Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . .

Explanation of signal words

for safety . . . . . . . . . . . . . . . . . . . . . . . .

Description. . . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . .

Installation. . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly and cleaning . . . . . . . . . .

Filter cleaning option . . . . . . . . . . . . . .

Filter cleaning option . . . . . . . . . . . . . .

Filter cleaning option . . . . . . . . . . . . . .

Bypass pin replacement. . . . . . . . . . . .

Removal . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . .

Filter assembly tips. . . . . . . . . . . . . . . .

Individual parts break down and

parts list. . . . . . . . . . . . . . . . . . . . . . . . .

Warranty . . . . . . . . . . . . . . . . . . . . . . . .

Safety

Read and carefully observe these operating

instructions before unpacking and operating

filter. Filter must be operated, maintained

and repaired exclusively by persons familiar

with operating instructions. Local safety

regulations regarding installation, operation

and maintenance must be followed.

Operate filter only after safety

instructions and this service manual are

fully understood.

Explanation of signal

words for safety

NOTE

Emphasizes useful hints and

recommendations as well as

information for efficient and trouble-

free operation.

DANGER

Indicates a dangerous situation that can

lead to death or severe injury if

precautionary measures are ignored.

Specifications

Model Model A

Collapse pressure psi (41,4 bar) psi (41,4 bar)

Screen size mm

Inlet 1/2 in NPTF 1/2 in NPTF

Outlet 1/2 in NPTF 1/2 in NPTF

Maximum working pressure 5 000 psi (344,7 bar) 5 000 psi (344,7 bar)

Maximum flow rate 1 gallon/minute

(3,8 liters/minute)

1.25 gallons/minute

(4,7 liters/minute)

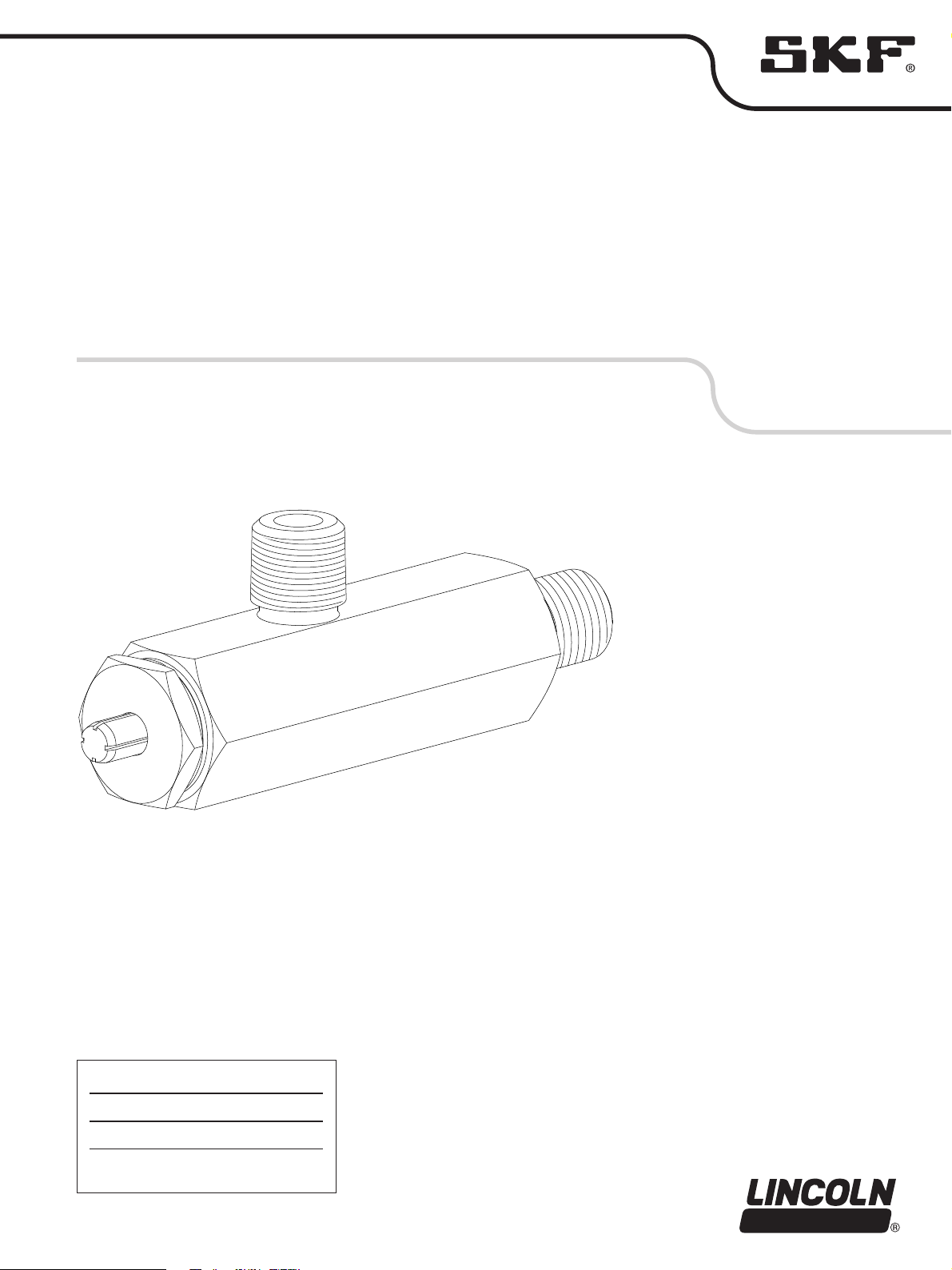

Description

Model and A are grease filters

for refilling small reservoirs of pumps such

as model QuickLub pumps.