Jeio tech ISF-7100 User manual

Operating Manual

Shaking Incubator

Model : ISF-7100, ISF-7200, ISF-7100R, ISF-7200R

Menual no. : XXXXXXXXXXX

Before using this product, read this entire Operator's Manual

carefully. Users should follow all of the Operational Guidelines

contained in this Manual and take all necessary safety

precautions while using this product. Failure to follow these

guidelines could result in potentially irreparable bodily harm

and/or property damage.

Thank you for purchasing Jeio Tech’s products.

We are doing best for customer’s satisfaction.

Quality Management System

Jeio Tech Co, Ltd. is dedicated to providing world-best

product quality and customer satisfaction. To ensure

we maintain this commitment we have developed and

implemented a total quality program, which conforms

to the requirements according to DIN EN ISO

9001:2000 for the design, development, production,

sales and servicing of biotechnology, environmental

chemical engineering related products, and reliable

measuring equipment for electric and electronics

(ovens, incubators, constant temperature humidity

chambers, constant temperature baths, refrigerating

bath circulators, heat exchangers and shakers).

Visit our Web site at www.jeiotech.com to view a copy of our certificate.

Disclaimer

Jeio Tech Co., Ltd. is committed to a continuing program of product development and improvement,

and reserves the right to change information, such as specifications, appearance, and dimensions,

described in this document without notice.

Copyright

No part of this manual may be reproduced or transmitted in any form or by any means, including

photocopying, recording, or using information storage and retrieval systems, for any purpose other

than the purchaser's own use, without the express written permission of Jeio Tech Co., Ltd.

© 2014. All Rights Reserved. Jeio Tech Co., Ltd.

Any other product names and services identified in this manual are trademarks or registered trademarks

of their respective owners. No such use, or the use of any trade name, is intended to convey

endorsement or other affiliation with Jeio Tech Co., Ltd

CONTENTS

1Safety ..........................................................................................................................................................................................1

1.1 How to use manual....................................................................................................................................................1

1.2 Symbols used in this Manual................................................................................................................................1

1.3 Exemption for responsibility...................................................................................................................................2

1.4 Caution statement......................................................................................................................................................2

1.5 Caution statement for safe use............................................................................................................................3

2Functional Description..........................................................................................................................................................5

2.1 Introductions.................................................................................................................................................................5

2.2 Features .......................................................................................................................................................................5

2.2.1 High Performance................................................................................................................................................5

2.2.2 Advanced Convenience.....................................................................................................................................6

2.2.3 Advanced Safety...................................................................................................................................................6

2.3 Structure.......................................................................................................................................................................7

3Installation ............................................................................................................................................................................11

3.1 Unpacking and Checking...................................................................................................................................11

3.2 Component.............................................................................................................................................................11

3.3 Preparation before installation.......................................................................................................................12

3.3.1 Space requirements.......................................................................................................................................12

3.3.2 Environmental Setting...................................................................................................................................13

3.4 Installation...............................................................................................................................................................14

3.4.1 Caution for Installation..................................................................................................................................14

3.4.2Adjusting the Horizontality...........................................................................................................................15

3.5 Attaching Condensate Drain.............................................................................................................................16

3.6 Attaching/Detaching External Refrigeration (ISF-7100, ISF-7200 Only).......................................16

3.7 Connecting Power................................................................................................................................................18

4Operation..............................................................................................................................................................................19

4.1 Controller..................................................................................................................................................................19

4.2 How to use the controller...................................................................................................................................20

4.2.1Temperature control .......................................................................................................................................22

4.2.2 ShakingControl................................................................................................................................................22

4.2.3 Shaking Timer ..................................................................................................................................................23

4.2.4 Alarm and Stop by force...............................................................................................................................24

4.2.5 Defrost (Refrigerated model, ISF-7100R, ISF-7200R Only).........................................................27

4.3 General Settings..................................................................................................................................................27

4.4 System Settings...................................................................................................................................................28

