors are acve.

9

Air/water inverter chillers and heat pumps with axial fans

MENU

The items controlled by the main menu are listed below. Some of this are only visible to the installer, who must access to the PSS menu to enter

the password and enable higher privilege access.

MENU LABEL LEVEL OTHER CONDITIONS

Setpoint Set User Not accessible if connected at Hi-T2

Password PSS User ---

Alarms Err User Only if acve alarms

Probes tP Installer ---

Digital inputs Id Installer ---

Parameters Par Installer ---

Hours of oper-

aon oHr Installer ---

Alarm log Hist Installer Only if the log contains data

Firmaware

Version Fir Installer ---

USB USb Installer Only with USB key with update les is present

Set

In this menu, it is possible to display and modify the various set-points.

Set DESCRIPTION DEFAULT RANGE UNIT

Coo First Summer setpoint 7.0 5 ÷ Coo2 °C

Hea First Winter setpoint 45.0 Hea2 ÷ 60 °C

*San Sanitary setpoint 48.0 25 ÷ 60 °C

Coo2 Second Summer setpoint 18.0 Coo ÷ 25 °C

Hea2 Second Winter setpoint 35.0 25 ÷ Hea °C

(*) If sanitary funcon is enabled, see par. 12.

Enter the password for the desired access level. Conrming the value with the PRG key automacally acvates the access level and the menu

items enabled by that level will appear. Once you have exited the menus completely, the password privilege is lost and must be entered again.

Err

This menu allows you to see all acve alarms, if any. For more details see par. 9.

tP

Entering with the installer password, the values of the present temperature and pressure sensors can be read in this menu.

tP DESCRIPTION UNIT

t01 Water inlet temperature °C

t02 Water outlet temperatura °C

t03 Compressor sucon temperature °C

t04 Compressor discharge temperature °C

t05 Outside air temperature °C

t06 Domesc hot water temperature (if enabled) °C

t07 System remote probe temperature (if enabled) °C

t09 Low pressure bar

t10 High pressure bar

The number of visible probes depends on the presence or absence of expansion modules.

Parcular situaons:

Err: probe faulty

--- = probe not used (no funcon associated to that probe)

Air/water inverter chillers and heat pumps with axial fans

10

Id

Entering with the installer password, the status of the digital inputs can be view in this menu:

0 = input disabled

1 = input enabled

--- = input not congured

Par

Entering with installer password, in this menu you can modify the the main parameters of the unit. The parameters are collected in groups, each

group is idened by a three-digit code, while the index of each parameter is preceded by a leer.

Par DESCRIPTION INDEX OF THE PARAMETER

CnF Conguraon H--

ALL Alarms A--

CP Compressor C--

rE Regulaon b--

PUP Pump P--

Fro Electrical resistances r--

dFr Defrosng d--

LbH Minimum Hz L--

rEC Desuperheater rE

oHr

Entering with the installer password this menu displays the operang hours of the compressor (oH1) and of the circulator (oHP1).

It is possible to reset the displayed count by pressing the ESC key for 3 seconds

HiSt

This menu appears, aer entering the installer password, only if there is data in the alarm log.

Fir

Entering with the installer password, in this menu you can read rmware version (uEr), revision (rEu) and sub-revision (SUb).

This menu appears, aer entering the installer password, only if a USB key containing the relevant update les is connected to the card. The

available funcons are described below.

CAUTION: The access to the electrical panel is only allowed to QUALIFIED PERSONNEL.

FIRMWARE UPDATE [UPdF]

In case of rmware update, the following steps are necessary:

1. Copy the upgrade les into the main directory of a USB pen;

2. Set the unit to OFF on the keypad and remove power by seng the main switch to OFF;

3. Insert the ash drive into the USB port on the control;

4. Power up the unit, seng the mains witch to the ON posion;

5. Access the rmware update menu and start the procedure through the following sequence: PRG -> PSS -> PRG -> (enter installer password)

-> PRG -> USB -> UPdF -> PRG

6. A countdown advances on the display, at the end of the procedure the word "boot" appears and the 4 LEDs light up in sequence;

7. Switch o the unit, posioning the main switch on the OFF status;

8. Remove the drive from the USB port;

9. Switch the unit on by turning the main switch to the ON posion.

PARAMETERS UPDATE [UPPA]

In case of parameters update, the following steps are necessary:

