Sinclair SDV5-56FA User manual

FULL DC INVERTER SYSTEMS

INSTALLATION MANUAL

INDOOR HIGH STATIC PRESSURE DUCT UNIT SDV5-22-140DHA

COMMERCIAL AIR CONDITIONERS SDV5

Original instructions

IMPORTANT NOTE:

Read this manual carefully before installing or operating

your new air conditioning unit. Make sure to save this

manual for future reference.

1

Comply with local, national and international laws and

regulations.

Read "PRECAUTIONS" carefully before installation.

The following precautions include important safety items.

Strictly follow them.

Keep this manual with the owner's manual in a handy place

for future reference.

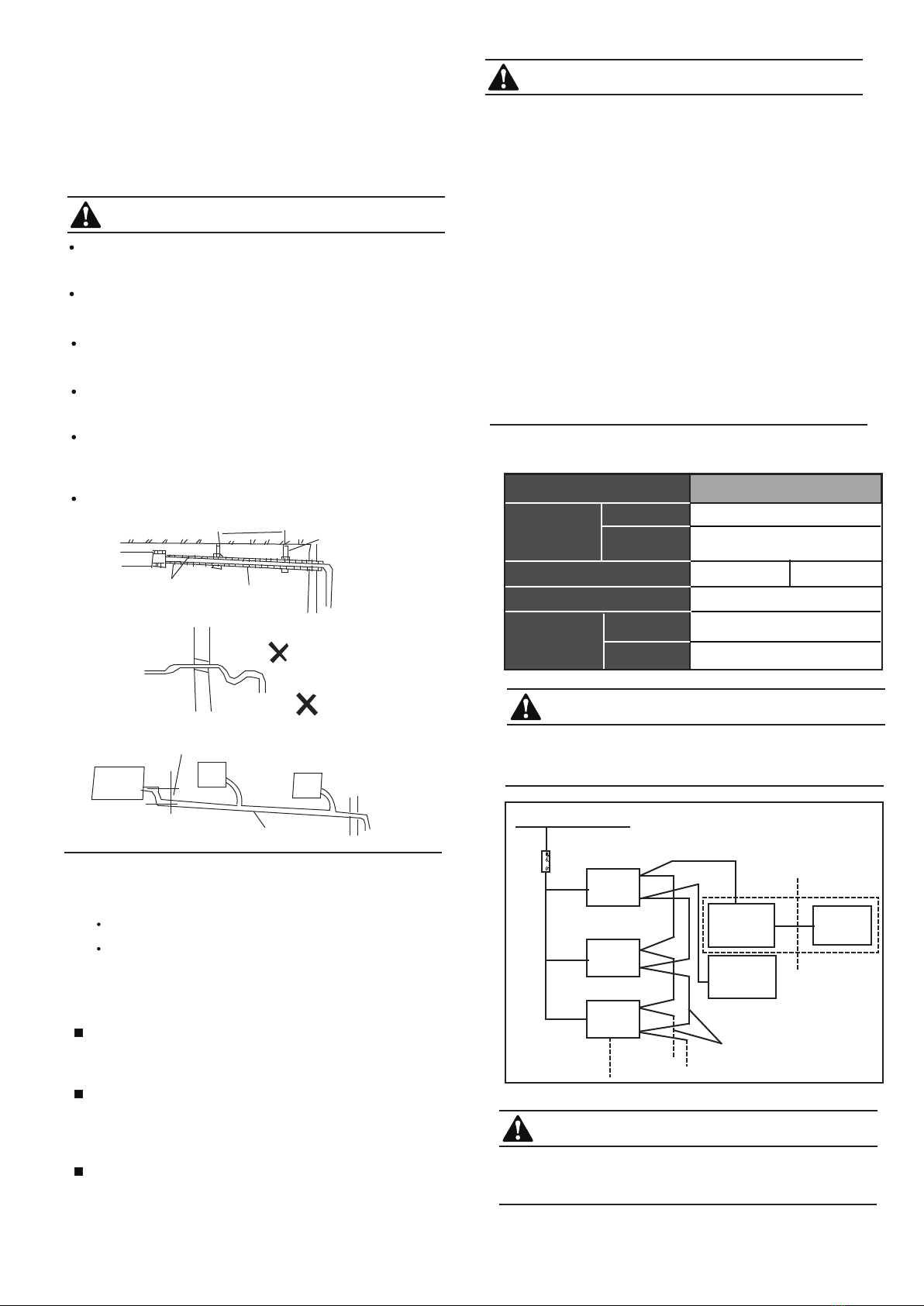

1. PRECAUTIONS

The safety precautions listed here are divided into two categories.

Read both carefully.

After completing the installation, ensure that the unit operates

properly during start-up. Instruct the customer on how to operate the

unit and keep it maintained. Also, inform customers that they should

store this installation manual along with the owner's manual for

future reference.

Only qualified service personnel can install, repair, or

service the equipment.

Improper installation, repair, and maintenance may result in

electric shocks, short-circuit, leaks, fire or other damage to

the equipment.

Failure to observe a warning may result in death.

Failure to observe a caution may result in injury or

damage to the equipment.

CONTENTS PAGE

PRECAUTIONS.......................................................................................1

INSTALLATION INFORMATION................................................................2

ATTACHED FITTINGS.............................................................................2

INDOOR UNIT INSTALLATION.................................................................3

INSTALL THE CONNECTING PIPE..........................................................5

CONNECTING THE DRAIN PIPE..............................................................6

WIRING.................................................................................................6

CONTROL OPERATION............................................................................7

TEST OPERATION................................................................................10

Strictly perform installation according to these

installation instructions.

