Skibo PEQUEA HT6102 User manual

Operator’s Manual

Pequea Turbo Tedder

Model HT6102

THIS MANUAL MUST BE READ AND UNDERSTOOD BEFORE

Manual# 990136

Revised 03/2023

OPERATING THIS MACHINE!

2

COMPLETE YOUR WARRANTY REGISTRATION TO

ACTIVATE YOUR WARRANTY AND TO QUALIFY FOR

PARTS AND SERVICE

To the Owner

Thank-You for choosing a quality product from Pequea Machine, Inc. We

strive to give you the best equipment and the best level of service of any

company. With a little care and maintenance, this machine will do your work

for you for many years. In this manual, we make an eort to get you better

acquainted with the machine so you can achieve maximum performance. We

design and build all of our equipment with the end user in mind so we wel-

come any suggestions or ideas for improvement. Please note that it is within

our rights to make changes or improvements to our equipment without up-

dating the equipment that was manufactured before the change took place.

Please take a few minutes to ll out the area below. This information will be

valuable to you when ordering parts or requesting service from your dealer.

Dealer Name:_____________________________

Dealer Phone Number:______________________

Service Manager/Technician:_________________

Model# and Description:_____________________

Serial Number:____________________________

Date of Purchase:__________________________

1

TABLE OF CONTENTS

Introduction ……………………………………………………………… 2

Intended Use ………………………………………………… 3

Serial Number …………………………………………….… 3

Specications ………………………………………………… 3

Safety …………………………………………………………………….… 4

Power Source Safety ………………………………………… 4

Safety Decals and Reectors ……………………………… 5-6

Folding for Transport ....……………………………………………… 7

Dealer Setup Instructions ....………………………………………… 8

Middle Wheels …………………………………….............… 8

Wheel Lock Links .……………………………….............… 9

Hitching ……………………………………………………………………10

Attaching to the Tractor ……………………………………… 10

Transporting ……………………………………………………………… 11

Field Transport ……………………………………………… 11

Road Transport ……………………………………………… 11

Field Set-up ………………………………………………………………12

Adjustments ………………………………………………………………13

Tine Pitch Adjustment ……………………..………………13

Axle Adjustments …………………………………………..14

Lubrication and Maintenance …………………………………… 15

Gearbox Lubrication ………………………………………… 15

General Lubrication ……………………………………… 16

PTO Shaft Lubrication ……………………………………17-18

Transport Latch Lubrication ………………………………… 19

General Maintenance ……… ………………………………… 20

Wheel Bearings …………………………………………… 20

Electrical ………………………………………………………………… 21

Technical ………………………………………………………………… 22

Replacing the Flotation Springs …………………………… 22

Factory Timing............................ …………………………… 23

Fixing Timing the Outer Rotors……..…………………… 24-27

Warranty …………………………………………………………………… 28

2

INTRODUCTION

At Pequea, we have a strong commitment to ensuring farmers can access the

best agriculture technology in the industry. You put in hard work and long days,

so we do what we can to oer new products that help farms save time, money,

and resources, while increasing their yield. We’ve rened our products over the

years with new upgrades and innovations to treat your land with the respect it de-

serves, using feedback from actual farmers and our engineering team. Whether

you purchase a hay tedder, spreader, trailer, or any of our other ne products,

Pequea – and the agricultural equipment suppliers we work with – are here for

you with the quality you’re searching for to keep your farm running.

Like all Pequea products, we manufacture our leading hay tedders and forage

equipment in our New Holland Pennsylvania facility, using quality components

and expert craftsmanship every step of the way. The TurboTedder stands apart

from other rotary tedders thanks to its round tube arms, carbo-austempered n-

ger joints and asymmetrical tine conguration. All models feature fully enclosed

oil-bath gearboxes, heavy-duty hubs, large tires and a standard tilt cylinder.

Pequea is more than just an agricultural machinery manufacturer. We provide

parts, service, and support for your new equipment. This manual is provided to all

new owners of the Turbo Tedder Model HT6102 to make you aware of all mainte-

nance expectations, safety concerns, and issues you may encounter when own-

ing this piece of equipment. Be sure to keep this manual for future references.

Please review all instructions carefully, taking special note of all safety notica-

tions. Should you have any questions related to your new equipment, please

contact your dealer prior to proceeding. Also, be sure to review the Pequea Ma-

chine’s Limited Warranty and our industry leading Extended Gearbox Warranty,

found on page 28.