4.4.1 Control Deviation Limit .................................................................................................................................28

4.4.2 External Start/Stop Key................................................................................................................................28

4.4.3 Calibration..........................................................................................................................................................29

4.4.4 Auto Tuning........................................................................................................................................................31

4.4.5 Operating Parameters ..................................................................................................................................31

4.4.6 Reset....................................................................................................................................................................31

4.5 Safety Tool...............................................................................................................................................................32

4.5.1 Over Temp. Limiter.........................................................................................................................................32

4.5.2 High/Low Temp. Limiter................................................................................................................................32

4.5.3 Glass Fuse.........................................................................................................................................................32

5Maintenance........................................................................................................................................................................33

5.1 Inspection Period ..................................................................................................................................................33

5.2 Cleaning....................................................................................................................................................................34

5.3 Air filter cleaning (ISF-7100R/ISF-7200R)..................................................................................................35

5.4 Fuse Replacement...............................................................................................................................................36

6 Troubleshooting ..................................................................................................................................................................38

6.1 Stop during the operating..................................................................................................................................38

6.2 Another problem and solution..........................................................................................................................39

7Accessories..........................................................................................................................................................................41

7.1 Mountable maximum quantity..........................................................................................................................41

7.1.1 Universal Platform + Flask Clamp...........................................................................................................41

7.1.2 Universal Platform + Plastic Flask Clamp............................................................................................41

7.1.3 Universal Platform + Funnel Clamp........................................................................................................42

7.1.4 Universal Platform + Microplate Holder.................................................................................................42

7.1.5 Universal Platform + Test Tube Rack.....................................................................................................42

7.1.6 Spring Wire Rack + Flask............................................................................................................................43

8.0 S/W.......................................................................................................................................................................................44

8.1 Monitoring Program installation......................................................................................................................44

8.2 Communication Protocol....................................................................................................................................46

8.2.1 Physical Layer..................................................................................................................................................46

8.2.2 Model System number..................................................................................................................................46

8.2.3 Modbus Protocol Address Definition.......................................................................................................47

8.2.4 Modbus Protocol Description.....................................................................................................................48

9.0 Appendix ............................................................................................................................................................................52

9.1 Technical Specifications.....................................................................................................................................52

9.2 How to use High/Low Temp. Limit..................................................................................................................53

9.3 Circuit Diagrams....................................................................................................................................................54

9.3.1 Incubator circuit diagram .............................................................................................................................54

9.3.2 Shaker circuit diagram..................................................................................................................................55

9.3.3 External Refrigeration connection system (ISF-7100/ISF-7200)................................................56

9.3.4 Internal Refrigeration system (ISF-7100R/ISF-7200R) ..................................................................56

9.4 Disposing of products..........................................................................................................................................57

9.5 Warranty....................................................................................................................................................................57

9.5.1 Terms of Warranty Service..........................................................................................................................57

9.5.2 Warranty exception........................................................................................................................................58

9.5.3 Service and technical advice.....................................................................................................................58

1

1 Safety

1.1 How to use manual

This manual is intended for individuals requiring information about the use of product. Use

this manual as a guide and reference for installing, operating, and maintaining your Jeio

Tech product. The purpose is to assist you in applying efficient, proven techniques that

enhance equipment productivity

This manual covers only light corrective maintenance. No installation, service procedure or

other maintenance should be undertaken without first contacting a service technician, nor

should be carried out by someone other than a service technician with specific experience

with laboratory equipment and electricity.

1.2 Symbols used in this Manual

(1) The alert marks are for safety operation and protect user and instrument from Damage.

(2) Signal word panels are a method for calling attention to a safety messages or property

damage messages and designate a degree or level of hazard seriousness.

(3) Pay attention enough to the contents of alert marks.

Signal word panels

Uses

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates a property damage message.

2

1.3 Exemption for responsibility

(1) The claim which is out of the quality guaranteed by the manufacturer is out of manufacturer’s

responsibility.