Faulty installation may cause water leaks, electric shocks and

fires.

When installing the unit in a small room, take measures

to keep the refrigerant concentration from exceeding

allowable safety limits in the event of refrigerant leakage.

Contact the place of purchase for more information.

Excessive refrigerant in a closed ambient environment can

lead to oxygen deficiency.

Only use the attached accessories parts and specified

parts for installation.

Otherwise, the set may fall and cause water leaks, electric

shocks and fire.

Install at a strong and firm location that can bear the

set's weight.

If the installation area is not strong enough or installation is

not properly done, the set may fall and cause injury.

The appliance should not be installed in a laundry room.

Before obtaining access to terminals, all supply circuits

must be disconnected.

The appliance must be positioned so that the plug is

accessible.

The enclosure of the appliance must be marked by word

or symbols, including the direction of fluid flow.

For electrical work, follow the national wiring standards,

regulations, and these installation instructions. An

independent circuit and single outlet must be used.

If the electric circuit capacity is insufficient or electrical work

is defective, an electrical fire may result.

Use the specified cable, connect it tightly and clamp the

cable so that no external force will act on the terminal.

If connection or fixing is imperfect, over-heating or a fire at

the connection point may occur.

Wiring routing must be properly arranged so that the

control board cover is fixed properly.

If the control board cover is fixed imperfectly, it may cause

overheating at the connection point of the terminal, a fire, or

electric shocks.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or a similarly qualified

person to avoid a hazard.

A disconnection switch with at least 3mm separation

should be connected in the fixed wiring of all poles.

When connecting the pipes, do not let air get into the

refrigeration cycle.

Otherwise, it will lower capacity and may cause abnormally

high pressure in the refrigeration cycle, an explosion, and

injury.

Do not modify the length of the power supply cord or use

an extension cord, and do not share the single outlet

with other electrical appliances.

Otherwise, it may cause a fire or electric shocks.

Carry out the specified installation work after

considering the possibility of strong winds, typhoons or

earthquakes.

Improper installation work may result in the equipment falling

and causing accidents.

CAUTION

WARNING

WARNING

1

1

2

4

Name of

Accessories

Installation manual

Hook

Hanging arm

Weak electric cable group

1

Drainage pipe

Bolt assembly

Qty

2

(This manual)

Usage

Outline

.

Drainage

1

Copper

Use for pipe connection

of engineering

installation

1

Snapring

Use for fastening the

drainage pipe

Ground the air conditioner.

Do not connect the ground wire to gas or water pipes,

lightning rods, or a telephone ground wire. Incomplete

grounding may result in electric shocks.

Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in

electric shocks.

Connect the outdoor unit wires, then connect the indoor

unit’s wires.

Do not connect the air conditioner with the power source until

the wiring and piping is completed.

When following the instructions in this installation

manual, install drain piping to ensure proper drainage

and insulate piping to prevent condensation.

Improper drain piping may result in water leaks and property

damage.

Install the indoor and outdoor units, power supply wiring

and connecting wires at least 1 m away from televisions

or radios to prevent image interference ornoise.

Depending on the radio waves, a distance of 1 m may not be

sufficient to eliminate noise.

The appliance is not intended for use by young children

or the elderly without supervision.

Do not install the air conditioner in the following

locations:

Where there is petroleum.

There is salty air surrounding (near the coast). If this

cannot be avoided, choose an anticorrosive model.

Where there is caustic gas (e.g., sulfide, such as near a

hot spring).

Where the voltage vibrates greatly (in factories).

In buses or cabinets.

In kitchens due to oil vapor.

Where there is a strong electromagnetic wave.

Where there are inflammable materials or gas.

Where acid or alkaline liquid evaporates.

Other special conditions.

The appliance should not be installed in a laundry room.

If the refrigerant leaks during installation, ventilate the

area immediately.

Toxic gas may be produced if the refrigerant comes into

contact with fire.

The temperature of the refrigerant circuit will be high, so

please keep the interconnection cable away from the

copper tube.

After completing the installation work, check that the

refrigerant does not leak.

Toxic gas may be produced if the refrigerant leaks into the

room and comes into contact with a source of fire such as a

fan heater, stove or cooker.

CAUTION

To install the unit properly, please read this Installation

Manual.

The air conditioner must beinstalled byqualified personnel.

When installing the indoor unit or its tubing, follow this

manual as strictly as possible.

If the air conditioner is installed on a metal part of the

building, it must be electrically insulated according to the

relevant standards for electrical appliances.

When all the installation work is completed, please turn on

the power only after it has been thoroughly checked.

Notice will not be given regarding any changes to this

manual due to product improvements.

2. INSTALLATION INFORMATION

INSTALLATION ORDER

Select the location;

Install the indoor unit;

Install the outdoor unit;

Install the connecting pipe ;

Connect the drain pipe;

Wiring;

Test operation.

