1 General information .............................. 3

1.1 Information on this manual ...................... 3

1.2 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Limitation of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Warranty terms ............................... 5

1.5 Customer service.............................. 5

2 Safety ......................................... 6

2.1 Intended use ................................. 6

2.2 Responsibility of the owner and processor........... 6

2.3 Personnel requirements . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.1 Qualifications........................... 7

2.4 Specificdangers .............................. 8

2.5 Safetyequipment............................. 9

2.6 Changes and modifications on the actuator .......... 11

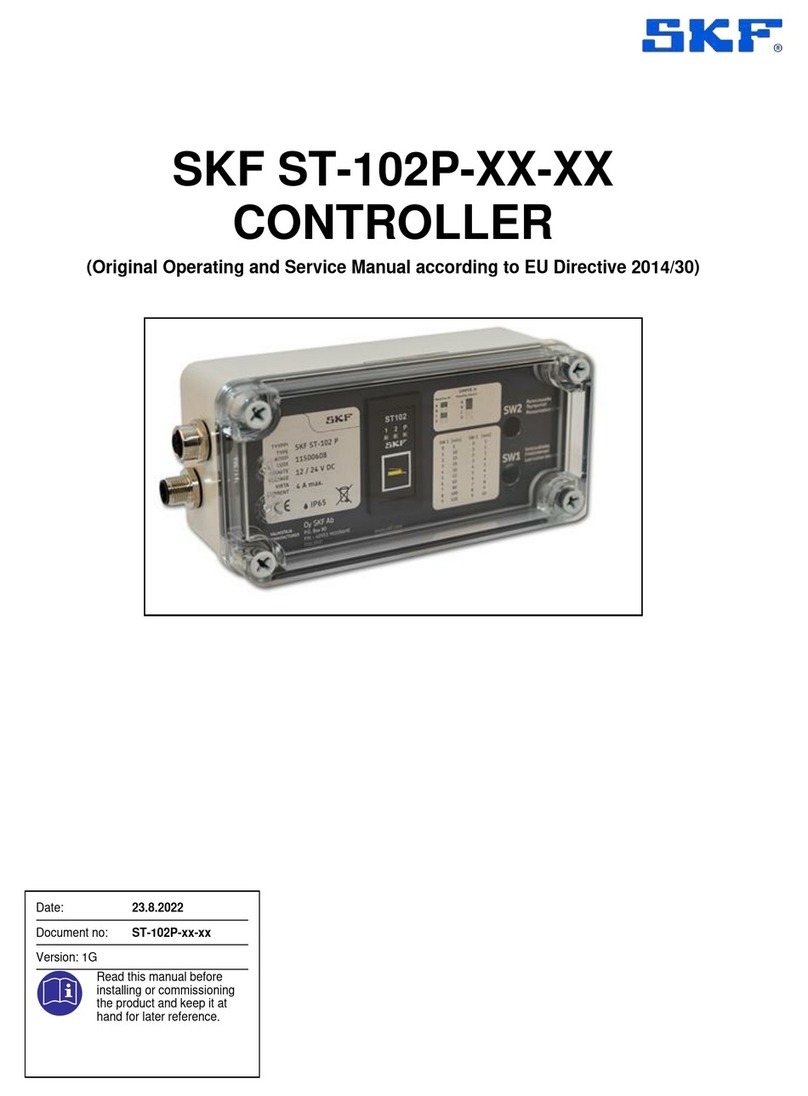

3 Technical data................................... 12

3.1 Operating conditions ........................... 12

3.2 Product label ................................. 12

4 Structure and function ............................ 13

4.1 Overview .................................... 13

4.2 Briefdescription.............................. 14

4.3 Special features............................... 15

4.4 Construction group description ................... 15

4.5 Connections ................................. 16

4.6 Options ..................................... 16

4.6.1 Limitswitch ............................ 16

4.6.2 Potentiometer .......................... 17

4.6.3 Thermal switch .......................... 17

5 Transport, packaging and storage................... 18

5.1 Safety information for the transport . . . . . . . . . . . . . . . 18

5.2 Transport inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Return to the manufacturer...................... 19

5.4 Packaging................................... 19

5.5 Storage ..................................... 20

Contents

6 Installation and first operation ..................... 21

6.1 Installation location ............................ 22

6.2 Installation .................................. 22

6.3 Inspections prior to first operation................. 24

6.4 Connect to power supply ........................ 24

7 Operation ...................................... 25

7.1 Safety...................................... 25

7.2 Action before operation ......................... 26

7.3 Action during operation ......................... 27

7.3.1 Normal operation ........................ 27

7.4 Disengagement in case of emergency .............. 29

7.5 Action after use ............................... 29

8 Maintenance .................................... 30

8.1 Spare parts.................................. 30

8.2 Maintenanceplan............................. 31

8.3 Maintenance work............................. 32

8.3.1 Cleaning ............................... 32

8.3.2 Inspections and readings . . . . . . . . . . . . . . . . . . 32

8.3.3 Check of visual condition................... 33

8.4 Measures after completed maintenance . . . . . . . . . . . . 33

9 Malfunctions .................................... 34

9.1 Malfunction table.............................. 36

9.2 Start of operation after fixing malfunction........... 37

10 Dismantling ................................... 38

10.1 Dismantling................................. 39

10.1.1 Dismantling of CAHB-20 . . . . . . . . . . . . . . . . . 39

10.2 Disposal ................................... 39

11 Appendix ...................................... 40

2