NAV_PSL_ 2008/07_UK_v4

2

TABLE OF CONTENTS:

1 INTRODUCTION ........................................................................................................................... 4

2 PURPOSE OF PNEUMATIC PRESS ............................................................................................ 4

3 GUARANTEE ................................................................................................................................ 4

4 HEALTH AND SAFETY................................................................................................................. 5

4.1 Meaning of the symbols....................................................................................................... 5

4.2 GENERAL SAFETY PRECAUTIONS .................................................................................... 5

4.3 SAFETY DEVICES................................................................................................................. 6

4.3.1 Emergency STOP button................................................................................................. 6

4.3.2 Safety cord ...................................................................................................................... 7

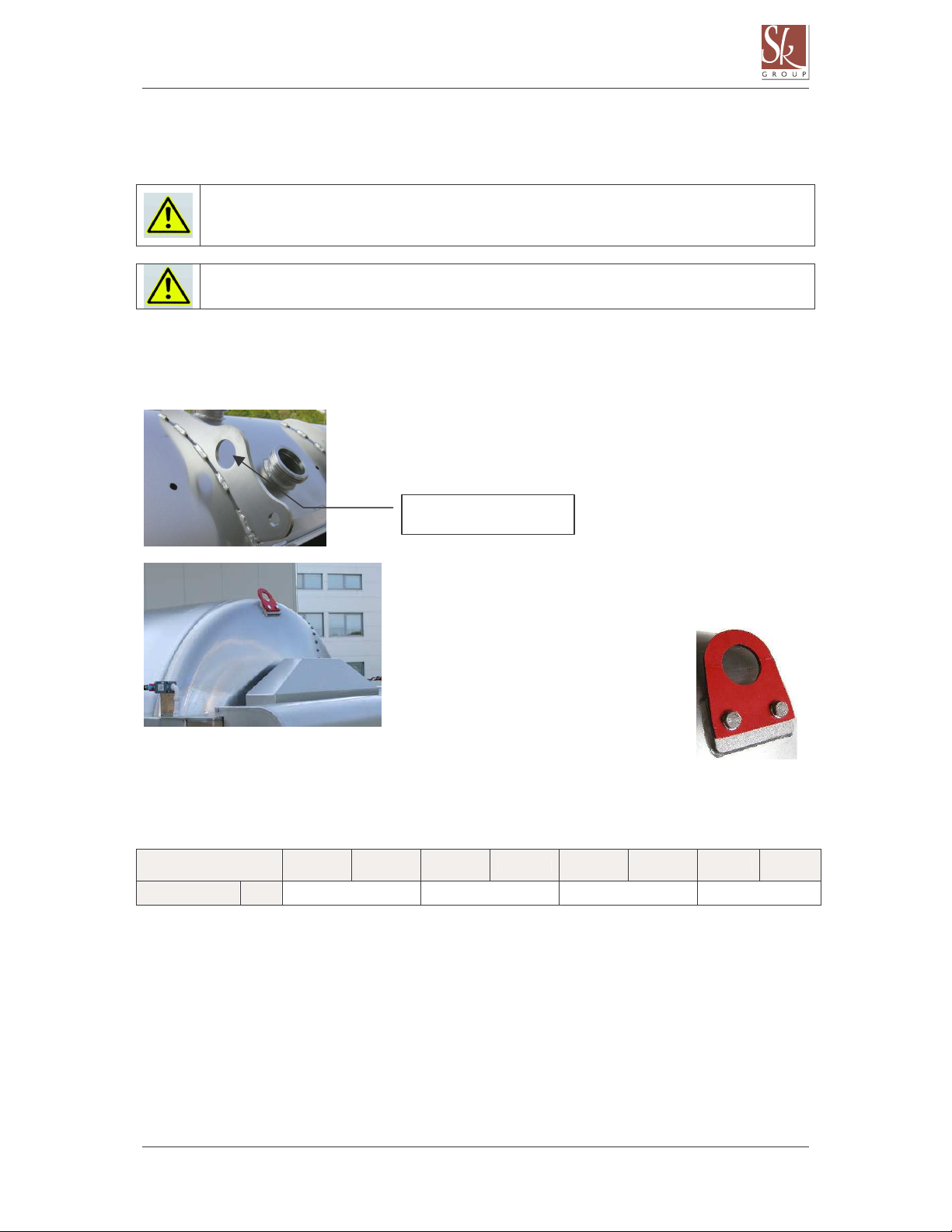

4.3.3 Protection against overpressure in the drum ................................................................... 8

4.3.4 Overload relays ............................................................................................................... 8