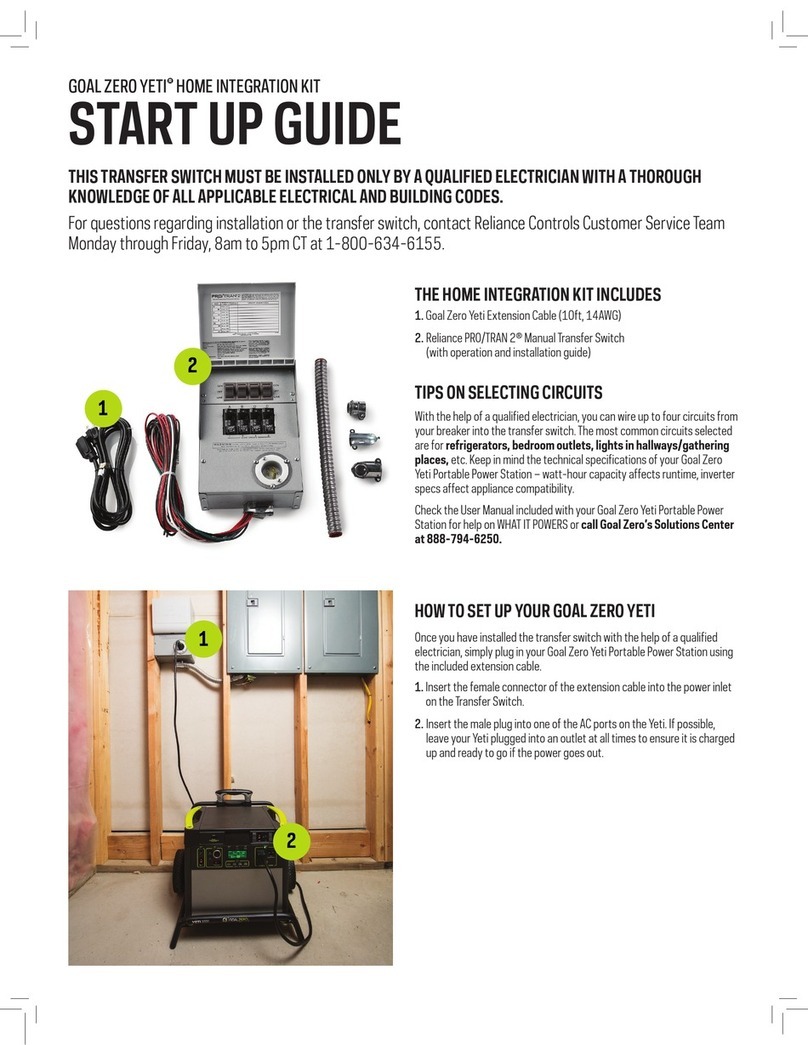

3. ATTACHED FITTINGS

Please check whether all the following fittings have been included.

If there are some spare fittings, please store them carefully.

