Simrad PI44

II 851-165101 / Rev.A

1 INTRODUCTION 1.........................................

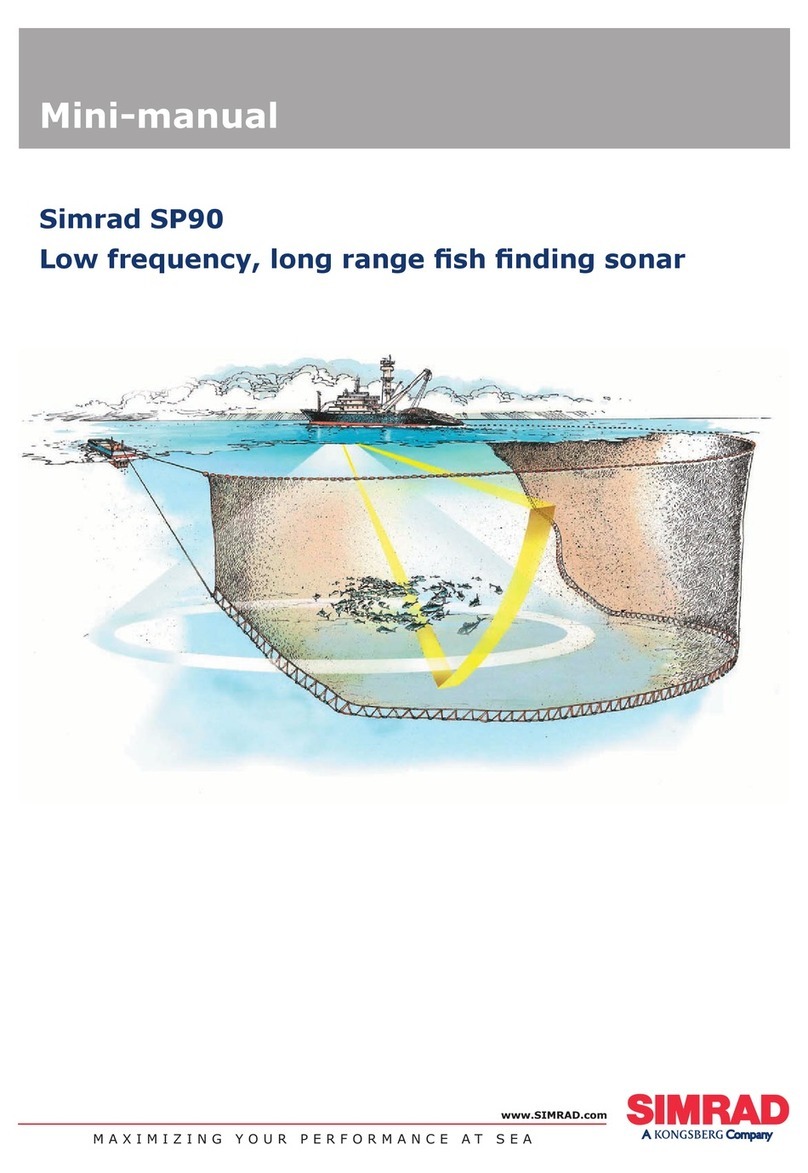

System diagram 2..........................................

Scope of supply 3..........................................

Supply conditions 5........................................

General installation requirements 6............................

Equipment handling 7......................................

11 TRANSDUCER INSTALLATION 18..........................

Purpose 18................................................

Transducer location 19.......................................

External mounting 23........................................

Transducer blister 28........................................

Box keel 33...............................................

Cable glands 35............................................

Cable in steel conduit 39.....................................

Handling and maintenance 40.................................

Approved anti-fouling paints 41...............................

12 PURSE SEINE HYDROPHONE 42...........................

Purpose 42................................................

Installation precautions 43....................................

Considerations 44...........................................

Pre-installation check-list 48..................................

Optimal location of purse seine hydrophones 50...................

Coverage area, orientation and tilt 51...........................

Mounting arrangement 54....................................

Dual hydrophone installation 57...............................

Hydrophone protection 59....................................

Hydrophone cable 62........................................