1. Copy the upgrades les into the main directory of a USB pen;

2. Set the unit to OFF on the keypad and remove power by seng the main switch to OFF;

3. Insert the ash drive into the USB port on the control;

11

Air/water inverter chillers and heat pumps with axial fans

4. Power up the unit, seng the mains witch to the ON posion;

5. Access the rmware update menu and start the procedure through the following sequence: PRG -> PSS -> PRG -> (enter installer password)

-> PRG -> USB -> UPPA -> PRG

6. A countdown advances on the display, at the end of the procedure the word "boot" appears and the 4 LEDs light up in sequence;

7. Remove the drive from the USB port;

8. Switch the unit on by turning the main switch to the ON posion.

5. SYSTEM RESOURCES

The inputs and outputs (I/O) that can be set to acvate the control funcons are listed below. To congure the I/O, use the installer password to

access the conguraon parameters: PRG -> PSS -> PRG -> (enter installer password) -> PRG -> PAr -> PRG -> CnF.

Resource Parameter

Default

value

ST6 H17 XC-12.1

XC-12.2 0 Not set Analogue input congurable with an NTC-10kΏ

probe at 25°C β 3435

ST7 H18 XC-13.1

XC-13.2 0 Not set Analogue input congurable with an NTC-10kΏ

probe at 25°C β 3435

ST11 H22 XC-19.1 (GND)

XC-19.2 (+)

XC-20.1 (5V) 0Voltage input 0-10 Vdc input (XC-19.1/2)

Raometric / PWM input

DI2 H46 XC-4.1

XC-4.2 0Remote summer/winter mode

change Voltage free digital input.

To acvate the funcon see par.13.2

DI3 H47 XC-3.1

XC-3.2 2Remote on/o Voltage free digital input. Acve funcon by default

(par. 13.1).

DI9 H53 XC-14.1

XC-14.2 0 Not set Voltage free digital input

DO3 H81 XP-4.1 (N)

XP-4.2 (fase) 22 System integraon heater com-

mand Voltage output 230Vac, 50Hz, 2A (AC1)

(see paragraph 18.1)

DO6 H84 XP-7.1 (N)

XP-7.2 (fase) 6 HDW valve control Voltage output 230Vac, 50Hz, 2A (AC1)

(see paragraph 12)

DO7 H85 XP-8.1 (N)

XP-8.2 (fase) 25 Double setpoint valve control Voltage output 230Vac, 50Hz, 2A (AC1)

(see paragraph 15)

Modbus

RTU RS485 -- XC-1.1 (GND)

XC-2.1 (R-)

XC-2.2 (R+) -- -- Factory enabled with CM accessory

For a detailed descripon of the terminal block, please refer to the user/installer manual.

6.

The regulaon control allows you to modify the set-point by adding an oset value depending on the outside air temperature. To use this func-

on, modify the values of the regulaon parameters, from b08 to b14, following the informaon in this paragraph.PRG -> PSS -> PRG -> (enter

installer password) -> PRG -> PAr -> PRG -> rE

Parameters of regulator:

• b08 = 1 to enable the dynamic set-point / b08 = 0 to disable the dynamic set-point (default)

• b09 = maximum cooling oset

• b10 = maximum heang oset

• b11 = Cooling outdoor temperature seng

• b12 = Heang outdoor temperature seng

• b13 = Cooling temperature delta

• b14 = Heang temperature delta

Edit the setpoint depending on the outdoor temperature:

HEATING COOLING

Set temp. est

b12

b10

b14

Delta <0 Delta >0

Temp.

est

Temp.

set

Offset >0

Hea

Set temp. est

b12

b10

b14

Delta <0 Delta >0

Temp.

est

Temp.

set

Offset >0

Hea

Air/water inverter chillers and heat pumps with axial fans

12

EXAMPLE: consider that we want to obtain the following condions in heang mode:

• set-point of 28°C with external temperature of 18°C

• set-point of 45°C with external temperature of 2°C

Set Hea = 28 e b08 = 1, while the other parameters will be calculated as follows:

• b10 = 45 – 28 = 17

• b12 = 18

• b14 = 2 – 18 = -16

EXAMPLE: consider that we want to obtain the following condions in cooling mode:

• set-point of 12°C with external temperature of 25°C

• set-point of 7°C with external temperature of 35°C

Set Coo = 12 e b08 = 1, while the other parameters will be calculated as follows:

• b09 = 7 – 12 = -5

• b11 = 25

• b13 = 35 – 25 = 10

7.