2

3

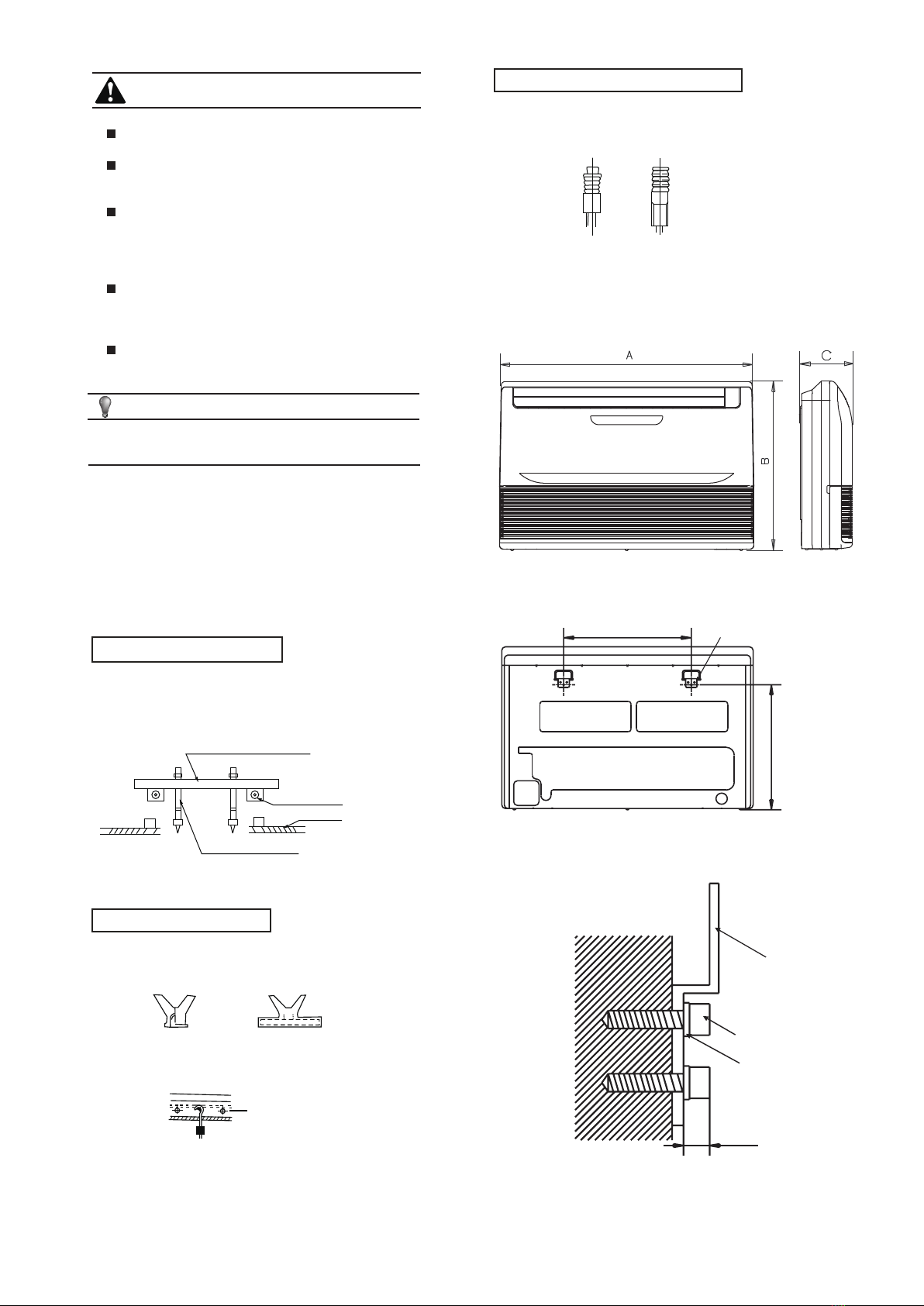

Fig.4-4

FOR ORIGINAL CONCRETE BRICKS

Install the hanging hook with expansible bolt into the concrete

deep to 45~50mm to prevent loose.

4.2 Wall Mounting Installation

Fig. 4-5

Hook

D

E

Washer

2.Hangtheindoorunitonthehook.

Tappingscrew

<6mm

Hook

1.Fix the hook with tapping screw onto the wall.(Refer to Fig. 4-8)

Fig. 4-6

Never throw or strike the controller.

Before installation, test the remote controller to

determine its location in a reception range.

Keep the remote controller at least 1 m away

from the nearest TV set or stereo. (It is

necessary to prevent image and noise

interference.)

Do not install the remote controller in direct

sunlight or close to a heating source such as a

stove.

Note that the positive and negative poles are in

the right positions when loading batteries.

CAUTION

Fig.4-1

Fig.4-2

Fig.4-3

WOODEN CONSTRUCTION

NEW CONCRETE BRICKS

Steel bar

Embedding screw bolt

(Pipe hanging and embedding screw bolt)

(Blade shape

insertion)

(Slide insertion)

Roof beam

Hanging screw bolts

Ceiling

Timber over the beam

Place the square timber transversely over the roof beam. Then

install the hanging screw bolts.

Inlaying or embedding the screw bolts.

4. INDOOR UNIT INSTALLATION

NOTE

This manual is subject to changes due to technological

improvement without further notice.

4.1 The units may be mounted vertically providing that

the correct clearances for positioning are maintained.

(Refer to Fig. 4-1 )

