Simon M-SHEV-10-AP User manual

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

BA M-SHEV-10-AP (ECO) M-SHEV-10 / -24 / -48 / -72 (ECO) EN 1.7

Operating manual

Modular control panel of the M-SHEV product family

Copyright by SIMON PROtec Systems GmbH

Subject to technical changes and errors. All figures are exemplary.

Only valid with the supplementary sheet: “Safety instructions and warranty conditions“!

Operating manualModular control panel of the M-SHEV product familyBA_M-SHEV_DE_161.7/07.2019BA M-SHEV-10-AP / M-SHEV DE 1.5

For further information please visit

our product website

short.simon-protec.com/msheven

BA_M-SHEV_EN_17 Date: 30.07.2019

Issue: 1.7/07.2019

Table of contents

Page 2

1. Preface ...............................................................................................................................................................4

1.1 Foreword to this manual ................................................................................................................................4

1.1.1 Validity of the manual ................................................................................................................................4

1.1.2 SIMON LINK ............................................................................................................................................4

1.1.3 SIMON PLUS ...........................................................................................................................................4

1.1.4 M-SHEV ECO ...........................................................................................................................................4

1.2 Use for the intended purpose ........................................................................................................................4

1.3 Functional description ...................................................................................................................................5

2. Components ......................................................................................................................................................6

2.1 Power supply ................................................................................................................................................6

2.1.1 Emergency power supply ........................................................................................................................... 7

2.1.2 Regulating the I/U charge ..........................................................................................................................7

2.1.3 Monitoring the monitor input for sequential control (mains/emergency operation) .............................................7

2.1.4 Technical data (rated values) .....................................................................................................................7

2.2 Fault mode ....................................................................................................................................................9

2.3 Internal BUS connection ...............................................................................................................................9

2.3.1 Terminal plugs AS-110 ..............................................................................................................................9

2.4 Central Interface – ZI-100 ...........................................................................................................................10

2.4.1 General functions .................................................................................................................................... 10

2.4.2 Ventilation ..............................................................................................................................................10

2.4.2.a Wind/rain detector (WTS) connection ................................................................................................10

2.4.3 Global ventilation button ..........................................................................................................................10

2.4.4 Digital inputs ...........................................................................................................................................10

2.4.5 Maintenance counter ...............................................................................................................................10

2.4.6 Technical data ZI-100 (-ZI1) ..................................................................................................................... 10

2.5 Sensor Interface – SI-100 ...........................................................................................................................11

2.5.1 Trigger or indicating lines (line monitored) ..................................................................................................11

2.5.2 Indicators ...............................................................................................................................................11

2.5.3 ALARM mode reset .................................................................................................................................11

2.5.4 DIP switches ..........................................................................................................................................11

2.5.5 Reset function ........................................................................................................................................11

2.5.6 Fire alarm system AUTORESET function ..................................................................................................12

2.5.7 Fault triggered only on power outage ........................................................................................................12

2.5.8 Fireman’s override switch / SI-100-MASTER ..............................................................................................12

2.5.9 SI-100-SP ..............................................................................................................................................12

2.5.10 Technical data SI-100 (-SI1) ................................................................................................................... 12

2.6 Motor Relay – MR-120 ...............................................................................................................................13

2.6.1 Triggering of the load relays (“S” and “O” terminals) ....................................................................................13

2.6.2 ALARM functions ....................................................................................................................................13

2.6.2.a Open delay in alarm mode ...............................................................................................................13

2.6.2.b Priority function (Basic) ....................................................................................................................13

2.6.2.c Priority function (Extended) ..............................................................................................................13

2.6.2.d Retriggering function (deadlock) .......................................................................................................14

2.6.2.e Alarm ONLY with analog input (optional) — Dependency logic .............................................................14

2.6.3 Ventilation functions ................................................................................................................................14

2.6.3.a Connection ventilation button/input ventilation signals .........................................................................14

2.6.3.b Action behaviour of ventilation buttons ............................................................................................... 14

2.6.3.c Open delay in vent mode .................................................................................................................14

2.6.3.d WTS (wind /rain-detector) .................................................................................................................14

2.6.3.e Gap ventilation ................................................................................................................................14

BA_M-SHEV_EN_17 Date: 30.07.2019

Issue: 1.7/07.2019 Page 3

Table of contents

2.6.3.f Automatic close ............................................................................................................................... 14

2.6.3.g Eco mode ....................................................................................................................................... 15

2.6.3.h Time until next thermostat query ....................................................................................................... 15

2.6.3.i Ventilation ONLY with analog input (optional) — Dependency logic ....................................................... 15

2.6.4 Analog input (optional) ............................................................................................................................ 15

2.6.5 Technical data MR-120 (-MR1) ................................................................................................................. 15

2.7 Message Interface – MI-100 (optional) ....................................................................................................... 16

2.7.1 Triggering the dry signal contacts ............................................................................................................. 16

2.7.2 Assigning parameters to the dry signal contacts ......................................................................................... 16

2.7.2.a Condition (logical operation) ............................................................................................................. 16

2.7.2.b Switching delay ............................................................................................................................... 17

2.7.2.c Hold time ........................................................................................................................................ 17

2.7.3 Technical data MI-100 (-MI1) ................................................................................................................... 17

2.8 BUS Interface – BI-100 (optional) ............................................................................................................... 18

2.8.1 MODBUS ............................................................................................................................................... 18

2.8.2 Digital inputs .......................................................................................................................................... 18

2.8.3 Technical data BI-100 (-BI1) .................................................................................................................... 18

3. Mechanical connection .................................................................................................................................. 19

3.1 M-SHEV-10-AP ........................................................................................................................................... 19

3.2 M-SHEV ...................................................................................................................................................... 19

4. Electrical connection ...................................................................................................................................... 20

4.1 230 V AC connection (-x1) .......................................................................................................................... 20

4.2 Central interface – ZI-100 ........................................................................................................................... 21

4.3 Sensor interface – SI-100 ........................................................................................................................... 21

4.4 Motor relay – MR-120 ................................................................................................................................. 22

4.4.1 Motor cable monitoring by DD-100 ............................................................................................................ 22

4.5 Message interface – MI-100 (optional) ....................................................................................................... 22

4.6 BUS interface – BI-100 (optional) ............................................................................................................... 22

5. Commissioning ................................................................................................................................................ 23

5.1 M-SHEV-10-AP ........................................................................................................................................... 23

5.2 M-SHEV ...................................................................................................................................................... 23

6. Appendix .......................................................................................................................................................... 24

6.1 Care and Maintenance ................................................................................................................................ 24

6.2 General business and delivery terms .......................................................................................................... 24

6.3 Company Addresses ................................................................................................................................... 24

7. Manufacturer's declaration ............................................................................................................................ 24

8. EC manufacturer’s declaration (distributor) ................................................................................................ 24

Preface

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

info@simon-protec.com Issue: 1.7/07.2019

Page 4

Operating manual

1 Preface

1.1 Foreword to this manual

This manual is intended for professional operation, installation

and maintenance by trained, knowledgeable and qualified

personnel (such as mechatronics engineer or electrician) and/

or qualified personnel who know how to install electrical equip-

ment.

Read this operating manual carefully and pay particular atten-

tion to the hazard warnings. Store this operating manual for

future reference/maintenance. Please pay close attention to

the terminal assignment, the minimum and maximum perfor-

mance data (see “Technical Data”) and the installation instruc-

tions. Incorrect use or improper operation/mounting may

cause loss of system functionality and damage to property

and/or people.

The following symbols can be found in this manual:

Operating procedures are marked this way.

