1 General information ............................. 5

1.1 Information on this manual ..................... 5

1.2 Explanation of symbols ........................ 6

1.3 Limitation of liability ........................... 6

1.4 Copyright ................................... 7

1.5 Spare parts ................................. 7

1.6 Warranty terms .............................. 7

1.7 Customer service ............................. 7

2 Safety ......................................... 8

2.1 Use ....................................... 8

2.1.1 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Unintended and excluded use............... 9

2.1.3 Essential performance .................... 9

2.2 Responsibility of the owner and processor .......... 8

2.3 Personnel requirements ....................... 9

2.3.1 Qualifications ........................... 9

2.4 Specific dangers .............................. 10

2.5 Safety equipment ............................. 11

2.6 Safeguard against restart ...................... 13

2.7 Changes and to the device ...................... 13

2.7.1 Warning labels .......................... 15

2.7.2 Information labels ....................... 15

2.8 Manufacturer’s declaration of EMC compliance ...... 16

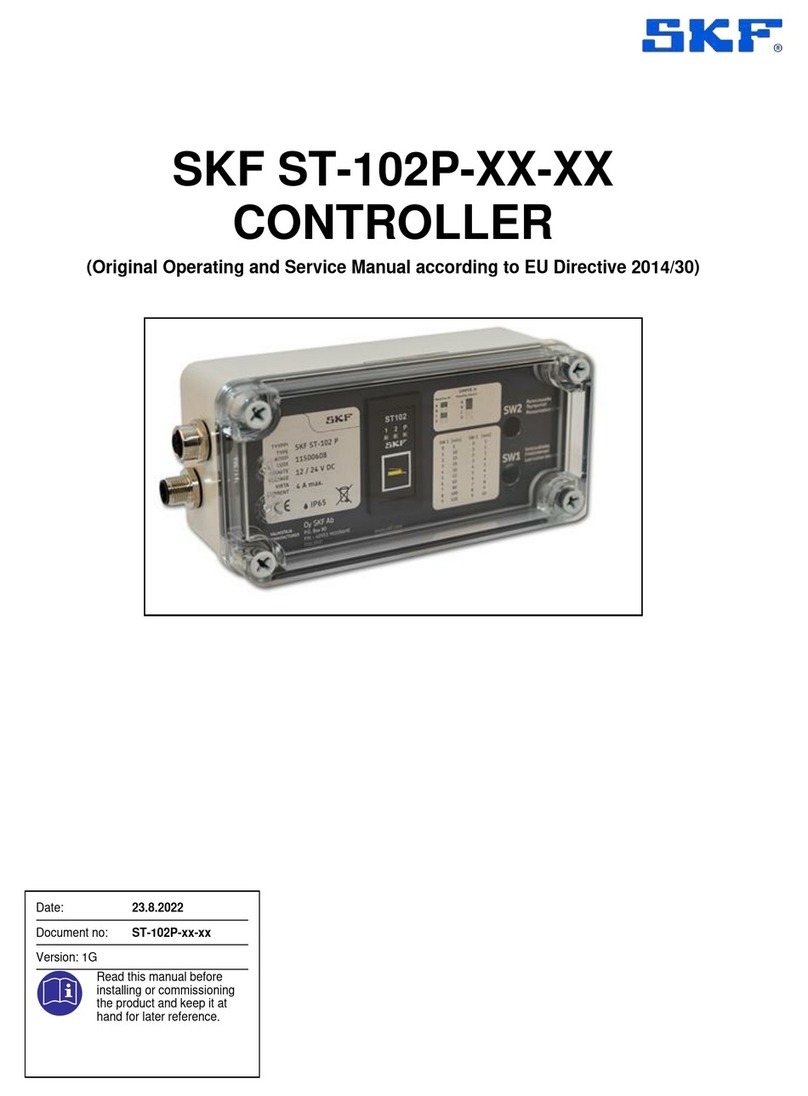

3 Technical data .................................. 24

3.1 Operating conditions .......................... 24

3.2 Product label ................................ 24

4 Structure and function ........................... 25

4.1 Overview ................................... 25

4.1.1 Matrix MAX1 and MAX3 .................. 25

4.1.2 Matrix MAX6 ........................... 25

4.2 Brief description ............................. 26

4.3 Special features .............................. 27

4.4 Construction group description .................. 28

4.5 Requirement for 3rd party power supply ........... 28

4.6 Connections ................................. 29

4.7 Operating elements ........................... 30

4.8 Options .................................... 31

4.8.1 Emergency lowering device ................ 31

4.8.2 Quick adjustment ........................ 31

4.8.3 Electrical pinch protection ................. 32

4.8.4 Life span display ........................ 33

4.8.5 Mechanical pinch protection ............... 33

4.8.6 Master slave actuator function .............. 33

4.8.7 Impulse transmitter ...................... 33

4.9 Accessories ................................. 34

Contents

5 Transport, packaging and storage . . . . . . . . . . . . . . . . . . . 35

5.1 Safety information for the transport . . . . . . . . . . . . . . . 35

5.2 Transport inspection .......................... 35

5.3 Return to the manufacturer ..................... 36

5.4 Packaging .................................. 36

5.5 Storage .................................... 37

6 Installation and first operation ..................... 38

6.1 Installation location ........................... 39

6.2 Inspections prior to first operation ................ 39

6.3 Installation .................................. 41

6.4 Connection to the control Unit ................... 44

6.5 Connection to operating element ................. 47

6.5.1 Connect MAX1 and MAX3 to operating element 47

6.5.2 Connect MAX6 to operating element ......... 47

6.6 Connect to power supply ....................... 51

6.6.1 Connect MAX1 and MAX3 to power supply .... 51

6.6.2 Connect MAX6 to energy supply ............ 51

6.7 Requirements concerning the installation of the

actuators with options ......................... 54

6.7.1 Emergency lowering device ................ 54

6.7.2 Quick adjustment ........................ 55

6.7.3 Electrical pinch protection ................. 55

6.7.4 Mechanical pinch protection ............... 56

6.7.5 Master-slave actuator function ............. 56

7 Operation ...................................... 59

7.1 Safety ..................................... 59

7.2 Turn on .................................... 60

7.3 Turn off .................................... 60

7.4 Action before Use ............................. 61

7.5 Action during the operation ..................... 62

7.5.1 Normal operation ....................... 62

7.5.2 Operate emergency lowering device ......... 62

7.5.3 Operate quick adjustment ................. 64

7.6 Disengagement in case of emergency ............. 67

7.6.1 Shut down MAX1 and MAX3 ............... 68

7.6.2 Shut down MAX6 ........................ 69

7.7 Action after use .............................. 69

2