Another type of regulaon allows the set-point to be modied by adding (or subtracng) a value according to the voltage input ST11. To enable

this funcon it is necessary to connect the signal between the terminals indicated in chapter 5 and set the parameter H22 = 40. To use this func-

on, change the values of the following control parameters:

• b15 = Maximum decalibraon value

• b20 = 0 for input type 0-10 V (default)

• b20 = 1 for raometric input

Correcon calculaon with input 0-10 V (b20=0):

• With input at 0 Volt the current set-point will be: set (Coo/Hea) – b15/2

• With 5 Volt input the set-point will be the one set (Coo/Hea)

• With an input at 10 Volt the current set-point will be: set (Coo/Hea) + b15/2

SETPOINT FROM ANALOGUE INPUT

Input 0-10V

Ra�ometric input

Temp.

set

Coo/Hea

Coo/Hea + b15/2

Coo/Hea

-

b15/2

0 V

0 %

5 V

50 %

10 V

100 %

Correcon calculaon with raometric input (b20=1):

• With input at 0% the current set-point will be: set (Coo/Hea) – b15/2

• With input at 50% the set-point will be that set (Coo/Hea)

• With input at 100% the current set-point will be: adjusted set (Coo/Hea) + b15/2

8. CIRCULATOR

The circulator of the unit can be set in the following operang modes. To congure the circulator is necessary to access the relevant parameter.

PRG -> PSS -> PRG -> (insert installer password) -> PRG -> PAr -> PRG -> PUP

The circulator can be congured to operate independently of the compressor or on call:

• P03 = 0 for connuous operaon (default)

• P03 = 1 for operaon on thermoregulator call

13

Air/water inverter chillers and heat pumps with axial fans

NOTE:

CONTINUOUS OPERATION

The factory conguraon of the unit is for connuous operaon (P03 = 0). In this mode, the circulator is only switched o with the unit in OFF,

in all other cases it is on. When the unit goes into stand-by, the circulator is switched o with a delay that can be set by parameter P02 in tenths

of a minute (default P02 = 20, i.e. 2 minutes).

OPERATION ON CALL BY TEMPERATURE CONTROLLER

Subsequently, the compressor is also switched on, aer a delay me of P01 seconds (default P01 = 30) since the pump was switched on. In the

switch-o phase, the pump is switched o with a delay me of P02 minutes (default P02 = 2) from the switch-o of the compressor.

OPERATION ON CALL FROM TEMPERATURE CONTROLLER

Temperature controller

ON

OFF

�me

Compressor

�me

Pump

�me

P01

P02

ON

OFF

ON

OFF

OPERATING ON CALL BY TEMPERATURE CONTROLLER WITH PERIODIC ACTIVATION

With P03 = 1, you can also congure the circulator to run periodically according to the following parameters:

• P16 = Periodic acvaon me interval (in minutes)

• P17 = Pump acvaon me (in seconds)

In pracce, when the pump is turned o for sased thermoregulaon, the countdown dened by parameter P16 begins and at each interval of

me P16 the circulator is turned on for a me equal to P17 seconds.

The funcon is disabled with P17 = 0 (default). The periodic funcon is suspended in the case of anfreeze mode intervenon.

OPERATION WITH INTEGRATION RESISTOR ACTIVE

If parameter r33 > 0, the circulator can also be switched on when the system and/or sanitary heang element is acvated.

ANTIFREEZE HYDRAULIC PUMP OPERATION

In this mode, the circulator is always on. Anfreeze operaon is enabled if the control temperature falls below P04 (default P04 = 5.0°C), it is

disabled if the control temperature rises above P04 + P05 °C (default P05 = 2.0°C).