Consequences are presented this way.

•Buttons or switches to be pressed/activated are shown

in bold.

• “Indicators” are placed in quotation marks.

1.1.1 Validity of the manual

1.1.2 SIMON LINK

1.1.3 SIMON PLUS

1.1.4 M-SHEV ECO

1.2 Use for the intended purpose

The M-SHEV product family (Modular Smoke and Heat

Exhaust Ventilation) consists of electrical control devices in a

sheet steel housing with power supply, emergency power

supply and complete control and regulation electronics for the

operation of 24 V DC actuators.

Ventilation signals from

• ventilation buttons

• wind/rain detectors

and alarm triggering of three monitored indicating lines

• emergency button

(SHEV-emergency button)

•smoke/thermal detectors

• fire alarm control system (FAS)

can be processed.

The M-SHEV modular control units control actuators both in

the event of fire (as smoke and heat extraction systems) and

for daily ventilation. In the event of a power failure, the

emergency power supply ensures the function of the SHEV

system for at least 72 hours.

INFORMATION

An information text gives you additional hints!

ATTENTION

This warning notice alerts you to potential hazards that

may impact the product!

DANGER

This warning notice alerts you to potential hazards to your

life or health!

ENVIRONMENT NOTICE

This notice alerts you to potential environmental hazards!

INFORMATION

As of July 2019, this manual applies to M-SHEV control

systems with firmware version from mid 2019 and

SIMON LINK 2.2.0 or higher!

INFORMATION

Functions that can be configured or

enabled with SIMON LINK are marked

with the SIMON LINK logo!

You can find more information about

SIMON LINK on our website

short.simon-protec.com/slen

INFORMATION

SIMON PLUS are extra features, available at an additional

charge, which must be enabled ex works or on site by a

SIMON service technician.

For more information, please contact our technical sales

department.

INFORMATION

The here described factory configuration for control units

of the ECO product class cannot be changed via

SIMON LINK.

Status messages can be read out.

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

Preface

1.3 Functional description

The control modules of the electrical control system M-SHEV

use bus technology to communicate with each other. In case

of an ALARM-trigger or during daily ventilation operations, the

M-SHEV controls the connected opening actuators.The

ventilation functions also serve as regular functional checks

of the smoke and heat ventilation system.

Smoke and heat extraction systems belong to the field of

preventive fire protection. By installing them, lives can be

saved in an emergency. The building permit authority decides

whether and how the smoke control system must be installed

in the building. Before proceeding with the installation, please

check once again if the size of the smoke and heat extraction

system is compliant with the official regulations in order to

ensure sufficient system functionality.

The control systems of the M-SHEV product family consist of

four components (optionally up to six):

• Power supply

(switching power supply, charging device and battery)

• Central interface ZI-100

• Sensor interface SI-100

• Motor relay MR-120

• Message interface MI-100

(optional/not included in the standard scope of delivery)

• Bus interface BI-100

(optional/not included in the standard scope of delivery)

All components are equipped with tension spring terminals

(0.5 mm² – 2.5 mm²).

Table 1: Mechanical properties M-SHEV-10-AP

Dimensions (W x H x D)

Weight (including battery) 14.3 kg

Protection rating IP20 according to EN 60529

Housing Steel sheet (powder-coated)

Colour RAL 9010

Table 2: Mechanical properties M-SHEV

Dimensions (W x H x D)1

1. Standard sizes; dimensions may vary according to customer

requirements.

Protection rating2

2. If suitable cable glands are used.

IP66 according to EN 60529

Housing Steel sheet (powder-coated)

Colour RAL 7035

Table 3: Connection and operation

Connection See Chapter 4 “Electrical

connection” on page 20.

Actuator cut-off in every position

(STOP command) Yes1

1. Only in ventilation mode, without dead man's function.

Deadlock function according

prEN 12101-9 (re-triggering)

Deadlock enabled

(can be activated/deactivated

via SIMON LINK on the

MR-120)

Maximum cable length between

control unit and actuator

See Chapter 4.4 “Motor relay

– MR-120” on page 22.

Maintenance

See supplementary sheet

“Safety instructions and

warranty conditions”!

Table 4: Installation and ambient conditions

Operational temperature

-5 to 40 °C

1

1. This temperature range applies to all components of the M-SHEV

System (incl. battery).

Storage temperature

Suitable for external installation

Only with special types of

housings – in case of doubt,

please contact our technical

sales department.

Table 5: Approvals and certificates

EU compliant

In accordance with

EMC Directive 2014/30/EU and

Low Voltage Directive 2014/35/EU.

Power supply EN 12101-10 (Smoke and heat control sys-

tems – Part 10: Power supplies)

• M-SHEV-10-AP:

406 x 444 x 170 mm

• M-SHEV-10:

400 x 600 x 200 mm

• M-SHEV-24:

500 x 500 x 200 mm

• M-SHEV-48:

600 x 600 x 250 mm

• M-SHEV-72:

800 x 800 x 250 mm

Components — Power supply

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

info@simon-protec.com Issue: 1.7/07.2019

Page 6

2 Components

— Power supply

2.1 Power supply

The power supply of the M-SHEV product family comprises

three components:

• Switching power supply

• Charging device

• Lead battery

The choice of the switching power supply and the corre-

sponding charging device with battery varies according to the

specific power variant. For power supply with more than 72 A,

several power supply units (switching power supply/charging

device/battery) are used cascaded.The following figures may

vary depending on the size of the housing and number of

modules.

According to EN 12101-10, both the primary (switching power

supply unit) and the secondary (batteries) power supplies are

designed for delivering the full output independently from

each other.

Figure 1: M-SHEV-10-AP power supply

Figure 2: M-SHEV-10 power supply

Figure 3: M-SHEV-24 power supply

Switching power

Charging device (-LB120/B1)

Pre-fuse (-F1)

Lead batteries

(2 x 7 Ah)

supply (-G1)

Lead batteries

Switching power

Charging device (-LB120/B1)

Pre-fuse (-F1)

(2 x 7 Ah)

supply (-G1)

Lead batteries

Switching power

Charging device

Pre-fuse (-F1)

supply (-G1)

(2 x 12 Ah)

(-LB120/A1)

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

Components — Power supply

Figure 4: M-SHEV-48 power supply

Figure 5: M-SHEV-72 power supply

2.1.1 Emergency power supply

The emergency power supply of the M-SHEV product family

is ensured by two 12 V backup batteries. Only VdS approved

lead batteries are permitted.

Switching between mains and emergency operation is auto-

matic if necessary.

2.1.2 Regulating the I/U charge

Lead batteries are charged in accordance with the re-

quirements of EN 12101-10. The control system recognises if

a lead battery is missing or faulty (self-diagnosis) and gener-

ates an error signal on the SHEV-emergency button (yellow

LED) and the central interface (yellow LED).

2.1.3 Monitoring the monitor input for sequential

control (mains/emergency operation)

The charging device switches to emergency power supply

(monitoring function) in case of a mains failure, undervoltage

of the power supply or if the primary power supply fails.