(2) The damage which is from unexpected fault or damage of user by Acts of God is out of

Manufacturer’s responsibility

1.4 Caution statement

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Please use the product in safety facility installing laboratory in case of accident. Installed

the product on durable and flat surface.

Please, make sure safety equipment with relevant provision before handling the sample which

may cause flammable or toxic gases.

Do not use the machine near to places where explosion can be happened due to organic

evaporating gases.

Explosive materials: Acid, Esther, Nitro compound

Inflammable materials: salt peroxides, inorganic peroxide, salt acids.

Do not use the machine at places where moisture is high and flooding can be happened.

Please check and connect properly -the voltage, phase and capacity of power supply on

the ID plate before installation.

Be sure to install a separate power wiring and use a dedicated power supply.

3

Power supply must be properly grounded.

Abnormal grounded connection causes serious damage. Grounded connection must not be on

the water pipe and gas pipe.

Put off the power plug if some sounds and burning smell, smokes are happened. And

request the service

Stop the product operation and request service.

Do not assemble, repair, modify on your own.

The product may not work well and electric shock in the efficiency of the product. Also you

cannot get after service by warranty regulation.

1.5 Caution statement for safe use

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury.

Be sure to disconnect the power after turning off the power switch.

This is the safety regulation for next user.

Do not put heavy things on the power line. Do not put the machine on the line.

It may take off the wire coating and causes the electric shock or fire.

Do not touch it with wet hands and put the main plug correctly.

It may cause the electric shock or injuries.

Do not inject any liquid and inflammable things inside of product.

4

Do not let the product take any strong shock or vibration.

It causes abnormal operation or trouble. It may deteriorate the ability of the product and not

obtain correct results.

Do not install the stirrer neat machinery generating high frequency noise.

Please avoid installed from high frequency- welding machine, sewing machine, and mass SCR

controller

Do not sprinkle insecticide or flammable spray on the product. Use smooth cloths.

Cleaning with solvent can cause fire and deformity.

Please power off while product cleaning.

It may cause the electric shock or fire

Wear protective gloves.

Wear eye protection.

No water

No corrosive

Electrical shock.

Flammable

Foot crush.

Hand crush or pinch.

Lifting hazard.

Do not take the device apart

deliberately.

5

2 Functional Description

2.1 Introductions

The cultivation environment such as temperature, pH, oxygen concentration, nutrition supply have

a significant impact on cell cultures of animals and plants or proliferation of microorganisms.

This incubated shaker is to provide a suitable environment for the cultivation through controlling

constant temperature and shaking speed.

Cell culture

Extractions

Solubility studies

Hybridization

Plasmid purification

Protein expression

2.2 Features

2.2.1 High Performance

(1) Precise and fast temperature / shaking speed control is available by microprocessor PID

feedback control. PID feedback control ensures the same experimental environment

conditions for the user. The device’s deviation of set temperature and set rpm are each under

± 0.1 ℃(standard: 37 ℃), ± 1% (standard: set rpm) which are regarded as very precise value.

If the deviations go above a certain level, alarm will be activated to the user.

(2) Control range of temperature and stirring speed is wide. Temperature control up to 60 ℃and

stirring speed control up to 500rpm are available to provide users wider experimental

conditions.

(3) Optimizing the structural design of the product enables stable shaking even with heavy load.

Low center of gravity minimizes noise and vibration.

(4) More precise temperature control by 3ea temperature points.

User can mate temperature measuring instrument and the unit’s temperature by 3 temperature

points.

6

2.2.2 Advanced Convenience

(1)User friendly interface according to Touch LCD.

Eidetic unit operation check and easy to control.

(2)Timer and operation time check of shaking performance is available. Setting and checking the

value is available up to 999 hours and 59 minutes.

(3)Large window with LED lamp on the door offers the convenience to monitor the samples in the

chamber without opening the door in the dark place.