PROPORTIONAL REGULATION

In cooling or heang mode, the speed of circulator changes depending on the temperature dierence between the inlet water and outlet water

of the heat exchanger according to the diagram below, where:

• P06 = Set ΔT water inlet/outlet in heang mode (default P06 = 4,0°C)

• P07 = Maximum speed (100%)

• P08 = Minimum speed

• P09 = Set ΔT water inlet/outlet in cooling mode (default P09 = 2,0°C)

• P10 = Modulang pump Delta (default P10 = 3,0°C)

Air/water inverter chillers and heat pumps with axial fans

14

PROPORTIONAL REGULATION

ΔT

[°C]

Speed

[%]

P07

P08

P06/P09

P10

In pracce, in cooling mode, if the temperature dierence between the inlet and outlet is greater than P09 + P10, the circulator runs at maximum

speed, but if the dierence is less than P09 - 0.2°C, it runs at minimum speed; in the remaining cases, the pump modulates the speed propor-

onally. In heang mode, the same consideraons apply, replacing parameter P06 with parameter P09.

In sanitary producon the circulator always runs at maximum speed.

SYSTEM VENTING

The control allows the use of a manual system venng funcon with the circulator at maximum speed.

To enable the funcon the operaons to follow are:

• Set unit to OFF

• Access with maintenance privilege PRG -> PSS -> PRG -> (enter installer password) -> PRG

• Press UP and DOWN simultaneously for 3 seconds.

It is possible to exit the system venng cycle manually by pressing the MODE/ESC buon,or by pressing UP and DOWN keys simultaneously for

3 seconds.

water inside the system.

9. COMPRESSOR ON/OFF LOGIC

The restart of compressors is in operaon of a set point refered to the inlet and outlet water temperature. It is based on calculaon of that

is the dierence between outlet and inlet water temperatures, detected while the compressor for thermoregulaon is turning o.

REGULATION IN COOLING MODE

• Tw,out,set = setpoint in cooling mode

• = Tw,out,set – Tw,in,set

• b05 = compressor delta cut-o set = 0,2°C (default)

• b25 = delta cut-on regolazione compressor set = 2°C

RPM

Tw,out (outlet water temp.)

Tw,out,set

HzMaxReg

OFF

HzMin

b05

∆T,set + b25

15

Air/water inverter chillers and heat pumps with axial fans

• The compressor shutdown is set by the parameter b05: the compressor shutdown when Tw,out < Tw,out,set - b05

• The compressor restart when : se , the compressors restart when the discharge

probe temperature is lower than the setpoint 10°C:

REGULATION IN HEAT MODE

• Tw,out,set = seng setpoint in heat mode

• = Tw,out,set – Tw,in,set

• b05 = compressor regulaon delta cut-o = 0,2°C (default)

• b25 = compressor regulaon delta cut-on= 2°C

RPM

Tw,out (outlet water temp.)

Tw,out,set

HzMaxReg

OFF

HzMin

b05

∆T,set + 2°C

• The compressor shutdown is regulated by parameter b05: the compressor shutdown when

• The compressor restart when

EXCEPTION: if , the compressors restart when the discharge probe temperature is lower than the setpoint 10°C:

10. FAN

The unit's fan is controlled depending on the operaon of the compressor. Venlaon is controlled according to the condensing pressure in

cooling mode or according to the evaporang pressure in heang mode. Pre-venlaon takes place every me the compressor is switched on

and o.

SILENCED VENTILATION

Conguring a digital input DI9 with parameter H53=25 it is possible to manage the funcon of silent venlaon management.

Parameter VALUE

H53

0 (default) Funcon disabled

25 Open contact -> standard mode

Close contact -> silenced mode

With the funcon acve, the noise, output and power of the unit are limited, for addional informaon see the installer user manual.

11. COMPRESSOR CRANKCASE RESISTENCE

The crankcase resistence is acvated if the compressor has been o for at least 30 minutes and if the temperature measured by the discharge

probe is below 20 °C (with a hysteresis of 2.0 °C). When the compressor restarts, the crankcase resisitence is disabled.

12. ENABLING DOMESTIC HOT WATER PRODUCTION

To enable the producon of domesc hot water it is necessary to connect a probe to the analogue input ST6 to be posioned inside the tank (the

relave terminals are indicated in chapter 5 or on the electrical diagram). Once the DHW temperature probe has been posioned and connected,

it must be enabled by seng parameter H17 = 6.

The DHW valve must be connected to digital output DO6 (see Chapter 5), and the relave control must also be enabled with parameter H84 =

6 (default).

The domesc hot water (DHW) funcon is controlled through parameter H10:

Parameter VALUE

H17 6DHW temperature probe

H84 6 DHW valve control

Air/water inverter chillers and heat pumps with axial fans

16

Parameter VALUE

H10

0 (default) Funcon disabled

1Funcon acve in heang and cooling mode.