2.1.4 Technical data (rated values)

Table 6:

Operating voltage

(continuous operation) 230 V AC

Permissible voltage range

(short-time operation) 195 V AC to 264 V AC

Power consumption1

1. Power consumption at maximum output load.

1.45 A (M-SHEV-10)

4.4 A (M-SHEV-24)

8.8 A (M-SHEV-48)

13.2 A (M-SHEV-72)

Pre-fuse for mains isolation (-F1) D01 16 A (gL/gG)

Connection power

385 VA (M-SHEV-10)

1012 VA (M-SHEV-24)

2024 VA (M-SHEV-48)

3069 VA (M-SHEV-72)

Inrush current ≤30 A

≤45 A (M-SHEV-10)

Frequency range 47 Hz to 63 Hz

Power supply conductor

cross-section at least 1.5 mm²

Terminal design 0.5 mm² – 2.5 mm²

Protection class

I

Mains connection data

Table 7: Technical data for the switching power

supply 10 A (-G1)

Input voltage 195 – 264 V AC

Output voltage 24 V DC (±1%)

Output voltage ripple ≤80 mV (Vpp)

Output power 0 – 10 A / 240 W

Lead batteries

Switching power

Charging device

Pre-fuse (-F1)

Switching power

supply (-G2)

(2 x 17 Ah)

(-LB140/A1)

supply (-G1)

Lead batteries

Switching power Charging device

Pre-fuse (-F1)

Switching power

Switching power

supply (-G2)

supply (-G3)

(-LB160/A1)

supply (-G1)

(2 x 24 Ah)

Components — Power supply

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

info@simon-protec.com Issue: 1.7/07.2019

Page 8

Table 8: Technical data for the switching power

supply 24 A (-G1/-G2/...)

Input voltage 195 – 264 VAC

Output voltage 24 V DC (±1%)

Output voltage ripple ≤80 mV (Vpp)

Output power (permanent operation) 0 – 20 A / 480 W

Output power (short-time operation) 0 – 24 A / 576 W

Table 9: Power supply

Power supply Short-time load

(3 minutes)

Continuous load

(mains operation)

M-SHEV 10

M-SHEV 24

M-SHEV 48

M-SHEV 72

Table 10: Technical data for the charging device

(-LB120/B1)

Voltage output (mains operation) 23.6 – 24.8 V DC

Voltage output

(emergency operation/output

voltage lead battery)

21.0 – 28.2 V DC

Power fuse (internal)

Fuse character type T 15 A

Charging fuse (internal)

Fuse character type T 3.15 A

Charging voltage 26.7 – 27.9 V DC

Charging current ≤0.5 A

Interruption time none

LED indicator for mains operating state Continuous green light –

mains present

LED indicator for lead battery operating

state (“O.K.”)

Continuous green light –

battery is present and

charged

(charge is maintained)

Table 11: Technical data for the charging device

(-LB120/A1 / -LB140/A1 / -LB160/A1)

Voltage output (mains operation) 23.6 – 24.8 V DC

Voltage output (emergency operation) 21 – 28.2 V DC

Power fuse (internal)

Fuse character type T 25 A

Charging fuse (internal)

Fuse character type T 3.15 A

Charging voltage 26.7 – 27.9 V DC

Charging current ≤1.1A

Interruption time no interruption

LED indicator for mains operating state Continuous green light

– mains present

LED indicator for lead battery operating

state (“O.K.”)

Continuous green light

– battery is present and

charged

(charge is maintained)

Figure 6: LB-120 charging device

Table 12: Technical data for the M-SHEV-10(-AP)

lead battery

Maintenance-free lead battery 2 pieces

Dimensions (L x W x H) (mm) 151 x 65 x 97.5

Weight (per battery) 2.2 kg

VdS approval G189099

Output voltage per battery 10.5 V DC – 14.1 V DC

Total output voltage

(through series connection) 21.0 V DC – 28.2 V DC

Rated capacity (total) 7.0 Ah

Service life approx. 4 years

Table 13: Technical data for the M-SHEV-24 lead battery

Maintenance-free lead battery 2 pieces

Dimensions (L x W x H) (mm) 151 x 98 x 97.5

Weight (per battery) 4.05 kg

VdS approval G189170

Output voltage per battery 10.5 V DC – 14.1 V DC

Total output voltage

(through series connection) 21.0 V DC – 28.2 V DC

Rated capacity (total) 12.0 Ah

Service life approx. 4 years

Table 14: Technical data for the M-SHEV-48 lead battery

Maintenance-free lead battery 2 pieces

Dimensions (L x W x H) (mm) 181 x 76 x 167

Weight (per battery) 6.10 kg

VdS approval G197022

Output voltage per battery 10.5 V DC – 14.1 V DC

Total output voltage

(through series connection) 21.0 V DC – 28.2 V DC

Rated capacity (total) 17.0 Ah

Service life approx. 4 years

10 A 8 A

24 A 20 A

48 A 40 A

72 A 60 A

Power fuse Charging fuse

LED indicators

15 / 25

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

Components — Fault mode & Internal BUS connection

Table 15: Technical data for the M-SHEV-72 lead battery

Maintenance-free lead battery 2 pieces

Dimensions (L x W x H) (mm) 166 x 175 x 125

Weight (per battery) 9.0 kg

VdS approval G182026

Output voltage per battery 10.5 V DC – 14.1 V DC

Total output voltage

(through series connection) 21.0 V DC – 28.2 V DC

Rated capacity (total) 24.0 Ah

Service life approx. 4 years

— Fault mode & Internal BUS connection2.2 Fault mode

There are two fault modes into which the control can fall due

to impairment of the power supply:

• mains failure

• battery is faulty/missing

If the control system is in the “mains failure” fault mode, new

ventilation commands (including closing via the wind/rain de-

tector) are not accepted. Pre-existing ventilation commands

are kept for 3 minutes before the outputs of the MR-120 are

disconnected from the power supply.

If the control system is in the “faulty battery” fault mode, the

fault is indicated on the control system of the ZI-100 and on

the main emergency switch; this fault does not affect the

ventilation function.

2.3 Internal BUS connection

The individual modules of the M-SHEV control panel are con-

nected to each other through the BUS connections (RJ45

sockets).

2.3.1 Terminal plugs AS-110

The AS-110 terminating plugs are necessary for reliable

operation of the BUS connection and must be plugged into

the BUS ends (first and last module).

Figure 7: AS-110 terminal plug

ATTENTION

The connected actuators can then only be closed by

pressing the reset button on the main emergency switch.

The control system only reacts on pressing the RESET

button for more than 5 seconds and then automatically

switches it in dead man mode.

INFORMATION

It is possible to activate the “Immediate WTS signal in

case of mains failure” function (WTS stands for wind/rain

signal CLOSE) on the central interface (ZI-100). This

causes the connected actuators to close automatically in

case of mains failure (max. closing time: 3 min). To do

this, the WTS function must have been activated via

SIMON LINK at the desired outputs (MR-120) in the

“Ventilation” subfolder.

ATTENTION

The RJ45 sockets installed on the M-SHEV modules are

only intended for the internal BUS communication of the

modules.

Do not connect to an external LAN port or anything similar!

ATTENTION

Do not remove the AS-110 terminal plugs. Removing the

BUS terminating plugs leads to failure of the BUS connec-

tion - and thus of the entire control system.

AS-110

Components — Central Interface (ZI-100)

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

info@simon-protec.com Issue: 1.7/07.2019

Page 10

— Central Interface (ZI-100)2.4 Central Interface – ZI-100

Figure 8

The ZI-100 is the central module of the M-SHEV modular con-

trol panel.

The ZI-100 performs the following tasks:

• Control of the connected bus participants

• Interface for SIMON LINK

• Interface for a remote maintenance module via mobile

communication (GPRS)

•Wind/rain detector (WTS) connection

• Digital input (e.g. for central ventilation system)

• Visual indicators:

– green LED – “OK” mode

–yellow LED – “Failure” mode

– white LED – “WTS triggered”

2.4.1 General functions

If secondary power supply is active (batteries), the yellow

LED on the ZI-100 flashes.