Version I

4

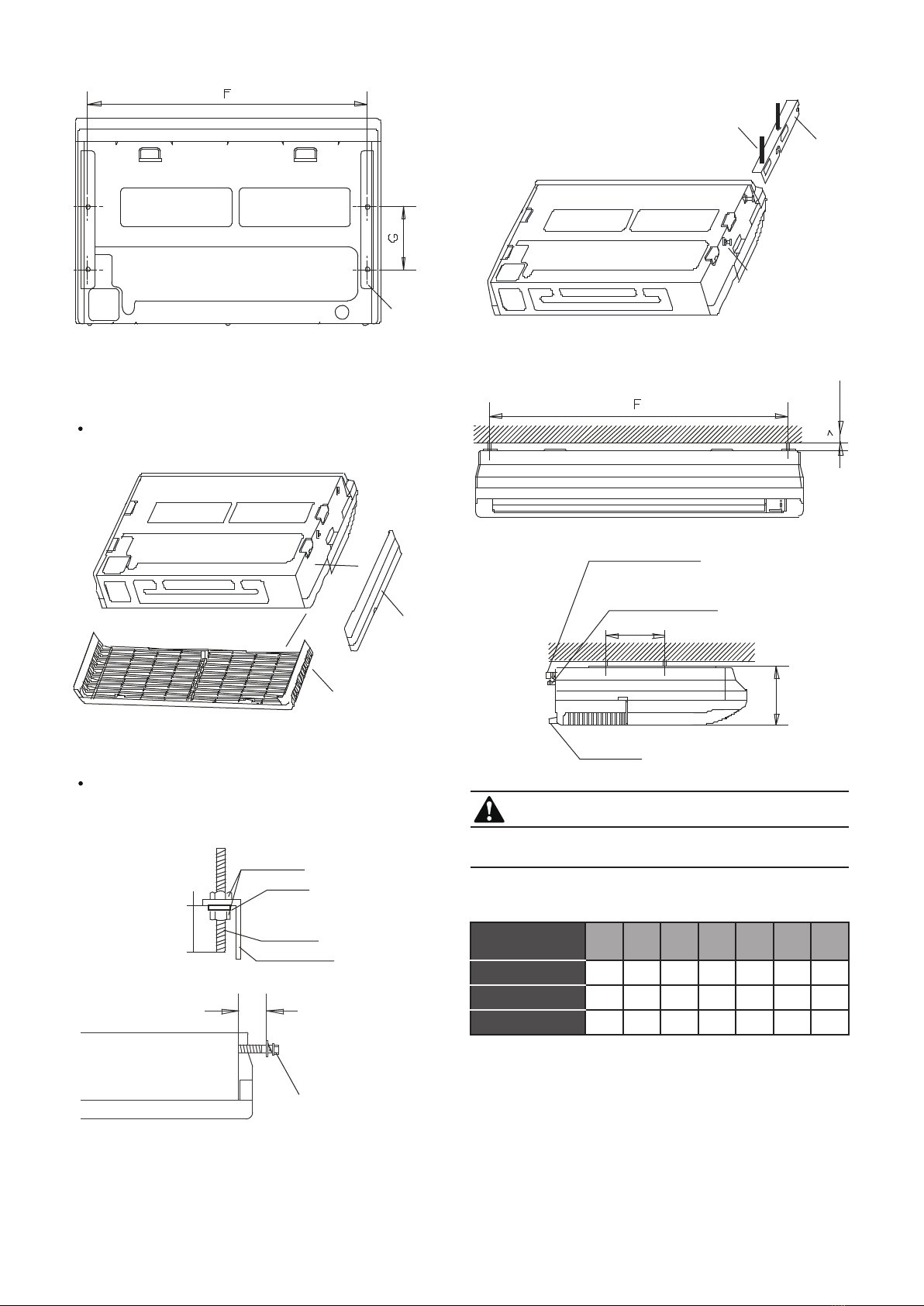

Fig.4-7

Hanging arm

Remove the side board and the grille.(Refer to Fig. 4-8)

(For models 112 and 140, do not remove the grille.)

Fig. 4-8

Side board

Grille

Locate the hanging arm on the hanging screw bolt.

(Refer to Fig. 4-9)

Prepare the mounting bolts on the unit.( Refer to Fig. 4-10)

Screw nut

Washer

Hanging

screw bolt

Hanging arm

Fig.4-9

20~25mm

Hang the unit on the hanging arm by sliding backward. Securely

tighten the mounting bolts on both sides.(Refer to Fig. 4-11)

Mounting bolt(max.40mm)

Fig. 4-10

8~13mm

INDOOR UNIT

4.3 Ceiling Installation

(model 36 ~ 140)

The dimension of the unit (Unit: mm)

4.4

Hanging arm

Mounting bolt

Hanging

screw bolt

D. Connecting point of

refrigerant pipe

(D.gas side)

Drain point

E. Connecting point of

refrigerant pipe

(E. Liquid side)

Fig. 4-11

The figures above are based on model 45 as rated

capacity,which may differ from the unit you purchased.

Table 4-1

20mm

1670 680 244 1070 450 1542 200

MODEL

36~71

80~90

112~140

A B D E F GC

990 660 203 505 506 907 200

1280 660 203 795 506 1195 200

CAUTION

G

C

3.Hang the unit on the hanging arm by sliding backward. Securely

tighten the mounting bolts on both sides.

5

Pipe Materi al

Size(mm)

Copper Pipe for Air Conditio ner

Mode (R22/R 407C) 112~140

36~45 56~90

Pipe Materi al

Size(mm) J(Gas side)

Copper Pipe for Air Conditioner

Mode(R 4 10 A) 36~45 56~140

I(Liquid side) Φ

Φ6.4 Φ9.5 Φ9.5

J(Gas side) Φ

Φ12.7 Φ19.1Φ15.9

Φ12.7

I(Liquid side) Φ6.4 Φ9.5

Φ15.9

5. Install the connecting pipe

Do not let air, dust, or other impurities enter the pipe system

during installation.

The connecting pipe should not be installed until the indoor and

outdoor units have been fixed.

Keep the connecting pipe dry and do not let moisture in during

installation.

The temperature of the refrigerant circuit will be high, so please

keep the interconnection cable away from the copper tube.

CAUTION

Table 4-2

Table 4-3

4.5 Material and size of the piping

5.1 The Procedure of Connecting Pipes

5.1.1 Measure the necessary length of the connecting pipe, and

make it as follows.

1) Connect the indoor unit at first and then the outdoor unit.

a. Bend the tubing in proper way. Do not damage them.

1. Coat the surfaces of the flare pipe and the joint nuts with

frozen oil. Turn by hand 3-4 times and then fasten them with a

wrench.

2. Use two wrenches simultaneously when you connect or

disconnect the pipes.

CAUTION

2) The stop valve of the outdoor unit should be fully closed (as

per the original state). Every time you connect the pipes, first

loosen the nuts at the stop valve. Then connect the flare pipe

(within in 5 minutes). If the nuts have been loosened for a long

time, dust and other impurities may enter the pipe system and

cause a fault. Expel the air out of the pipe with refrigerant

before connecting it.

3) Expel the air (refer to the “Expel The Air”) after connecting

the refrigerant pipe with the indoor unit and the outdoor unit.

Then fasten the nuts at the repair points.

Note for Bendable Pipes.

The bending angle should not exceed 90°.

The bending position is preferably for the bendable pipe. The

larger it is, the better it is.

Do not bend the pipe more than three times.

Bend the connecting pipe of a small wall thickness.

Cut out a desired concave at the bending part of the insulating

pipe.

Then expose the pipe (cover it with tape after bending).

To prevent collapsing or deformation. Bend the pipe at its

widest radius.

Use a bender on low radius pipes.

Use a normal brass pipe.

Use the same insulating materials for the brass pipe. (More than

9 mm thick)

Fig. 5-1

Fig. 5-2

Fig. 5-3

Use frozen oil

Bend the pipe with your thumb

Min-radius 100mm

Make the ends straight

2. Locate the Pipe

1) Drill a hole in the wall (suitable just for the size of the wall

conduit, 90 mm in general), then set on the fittings such as the wall

conduit and its cover.

2) Bind the connecting pipe and the cables together tightly with

binding tape. Do not let air in to avoid leaks due to condensation.

3) Pass the bound connecting pipe through the wall conduit from

outside. Consider the pipe allocation to do no damage to the

tubing.

