110s2AEN.doc 16.01.2013 Rev. 2A

TABLE OF CONTENTS

1 EC Declaration of conformity ........................................................................................................................1

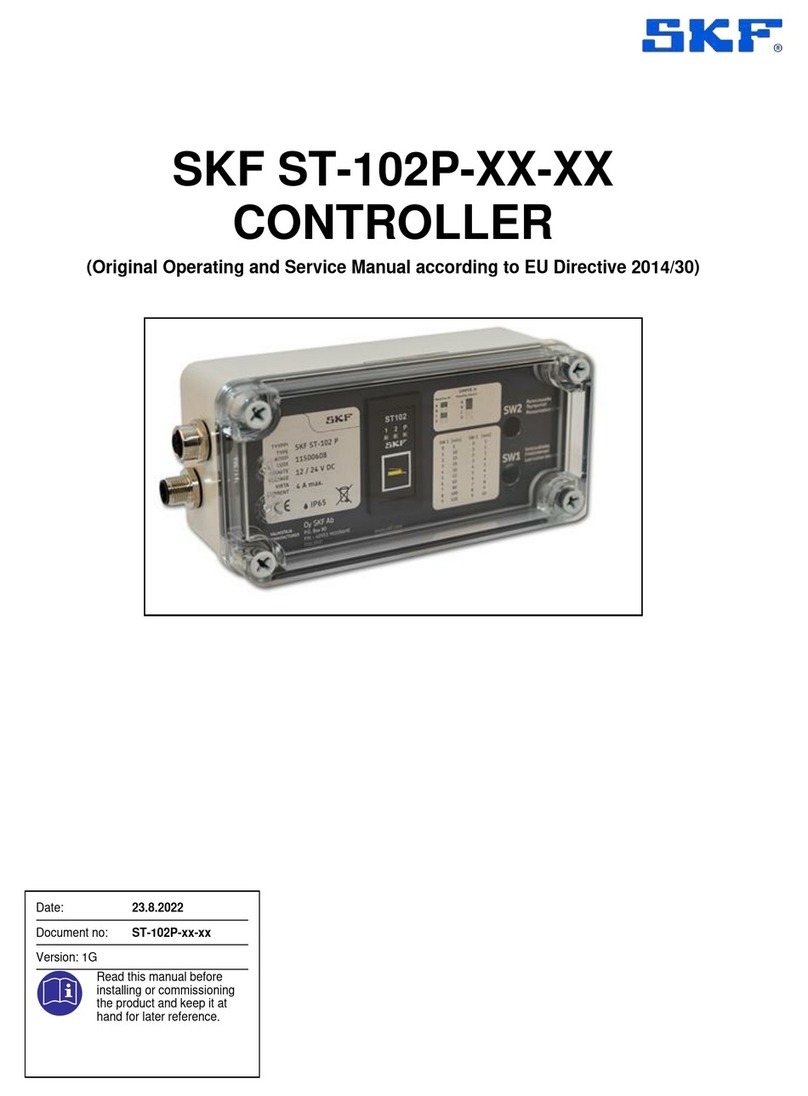

2 General description ......................................................................................................................................2

3 Design..........................................................................................................................................................2

3.1 Cover ............................................................................................................................................................................................3

3.1.1 Indicator lamps....................................................................................................................................................................3

3.1.2 Buttons.................................................................................................................................................................................3

3.2 Control panel...............................................................................................................................................................................3

3.2.1 General .................................................................................................................................................................................3

3.2.2 Buttons.................................................................................................................................................................................3

3.2.3 LED-signals..........................................................................................................................................................................4

3.2.4 Display ..................................................................................................................................................................................4

4 Operation.....................................................................................................................................................5

4.1 Lubrication modes......................................................................................................................................................................5

4.1.1 Automatic lubrication (1)....................................................................................................................................................5

4.1.2 Automatic lubrication (2)....................................................................................................................................................6

4.1.3 Manual lubrication (1) ........................................................................................................................................................6

4.1.4 Manual lubrication (2) ........................................................................................................................................................6

4.2 Lubrication...................................................................................................................................................................................6

4.3 Alarms..........................................................................................................................................................................................7

4.4 Air blowing...................................................................................................................................................................................7

4.5 Power failure...............................................................................................................................................................................7

5 Settings .......................................................................................................................................................7

5.1 General.........................................................................................................................................................................................7

5.2 Entering password......................................................................................................................................................................8

5.3 Entering settings.........................................................................................................................................................................8

5.3.1 Lubrication counter.............................................................................................................................................................8

5.3.2 Lubrication interval.............................................................................................................................................................9

5.3.3 Link pins per rotation .........................................................................................................................................................9

5.3.4 Lubrication mode ................................................................................................................................................................9

5.3.5 Pressure control..................................................................................................................................................................9

5.3.6 Configuration settings ........................................................................................................................................................9

6 Start-up.....................................................................................................................................................10

7 Technical specifications ..............................................................................................................................11