2.4.2 Ventilation

2.4.2.a Wind/rain detector (WTS) connection

The wind/rain detector (WTS) automatically closes the flaps/

windows that are opened for ventilation. The signal of the

wind/rain detector is only overridden by ALARM triggering.

WTS must be enabled in the “Ventilation” subfolder of the

corresponding motor relay MR-120.

2.4.3 Global ventilation button

Global ventilation buttons can be connected and

configured at the digital inputs. At the MR-120

modules it is possible to set whether and how to

react to this these buttons (ZI-100 digital inputs).

2.4.4 Digital inputs

Five digital inputs can receive different functions,

such as time switch signals. They can be evaluat-

ed independently of each other as normally open

or normally closed. Two 24

V DC terminals (mains/backup)

are available to connect the inputs.

The respective functions are shown in the connection plan

according to customer requirements. Should you require any

changes, please contact our technical sales department.

2.4.5 Maintenance counter

The M-SHEV control panels product family has a

maintenance counter which optionally outputs a

fault after a set time if no maintenance is carried

out. This function is switched off by default.

2.4.6 Technical data ZI-100 (-ZI1)

Table 16

Permissible voltage range 21 – 28.2 V DC

Power consumption max. 30 mA

Wind/rain detector (WTS) connection

See Chapter 4.2 “Cen-

tral interface – ZI-100”

on page 21.

Output voltage range

(E WTS / mains operation)1

1. Switched off in emergency power mode

23.6 – 24.8 V DC

Current rating WTS max. 150 mA

Digital input connection

See Chapter 4.2 “Cen-

tral interface – ZI-100”

on page 21.

Output voltage range

(digital input – 24 V DC mains)2

2. Switched off in emergency power mode

23.6 – 24.8 V DC

Output voltage range

(digital input – 24 V DC backup)3

3. Remains steady even during emergency operation

21.0 – 28.2 V DC

Current rating max. 150 mA

SIMON LINK connection 6-pin

LED indicator

white: “WTS”

yellow: “Failure”

green: “OK”

ZI-100

Zentralinterface

Central Interface

M–SHEV®

SIMON LINK

Factory-configured

(internal

Internal

power supply)

WTS Connection for

BUS connection

Digital Input connection

INFORMATION

The WTS function can also be used for safe closing in

case of mains failure. For further relevant information, see

Chapter 2.2 “Fault mode” on page 9.

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

Components — Sensor Interface (SI-100)

— Sensor Interface (SI-100)2.5 Sensor Interface – SI-100

Figure 9

The triggering components – emergency button, smoke

detector and on-site fire alarm system – are connected to the

sensor interface.

A sensor interface (SI-100) defines an ALARM group within a

M-SHEV control panel. You can assign any number of motor

outputs (MR-120) to the SI-100. These motor outputs then

react according to the commands generated by the SI-100

with closing or opening operations. The default settings are

set on the SI-100 and MR-120 according to prEN 12101-9

(unless factory-set by customer request).

2.5.1 Trigger or indicating lines (line monitored)

Three different triggering units can be connected to one SI-100:

• Emergency button type HE (first detection line B1)

• Smoke detector type RM (second detection line B2)

• On-site dry contact, e.g. a fire alarm system

(third detection line B3)

The electrical connection of the respective triggering unit is

carried out according to the diagram on page 21 of this man-

ual. The three detection lines (B1, B2 and B3) have the same

triggering priority by default.

The outputs to these triggering units are monitored for short

circuit and line interruption according to prEN 12101-9.

In the event of a short circuit or power interruption in the con-

nection line, the SI-100 and the control system will switch to

ALARM mode. All allocated MR-120 are triggered – the

connected actuators move to the intended ALARM position.

2.5.2 Indicators

The SI-100 is provided with the following indicators:

• Indicating line is triggered

(separate for B1, B2 and B3) – red,

• “Failure” (faults of the SI-100) – yellow,

• “OK” operating state – green.

2.5.3 ALARM mode reset

After a SI-100 has switched to the ALARM mode, it is reset to

standby mode by a RESET command. This is only possible if

all monitored triggering criteria (e.g. triggered smoke detec-

tor) have been reset. The RESET command can be given

through the RESET button of the

• Emergency button

•SI-100

For further information about the RESET function, see

Chapter 2.5.5 “Reset function” on page 11.

2.5.4 DIP switches

The SI-120 has four DIP switches with the following functions:

• DIP switch 1: Activates/deactivates detection line B1

• DIP switch 2: Activates/deactivates detection line B2

• DIP switch 3: Activates/deactivates detection line B3

• DIP switch 4: Activates/ deactivates Autoreset function of

detection line B3 (FAS)

Figure 10: SI-100 DIP switch

2.5.5 Reset function

The ALARM signal can be reset on the emergency button or

at the sensor interface as described in Chapter 2.5.3 “ALARM

mode reset”. When you press the RESET button for the first

time, only the ALARM signal is reset. The opening actuators

stay in the intended ALARM position.

When you press the RESET button for the

second time, a ventilation signal CLOSE is

generated. For this signal to have an effect on the

MR-120, the ventilation source SI x/Reset must be enabled

on the MR-120.

INFORMATION

The respective triggering action on the MR-120 can be ad-

justed via SIMON LINK (see chapter 2.6.2 “ALARM func-

tions” on page 13).

SI-100

Sensorinterface

Sensor Interface

M–SHEV®

Factory-configured

(internal

RESET

Emergency Button HE

DIP

Internal

power supply)

BUS connection

switches

button

Smoke detector FAS

SI-100

Sensorinterface

Sensor Interface

M–SHEV®

Components — Sensor Interface (SI-100)

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

info@simon-protec.com Issue: 1.7/07.2019

Page 12

2.5.6 Fire alarm system AUTORESET function

Generally, all SHEV-alarms must be reset manually by

pressing the RESET button (onboard/emergency button).

For detection line 3 (FAS – fire alarm system), the AUTORE-

SET function can be activated, which will reset the SHEV and

power the relays into CLOSE direction, after the FAS has

been reset.

For an additional ventilation command CLOSE to

be generated on the MR-120, the ventilation

source SIx /Autoreset must be enabled on the

MR-120.

2.5.7 Fault triggered only on power outage

If this function is enabled, a fault is indicated at

the central interface, sensor interface and emer-

gency button only if there is a line interruption at

the indicating lines 1–3.

2.5.8 Fireman’s override switch / SI-100-MASTER

This gives the fire brigade top priority and enables it to close

windows that have already been opened in the event of an

alarm, even if alarms are present. For this function you need

a SI-100-MASTER module. A suitable triggering device (op-

tional) is recommended for control. Make sure that the speci-

fied current values (see Table 18 on page 12) are not

exceeded.

To be able to use the connected fire service-

button as fireman’s override switch, the functions

“Fireman’s button” and “RZ triggers alarm over-

ride” must be activated in the SI-100-MASTER module. The

SI-100-MASTER must be assigned to the MR-120 and the

“Accept fireman's button commands” function must be acti-

vated.

2.5.9 SI-100-SP

This variant of the SI-100 module enables the connection of

emergency buttons with 3-wire technology (level monitoring),

such as HE-077 or HE-083. For further information, please

contact our technical sales department.