3. Connect the pipes.

4. Then, open the stem of the stop valves of the outdoor unit to

ensure regular flow in the refrigerant pipe that connects the indoor

and outdoor units.

5. Ensure there are no leaks by checking with a leak detector or

soapy water.

6. Cover the joint of the connecting pipe to the indoor unit with the

soundproof/insulating sheath (fittings), and bind it well with tape to

prevent leaks.

6

7.1 The specification of power

CAUTION

A disconnection device having an air gap contact separation

in all active conductors should be incorporated in the fixed

wiring according to the National Wiring Regulation.

CENTRAL CONTR OL

MONITOR(CCM)

IN DOOR UNIT

OUTDO OR UNI T

COMP UTER

IN DOOR UNIT

IN DOOR UNIT

The shield twisted-pair wire

Power (220-240V~ 50Hz/220-240V~ 50/60Hz)

CAUTION

The reserved function is indicated in broken line table,users

can select it when necessary

Fig. 7-1

Table 7-1

TYPE (W) 3600-14000W

1-PHASE

Power

Phase

Frequency

& volt

Circuit breaker/fuse (a)

Indoor/outdoor

connecting wire

(mm2)

Ground

wiring(mm2)

Weak electric

signal

5/3 5/5

1.0

0.75

220-240V~ 50Hz

220-240V~ 50/60Hz

Indoor unit power wiring(mm2) 1.0

CAUTION

The drain pipe and connections of the indoor unit must be heat

insulated, or it attracts condensation.

A hard PVC binder must be used to connect the pipes. Ensure

there are no leaks.

6. CONNECTING THE DRAIN PIPE

6.1 Install the drainpipe of the indoor unit

The outlet has a PTI screw bread. Use sealing materials and a

pipe sheath (fitting) when connecting PVC pipes.

6.2 Drainage test

Check whether the drainpipe is unhindered.

Newly built house should be tested before decorating

the ceiling.

When connecting to the indoor unit, do not put pressure on the

side of the indoor unit’s pipes.

Avoid winding when the declivity of the drain pipe in the

downwards direction is over 1/100.

The total length of the drain pipe when pulled out must not

exceed 20 m. When the pipe is too long, install a prop stand to

prevent winding.

Refer to the Fig.8-1 for the installing the pipes.

1.5m~2m

Insulating

material

Downward declivity

lower than 1/100

Bend

S shape

VP 30

Downward declivity

lower than 1/100

Put as deep as possible

(about 10cm)

Fig. 6-1

7. WIRING

Specified power cables should be used. Do not apply any

pressure on the terminals that will be connected.

Improper connection may cause a fire.

Grounding must be properly done.

The grounding wire should be away from gas pipes, water

pipes, telephones, lightning rods or other grounding wires.

Improper grounding may cause electric shocks.

Wiring must be done by professionals. Use a separate

circuit according to national regulations.

If the wiring capacity is not enough, electric shocks or fire may

occur.

CAUTION

1. Be sure to Install Current Leakage Protection Switch, Or

electric shock may occur.

2. Power cord is to be selected according to national regula-

tions.

3. An all-pole disconnection device which has at least a 3 mm

separation distance between all poles and a residual current

device (RCD) with a rating above 10 mA must be incorporated

in the fixed wiring according to national regulations.

4. Select and connect outdoor unit power cords according to the

outdoor unit installation manual.

5. Wiring should be away from high temperature components,

or the insulation layer of the wires may melt.

6. Use a wire clamp to fix the wires and terminal block after

connection.

7. Control wire should be wrapped together with heat insulated

refrigerant pipes.

8. Connect the indoor unit to power only after the refrigerant

has been vacuumed.

9. Don’t connect the power wire to the signal wire connection

end.

7

8.3 DISPLAY BOARD

8. CONTROL OPERATION

Base on different purposes to setting the switch cords on PC panel

of indoor electrical control box. Once finish the setting, please cut off

the main power, and then input power again, otherwise, setting

function could not work.

8.1 Horsepower set

Horsepower code

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

ENC1

POWER_S

8.2 Network address set

ENC1

1

2

3

4

6

5

7

2800 W

Code

Switch For setting the cooling output

Capacity

Note: No one

are permitted to

alter the cooling

output which be

set before

shipping from

factory, except

licensed

maintain

personnel.

Table: 8-1

8000 W

7100 W

5600 W

4500 W

3600 W

9000 W

A

B

12500 W

14000 W

11200 W

10000 W

8

9

0 2200 W

7.2 Indoor/outdoor unit signal wire

Connect the wire according to their numbers.

Incorrect connection may cause an error.

7.3 Wiring connection

Seal the wiring connection with the insulation material, or the

condensation will be caused.

7.4 Panel Wiring

7.5 Terminal Board Diagram

Please refer to the indoor unit wiring diagram.

Note: The air conditioners can connect to the Central Control

Monitor (CCM). Before use, ensure the wiring is correct and

set the system address and network address for the indoor

units.

Connect the Swing Motor terminal block according to the

Panel Installation Manual.

To indoor power

220-240V~50Hz

(208-240V~50/60Hz)

Signal-phase power supply model

To indoor power

220-240V~50Hz

(220-240V~50/60Hz)

LN

Fig. 7-2

Display

board

Wire

controller

Use the shielded twisted-pair

wire, and connect the shielded

To wire controller

The reserved wire control

function is indicated in the

broken line table. The user

can purchase the wire controller

if necessary.