The remote on/o funcon does not disable DHW producon.

2Funcon acve in heang and cooling mode.

The remote on/o funcon disables DHW producon.

3Funcon acve only in heang mode

The remote on/o funcon disable DHW producon.

4Funcon acve only in heang mode

The remote on/o funcon disable DHW producon

5 Funcon acve only in cooling mode

The remote on/o funcon not disable DHW producon

6Funcon acve only in cooling mode

The remote on/o not disable DHW producon

If the DHW temperature is lower than the DHW set (set to 48°C by default), the machine acvates the DHW valve and the compressor is set to

the maximum frequency, starng the modulaon one degree before the set and switching o one degree aer the set. Once the set point has

been reached, the valve returns to rest mode and the compressor starts to regulate normally. Switching from winter operaon to domesc hot

water operaon, the compressor does not switch o, while switching from summer operaon to domesc hot water operaon the compressor

is switched o to wait for the safety me.

If H10 = 1/2/3, switching the unit o remotely (remote on/o, see paragraph 13.1) does not aect the DHW operaon

If H10 = 2/4/6, the remote on/o funcon disables domesc hot water producon and operaon of the unit in heang or cooling mode.

MEMORISING THE PROBE IN HEATING MODE

When switching from the system to DHW, the reference probe changes from "water outlet probe" to "DHW probe". The display on the machine

shows the temperature read by the probe located inside the DHW tank; once the DHW cycle is over, the display returns to show the water outlet

temperature. In heang mode, before entering DHW mode, the last value read by the ow probe of the heat pump is memorised. Once the DHW

temperature control is sased, the reference temperature on the system side returns to the previously memorised one.

La funzione di memoria si interrompe:

• when the temperature read by the probe becomes lower than the stored value;

• or a me equal to b06 seconds has elapsed (default b06 = 45).

HEATING MODE ON DHW STORAGE TANK

If parameter H130 = 1, the machine also uses the DHW storage tank for heang on the system side. Under these condions, the DHW valve

output is also acve during hot operaon. The valve is deacvated during defrosng and in cold mode. In this mode (H130 = 1) it is possible to

make the domesc hot water integraon resistor also act as integraon resistor on the system side.le to make the DHW integraon resistor also

act as an integraon resistor on the plant side.

INSUFFICIENT HEAT EXCHANGE IN A DHW SYSTEM

During DHW producon, if the heat pump ow probe detects a temperature higher than 60°C, the DHW valve output is de-energised (DO6), and

the value of the DHW probe at this me is recorded (Tsan,set).

• if the operaon is San or Cool+San the compressor is stopped.

• if the operaon is Heat+San, the system evaluates for b06 seconds whether there is a demand for heang from the system. If the system

requires it, the compressor connues to work on the system, otherwise it is switched o.

• if the DHW resistor is present (e.g. DO3, H81=26), r15 = 0 or 1 and r24=2 or 3 it is acvated unl the DHW setpoint detected by the DHW

probe is met (and any oset).

The compressor restarts when the ow temperature of the heat pump falls below 60°C again and the temperature measured by the DHW probe

is lower than Tsan,set - 4°C.

13. REMOTE FUNCTION

The terminal block has digital inputs to control the unit via an external consent (see chapter "5. SYSTEM RESOURCES").

ON/OFF

The funcon is enabled by default on digital input DI3 (parameter H47 = 2), to acvate it, the electrical bridge must be removed from the terminal

block. With the contact open, the unit will be in stand-by mode, in this state the message E00 will appear on the display on the machine. When

the contact is closed, the machine comes out of stand-by and the circulator is acvated for 2 minutes.

The funcon is disabled by reinserng the electrical bridge or seng parameter H47 = 0.

17

Air/water inverter chillers and heat pumps with axial fans

SUMMER/WINTER MODE CHANGE

The control oers the possibility to remotely manage the operang mode of the machine in heang or cooling mode.

The funcon can be set on digital input is seable DI2 via parameter H46:

Parameter VALUE

H46

0 (default) Funcon disabled

3Open contact -> cooling mode

Closedd contact -> heang mode

The polarity of the digital input DI2 can be reversed by seng H75 = 2.