2.5.10 Technical data SI-100 (-SI1)

Table 17:

Permissible voltage range 21 – 28.2 V DC

Power consumption (standby mode) 10 – 20 mA

Power consumption (ALARM mode) max. 80 mA

Emergency button connection 7 terminals

(OK/Y/M/–/RZ/RA/B1)

Smoke detector connection 3 terminals (B2/–/RA)

Fire alarm system connection 3 terminals (B3/–/RA)

DIP switch position

(default/delivery condition)

1 – 3: ON

4: OFF

LED indicator

3 x red: “ALARM release”

yellow: “Failure”

green: “OK”

Table 18: Connection data for emergency button

(HE buttons)

Maximum amount

main emergency switch 1

Maximum amount

off side switch 7

Output voltage range (B1) 17.5 V DC – 18 V DC

Current rating (B1) max. 120 mA

Current monitoring window

(OK range) 100 µA to 5 mA

Output voltage range (OK) 21 V DC – 28.2 V DC

Output voltage range (Y) 21 V DC – 28.2 V DC

Output voltage range (M) 21 V DC – 28.2 V DC

Input voltage range (RA) 15 V DC – 30 V DC

Input voltage range (RZ) 15 V DC – 30 V DC

Current rating (OK) max. 80 mA

Current rating (Y) max. 80 mA

Current rating (M) max. 80 mA

Table 19: Connection data for smoke detector

(RM 3000 / RM 2860) or thermo detector (TH 4860)

Maximum amount

8 x RM 3000

(VdS approval

G203036) or

6 x RM 2860/TH 4860

(VdS approval:

G200017/G200060)

Output voltage range (B2) 17.5 V DC – 18 V DC

Current rating (B2) max. 120 mA

Current monitoring window (OK range) 100 µA to 5 mA

Reset time after ALARM reset

(by disconnecting power supply B2) 3 sec

Input voltage range (RA) 15 V DC – 30 V DC

INFORMATION

The smoke detector types offered by us and listed in

Table 19 have been tested and approved for unrestricted

functionality with the M-SHEV product family by SIMON

PROtec.

We cannot guarantee that the M-SHEV product family

works with other smoke detectors.

Table 20: Connection data of the fire alarm system (FAS))

Output voltage range (B3) 17.5 V DC – 18 V DC

Current rating (B3) max. 120 mA

Current monitoring window (OK range) 100 µA to 5 mA

Reset time after ALARM reset

(by disconnecting power supply B3) 3 sec

Input voltage range (RA) 15 V DC – 30 V DC

ATTENTION

If this function is enabled, no ALARM is triggered at the

respective indicating lines 1–3.

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

Components — Motor Relay (MR-120)

— Motor Relay (MR-120)2.6 Motor Relay – MR-120

Figure 11

The MR-120 provides the output voltage for the actuators. The

output at terminals “S” and “O” is designed in the pole changing

technique.

OPEN: S=„+“ O=„–“

CLOSE: S=„–“ O=„+“

At the MR-120, you can find:

•a10A fuse for the motor outputs

• two interfaces for actuators including separate line

monitoring

• two contacts for ventilation function

(e.g. button/thermostat)

• analog input (0 – 10

V DC

/ 4 – 20 mA) for sequential

triggering of actuators for ventilation purposes

• visual indicators:

– two white LEDs – triggering in “OPEN”/“CLOSE”

direction

– yellow LED – “Failure”

– green LED – “OK”

2.6.1 Triggering of the load relays

(“S” and “O” terminals)

The power output for the smoke and heat exhaust actuators is

represented by two power relays which operate in pole chang-

ing technique to ensure OPEN/CLOSE triggering. The

M-SHEV motor outputs are fitted with overload protection.

During mains failure mode, the relays drop out immediately as

described in Chapter 2.2 “Fault mode” on page 9. They are on-

ly reactivated if an ALARM is triggered.

2.6.2 ALARM functions

2.6.2.a Open delay in alarm mode

The MR-120 allows you to set a start delay for

certain applications (e.g. in combination with sun

protection systems in front of windows). This

ALARM triggering will be displayed immediately, received

and processed and can be indicated by an MI-100 message

interface. After the intended ALARM start delay time has

been elapsed, the actuators move to the intended ALARM

position.

2.6.2.b Priority function (Basic)

The MR-120 module operates as standard with 3

priority levels for detection lines 1 (HE button), 2

(smoke detector) and 3 (BMZ). When an as-

signed sensor interface is triggered, the MR-120 reacts by

controlling the opening actuators in the OPEN direction. It is

only possible to configure 1 common group of SI modules for

all priority levels.

This function allows you to define any priority sequence for

the indicating lines. You can also invert every alarm trigger.

When this setting is enabled, the allocated opening units are

moved in the CLOSE direction instead of the usual OPEN

direction, if an alarm is triggered.

2.6.2.c Priority function (Extended)

The extended priority function allows to configure

an individual SI-100 group for each priority level.

MR-120

Motorrelais

Motor Relay

M–SHEV®

Factory-configured

Motor

Fuse

Internal

(internal

power supply)

Ventilation 1/

Ventilation 2

Motor 1| Motor 2 Analog

connection input

BUS connection

INFORMATION

The triggering priorities and other functions can be

modified on request using the SIMON LINK configuration

software.

ATTENTION

This function can affect standards-compliant processing of

alarm signals. Please check with the approval authorities

regarding this function.

INFORMATION

If you change a setting at this point, please remember to

apply a functionally identical setting to the ventilation func-

tions (see chapter 2.6.3.c “Open delay in vent mode” on

page 14).

INFORMATION

If the ALARM release is inverted on the FAS indicating line

(set to CLOSE), it is recommended to use the setting “FAS

auto-reset” on the SI-100! (See Chapter 2.5.6 “Fire alarm

system AUTORESET function” on page 12.)

This has the advantage that the BMZ-ALARM is automati-

cally deleted after the release by the BMZ and the ventila-

tion function is available again via the ventilation button.

Components — Motor Relay (MR-120)

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

info@simon-protec.com Issue: 1.7/07.2019

Page 14

2.6.2.d Retriggering function (deadlock)

The M-SHEV product family meets the requirements of

prEN 12101-9 with regard to deadlock, e.g. frozen NSHEVs

(natural smoke and heat exhaust ventilation). This means that

after an ALARM triggering, the actuators are actuated

15 times in the OPEN direction. A new start attempt is made

with initial short closing for 3 seconds in the CLOSE direction

(to protect actuators without restart interlock) at intervals of

2 minutes. A waiting time of 500 ms is observed between

each change of direction. After 30 minutes the triggering

OPEN remains active.

The re-triggering function is switched off by

default and can be individually enabled for each

MR-120.

2.6.2.e Alarm ONLY with analog input (optional) —

Dependency logic

With this function, the analog input is used with

the aid of an external analog circuit as an addi-

tional condition for the execution of a ventilation

function (dependency logic). For this purpose, the analog

input (terminal "+") is permanently checked for a continuous

signal (min. 0.8 mA). As long as the signal is present, an

ALARM function can be performed. If this is not the case,

none of the connected actuators is electrically controlled

2.6.3 Ventilation functions

The ventilation functions are only enabled in mains operation;

if the system switches to emergency power operation, no new

ventilation commands are accepted. Pre-existing ventilation

commands are kept for 3 minutes

2.6.3.a Connection ventilation button/

input ventilation signals

Two ventilation buttons or comparable ventilation signals can

be connected in parallel to the M-SHEV. The behaviour of the

ventilation function is influenced by the triggering type and

duration.

It is possible to use input signals from other

modules.

2.6.3.b Action behaviour of ventilation buttons

The dead man’s function activates automatically if the venti-

lation button is pressed for more than three seconds (auto

dead man’s function). The dead man’s function is a safety

function in which the actuators only move as long as the

respective direction button is pressed. The actuators stop as

soon as the button is released.

