Sindoh M400 User manual

CS

2011 - 4 - 1

CE

Confidential

SERVICE MANUAL

M400 Series(M400 / M401 / M402 / M403)

M400 Series(M400/401/402/403) MFP

FIELD SERVICE MANUAL

Specifications

Main Body

Duplex Unit(H type)

Option

Paper Feed Unit

Installation

Installing Conditions

Environments

Installation

Unpacking and Checking Components

Option tray

Image Cartridge

Maintenance

Preventive Maintenance

User Replaceable Items

Other maintenance items

Detailed Description

IMAGE PROCESS

Electrification

Exposure

Development

Transfer

Cleaning

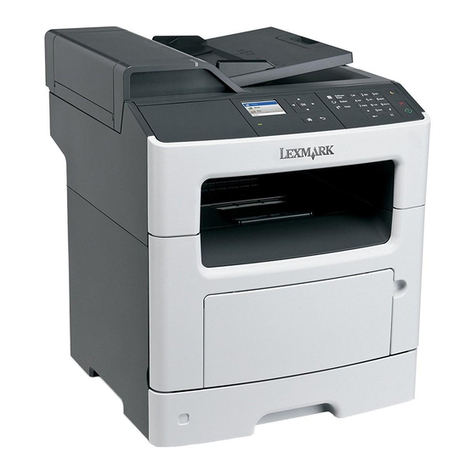

Printer Overview

Printer Components

Paper Path

Electrical Components

Drive Chain

Main Driving Gear Units

Laser Unit

Structure and Optical System Path

AIO Cartridge

Overview

Drum Cartridge Components

Toner Cartridge Components

Drum Cartridge Drive

Toner Cartridge Drive

Drum Cartridge Applied Voltage

Toner Cartridge Applied Voltage

Toner Cartridge and Drum Unit Replacement

Paper Feed

Overview

MainTray Components and Feeding and Isolating Mechanism

Main Body’s Pickup Part Components and Driving Mechanism

Main Paper Feeder Drive

MPT(Multipurpose Tray)

Duplex Unit Components

Duplex Unit Drive

Registration Unit

Image Fusing

Overview

Delivery Unit

Overview

Delivery Unit Components

Delivery Unit Drive

Understanding Control Panel

Overview

Flatbed Scanner

Overview

Scan Cover ASSY Components

CIS ASSY Components

Drive ASSY Components

Scan Frame ASSY Components

CIS Drive

Optical System

ADF (Auto Document Feeder)

Overview

ADF’s Top Cover ASSY Components

Pick Up ASSY Components

Tray ASSY Components

Motor ASSY Components

Top Guide ASSY Components

A3 ASSY Components

Front Part Overview

System Card Components and Main Functions

User Interface Controller Card (UICC) Components and Main Functions

FAX Components and Main Functions

LVPS Components and Main Functions

HVPS Components and Main Functions

Replacement and Adjustment

Before Starting

Exterior Cover

Rear Door and Cover

Left Cover

Right Cover

Front Door

Upper Cover

Paper Delivery Cover

Laser Optics

Laser Unit Removal

Main Driving Motor

Main Driving Gear Unit

Main Driving Gear Unit Removal

Drum and Development Unit

Removing Image Cartridge from the Main Body

Separating Drum Unit and Development unit

Transfer Roller

Fusing Unit

Fusing Unit Removal

Fusing Lamp

Thermostat and Fuse

Cooling Fan

Paper Feed

Separating Main Feed Roller

Paper Detection Sensor

Manual PaperTray (MPT)

MPT’s Bottom Body A’ssy Friction Pad Replacement

MPT Paper Detection Sensor Removal

Pick Roll’s Top Body A’ssy Removal

Option tray Unit Cover Removal

Option tray Pickup Roller Removal

Option tray Feeding Roller Removal

Registration Guide A’ssy

Registration Roller Removal

Paper Delivery Unit

Duplex Unit

Duplex Unit Removal

Front Part

Main Board

PDU

ADF Exterior Cover

ADF Front Cover

ADF Rear Cover

ADF Top Cover

ADF Unit

ADF Pick up Assembly

ADF Isolation Pad

ADF Idle Guide

ADF Pressure Plate

ADF’s Document Tray Assembly

ADF Assembly Removal

ADF Top Guide and Motor Assembly

A3 Clutch Assembly

Scanner Flat Bed Unit

Scanner Flat Bed Assembly Removal

Scanner Unit

Left Scanner Cover

Right Scanner Cover

Rear Scanner Cover

Control Panel

Scan Cover Assembly

CIS Assembly

Scanner Drive Assembly

Troubleshooting

Error Messages and Error Codes

Service Error Code

User Interactive Messages and Paper Jam Message

Paper Jam

Service Menu

Diagnosis Menu

Diagnosis Mode

Optional Tray S/W Upgrade (Download)