Congratulations and Thank You for choosing

Pequea Machine!

3

Intended Use

Pequea TurboTedders are designed for evenly distributing and drying hay crops

only. Pequea will not cover under warranty a tedder that has been used outside

of these crops.

Serial Number

The tedder’s serial number can be found

on the tongue directly under the driveline.

Please use this number when requesting

service, seeking information, or ordering

parts. For the operator’s convenience,

space to record the serial number, model

number, purchase date, and dealer has

been provided inside the front cover of this

manual.

SPECIFICATIONS

Specications HT4102 HT6202 HT6102 HT8101

Transport Width 9’ 2” 9’2” 11’ 0” 11’ 7”

Working Width 18’ 26’6” 26’6” 35’

Number of Rotors 4 668

Arms Per Rotor 7 7 7 7

Arm Construction Round Tubular Round Tubular Round Tubular Round Tubular

Rotor Gearbox Lubrication Grease NLGI #0 Grease NLGI #0 Grease NLGI #0 Grease NLGI #0

Center Gearbox Lubrication 80W-90 Gear Oil 80W-90 Gear Oil 80W-90 Gear Oil 80W-90 Gear Oil

Center Gearbox Capacity 64 oz. 64 oz. 64 oz. 64 oz.

Arm Construction Round Tubular Round Tubular Round Tubular Round Tubular

PTO HP Recommended 35+ 55+ 55+ 75+

Spindle Size 1-3/8” 1-3/8” 1-3/8” 1-3/8”

Hub

4-Bolt w/ Tapered

Bearings

4-Bolt w/ Tapered

Bearings

4-Bolt w/ Tapered

Bearings

4-Bolt w/ Tapered

Bearings

Wheels

4-Bolt Heavy Duty,

Painted

4-Bolt Heavy Duty,

Painted

4-Bolt Heavy Duty,

Painted

4-Bolt Heavy Duty,

Painted

Transport Wheels N/A 18.5 x 8 Load Range D 27 x 7.75 R15 27 x 7.75 R15

Rotor Tires 18.5 x 8 18.5 x 8 18.5 x 8 18.5 x 8

Hydraulic Requirement 1200 psi 1700 psi 1800 psi 1950psi

Figure 1

4

SAFETY FIRST!

This symbol precedes specic safety instructions throughout this manual. When read-

ing the manual, pay close attention to the information that follows this symbol.

FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL COULD RESULT IN PERSONAL

INJURY OR DEATH. READ ENTIRE MANUAL BEFORE OPERATING THE TEDDER.

Keep hands, feet and clothing away from the machine’s power take-o (PTO) shaft and any

other moving parts until the machine has been shut down and the power source has been

locked out.

Do not adjust, unclog, lubricate, or service the tedder until it has been shut down.

Support the tedder securely while working under it.

Be certain all bystanders and animals are a safe distance away before folding or unfolding

the tedder.

Never allow anyone to ride on the tractor or the tedder.

Before transporting, make sure hands-free transport lock is latched in place.

When transporting, never exceed a speed of 25 MPH and avoid sudden turns.

Be constantly aware of the ends of the machine to avoid collision with other objects.

When transporting the machine on public roads, use the proper reectors, lights, and slow

moving vehicle signs required by local government agencies. Pequea will not be liable for any

trac violations.

Be sure to check all fasteners before and after every use. This is especially important when

the tedder is new but is a good practice on any machinery with high vibration levels.

Be careful around hydraulic hoses and ttings. Never go near hydraulic leaks. High pressure

leaks can puncture skin and cause serious injury or death!

Do not attempt to fold the tedder until the machine is on at ground. Folding on uneven terrain

can cause the tedder to ip over.

Power Source Safety

Do not use a PTO shaft without a rotating shield in good working order. Make sure drive sys-

tem safety shields are in place on both the tractor and the tedder.

Do not overextend the PTO Shaft

PTO shield chains must be attached to the tractor and/or the tedder to keep the shield from

rotating.

5

SAFETY

Safety Decals and Reectors

Safety decals and reectors are for the safety of yourself and others, and must

be heeded at all times. If any decals are missing, faded, or damaged in any way,

please contact your dealer for replacements immediately. Shown below are some

of the decals used on your tedder.