TO CCM

COMM.BUS

TO INDOOR&OUTDOOR

COMM.BUS

layer to (E)

The system comprises 64 units (0-63) Each has a unique

address. A repeated address in the same system will cause

an error.

Switch off the power before changing a setting or an error

may occur.

CAUTION

1) The network address is set based on communication

between the indoor and outdoor units. The address is the same

as the indoor address, and there is no need to set them

separately.

2) The central control of indoor units can be done on an

outdoor unit. There is no need to control indoor unit separately.

For details, please refer to V4+ outdoor unit manual.

3) For previous control of the indoor units, the network can be

set by connecting (X, Y, E) terminals. There is no need to set

the network address. The network can also be set by outer

network module and main board (CN20).

DEFROST/

FAN LIGHT ALARM LIGHT

OPERATION

LIGHT

TIMER LIGHT INFO BUTTON

a

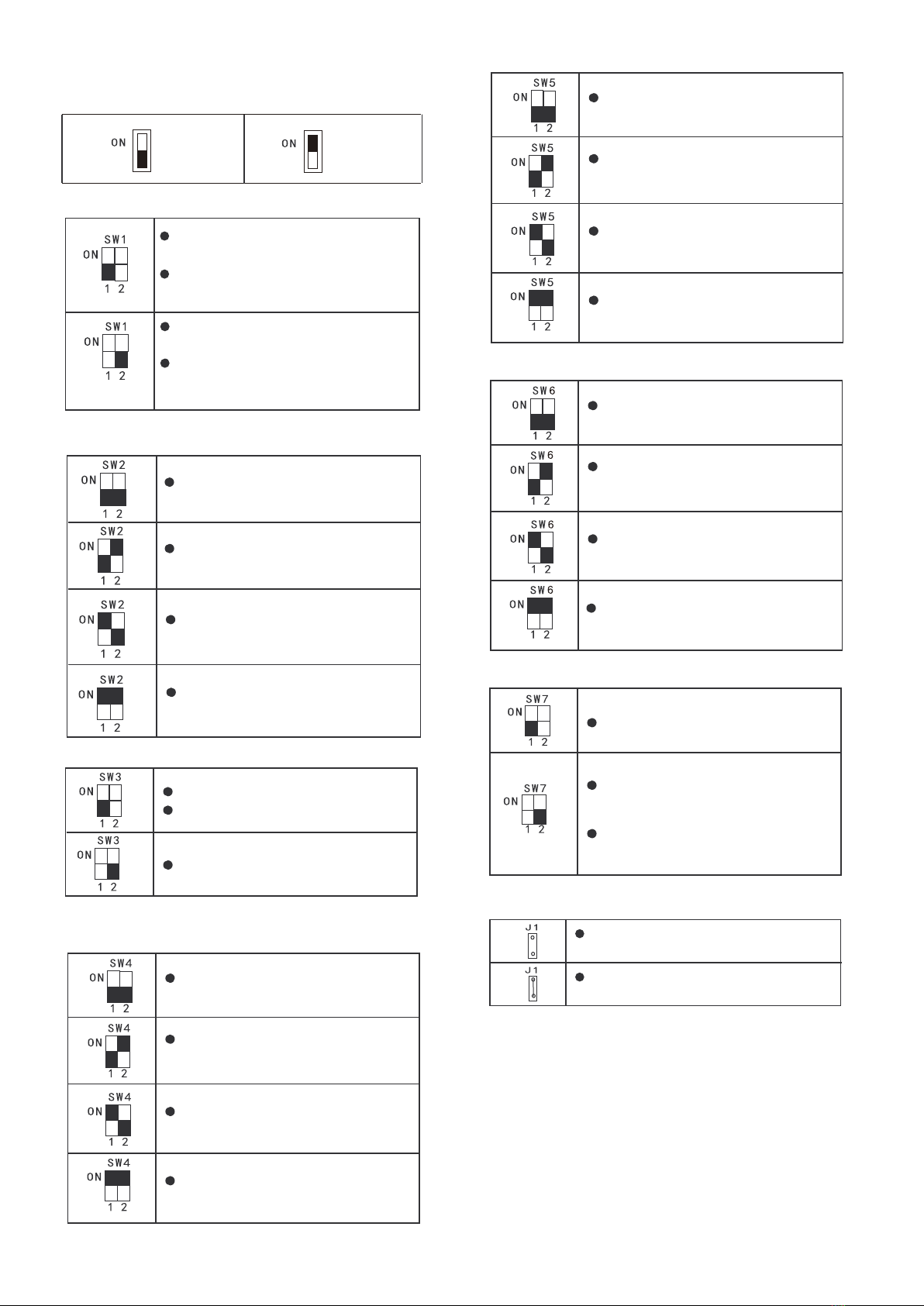

means 0 means 1

0/1 definition of each dial code switch:

0 means cooling mode temperature

compensation is 0°C (default)

1 means cooling mode temperature

compensation is 2°C

0 means EXV positions 96 (steps)

in standby in heat mode (default)

1 means EXV positions 72 (steps)

in standby in heat mode

SW1 definition

00 means external static pressure

mode 1 (default)

01 means external static pressure

mode 2

10 means external static pressure

mode 3

11 means external static pressure

mode 4

SW2 definition

0 means no action (default)

1 means clear indoor unit address

Reserved (defaults 0)

SW3 definition

00 means the time of stopping

TERMAL fan is 4 mintue (default)