If the ventilation button is touched only briefly, the ventilation

command is switched to continuous triggering. A stop func-

tion is achieved by briefly re-pressing the ventilation button in

the OPEN direction, e.g. when opening (tip-stop function).

Each motor relay can be readjusted per ventila-

tion button connection (LT1/LT2, mode open/

close) ) as follows:

• auto dead man + tip-stop

• auto dead man

• no dead man + tip-stop

• no dead man

• dead man only

2.6.3.c Open delay in vent mode

The MR-120 allows you to set a start delay for

certain applications (e.g. in combination with sun

protection systems in front of windows). This

ventilation triggering will be displayed immediately, received

and processed and can be indicated by a MI-100 signal inter-

face. After the intended ventilation start delay time has been

elapsed, the actuators move to the intended ventilation posi-

tion.

2.6.3.d WTS (wind /rain-detector)

For each motor relay it can be defined whether it

should react to the central WTS signal (ZI-100).

2.6.3.e Gap ventilation

The gap ventilation function allows the user to

open the smoke and heat exhaust/vents up to

any defined stroke. The gap ventilation function

and the gap ventilation time can be set with SIMON LINK.

When the ventilation button is pressed, the actuators open to

the set position or to the full opening stroke in ALARM mode.

2.6.3.f Automatic close

This function closes the opening units automati-

cally following a freely adjustable ventilation time.

This function is used to set the waiting time after

which the drives are to be closed automatically. This setting

can be parameterized in seconds (s), minutes (min) or hours

(h) up to a maximum of 24 hours.

ATTENTION

The continuous signal is only detected from 0.8 mA. The

maximum current at the input must not be exceeded!

This input is deactivated by default.

INFORMATION

The ventilation functions can be modified on request using

the SIMON LINK configuration software.

INFORMATION

If you change a setting at this point, please remember to

apply a functionally identical settings to the ALARM func-

tions (see chapter 2.6.2.a “Open delay in alarm mode” on

page 13).

ATTENTION

A new OPEN command is only accepted by the MR-120

after the CLOSE gap ventilation time has fully elapsed.

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

Components — Motor Relay (MR-120)

2.6.3.g Eco mode

If this function is activated, the motor outputs are

de-energised 3 minutes after receipt of the last

ventilation command.

2.6.3.h Time until next thermostat query

If a connected thermostat is overridden by a

manual command (e.g. by desired intermittent

ventilation through a connected ventilation but-

ton), it must be determined how long the control system must

wait before sending a new query to the thermostats. This

waiting time can be set from 10 seconds to 12 hours in

1 second steps.

To be able to use this function, at least one button under the

ventilation sources must be assigned “T” for thermostat.

2.6.3.i Ventilation ONLY with analog input (optional) —

Dependency logic

With this function, the analog input is used with

the aid of an external analog circuit as an addi-

tional condition for the execution of a ventilation

function (dependency logic). For this purpose, the analog

input (terminal "+") is permanently checked for a continuous

signal (min. 0.8 mA). As long as the signal is present, a ven-

tilation function can be performed. If this is not the case, none

of the connected actuators is electrically controlled

2.6.4 Analog input (optional)

This input allows a gap or partial ventilation to be

controlled. For example, this control signal can

come from a building control system.

For this purpose, the total opening and closing times must be

measured and then entered on site. The connected actuators

then move to the required position, proportional to the applied

supply voltage or current. To ensure that this opening

mechanism works properly, the actuators must be closed

completely at least once daily.

2.6.5 Technical data MR-120 (-MR1)

Table 21

Permissible voltage range 21 – 28.2 V DC

Power consumption (standby mode) 5 mA – 20 mA

Power consumption (ALARM mode) max. 12 A

Actuator connection 2 x 3 terminals (S/G/O)

Ventilation connection 2 x 3 terminals (E/Z/A)

Analog input connection 1 x 2 terminals (+/–)

LED indicator

yellow: “Failure”

green: “OK”

white: “OPEN”

white: “CLOSE”

Table 22 Motor channel output data

Switch-on duration SD 30%

Permissible voltage range

(mains operation) 23.0 V DC – 24.5 V DC

Permissible voltage range

(battery operation) 21 V DC – 28.2 V DC

Continuous operation:

Output current (Iout)

(Iout = Imot1 + Imot2)

10 A

Short-time operation:

Output current (Iout)

(Iout = Imot1 + Imot2)

12 A

Pause time between change of

direction 500 ms

Output fuse for actuators

Fuse character type T (delayed) 10 A

Output voltage ripple Vpp

(0 A < Iout < 10 A) 500 mV

Table 23 Connection data for ventilation connections

Output voltage range (E) 23.0 V DC – 24.5 V DC

Current rating (E) max. 150 mA

Table 24 Connection data for analog input

Permissible voltage range 0 V DC – 10 V DC

Permissible current range 4 mA to 20 mA

ATTENTION

The continuous signal is only detected from 0.8 mA. The

maximum current at the input must not be exceeded! This

input is deactivated by default.

ATTENTION

Before connecting, the type of the input signal (current/

voltage) must be determined via SIMON LINK. The analog

input is deactivated by default.

Components — Message Interface (MI-100)

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

info@simon-protec.com Issue: 1.7/07.2019

Page 16

— Message Interface (MI-100)

2.7 Message Interface – MI-100 (optional)

Figure 12

The MI-100 is an optional alarm module. If an MI-100 was

supplied with this controller,the dry contacts(relay:NC/C/NO)

are assigned by default as follows:

• Contact 1 – ALARM mode

• Contact 2 – OK indication

• Contact 3 – WTS triggered

• Contact 4 – Mains operation

This assignment may differ from the standard due to

customer requirements.

The MI-100 has following additional visual indicators:

• one white LED each (next to the signal relay terminal

block) – “Relay ON”

• yellow LED – “Failure”

• green LED – “OK”

2.7.1 Triggering the dry signal contacts

During emergency power operation, all messages except the

“OK” and “Mains” messages remain active. Depending on the

settings of the MI-100 the status can be output via the dry

contacts.

2.7.2 Assigning parameters to the dry signal

contacts

For each contact (relay) the following parameters can be set:

•Condition (logical operation)

•Switching delay: 0 seconds (Off) to 1 hour

•Hold time: 0 seconds(unlimited) / 1 second to 1 hour

2.7.2.a Condition (logical operation)

The logical operators NOT, AND, OR and enclos-

ing brackets can be used to parameterize the

dry contacts. A statement always consists of

three elements:

–a logical statement (no entry = “statement is true” or

NOT = “the statement is negated”)

– the origin of the statement

–and the statement

Origin of the statement

Various sources are available as the origin of the statement

(the names of the sources correspond to the respective mod-

ule identifiers):

–“*”: all modules of the control system

–“SI*”: all SI-100 of the control system

– “MR*”: all MR-120 of the control system

– “ZI1”: the ZI-100 of the control system

– “SI1”: the first SI-100 of the control system

“SI2”: the second SI-100 of the control system

...

– “MR1”: the first MR-120 of the control system

“MR2”: the second MR-120 of the control system

...

– “MI1”: the first MI-100 of the control system

“MI2”: the second MI-100 of the control system

...

INFORMATION

The pin assignments can be configured with SIMON LINK.

ATTENTION

To add an MI-100, it is essential to match the hardware

and software versions of the controller. For further infor-

mation, please contact our technical sales department and

keep the serial number of the control system at hand!