Specifications

Main Body

Main Body Components

1. Basic Components: Tray 1 (250 sheets) + MultipurposeTray (50 sheets)

2. Basic Components + 2 Option trays (250 sheets) + MultipurposeTray (50 sheets)

ADF

Scanner

250 Tray

1.Scan Speed: B&W 25PPM

Color 8.3PPM

2. Size: A5-Legal

3. ADF Capacity: 35 sheets

1. Type: Color CIS

2. Scan Speed: B&W 0.6ms/line

Color 1.8ms/line

3. Size: Max. A4(LT)

1. Capacity: 250 sheets/75gsm

60~120gsm

2. Media Size: Max-Legal, Min-

A5

3. Paper Type: Plain Paper

Printer Engine

Duplex Unit (30/35 PPM)

1.Print Speed: 24/34/38 ppm

2. Output Capacity: 150 sheets

3.Resolution: 600x600dpi

4.Noise: under 53dB(A)

5.Enclosed Cartridge: 2.5K

6.Drum Cartridge: 34K

7.A/M Toner Cartridge: 8K

1. Operation: Easy Paper Jam

Removal

2. Deskew : Active deskew

system

3. 16spm

MPT

Machine Size

Electric

1. Capacity: 50 sheets/80gsm

2. Media Weight: 60-163gsm

3. Media Type: Plain Paper,

Transparency, Envelope,

Label, Cover/Card Stock

4. Size: 3”x5”(Min.)

8.5”x14.0”(Max.)

Size: WxDxH=16.3”x14.8”x13.9”

Printer Height=8.1”

Paper Stack H = 2.3”

Scanner Height = 1.04”

ADF Height = 2.44”

1. 24PPM, Low Cost GDI SOC

2. 34/38PPM, PCL/PS, Network

3. Low cost LVPS/HVPS

4. LCD Display

5. Modem 33.6Kbps

Specifications

Category

L model(M400)

LF model(M401)

MF model(M402)

HF model(M403)

Print Speed (Letter)

24ppm

34ppm

38ppm

First Print Speed

Under 10 seconds

Resolution (dpi)

600X600(enhanced 1200)

Tray Capacity

250 sheets

Paper Size

A5 ~ Legal

Multipurpose Tray

Capacity

50 sheets

Output Capacity

150 sheets

ADF Presence and

Capacity

X

O (35 sheets)

Option

250 sheets Tray

250 sheets Tray, Wi-FI

Memory

128MB

256MB(Exp. Max.))

Duplex Unit

LCD Display

Mono, 2 line 16 chars

2.1" Monochrome Graphic LCD (128x32

Pixels)

Interface Port

1 USB

1 USB, Network, Ethernet

Emulation

GDI

PCL, PS, Network

Operating System

Windows XP(32/64bit), Windows Server 2003(32/64bit), Windows Vista(32/64bit),

Windows Server 2008(32/64bit), Windows 7(32/64bit), Linux, MAX OS 10.4 and later

Image Cartridge

2.5K(enclose), 2.5K/5K/8K(A/M)

2.5K(enclose), 2.5K/5K/8K(A/M)

Weight

12.2 kg

13.5 kg

14.7 kg

Dimension

(W X D X H)

16.3” X 14.8” X

12.3”

16.3”X 14.8”X 13.9”

Paper Specification

Feeder

By paper type

Paper Size

Main Feeder

250 sheets of plain papers, 50 labels, 50

sheets of thick papers

A4, A5, JIS B5, Folio, Letter, Legal,

Executive, Statement

Option tray

250 sheets of plain papers

A4, A5, JIS B5, Folio, Letter, Legal

Multipurpose Tray

50 sheets of plain papers, 5 envelops, 15

labels, 5 postcards, 50 sheets of Legal

Min. 76.2 X 127mm(3 X 5 inch)

Max. 216 X 355.6mm(8.5 X 14 inch)

size papers

2 Side Print

60 ~ 90 gsm of plain papers

(16 ~ 24 lb)

A4, Letter

ADF Tray

35 sheets of plain papers

A4, A5, JIS B5, Folio, Letter, Legal,

Executive, Statement

Duplex Unit (H type)

Duplex Unit Components

Duplex Unit Specification

Category

Description

Paper Weight

75g/㎡(20 lb), 60~90 g/㎡(16~24 lb)

Paper Size

Paper (A4 & Letter),

210~215.9 mm X 279.4~355.6 mm (W X L)

Sort Method

Left Alignment

Operation Method

Main operation and gear link operation

Paper Method

Peek-a-boo method

Paper skew size

x=0.015mm, y=0.01mm

Basic Mount

34 ppm/ 38ppm (M402/M403)

* Can be opened easily with a button in from ⇒easy to remove jams

Base Body

Upper Body

Front Body

Option

Paper Feed Unit

Feeder Components

Feeder Specification

Category

Description

Function

Increase Tray’s capacity

Speed

24ppm(M401) ~ 38ppm(M403)

Feeder Capacity

250 sheets (75gsm xerographic paper)

Supporting Papers

Min. A5 ~ max. Legal(xerographic or business paper)

(N/A: Envelops, universal, postcards, OHP, labels, etc.)

