Description

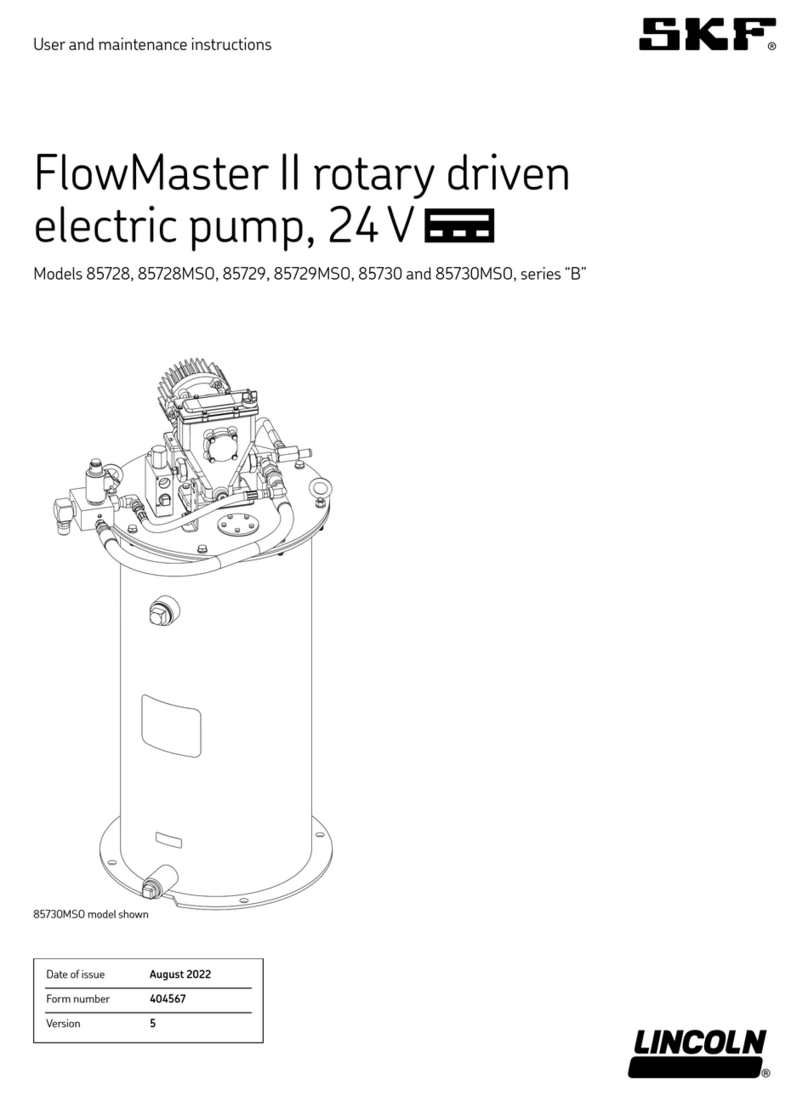

FlowMaster II rotary AC electric pump uses

an AC motor and two stage planetary

gear drive.

Grease output is proportional to pump

revolutions per minute. Pump is primarily

designed for centralized lubrication systems

such as single line parallel, single line pro-

gressive and two line systems.

Pump is driven by rotary motion of elec-

tric motor. Rotary motion is converted to

reciprocating motion through an eccentric

crank mechanism. Reciprocating action

causes pump cylinder to move up and down.

Unit is positive displacement double-acting

pump, as grease output occurs during both

up and down strokes.

During down stroke, pump cylinder is

extended into grease. Through combination

of shovel action and vacuum generated in

pump cylinder chamber, grease is forced into

pump cylinder. Simultaneously, grease is

discharged through outlet of pump. Volume

of grease during intake is twice amount of

grease output during one cycle.

During upstroke, inlet check closes, and

one half of grease taken in during previous

stroke is transferred through outlet check

and discharged to outlet port. Typical output

of pump is shown in Pump performance

(†Table 1, page 4).

Refer to Motor wiring diagram (†Fig. 2,

page 5) for pump motor.

NOTE

Pumps are not recommended for airless

spray systems. They should be con-

verted from : to : gear ratio.

Please contact technical services for

component requirement.

Table 1

Pump performance

Temperature @ rpm ) @ rpm )

°F (27 °C) . in/min (88 cm3/min) . in/min (110 cm3/min)

°F (4 °C) . in/min (85 cm3/min) . in/min (105 cm3/min)

°F (–7 °C) . in/min (82 cm3/min) . in/min (100 cm3/min)

Table 2

Pump specifications

Operating temperature – to °F (–40 to 65 °C)

Operating voltage / V AC, / Hz, phase

Motor speed rpm @ Hz, rpm @ Hz

Pump speed rpm @ Hz, rpm @ Hz

Motor power 1/2HP (0,37 kW)

Output/pump cycle . in(1,15 cm3)

Pump outlets 1/4NPTF internal

Maximum outlet pressure psi (345 bar)

Current drawing †Table 3 and Table 4, (page 8)

Inspection

If over pressurizing of equipment is believed

to have occurred, contact factory authorized

warranty and service center for inspection.

Specialized equipment and knowledge is

required for repair of pump.

Annual inspection by factory authorized

warranty and service center is

recommended.

Damaged pumps

Do not use any pump that appears to be

damaged, badly worn or operates abnor-

mally. Remove pump from service and con-

tact factory authorized warranty and service

center for repairs. A listing of authorized

warranty and service centers is available

upon request.

) Test conducted with Alvania NLGI at psi (68 bar) back pressure.

Appropriate use

All pump models are exclusively designed to

pump and dispense lubricants using electric

power. Specifications are shown in Pump

specifications (†Table 2, page 4). Do not

exceed maximum specification ratings.