5 PRESS TRANSPORT AND SETTING UP..................................................................................... 9

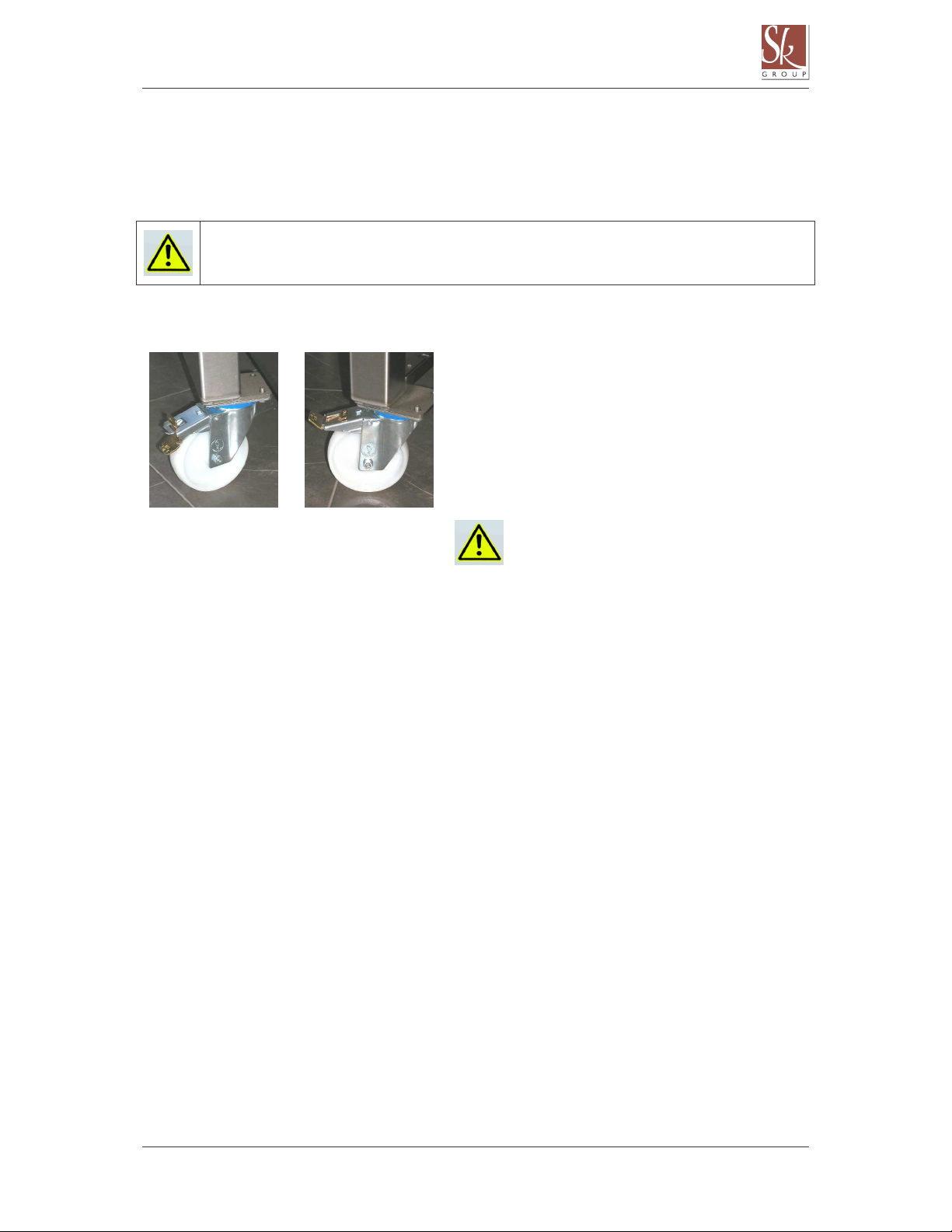

5.1 Transport of the press.......................................................................................................... 9

5.2 Mounting and storage of the press ................................................................................... 10

6 SWITCHING ON THE PRESS..................................................................................................... 11

6.1 Electrical connection.......................................................................................................... 11

6.2 Rotating direction of the drum .......................................................................................... 12

7 GENERAL DATA......................................................................................................................... 13

7.1 Technical data (dimensions and capacity) ....................................................................... 13

7.2 Press orientation ................................................................................................................ 14

7.3 Pneumatic press operation................................................................................................ 15

8 DESCRIPTION OF THE PNEUMATIC PRESS ........................................................................... 16

8.1 Components........................................................................................................................ 16

8.2 Built-in components........................................................................................................... 17

8.3 Materials.............................................................................................................................. 18

8.4 Sliding hatch....................................................................................................................... 18

8.4.1 Double sliding hatch (manual opening/closing).............................................................. 18

8.4.2 Double hatch with pneumatic drive (optional) ................................................................ 20

8.4.3 Hermetic hatch with manual opening/closing (optional for PST).................................... 21

8.4.4 Hermetic hatch with pneumatic drive (optional for PST) ................................................ 22

8.5 Press drum.......................................................................................................................... 23

8.6 Juice collection pan ........................................................................................................... 24

8.6.1 Small pan on guides (optional on PS_21 and PS_29) ................................................... 24

8.6.2 Large pan on wheels (optional on PS_21 and PS_29) .................................................. 25

8.6.3 Pan on guides (PS_42 and PS_55)............................................................................... 25

8.7 Control box ......................................................................................................................... 26

8.8 Optional equipment............................................................................................................ 26

8.8.1 Strainer on the collection pan outlet .............................................................................. 26

8.8.2 Level switch in the collection pan .................................................................................. 27

8.8.3 Equipment for macaration (only models PST) ............................................................... 28

9 OPERATING THE PRESS .......................................................................................................... 29

9.1 Before use........................................................................................................................... 29

9.2 Filling of the press.............................................................................................................. 29

9.2.1 Filling the press through the hatch................................................................................. 29

9.2.2 Filling the press through the central filling connector ..................................................... 30

9.3 Selecting the pressing program ........................................................................................ 32