DHW CALL FROM DIGITAL INPUT

If DHW operaon is enabled and parameter H51 = 28, is set, as an alternave to using the DHW temperature probe (H17 = 0), the DHW funcon

can be acvated by closing/opening digital input DI7. The unit goes into DHW mode when the contact closes and exits DHW producon when

the contact opens.

The polarity of digital input ID7 can be inverted by seng H75 = 64.

This funcon is recommended when using two or more heat pumps in cascade, hydronically connected to the same domesc hot water storage

tank. In this case, the acvaon of the domesc hot water funcon can be set on the rst machine via the DHW probe of the tank, while the

other machines are automacally enabled thanks to the consent given by the digital input.

SYSTEM WATER REMOTE PROBE

In some system soluons (e.g.: heat pump in parallel with the boiler on the same hydronic circuit and exclusion diverter valve) it may be neces-

sary to enable a temperature probe of the system so that the on-board control can process the management correctly. The system remote probe

is acvated by seng parameter H18 = 41.

The system remote probe thermoregulates the heat pump only during the compressor start-up phase, the switch-o is managed by the probe

on the heat pump delivery.

In heang mode, the call is acve if the following condions are veried:

• Flow probe temperature < ;

• Temperature of the system remote probe < (default b22 = 5,0°C).

In cooling mode the call is acve if the following condions occur

• Flow probe temperature > ;

• Temperature of the system remote probe > (default b22 = 5,0°C).

14. DEFROSTING CYCLE

The defrost cycle is a funcon acve only in heat pump mode and is used to prevent the formaon of ice on the surface of the nned coil. The

formaon of ice on the evaporator, which occurs more frequently at very low external ambient temperatures, not only considerably reduces the

thermodynamic eciency of the machine, but also leads to the risk of damage to the machine itself.

15.

This funcon introduces a second working set-point on the plant side, both in cooling and heang mode.

The user terminal board allows a consent to be connected to switch from the rst to the second set-point and congured at digital input DI9 with

parameter H53 = 26. The valve,on the other hand, is connected in the terminal board to digital output DO7 and is congured via parameter H85.

Parameter VALUE

H53 26 Call for second set-point

H85 25 3-way valve for radiant panels

Air/water inverter chillers and heat pumps with axial fans

18

Parameter VALUE

H129

0Funcon disabled

1Funcon congured but not acve

2Enabled only in cooling mode

3Enabled only in heang mode

4Enabled in cooling and heang mode

16. MINIMUM HZ FUNCTIONS

Conguring parameter L02=1 and L03≠0 reduces the nominal operang Hz of the compressor.

Parameter VALUE

L02 0Funcon not acve

1Enable Hz minimum

L03

0Funcon not acve

1Funcon acve only in cooling mode

2Funcon acve only in heang mode

3Funcon acve only in sanitary mode

4Funcon acve in cooling and sanitary mode

5Funcon acve in heang and sanitary mode

6Funcon in cooling and heang model

7Funcon always acve

With the funcon acve, the output and power of the unit are limited, for addional informaon see the technical bullen in chapter 2.

17. MAXIMUM HZ FUNCTIONS

When the funcon is acvated, the power of the unit is increased, for informaon contact the company.

18. AUXILIARY RESISTANCES

In some system soluons it may be necessary to use an integraon heater for the system and/or for the sanitary area. This is an addional re-

source for heang in case the compressor cannot meet the set in a reasonable me. The resistor controller only operates in heang mode and

if r10 = 1.

To dene how the integraon resistors are to operate, parameter r24 must be se:

• r24 = 0 for integraon resisitors not used;

• r24 = 1 for use of system integraon resisitor;

• r24 = 2 for use of sanitary integraon resisitance;

• r24 = 3 for use of both the system integraon resistor and the sanitary integraon resistor.

SYSTEM RESISTANCE

The system resistance must be connected to the digital output DO3 and can be congured by seng parameter H81 = 22.

If the regulaon temperature remains lower than the hot water set-point (°C) for a me equal to r12 the integraon resistor is acvat-

ed according to the operaon of the machine in the combined or replacement bands.

The resistor is also acvated if the control temperature remains below the water set-point (°C) and the machine is in lockout due to

the intervenon of an alarm. It switches o when the machine exits the alarm block.

Seng r21 = 1, during the defrost cycle, if required (temperature lower than Hea - r11), the system resistor is acvated without waing for the

me dened by r12.

