!Notice

Use of end of line pressure

transducers recommended. Transducers

allow for detection of pressurization

failures, such as injector cycle and

injection venting failure.

Description

Functionality

LMC 101 controls both single line and

progressive lubrication systems. While

designed for off-the-road and mobile

equipment use, controller can be used for

any low voltage lubrication application.

Several controller features include:

• 12 and 24 V DC systems

• Time or controller mode

• Single line and progressive systems

• Various alarm condition settings,

including:

–cycle frequency

–alarm triggers

• Programming, data logging, and

reporting, including:

–system resets

–downloads to controllers

–lubrication activity

–lubrication cycles

–alarms.

Controller must be programmed via USB

connection to PC.

Timer mode

• In timer mode, lube cycle ends when

pre-assigned time has expired.

!Notice

Steady alarm light indicates

controller will attempt another

lubrication cycle.

Blinking alarm light indicates no

more lube cycles be attempted until fault

is corrected.

Controller mode

• In controller mode, lube cycle ends when

pressure switch, pressure transducer, or

piston detector actuates.

Single Line system

In single line systems:

• Pressure switches or pressure

transducers can be installed at pump and/

or end of supply line.

• System allows pressure to dissipate to

end of supply line once pressure at pump

is reached.

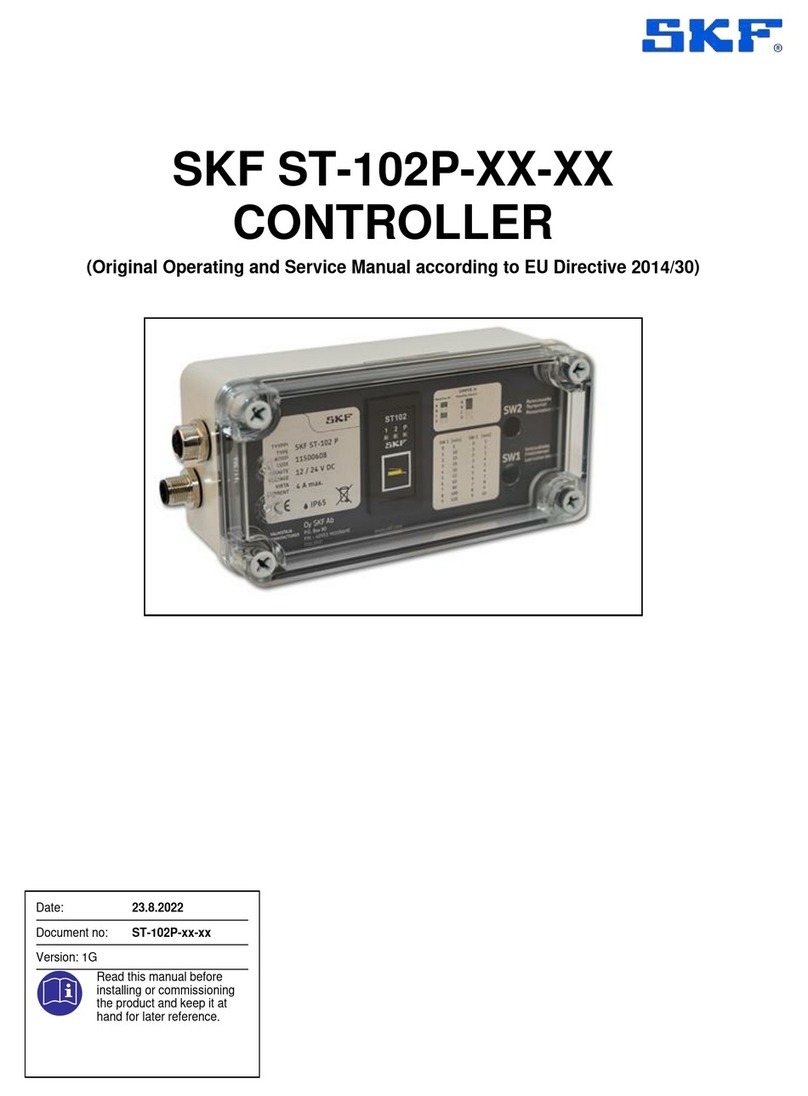

Enclosure lid

Enclosure lid features:

• Manual lubrication push button.

• Four LEDs:

–Power on/run

–Pump on

–Low level fault

–System fault (alarm)

Table 1

Product specification

Input voltage 12 V DC and 24 V DC -20%/ +30%

Current consumption 60 ma (less external load)

Pump relay contact 20 A at 30 V DC

Vent relay contact 2 A at 30 V DC

Alarm relay contact 2 A at 30 V DC

Enclosure rating NEMA 12

Temperature range –40 to 150 °F (–40 to 65 °C)

Net weight 2 lbs. (0,9 kg)

Off time (adjustable) 15 seconds to 99 hours

On time (adjustable) 15 seconds to 99 hours

Lubrication system Single line and progressive

Enclosure size 8.25 x 5 x 3.50 in. (20,9 x 12,7 x 8,9 cm)

Mounting dimensions 8.75 x 3.75 in. (22,2 x 9,5 cm)

Table 2

Parts list

Item no. Description Part no. Quantity

LMC USB Cable Kit 86505 1

3