INFORMATION

The video "Add message interface

MI-100" provides an exemplary expla-

nation for retrofitting a module. This

can be found on our YouTube channel

short.simon-protec.com/mi100video

M–SHEV®

MI-100

Meldeinterface

Message Interface

Dry contact 3/4

Factory-configured

Dry contact 1/2

Internal

(internal

power supply)

BUS connection

INFORMATION

The automatic relay drop-out during emergency operation

can be set via SIMON LINK.

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

Components — Message Interface (MI-100)

Statement

Various meaningful values are possible, depending on the

source of the statement (subject to SIMON LINK updates):

–*: Failure

–ZI:

~Failure

~ Mains failure

~ WTS close on wind/rain

~ Signal 1/2/3/4/5 (digital input)

–SI/SI*:

~Failure

~ALARM triggered

~ ALARM on line 1/2/3

~ Reset signal

–MR/MR*:

~Failure

~Alarm triggered

~ Command Open

~ Command Close

–MI:

~Failure

~Relay on 1/2/3/4

Logical operation

The relays only differentiate between ON and OFF and in the

same way the logic operations only differentiate between

YES and NO. This means:

NOT(NOT(statement)) = statement.

Logical operators are defined as follows:

–NOT:

–AND:

–OR:

Examples

–The statement “ALARM from indicating line 1” on the

SI-100 is to be evaluated:

SI*:Alarm_on_Line_1

–The system is in OK operating state:

NOT( *:Failure)

–The statement “ALARM from indicating line 2” of the first

SI-100 and not on the second SI-100 is to be evaluated:

SI1:Alarm_on_Line_2

AND

NOTSI2:Alarm_on_Line_2

–The statement “ALARM from indicating line 1” of the first

SI-100 and not from the other two indicating lines:

SI1:Alarm_on_Line_1

AND

NOT(SI1:Alarm_on_Line_2 OR

SI1:Alarm_on_Line_3)

2.7.2.b Switching delay

After reaching the condition (logical statement is

true), the dry contact (relay) is switched either as

long as the condition remains true or for a preset

time (1 second to 1 hour)

2.7.2.c Hold time

After reaching the condition (logical statement is

true), the dry contact (relay) is switched either as

long as the condition remains true or for a preset

time (1 second to 1 hour).

Even if the condition changes during the hold time, the relay

remains switched until the hold time has elapsed. Only after

the holding time has elapsed the relay is released and reacts

again to status changes of the condition.

2.7.3 Technical data MI-100 (-MI1)

Table 25

Permissible voltage range 21 – 28.2 V DC

Power consumption 37 mA – 100 mA

Connection of DRY contacts 1 and 2 2 x 3 terminals

(NO/C/NC)

Connection of DRY contacts 3 and 4 2 x 3 terminals

(NO/C/NC)

LED indicator

4x white: “Relay ON”

yellow: “Failure”

green: “OK”

Table 26: Connection data for dry signal contacts

“NO/C/NC”

Voltage rating of the switching

contacts (C - NO) max. 30 V DC

Voltage rating of the switching

contacts (C - NC) max. 30 V DC

Current rating of the switching

contacts (C - NO) max. 1 A

Current rating of the switching

contacts (C - NC) max. 1 A

Switching capacity per switching

contact 30 W

Statement is

true

Statement is

NOT true

Yes No

No Yes

Statement1

is true

Statement2

is true

Statement1 AND

Statement2 are true

Yes Yes Yes

Yes No No

No Yes No

No No No

Statement1

is true

Statement2

is true

Statement1 OR

Statement2 is true

Yes Yes Yes

Yes No Yes

No Yes Yes

No No No

Components — Bus Interface (BI-100)

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

info@simon-protec.com Issue: 1.7/07.2019

Page 18

— Bus Interface (BI-100)

2.8 BUS Interface – BI-100 (optional)

Figure 13

The BI-100 is an optional BUS interface.

The BI-100 supports 32 virtual ventilation buttons that can be

assigned to the individual MR120 modules as ventilation

sources using SIMON LINK. These virtual ventilation buttons

can be controlled via the external bus.Ventilation commands

like OPEN, CLOSE, STOP and OPEN with programmable

time limit can be executed.

The module also has two digital inputs that can be evaluated

through the external bus.

In addition, the BI-100 provides an overview of the entire

system. Detailed states of individual modules can be queried.

The optional watchdog enables the monitoring of the

communication flow and in the event of a bus communication

failure, it can also stop the ventilation function and report a

fault.

The BI-100 has the following additional visual indicators:

• green LED (next to the BUS terminal block)

• yellow LED – “Failure”

• green LED – “OK”

2.8.1 MODBUS

The BI-100 provides an EIA-485 RTU-MODBUS

TP interface (TP=twisted pair) and SG/A/B

terminals (SG=signal ground). The communica-

tion speed is adjustable from 300 bps to 57600 bps. It is also

possible to set the parity, stop bits and a watchdog function.

If the MODBUS communication is lost, the BI-100 goes into

fault mode.

2.8.2 Digital inputs

There are 2 digital inputs. A 24 V DC terminal

(mains) is available to connect the inputs.

Central ventilation commands (e.g. time control

signals etc.) can be connected to the digital input of the

BI-100. These are shown in the connection plan according to

customer requirements. Should you require any changes,

please contact our technical sales department.

— Bus interface (BI-100)

2.8.3 Technical data BI-100 (-BI1)

Table 27

Permissible voltage range 21 – 28.2 V DC

Power consumption max. 30 mA

MODBUS connection 2 x 3 terminals

(SG(signal ground)/A/B)

Digital input connection

See Chapter 4.6 “BUS inter-

face – BI-100 (optional)”

on page 22.

Output voltage range

(digital input – 24 V DC mains)1

1. Drops in emergency operation.

23.6 – 24.8 V DC

Current rating max. 150 mA

LED indicator

green: “BUS”

yellow: “Failure”

green: “OK”

ATTENTION

To add a BI-100, hardware and software versions of the

controller have to be synchronised. For further informa-

tion, please contact our technical sales department and

keep the serial number of the control system at hand!

M–VENT

BI-100

BUS Interface

BUS Interface

Digital Input

Factory-configured

External BUS

Internal

(internal

power supply)

BUS connection

INFORMATION

The video "Add message interface

MI-100" provides an exemplary expla-

nation for retrofitting a module. This

can be found on our YouTube channel

short.simon-protec.com/mi100video

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

Mechanical connection

3 Mechanical connection

3.1 M-SHEV-10-AP

Mark the positions of the mounting points of the

M-SHEV-10-AP (see Figure 14: “Mounting points”).

Drill the holes.

Fasten the M-SHEV-10-AP through the bottom of the

housing using four screws suitable for the respective

mounting surface (not supplied).

Figure 14: Mounting points

3.2 M-SHEV

Remove the 4 plastic caps on the back of the M-SHEV

housing.

Mark the positions of the housing’s direct mounting

points for the M-SHEV (see Figure 15: “Mounting points

(back of housing)”) or mount the four wall fixing lugs (see

Figure 16: “Wall fixing lugs”) supplied to the housing and

then mark the positions of the mounting holes to be

drilled.

Drill the holes.

Fasten the M-SHEV with four suitable screws (not sup-

plied) through the bottom of the housing or, if used, with

the aid of four wall fixing lugs.

Figure 15: Mounting points (back of housing)

Figure 16: Wall fixing lugs

ATTENTION

The openings of the battery cells (round lids on top of the

batteries) must not point downwards, because this would

lead to a leak out of the battery!

ATTENTION

Do not connect the battery during installation!

Mounting points

Mounting points

Electrical connection

BA_M-SHEV_EN_17 www.simon-protec.com Date: 30.07.2019

info@simon-protec.com Issue: 1.7/07.2019

Page 20

4 Electrical connection

Insert the connection cable.