The resistor switches o when the set-point is reached (also taking into account any oset set with parameters r29 or r30).

Parameter VALUE

H81 22 System integraon resistance

r10 1Enabling of system resistors

r11 5 (default) Delta resistances in system integraon (in tenths of °C)

r12 10 (default) System integraon acvaon delay (in minutes)

r21 1Enabling resistors during defrosng

r24 1/3 Type of use resistors

SANITARY RESISTANCE

This funcon can be acvated as an alternave to the system integraon resistance. The DHW resistance must be connected to digital output

DO3 and can be congured by seng parameter H81 = 26, in addion the DHW funcon must be acve.

The resistance is acvated if the producon of domesc hot water lasts longer than r16 (minutes) or if the machine goes into lockout due to

the intervenon of an alarm. It switches o when the machine nishes DHW producon (also taking into account any oset on the set-point set

with parameter r31).

19

Air/water inverter chillers and heat pumps with axial fans

Parameter VALUE

H81 26 DHW integraon resistor

r15 1Enabling of DHW resistors

r16 10 (default) Sanitary integraon acvaon delay (in minutes)

r24 2/3 Type of use of resistance

INDIVIDUAL SYSTEM/HEALTH INTEGRATION RESISTENCE

Conguring the DHW resistance it is also possible to use it as a system resistor, by seng the parameter r15 = 2 and r24 = 3.

In this way, in the event of a request for system integraon, the resistance declared as DHW integraon is acvated, thus making it possible to

have a single integraon resistance for the system, DHW and defrosng.

INTEGRATION RESISTANCE SELECTION MODE

The resistors can be acvated simultaneously if r14 = 0 (default), otherwise the priority of the order of acvaon of the system-side and DHW-

side integraon resistors can be set, in parcular the conguraons are:

• r14 = 1 for resistance acvaon in exclusion of each other;

• r20 = 0 for system priority (the domesc heang element is acvated only if the system-side thermoregulaon is sased);

• r20 = 1 sanitary priority (the system resistor is acvated only if the thermoregulaon on the sanitary side is sased).

CIRCULATOR MANAGEMENT WITH ACTIVE RESISTANCE

The circulator of the heat pump can be acvated when the plant and/or DHW integraons resistences are acve with the compressors not run-

ning (by substuon, by alarm or by integraon in bracket II or III):

• r33 = 0 for acvaon on request of the compressors or for any boiler request.

• r33 = 1 for acvaon with system resistance acve.

• r33 = 2 for acvaon with sanitary heang element acve.

• r33 = 3 for acvaon with system or sanitary resistor acve.

The circulator switched o aer post-pumping (P02).

BOILER ENABLING

Funcon which can be acvated instead of managing the double setpoint.

This is an addional resource to enable the boiler in integraon or substuon of the heat pump.

The relave digital output for enabling the boiler is DO7, it can be congured by seng parameter H85 = 29.

Dene the mode of use by seng parameter r23:

• r23 = 0 (default) for boiler not used (priority of resistor intervenon);

• r23 = 1 for boiler use on system only (priority of resistor intervenon);

• r23 = 2 for boiler use only in DHW mode (priority intervenon of the heaters);

• r23 = 3 per ulizzo caldaia sia in sanitario sia su impianto (priorità di intervento delle resistenze);

• r23 = 4 for boiler use in DHW and on system (priority intervenon of resistors);

• r23 = 5 for boiler use only in DHW mode with priority;

• r23 = 6 for boiler use in DHW mode and on system with priority;

Dene the boiler equipment by seng parameter r32:

• r32 = 0 for boiler without circulator with thermoregulaon charged to the heat pump;

• r32 = 1 for boiler with autonomous circulator with thermoregulaon charged to the heat pump;

• r32 = 2 for boiler without circulator with autonomous thermoregulaon;

• r32 = 3 for boiler equipped with circulator with autonomous thermoregulaon.

