Contents

PREFACE................................................................................................................................................................ 1

Ⅰ.SAFETY INSTRUCTIONS................................................................................................................................... 2

1. NOTES FOR OPERATION............................................................................................................................................... 2

2. NOTES FOR OPERATION ENVIRONMENT................................................................................................................ 4

Ⅱ. DESCRIPTIONS FOR BODY AND INSTALLATION .......................................................................................... 5

1. OPERATION ENVIRONMENT........................................................................................................................................ 5

2. MODEL DESCRIPTION.................................................................................................................................................... 6

4. LIST OF APPLICABLE NO-FUSE BREAKER............................................................................................................ 9

5. APPLICATION AND DESCRIPTION FOR AMBIENT EQUIPMENTS................................................................... 10

6. BASIC WIRING DIAGRAM............................................................................................................................................ 13

7. EXTERNAL DIMENSIONS............................................................................................................................................. 15

Ⅲ. DESCRIPTION OF OPERATION PANEL..........................................................................................................16

1. DESCRIPTION FOR DIGITAL OPERATION PANEL................................................................................................ 16

2. DESCRIPTION OF PANELOPERATION..................................................................................................................... 18

3. PRELIMINARY OPERATION-NOT CONNECTING WITH MOTOR....................................................................... 19

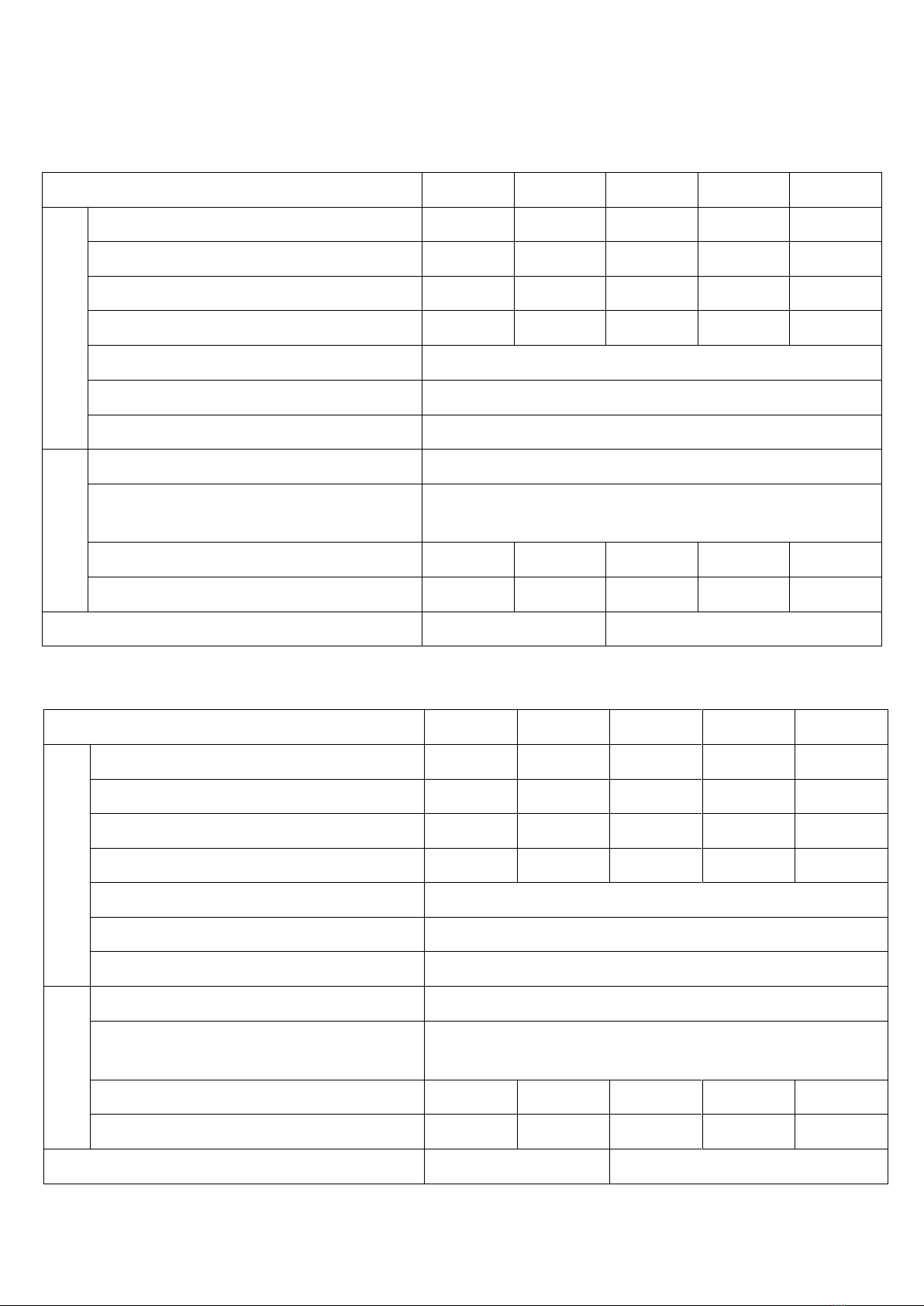

Ⅳ. LIST OF DESCRIPTIONS FOR FUNCTIONAL PARAMETERS........................................................................21

Ⅴ. DESCRIPTION OF FUNCTIONAL PARAMETERS...........................................................................................32

0. USER'S PARAMETERS................................................................................................................................................. 32

1. BASIC PARAMETERS ................................................................................................................................................... 35

2. OPERATION MODE PARAMETERS........................................................................................................................... 39

3. OUTPUT FUNCTION PARAMETERS......................................................................................................................... 43

4. INPUT FUNCTION PARAMETERS.............................................................................................................................. 48

5. MULTI-STEP AND AUTO-PROGRAM OPERATION PARAMETERS................................................................... 54

7. SPECIAL PARAMETERS............................................................................................................................................... 59

8. HIGH FUNCTION PARAMETERS................................................................................................................................ 60

9. COMMUNICATIONS PARAMETERS.......................................................................................................................... 63

A. WOBBLE FREQUENCY FUNCTION PARAMETERS............................................................................................. 73

Ⅵ. TROUBLE SHOOTING.....................................................................................................................................76

1. ALARM AND CORRECTIVE MEASURES................................................................................................................. 76

2. TROUBLESHOOTING FOR FAULTS IN GENERAL................................................................................................ 78

Ⅶ. MAINTENANCE AND AMBIENT ELEMENTS...................................................................................................79

Contents 1.............................................................................................................................................................81

1. Basic wiring diagram .................................................................................................................................................... 81

2.Control Circuit Terminal Position Map..................................................................................................................... 82

3.List of Brake Resistor .................................................................................................................................................... 82