6

Stay Clear of Rotating Drivelines

TS1644-UN-22AUG95 H96219-UN-29APR10

Entanglement in rotating driveline can cause serious injury or death.

Keep tractor master shield and driveline shields in place at all times. Make

sure rotating shields turn freely.

Wear close fitting clothing. Stop the engine and be sure that PTO driveline

is stopped before making adjustments, connections, or cleaning out PTO

driven equipment.

Do not install any adapter device between the tractor and the primary

implement PTO drive shaft that will allow a 1000 rpm tractor shaft to power

a 540 rpm implement at speeds higher than 540 rpm.

Do not install any adapter device that results in a portion of the rotating

implement shaft, tractor shaft, or the adapter to be unguarded. The tractor

master shield shall overlap the end of the splined shaft and the added adaptor

device as outlined in the table.

PTO Type

Diameter Splines

n ± 5 mm (0.20 in.)

1 35 mm (1.378

in.)

6 85 mm (3.35 in.)

2

35 mm (1.378 in.)

21 85 mm (3.35 in.)

3

45 mm (1.772 in.)

20 100 mm (4.00 in.)

SAFETY

7

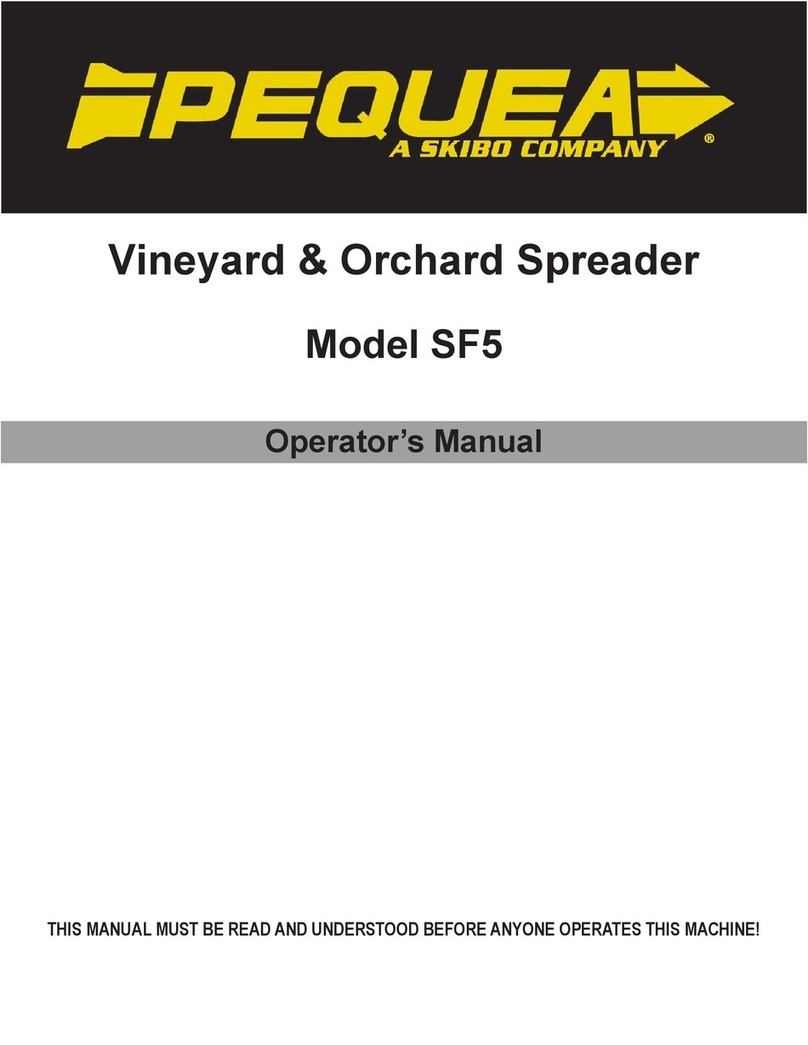

When tedding, the transport wheels can swivel and are spring loaded to support

the weight of the chassis. The springs will be compressed and the wheels locked

in the straight position when the tedder is folded up for transport. Figure 2 shows

the transport lock properly engaged. Do not transport the tedder until transport

lock is latched in place as shown.

Figure 2

Do not fold for transport unless the tedder is

on even ground. Folding on uneven ground

can cause the tedder to tip over.

