2

Introduction

The Optima Steamer continues to pursue environmentally friendly and effective cleaning

solutions. Optima Steamer which is safe, durable and easy to use will support your cleaning

operations for many years to come.

Applications

The Optima Steamer is capable of generating continuous, super-heated vapor steam.

The Optima Steamer is specifically used for various cleaning applications including

cleaning machinery & components, washing vehicle exteriors, interiors, engine

compartment, glass, metal surfaces, windows, wheel wells, vents, deodorizing bad odors,

sanitizing hazardous food-borne bacteria from food processing equipment, removing

weeds and more.

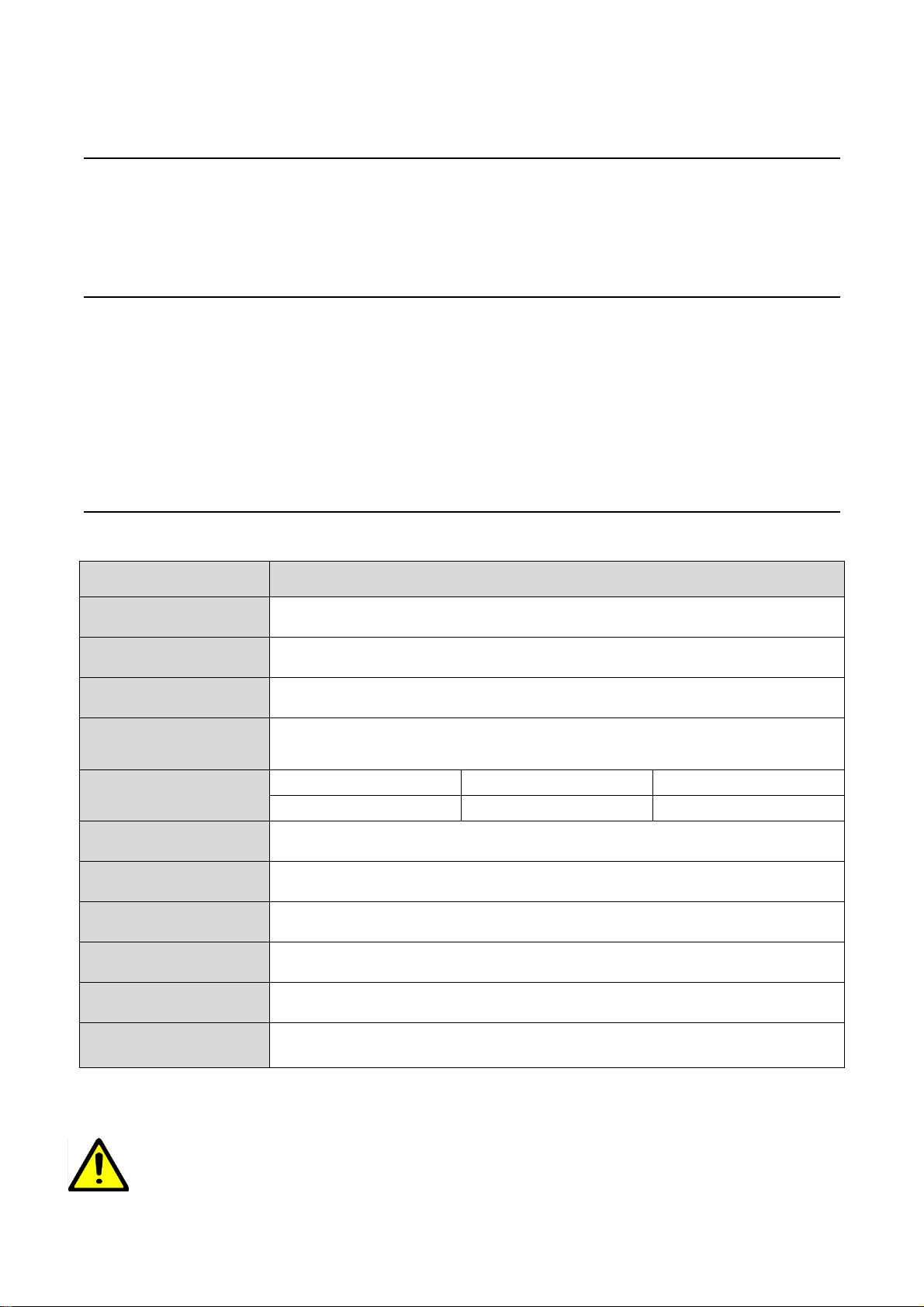

Product Specifications

(1) OPTIMA XD

Model OPTIMA XD

Working Pressure 7~8.5 kgf/㎠ / Max 9.5 kgf/㎠ (99~120.8 psi / Max 135.1 psi)

Steam Vessel Temp. 178℃ max.200℃ (352.4 ℉ max.392 ℉)

Preheating Time 2 ~ 3 min.

Voltage 100V~ / 110-120V~ / 220-240V~ 50/60Hz

(Customer configuration available)

Electrical Power 100V~ 110-120V~ 220-230V~

450W 350W 300W

Rated Flow Max. 300 ~ 1200cc/min. (0.08~0.32gpm)

Water Tank Capacity 36 ℓ ( 9.5 gals)

Fuel Tank Capacity 36 ℓ ( 9.5 gals)

Fuel Nozzle 1.10 gallon/hour @ 10.0 bar

Net Weight 93.5 kgs (206.1 lbs)

Product Dimensions

[L] x [W] x [H] 995 x 660 x 887 mm ( 39.1 x 25.9 x 34.9 inch)

*

Water consumption can be different depending on the use of the Moisture Control Valve.

(See page 15, “Moisture Control”)

※

For user's safety, DO NOT modify factory settings for steam pressure and

temperature.