Connect the cables according to the connection plan.

Where applicable, attach the strain relief to the cable

comb using cable ties.

Remove the termination resistors of the SHEV-emer-

gency buttons, smoke detectors and FAS contacts from

the terminals of the control panel and connect them to the

last triggering units.

4.1 230 V AC connection (-x1)

Connect the cables according to the connection plan

Figure 17: M-SHEV-10-AP

Figure 18: M-SHEV

DANGER

The system must be mounted by specialist

personnel (qualified electricians) only. All

relevant national safety regulations and

directives apply to mounting, installation

and commissioning.

Improper mounting can create a risk of elec-

tric shock. All safety regulations must be

complied with. Follow the current assembly

instructions. Wrong mounting can lead to

serious injury.

DANGER

Disconnect the connection cable completely (all-pole)

from the mains. No voltage must be present when con-

necting the M-SHEV!

DANGER

The testing of systems must be carried out in accordance

with the applicable national regulations (in Germany

among others. DIN VDE 0100 Part 600).

Make all necessary preparations for this: e.g. connect the

PE connection to the housing lid.

L1

N

PE

L1NPE

This manual suits for next models

5

Table of contents

Other Simon Control Panel manuals

Popular Control Panel manuals by other brands

Siemens

Siemens SXL-EX Operation, installation, and maintenance manual

Johnson Controls

Johnson Controls IQ4 NS installation manual

Sonniger

Sonniger INTELLIGENT eco manual

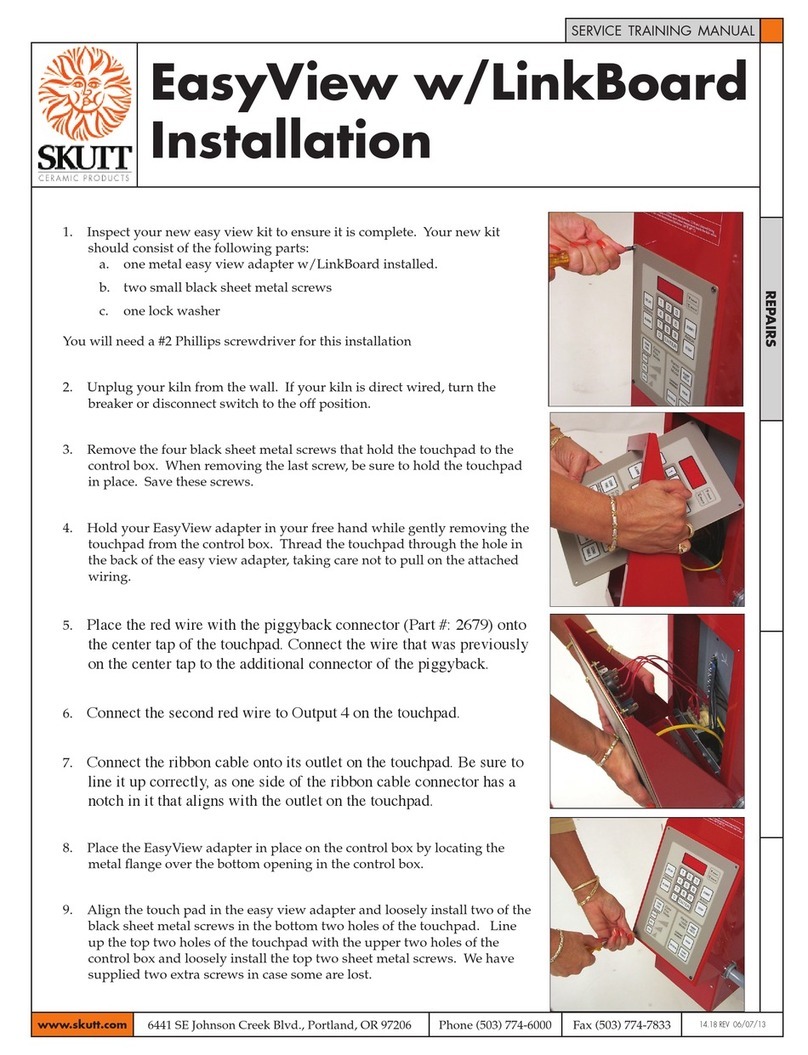

Skutt

Skutt EasyView w/LinkBoard Service training manual

Honeywell

Honeywell NOTIFIER INSPIRE E10 operating instructions

CAME

CAME zl92 installation manual

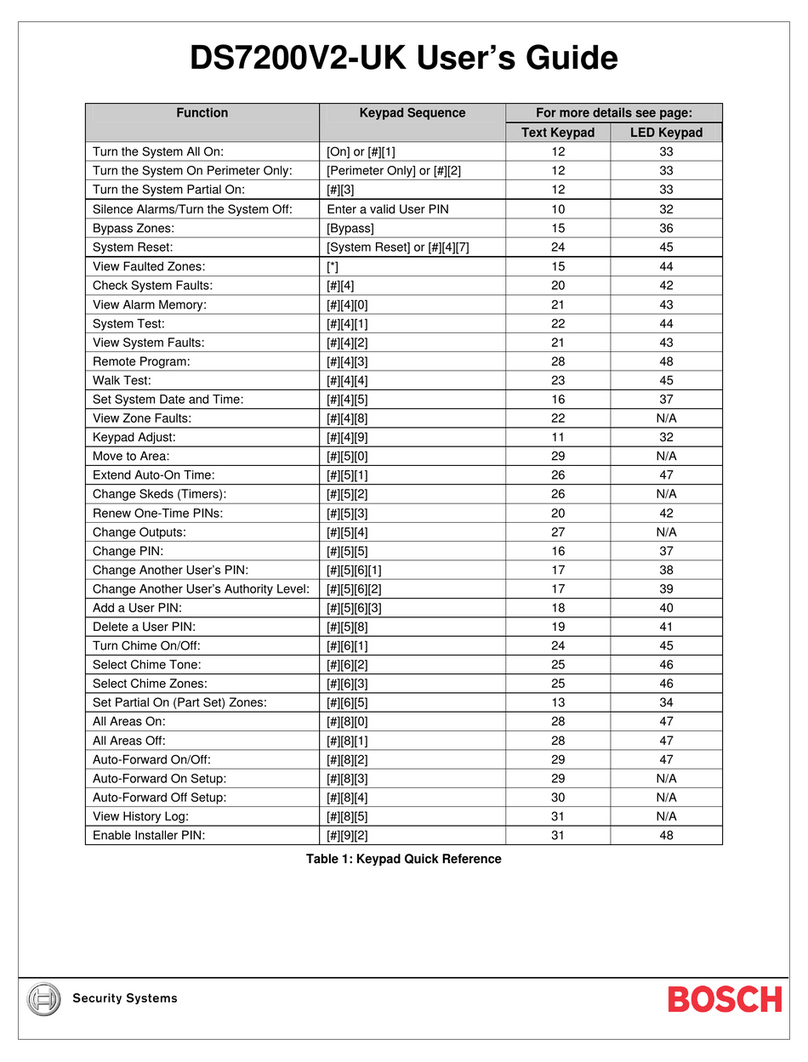

Bosch Security

Bosch Security DS7200V2-UK user guide

Stahl

Stahl ProVicom MT-65 operating instructions

SIGMA TEK

SIGMA TEK 1U619-001 installation manual

NAPCO

NAPCO Gemini GEM-P9600 Programming instructions

C-TEC

C-TEC XFP510-32 installation manual

Kentec Electronics

Kentec Electronics Sigma ZXT installation manual