(4)Easy connection from Unit to PC with RS232 Port and USB port and it allows easy monitoring

and control.

(5)By providing an automatic power failure recovery, even if the product gets power back after a

momentary power failure, the auto run function automatically runs the product.

(6)Adjustable caster for convenient relocation and installation.

(7)In case of the liquid leakage caused by spilled reagent or cracked flask inside of the chamber,

the liquid is designed to be drained out through the drain of the chamber bottom which is

connected to the port on the product’s side.

(8)This equipment is more convenient when mounting / desorption of the sample. When shaking

performance, operation always starts and stops at a specified location, the platform is fixed to

easily replace the sample. Also, when you open the door, the height of the chamber is similar to

the general sink, a shorter experimenter can also easily exchange samples.

2.2.3 Advanced Safety

(1) Smooth shaking start and stop mechanism minimizes the opportunity of reagent leakage.

(2) Unit can control possible RPM speed when the shaking that unit cannot control due to (overload

& high RPM, weight imbalance) is operated. There is no movement due to shaking vibration.

(3) There is an independent adjustable temperature limit device in addition to the main controller in

this device. If temperature rises more than the specified value due to equipment error, the

independent device protects the internal sample and equipment by blocking the power supply of

the temperature-related equipment.

(4) When shaking operation is not possible due to the obstacle interfering the system, over current

protection device stops the operation.

7

2.3 Structure

(1) LED Lamp

Long life span and energy efficient LED lamp offers bright observation of samples.

(2) Door Switch

There is a door limit switch between the door and the appliances mainframe’s upper parts. If the

door is opened, Shaking, Blower and Heater operation automatically stops. After 3 minutes at this

status, warning sound alarms users to close the door. If a user does not shut a door so that five

minutes passes, and an alarm sound continuously rings. And it blocks off the power to be

authorized with a power switch, and Off gets a power switch done and all blocks off 2 phase of the

power supplied with to an each part of appliances, and configuration does the safe state that only

a Ground part is connected.

(3) Shaking Table

Shaking table is connected to a shaking system andAccessory such as Universal Platform can be

equipped on shaking table. (Universal Platform is equipped in the figure.)

8

(4) Door Latch

Door latch is additionally equipped to advance the air tightness of the inner chamber. Close the

door and turn door latch to the right.

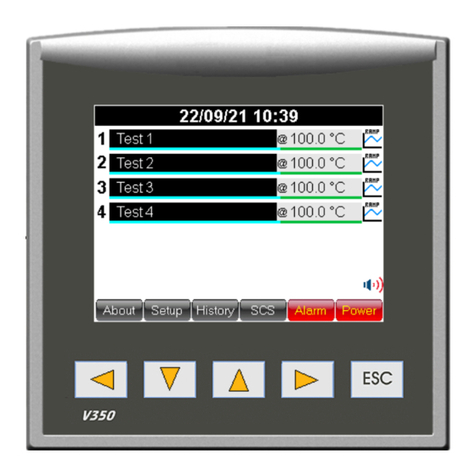

(5) Control Panel

Main control part. Improved immediacy and convenience by touch LCD.

User can set-up temperature and shaking control with this controller.

This controller includes Start/ Stop button and LED ON/OFF button.

(6) Filter

Clip-on type to avoid any dust in Condenser.

(7) Door Handle

To open/close the door.

(8) Transparent Viewing Window

User can monitor the inner samples without opening the door during operation.

(9) Gas Spring

To offer convenience for user during sample change, gas spring is fixed to open door.

(10) Door Packing

To absorb the shock when users open/ close door and to seal door to the chamber inside.

(11) Power Switch

To ON/OFF Unit main power.