01 means the time of stopping

TERMAL fan is 8 mintue

SW4 definition

10 means the time of stopping

TERMAL fan is 12 mintue

11 means the time of stopping

TERMAL fan is 16 mintue

00 means shutting down the unit to

"stop cold air" at 15℃(default)

01 means shutting down the unit to

"stop cold air" at 20℃

SW5 definition

10 means shutting down the unit to

"stop cold air" at 24℃

11 means shutting down the unit to

"stop cold air" at 26℃

00 means temp. compensation value

is 6°C under heat mode (default)

01 means temp. compensation value

is 2°C under heat mode

SW6 definition

10 means temp. compensation value

is 4°C under heat mode

11 means temp. compensation value

is 0°C under heat mode (follow me)

J1 definition

SW7 definition

Reserved (defaults 0)

Without jumper “J1” for auto restart

function

With jumper “J1” for manual restart

function

0 means

low power setting

(1.8kW - 25.2kW) (default)

1 means

high power setting

(28kW - 112kW)

8

8.4 Main board Code designation

Error Code List

No address when first time power on

M-Home not matched error(Reserved)

Mode conflict

Error of indoor temp. sensor (T1)

Error of pipe temp. sensor (T2)

Error of pipe temp. sensor (T2B)

EEPROM error

Outdoor unit error

Water level alarm

FE

H0

E0

E7

Ed

EE

E2

E3

E4

E1

DC FAN errorE6

Error of electronic expansion valve

E5 Reserved

Eb

Communication error of indoor and

outdoor units

9

9. TEST OPERATION

Testing must be carried out after installation is completed.

Please confirm the following points before the test:

2

1

According to the user's requirements, install the remote

controller frame where the remote controller's signal can

smoothly reach the indoor unit.

Test operation

4

3

The indoor unit and outdoor unit are installed properly.

The tubing and wiring have been correctly completed.

The refrigerant pipe system has been checked for leaks.

Drainage is unimpeded.

The heating insulation works well.

The ground wiring is connected correctly.

The length of the tubing and the added stow capacity of

the refrigerant have been recorded.

The power voltage fits the rated voltage of the air

conditioner.

There is no obstacle at the outlet and inlet of the outdoor

and indoor units.

The gas side and liquid side stop valves are both open.

The air conditioner is pre-heated by turning on the power.

Set the air conditioner in "COOLING" mode with the remote

controller, and check the following points. If there is an error,

please resolve it according to the chapter "Troubleshooting" in

the "Owner's Manual".

1) The indoor unit

a. Whether the switch on the remote controller is working

well.

b. Whether the buttons on the remote controller is working

well.

c. Whether the air flow louver moves normally.

d. Whether the room temperature is adjusted properly.

e. Whether the indicator lights normally.

f. Whether the temporary buttons works well.

g. Whether drainage is normal.

h. Whether there is vibration or abnormal noise during

operation.

I. Whether the air conditioner heats well in

HEATING/COOLING mode.

2) The outdoor unit

a. Whether there is vibration or abnormal noise during

operation.

b. Whether the generated wind, noise, or condensation

produced by the air conditioner affect your neighbors.

c. Whether any refrigerant leaks.

CAUTION

A protection feature prevents the air conditioner from being

activated for approximately 3 minutes when it restarts after

shut off.

NOTE CONCERNING PROTECTION OF

ENVIRONMENT

This product must not be disposed of via normal household waste after its service life, but must be

taken to a collection station for the recycling of electrical and electronic devices. The symbol on the

product, the operating instructions or the packaging indicate such disposal procedures. The materials

are recyclable in accordance with their respective symbols. By means of re-use, material recycling or

any other form of recycling old appliances you are making an important contribution to the protection

of our environment. Please ask your local council where your nearest disposal station is located.

INFORMATION CONCERNING USED REFRIGERANT

MEDIUM

This unit is containing fluorinated gases included in the Kyoto protocol. The maintenance and the liquidation must

be carried out by qualified personnel.

Type of refrigerant: R410A

The composition of the cooling medium R410A: (50% HFC-32, 50% HFC-125)

The quantity of the refrigerant: please see the unit label.

The value GWP: 2088 (1 kg R410A = 2,088 t CO2 eq)

GWP = Global Warming Potential

In case of quality problem or other please contact your local supplier or authorized service center.

Emergency number: 112

PRODUCER

SINCLAIR CORPORATION Ltd.

1-4 Argyll St.

London W1F 7LD

Great Britain

www.sinclair-world.com

This product was manufactured in China (Made in China).

REPRESENTATIVE

SINCLAIR Global Group s.r.o.

Purkynova 45

612 00 Brno

Czech Republic

TECHNICAL SUPPORT

SINCLAIR Global Group s.r.o.

Purkynova 45

612 00 Brno

Czech Republic

Tel.: +420 800 100 285

Fax: +420 541 590 124

www.sinclair-solutions.com

info@sinclair-solutions.com

This manual suits for next models

7

Table of contents

Other Sinclair Inverter manuals

Sinclair

Sinclair CCM04 User manual

Sinclair

Sinclair SDV6-DM Series Operating manual

Sinclair

Sinclair SDV6-C Series Operating manual

Sinclair

Sinclair SDV5 Series Operating instructions

Sinclair

Sinclair SDV6 User manual

Sinclair

Sinclair SDV4-140HB3P User manual

Sinclair

Sinclair SDV5 Series User manual

Sinclair

Sinclair SDV6 SCC-61 Operating manual

Sinclair

Sinclair SDV5-MOD User manual

Sinclair

Sinclair SDV5 Series Guide