Parameter VALUE

H81 29 Boiler enabling

r10 1Enabling in system integraon

r12 10 (default) System integraon acvaon delay (in minutes)

r15 1Enabling of sanitary integraon

r16 10 (default) DHW integraon acvaon delay (in minutes)

r23 1 ÷ 6 Type of boiler use

r32 1 ÷ 3 Boiler equipment

LOGIC OF INTEGRATION HEATERS AND/OR BOILER IN JOINT OPERATION OR IN SUB

STITUTION OF THE HEAT PUMP COMPRESSOR

The auxiliary parts that can be used for joint or for operaon in substuon are:

• boiler

• system integraon resistor

• domesc hot water integraon resistor

The parameters to be considered for adjusng this operang logic are:

Air/water inverter chillers and heat pumps with axial fans

20

• r22 = set for joint operaon with heat pump priority

• r28 = set for joint operaon with priority of auxiliary units

• r08 = set for replacement operaon

Considering the heang and/or DHW operang modes, there are 4 operang areas:

INTEGRATION LOGIC

r22

Heat pump + Boiler/Heater

JOINT OPERATION I ZONE

Boiler + Heat pump/Heater

JOINT OPERATION II ZONE

Boiler/Heater

OPERATION IN SUBSTITUTION

Heat pump

STANDARD WORKING

r28

r08

Outside

temp.

If it is necessary to change the values of the parameters, the formula must be followed.

Seng r22 = r28 it is possible to eliminate the zone relave to joint operaon 1st band; by seng r28 = r08 it is possible to eliminate the zone

relave to joint operaon 2nd band; by seng r22 = r28 = r08 it is possible to eliminate both bands relave to joint operaon.

The intervenon priories of the auxiliary heaters are dened by parameters r14, r20, r23, r24 (as described above).

OPERATION HEAT PUMP MODE

Normal operaon of the heat pump in which the integraon heaters and-or the boiler only intervene when a heat pump alarm is triggered.

If the outdoor temperature is between r22 and r28, the compressor operates in synergy with the auxiliary heaters in winter or DHW mode. In

this operang bracket, rst the heat pump is acvated and aer r12 minutes the plant side auxiliary heaters, or aer r16 minutes the sanitary

side auxiliary heaters.

Operaon returns to normal if the outside temperature is greater than °C.

Note: In the joint operaon band, the boiler is thermoregulated by the system water remote probe (if acve), in parcular if the temperature

detected by the remote probe is lower than the Hea setpoint,the boiler is acvated, and then deacvated when the temperature detected by

the remote probe is higher than Hea setpoint. The heat pump is also thermoregulated by the system water remote probe (as described above).

If the remote system water probe is not acve, the boiler is controlled by the ow probe of the heat pump.

If the outside temperature is between r28 and r08, the auxiliary heaters are enabled in combinaon with the heat pump in heang or DHW

mode. In this operang range, the boiler is acvated rst, then the heat pump and auxiliary heaters are acvated aer a me dened by r12

minutes for the system side or aer r16 minutes for the DHW sanitary.

Operaon returns to normal if the temperature rises above °C.

Note: In the joint operaon band, the boiler is thermoregulated by the remote system water probe (if acve), in parcular if the temperature

detected by the remote probe is lower than the Hea setpoint,the boiler is acvated, and then deacvated when the temperature detected by

the remote probe is higher than Hea setpoint. The heat pump is also thermoregulated by the system water remote probe (as described above).

If the remote system water probe is not acve, the boiler is controlled by the ow probe of the heat pump.

OPERATION IN SUBSTITUTION

If the outside temperature falls below r08 the heat pump compressor is disabled and the auxiliary devices operate in place of it. The compressor

is enabled again if the temperature rises above (default r09 = 1.0 °C).

If the auxiliary system consists of system and/or DHW resistors, they operate according to the mes dened by parameters r12 (minutes) for the

system side and r16 (minutes) for the DHW side. In the substuon operaon band, it is not necessary to enable the integraons with r10 or r15

since the resistances must operate as a replacement for the heat pump (it is therefore sucient to select the type of use from parameter r24).

If the auxiliary system is a boiler with autonomous thermoregulaon (r32 = 2 or 3),it is enabled independently of the thermoregulaon of the

heat pump.

This manual suits for next models

3

Table of contents

Other Sime Controllers manuals

Popular Controllers manuals by other brands

MTX

MTX Thunder Sports AWMC3 owner's manual

ICP DAS USA

ICP DAS USA WP-8000-CE7 Series user manual

Axis

Axis A1001 Installation guides

Analog Technologies

Analog Technologies ATLS500MA103 quick start guide

Samlexpower

Samlexpower samlexpower SCC-30AB owner's manual

Zencontrol

Zencontrol zc-controller instructions