(12) Temperature Limiter

Temperature limiter is independently configured from the main controller. The inner temperature of

the chamber exceeds more than the set temperature, the device cut off the power to the power

switch for the secure condition. (Refer to ‘4.5 Safety Device’)

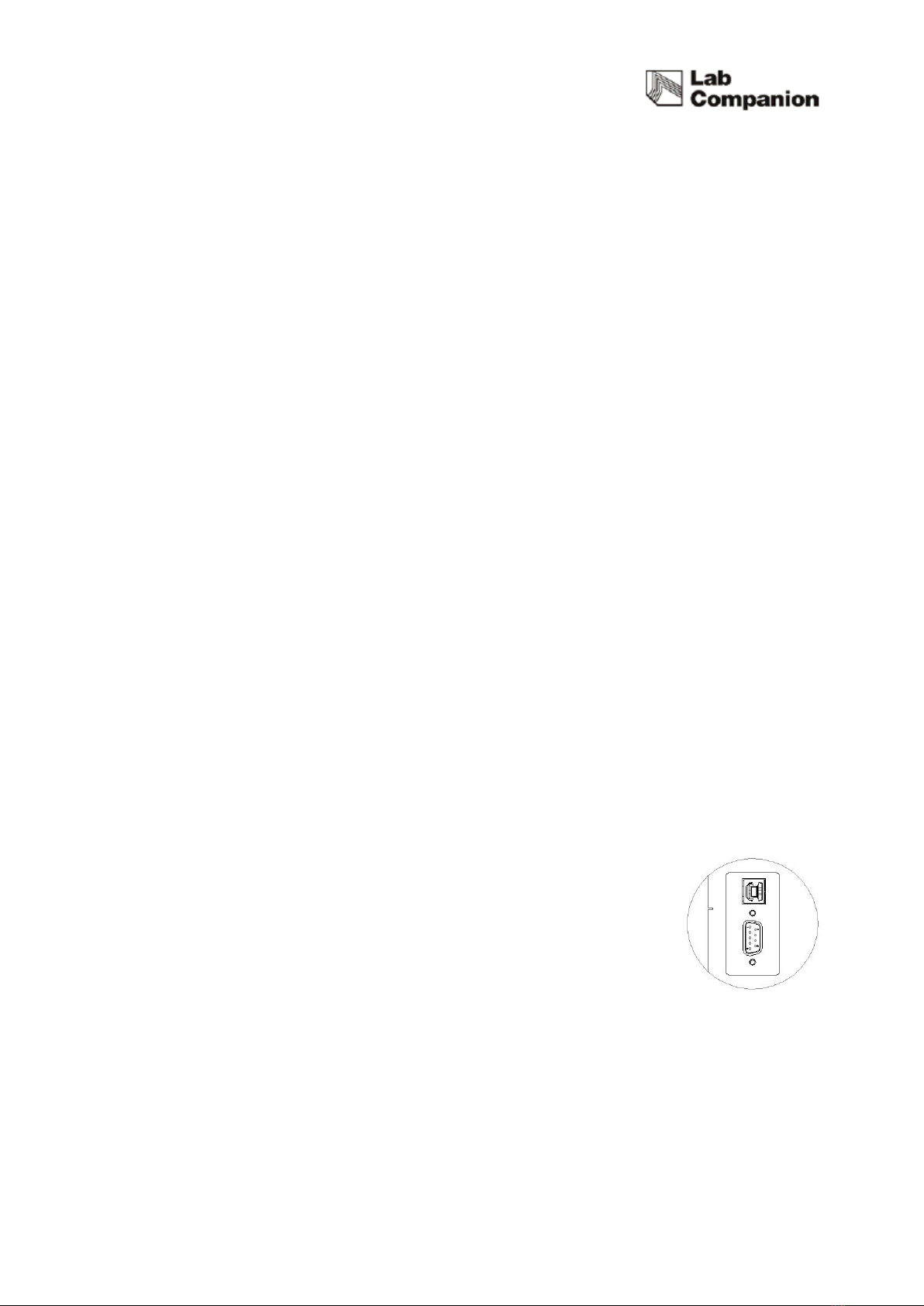

(13) Computer Interface

This unit can connect to PC by USB port and RS232 port.