Transport Lock Engaged

FOLDING FOR TRANSPORT

Pull forward with the tractor before folding.

This will straighten the wheels & position them

ready for folding up.

Be sure to have the wheels relatively straight before folding so the locks can en-

gage properly!

8

DEALER SETUP INSTRUCTIONS

Middle Wheels

The Middle Wheel frames are stored on the

Transport Arms for shipping. Unbolt the wheel

frames from the transport arm. Install onto the

rotor spindle casting with the “U” spindle to-

wards the center of the tedder. When Finished,

the tedder should look like shown in below in

Figure 4. The spindles should have alternating

directions. The hay movment between the ro-

tors when tedding should be in the open area-

between the wheels where there isn’t a spindle.

Figure 3

Figure 4

9

Wheel Lock Links

The Links for the wheel locks are positioned into

black forklift plates when the tedder arrives at

the dealer (Figure 5). This is so that the forklift

doesn’t bend the link arms when picking up. After

unloading the tedder, it is necessary to move the

link arms by removing the zip ties and securing

on the 3/4” bolt. The swivel eye on the link arm is

to be installed inbetween the two spacer wash-

ers as shown in gure

Place ring washers on

either side of ball

swivel.

Figure 6

Figure 5

10

HITCHING

Attaching to the Tractor

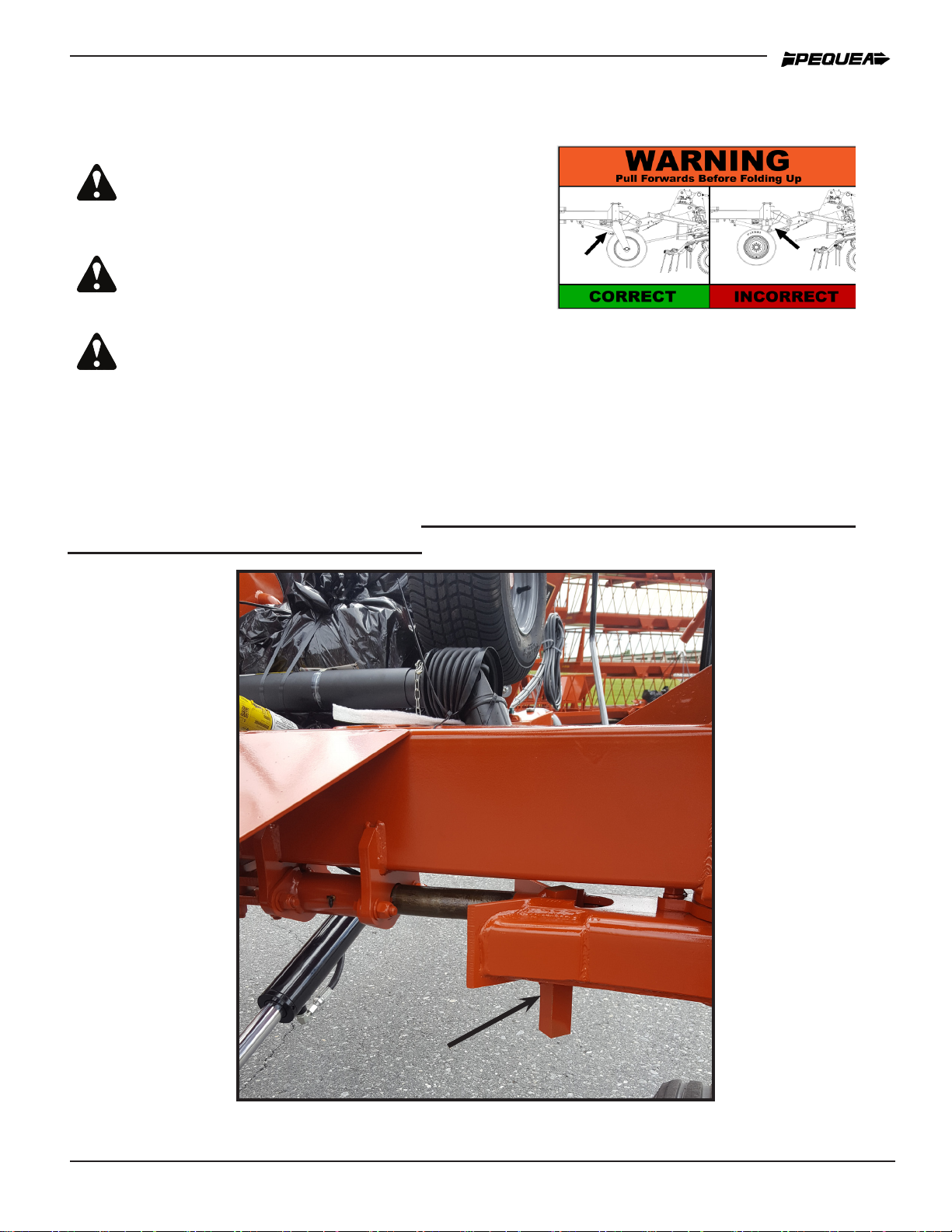

Figure 7

Crank the jack up or down to align the tractor draw bar with the hitch.

Figure 8

The tedder hitch is bolted on and can be adjusted up or down to accommodate various drawbar

heights (Figure 7). Select a height that keeps the tedder chassis level when it is connected to

the tractor.

When attaching to the draw bar always use a draw bar pin with a safety clip to ensure that the

tedder doesn’t bounce o of the tractor.

After attaching the tedder, crank the jack down until all the weight rests on the tractor drawbar,

then remove the jack and place it in the transport position. (Figure 8)

Attach the PTO shaft to the tractor. Make sure the locking balls in the splined coupling are oper-

ational and that the PTO shaft locks securely on the tractor output shaft. NOTE: Be sure to push

the PTO stand down against the tongue to avoid damage to the PTO shaft shielding.

The HT6102 is equipped with hydraulic cylinders to fold the machine for transport. The hoses

should be connected to a double acting valve at the rear of the tractor. The slotted holes on the

