Page 4

EN

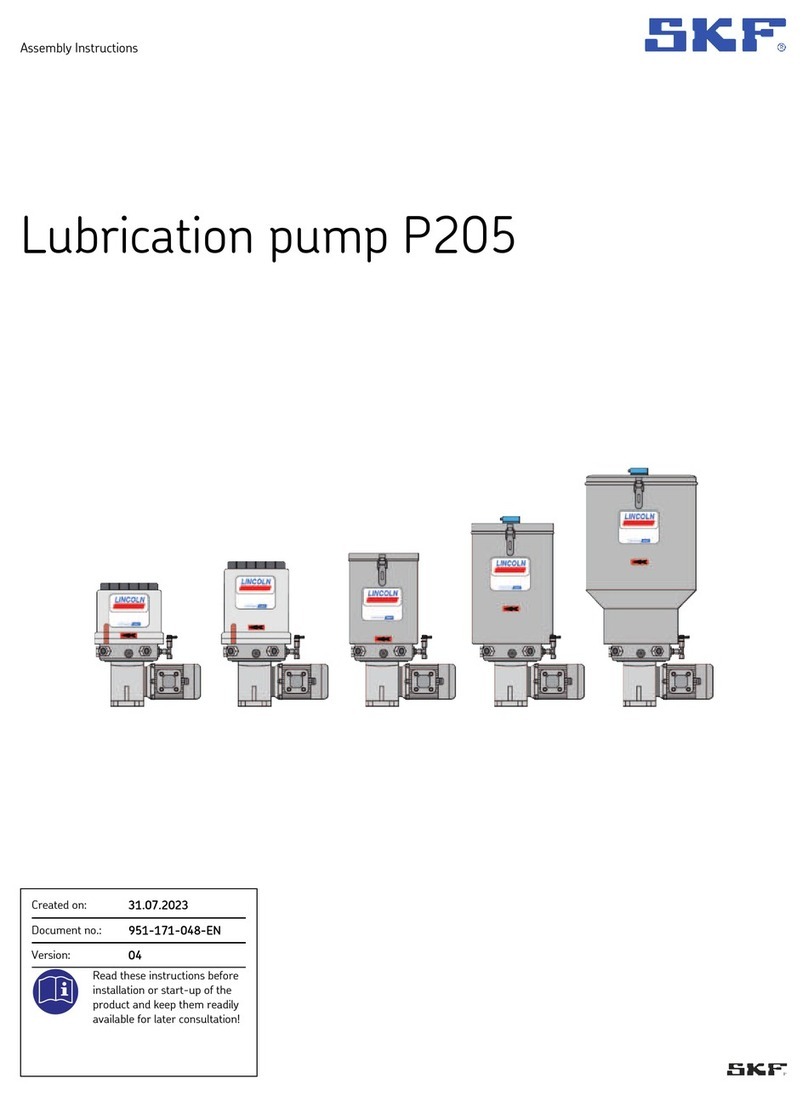

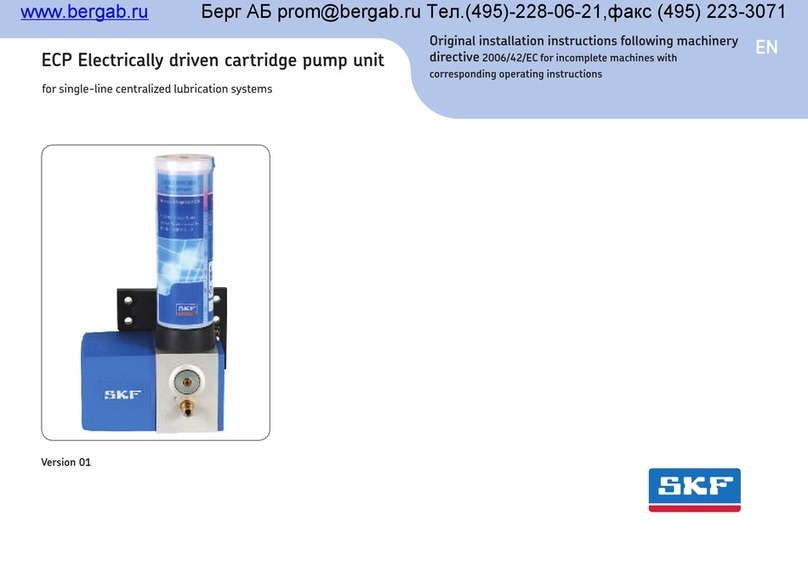

The product:

lubrication pump unit

of the series: FD3

is hereby confirmed to comply with the es-

sential protection requirements stipulated by

the following Directive(s) of the Council on the

approximation of laws of the Member States:

Machinery Directive 2006/42/EC

Low Voltage Devices 2006/95/EC

Electromagnetic Compatibility

2004/108/EC.

Notes:

(a) This declaration certifies compliance with

the aforementioned Directives, but does

not constitute a guarantee of characteris-

tics.

(b) The safety instructions in the documenta-

tion enclosed with the product must be

observed.

(c) The commissioning of the products here

certified is prohibited until the machine,

vehicle or similar in which the product is

installed conforms with the provisions and

requirements of the applicable Directives.

(d) The operation of the products at non-stan-

Information concerning EC Declaration of Conformity and EC Declaration of Incorporation

dard supply voltage, as well as non-ad-

herence to the installation instructions, can

negatively impact the EMC characteristics

and electrical safety.

We further declare:

The aforementioned product is, according to

EC Machinery Directive 2006/42/EC,

Annex II Part B, designed for installation

in machinery / for incorporation with other

machinery to form a machine.

Within the scope of the EC Directive, com-

missioning shall be prohibited until the

machinery in which this product is installed

conforms with the provisions of this Direc-

tive.

The aforementioned product may, with

reference to EC Directive 97/23/EC con-

cerning pressure equipment, only be used

in accordance with its intended use and in

conformity with the instructions provided in

the documentation. The following must be

observed in this regard:

The product is neither designed nor approved

for use in conjunction with fluids of Group 1

(Dangerous Fluids) as defined in Article 2, Para.

2 of Directive 67/548/EEC of June 27, 1967.

The product is neither designed nor approved

for use in conjunction with gases, liquefied

gases, pressurized gases in solution, vapors

or such fluids whose vapor pressure exceeds

normal atmospheric pressure (1013 mbar) by

more than 0.5 bar at their maximum permis-

sible temperature.

When used in conformity with their intended

use, the products supplied by SKF Lubrication

Systems Germany AG do not reach the limit

values listed in Article 3, Para. 1, Clauses 1.1

to 1.3 and Para. 2 of Directive 97/23/EC. They

are therefore not subject to the requirements

of Annex 1 of the Directive. Consequently,

they do not bear a CE marking in respect of

Directive 97/23/EC. SKF Lubrication Systems

classifies them according to Article 3, Para. 3

of the Directive.

The Declaration of Conformity and Incorpora-

tion forms part of the product documentation

and is supplied together with the product.