If it is connected, PC can monitor the unit operation status and start the unit

operation.

USB is connected preferentially if USB and RS232 are connected at the

same time.

9

(14) Drain Port and Valve for Spilled Liquids

In case of the liquid leakage caused by spilled reagent or cracked flask inside of the chamber,

the liquid is designed to be drained out through the drain of the chamber bottom which is

connected to the port on the product’s side.

(15) Adjustable Foot and Caster

Using an adjustable and retractable foot caster, it is easy to move and fix the device.

(16) Power Input and Fuse

Power input is connected to power cable. Fuse protects the device from instantaneous

overcurrent. In case of fuse replacement, check the rated power. (Refer to 5.4 Fuse

Replacement)

(17) Refrigerating System (ISF-7100R/7200R only)

It circulates refrigerant in the chamber. It is operated in case of low temperature control.

13

14

15

17

18

16

10

(18) External Refrigeration Port (ISF-7100/ISF7200 only)

Even if the model such as ISF-7100 which has no refrigerator, It can lower the temperature in

the chamber by receiving refrigerant from the external refrigerant device such as chiller. The

In/out ports (refer to the figure) are located on the back and bottom side of the device.

These brass push-to-connect fittings accept Ø 8mm OD hard-wall tubing and provide access

ports for external refrigeration. The barb on the right is to drain out the condensate comes

from evaporator. Therefore, please do not block the barb with other materials. (Refer to ‘3.5

Connection to Drain’ and ‘3.6 Connection to External Refrigeration System’)

11

3 Installation

3.1 Unpacking and Checking

(1) Inspect the shipping container carefully for any damage.

(2) Remove the outer container.

(3) Before use, inspect the product carefully for any damage that may have occurred during

shipping.

(4) Report any damage to your local Jeio Tech office or the distributor.

3.2 Component

(1) After unpacking, check the components.

(2) In the case of omission of components, contact to Jeiotech.

Item

Figure

Quantity

Description

Main Body

1

Fuse

250V, 10A

2

JEIOTECH

SOFTWARE CD

1

Cable for

Communication

(USB)

1

-

12

Power Cord

1

-

Operating

Manual

1

3.3 Preparation before installation

3.3.1 Space requirements

It is essential that the product to be situated in an area where there is sufficient space for the product.

Below figures show the minimum space requirements needed to properly operate and maintain the

product.

H: 1700 mm

W: 1128 mm

D: 935 mm

13

3.3.2 Environmental Setting

The unit can be operated properly under the following environmental conditions for a long

time running without any problem.

No direct sunlight on the product

Ambient temperature: 5℃~ 40℃(41℉~104℉)

Relative humidity not to exceed 80%

Altitude not to exceed 2000m (6,562 feet)

Connect the product to earth grounded terminals only.

•Please install on the sturdy surface laboratory which is set safety facility and make

sure horizontal align correctly.

•Do not use the Product near environments where flammable gas may leak.

•Moving casters must be changed height adjustable foots so that the unit is not

moving.

14

3.4 Installation

3.4.1 Caution for Installation

(1) The device is recommended to use under the room temperature and humidity (30°C, 80%RH)

do not install it near the Heat devices like a Heater.

(2) Have enough space for door opening. (refer to 3.3.1)

(3) Please install it on the sturdy surface laboratory and do not throw down or gives a big shock.

(4) Locate it 1.5m away from any light devices and 30 CM away from the wall.

(5) Install it on the sturdy leveled surface to prevent abnormal turbulence and noise.

This manual suits for next models

3

Table of contents

Other Jeio tech Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Hach

Hach TitraLab Total Hardness Basic user manual

Phcbi

Phcbi cellIQ Series operating instructions

Thermo Scientific

Thermo Scientific gibco CTS DynaCellect Magnetic Separation... user guide

Amos

Amos AST 550 Operation manual

TestEquity

TestEquity 123HS Operation and service manual

Phcbi

Phcbi MLR-352 Series Service manual