Paper Weight

16 ~ 28 lb(65 ~ 105gsm) paper

Dimension (H/W/D)

103 / 389 / 377mm

Weight

Appx. 3.5kg

Tray

1.Friction Pad assy

2.Center Alignment System

3. Rising Base Pin (1) + Rising Sprint (2EA)

4. 2 Step-End Fence

5.Tray Beam Detect Session

Frame & Exterior

1. Frame 2mold parts-1 Press part

2. Exterior 6mold parts

3. Printer and AIO’s Up/Down Installation

4. Dimension: 389(w)x377(D)X103(h)

Pickup & Feed Roll Assy

1.Pickup Roll Assy

-D-Roller, 2 Idler

-2 segment gear clutch assy

-DC solenoid (1)

2.Feed Roll Assy

-Rubber(EPDM)+TU

-Backup Roller (POM, 2), PAN Spring

Drive

1. Stepping Motor

-PM type, 1-2 Phase, 375’ step angle

2. Use train of gears

Installation

Installing Conditions

Environments

The printer must be installed at following places.

Good ventilation and flat surface

No obstacles within 8cm from printer’s right side for cooling fan to operate properly

No direct sunlight exposure and dustless and clean place

No direct cold or warm air blown from air conditioner or heater

Printer operating temperature: 15.6°C ~ 32.2°C (shipping and storage: -40.0°C ~ 60.0°C)

Installation

Unpacking and Checking Components

Unpacking

1. Take the printer and all components from the box.

2. Remove tapes in and on the printer.

3. Check the printer and included components.

Included components

No

Item No.

Item

Qty.

Remarks

1

-

Basic Tray

1

250 sheets

2

MM1A0556

AC power cord

1

110V

3

L0025703

USB cable

1

4

M0124133(M402/M403)

Quick installation manual

1

5

M0124112(M401)

M0124132(M402,M403)

Driver CD & User Manual

1

6.

M0124123

Paperport Utility CD

1

Option tray

Installation

Please proceed with the followings before installing the option tray after the printer

installation.

Turn the printer’s power off

Remove the power cord from the printer and remove all cables on the backside

1. Remove all wrappings and tapes on the feeder.

2. Pull the feeding unit out from the feeder.

3. Hold both edges of support and place it on the printer placing location.

4. Re-install the feeder. Push it in until it completely attaches.

2. Power cord

3. USB cable

4. Quick installation manual

5. Driver CD / 6. Paperport utility CD

1. Tray (basic 250 sheets), Cartridge (wrapped

and enclosed in the printer)

5. Hold both handles on the bottom sides and lift it up and place it on the placing location. Match the tab,

narrow hole and connector on the top of the feeder exactly with printer’s bottom.

Place it on the feeder and check if it is accurately on the feeder.

You must turn the printer’s power off before installing or removing option tray.

Handle

Hole

Connector

Tab

Image Cartridge

Installation

1. Open the top front cover.

2. Hold the cartridge handle and pull it out while lifting it up toward outside.

3. Remove the cartridge wrapping.

Cartridge handle

Do not touch the cartridge’s bottom drum with bare hands.

4. Hold cartridge handles and shake it lightly to spread toner evenly.

5. Hold cartridge handles and place the both cartridge hooks with the printer holes.

6. Push the cartridge in until it clicks and locks.

7. Close the front cover. Check if both ends of cover clicked and locked.

Check if multipurpose tray’s cover is closed when closing the front cover. If the front cover is closed while

multipurpose tray’s cover is open, it can cause paper jam and malfunction.

Maintenance

Preventive Maintenance

User Replaceable Items

Items

Life Cycle

Toner Cartridge

Enclosed:2.5K (M401/M402/M403)

AM : 2.5K/5K/8K (M401/M402/M403)

Drum Unit

34K

Conditions:

1. Above life Cycle was measured by A4 and 5% chart as base

2. Standard temperature and humidity conditions

3. Life Cycle may vary per ambient conditions and printing conditions

Other maintenance items

This product(MFP) does not require additional maintenance items. However, some items need to be

replaced periodically to guarantee it’s function.

1. Fusing unit: 100,000 sheets

2. Pick up roll tray: 80,000 sheets

3. Separation pad multipurpose tray: 30,000 sheets

4. Separation pad tray: 80,000 sheets

5. Transfer roller: 50,000 sheets

6. ADF separation pad: 30,000 sheets

The maximum monthly duty cycle of this product (MFP) is 50,000 sheets.

Detailed Description

IMAGE PROCESS

Electrification

Voltage of -1650V is applied to electrification roller from HVPS and the drum surface gets electrification

of 1100V.

Exposure

Laser scanning is performed to the image printing area and the surface electric potential of scanned

area drops to about -300V to form ‘Latent Image’.

Development

Images are formed on the drum surface by attaching the electrification toner with about -600V via

development roller and Doctor blade on the latent image area formed by laser from exposure stage.

Transfer

Images are formed by tonner transfer on the drum surface from the Development stage and when paper

passes, about over +2000V electric potential applied transfer roller pulls the image forming toner

particles on drum surface to form unsettled images on the paper.

Cleaning

Remaining toner on the drum surface after transferred to paper gets trimmed by cleaning blade before

getting into electrification roller and gets collected in the used toner collecting space.

Printer Overview

Printer Components

This manual suits for next models

3

Table of contents

Other Sindoh All In One Printer manuals