side of the tongue (Figure 7) are storage holes for the hoses

If your tedder is equiped with the lighting package option, you will need to connect the wiring

plug from the tedder into the female plug end on the tractor. Never travel on public roads without

proper lighting.

11

TRANSPORTING

Field Transport

Never allow any riders on the tractor or the tedder.

Remain fully aware of the width of the tedder in relation to objects you are passing.

Never travel at speeds of more than 12 MPH in the eld.

Road Transport

Adhere the suggestions for eld transport listed above.

Make sure the hands-free transport lock is latched in place properly (shown in Figure 2-pg 7).

ALWAYS FOLLOW LOCAL TRAFFIC LAWS IN REGARDS TO THE TRANSPORTING OF FARM

EQUIPMENT. PEQUEA WILL NOT BE HELD LIABLE FOR FINES INCURRED DUE TO TRAFFIC

VIOLATIONS.

Do not exceed 25 MPH on any public road. Excessive speeds combined with common road obstruc-

tions can cause failures.

Figure 9 Figure 10

Be sure the SMV (slow moving vehicle) Symbol is visible from the rear of the machine, as shown in

Figure 9.

Keep a close eye on the tedder wings when transporting on the road or in the eld. A leaky valve

in the tractor’s hydraulic system will cause the tedder to slowly unfold. If this occurs, you will want

to disconnect the hydraulics before transporting. Figure 10 shows the wings supported properly for

transport and the safety chains attached.

Be sure to use the lights when traveling on the road at night.

12

FIELD SET UP

To lower the tedder into tedding position, engage the hydraulics for the tilt cylinder rst to raise the

wings o of the chassis then engage the main hydraulics to unfold the wings. Be sure that nobody

is around the tedder or the tractor as the wings are lowering. The tines and arms can cause serious

injury to anybody that it comes into contact with. Make sure that the hitch is attached to the tractor

and the pin is installed when the wings are lowering. If the hitch is not properly attached to the trac-

tor, the weight of the rotors when it is unfolding could cause the hitch to whip up causing serious

personal injury or damage to equipment.

1-2”

NEVER RUN THE PTO WHILE THE TEDDER IS IN THE TRANS-

PORT POSITION! THIS CAN CAUSE DAMAGE TO THE JOINTS

AND ALSO POSES A PERSONAL INJURY HAZARD.

DO NOT ADJUST THE TEDDER UNLESS THE TRACTOR IS OFF AND THE PTO SHAFT

IS DISCONNECTED. ALWAYS ADJUST THE MACHINE BY YOURSELF. A SECOND

PERSON INCREASES THE CHANCE OF AN ACCIDENT.