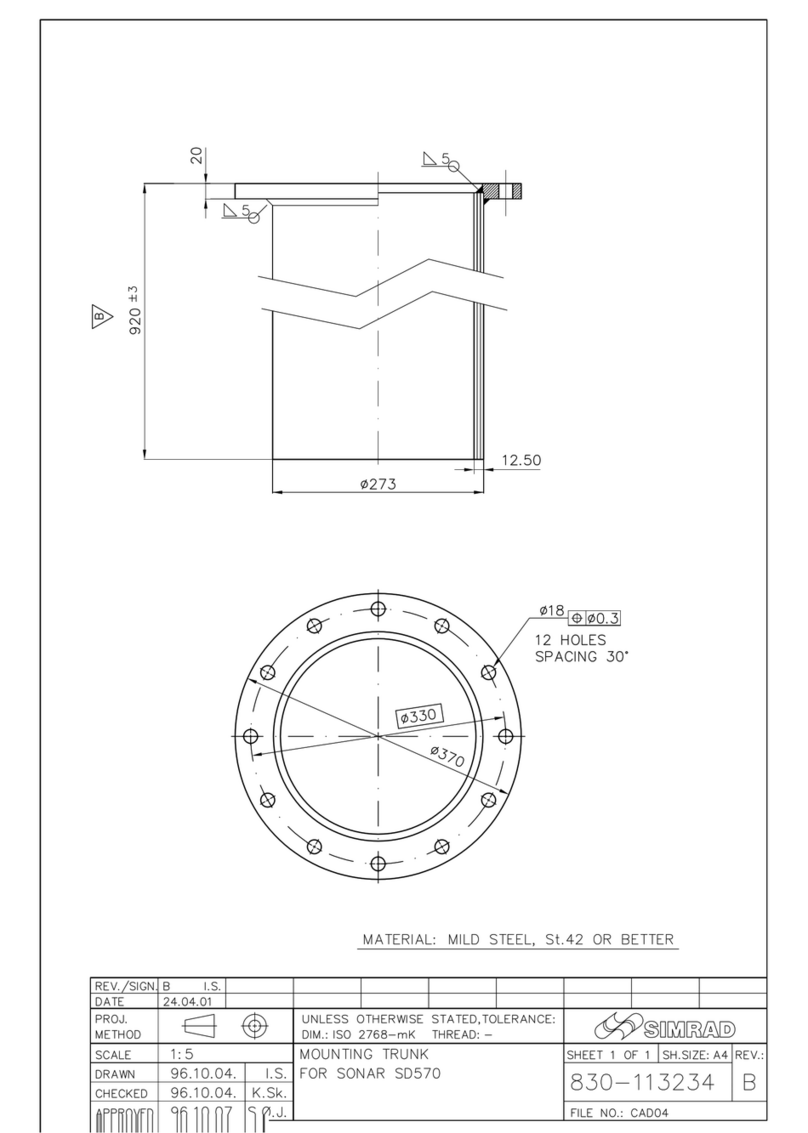

Installation drawings 67......................................

13 TRAWL HYDROPHONE 79...................................

Purpose 79................................................

Installation precautions 80....................................

Considerations 81...........................................

Pre-installation check-list 86..................................

Optimal location of trawl hydrophones 88.......................

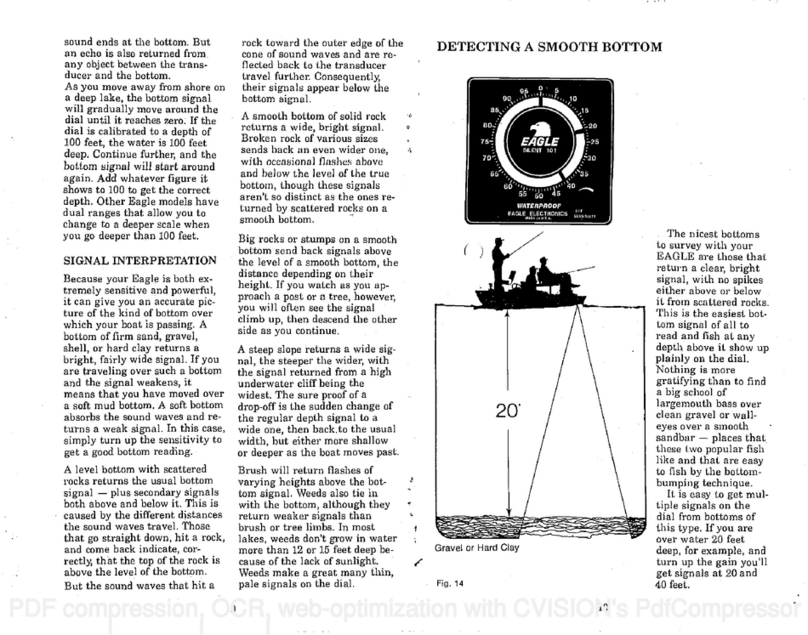

Coverage area, orientation and tilt 91...........................

Mounting arrangement 95....................................

Dual hydrophone installation 101...............................

Hydrophone protection 102....................................

Hydrophone cable 105........................................