The tine height adjustments can be made by turning the handle shown in Figure 11.

Turn the handle clockwise to raise the tine height.

Turn the handle counter clockwise to lower the tine height.

Generally, the tines should be around 1-2 inches from the ground for most crops (Figure

12). However, the stubble length or crop moisture content can change where the optimum

setting will be.

IT IS UP TO THE OPERATOR TO DETERMINE WHAT THE BEST POSITION SHOULD

BE.

Figure 11

Figure 12

13

ADJUSTMENTS

Tine Pitch Adjustments

Figure 13 Figure 14

Figure 16

Figure 15

The tine pitch (the angle of the tine in relation to the tine arm) can be adjusted

by reversing the eccentric spacer washer. The spacer position in Figure 13 will

give the tine a less aggressive position as shown in Figure 14.

The spacer position shown in Figure 15 will give the tine a more aggressive

position as shown in Figure 16.

A more aggressive tine position will throw the hay higher.

14

Axle Adjustments

The angle of the axles can be adjusted to raise

or lower the whole machine. This will allow you

to tilt the tedder forward more and get a more

aggressive tedding action. The tedders are set

at the factory to run in the middle setting (shown

at right). To adjust to the higher position you will

need to pick the tedder up o the ground using

a hoist or a lift. With the tedder’s weight sup-

ported properly with blocks, remove the 1/2”

bolt, pull the axle forward to meet the second

hole, and reinsert bolt. Repeat the process for

all the axles. The setting hole “1” corresponds

to the most aggressive angle. Setting “3” is the

least aggressive angle.(Figure 17) Figure 17

DO NOT BEGIN OPERATION UNTIL ALL OF THE SAFETY WARNINGS HAVE

BEEN READ AND UNDERSTOOD!

Once all of the adjustments and initial set up instructions have been followed and the proper ad-

justments made, the tedder is ready to operate in the eld.

Connect the tedder PTO shaft to the tractor by pulling the spring collar back and sliding the shaft

yoke onto the 6 splined tractor PTO shaft. Slide the shaft forward until it stops and then pull back

slowly until the balls engage into the ball groove on the tractor shaft.

DO NOT RUN THE PTO UNLESS THE LOCKING BALLS ARE ENGAGED. THE SHAFT COULD

SLIDE OFF DURING OPERATION AND CAUSE SERIOUS INJURY OR DEATH.

The PTO speed should never exceed 540 rpm. Generally, 450 rpm and a 6 mph ground speed

is a comfortable operating setting. Crop conditions and eld conditions will ultimately determine

the settings for the tedder and the tractor.

GENERAL OPERATION

1

2

3

15

LUBRICATION AND MAINTENANCE

NEVER PERFORM ROUTINE MAINTENANCE, REPAIRS OR INSPECTIONS ON ANY PIECE

OF EQUIPMENT UNLESS THE TRACTOR IS SHUT OFF AND DISCONNECTED FROM THE

MACHINE.

IT IS ALWAYS BETTER TO WORK WITH ANOTHER PERSON WHEN MAINTAINING OR

SERVICING A PIECE OF EQUIPMENT. ACCIDENTS CAN BE PREVENTED AND HELP CAN

BE ATTAINED EASIER WHEN ANOTHER PERSON IS AVAILABLE TO HELP.

Gearbox Lubrication

The oil in the center gearbox should be drained out and replaced every year. Be-

fore Servicing, make sure that the tedder is on level ground and the wing tunnels

are level. The tilt cylinder will need to be adjusted. The purpose is for leveling is

for accuracy when using the check plug.Take out the Drain Plug and drain all of

the oil. When relling the gearbox use approximatly 64 oz of 80W-90 gear oil.

Remove the ll plug and the check plug. Then ll up until oil comes to the bottom

of the check plug hole. Then put all plugs back in place with pipe sealing teon

tape. Check the oil level periodically throughout the season to ensure that it re-

mains full at all times.

Be sure to properly dispose of any used

oil or grease! Do not pour directly onto the

ground!

Figure 18

OIL FILL PLUG

OIL DRAIN PLUG

CHECK PLUG

16

Figure 19

The rotor gearboxes (Figure 19) have been

packed with grease at the factory and should not

need to be maintained. However, they should

be checked before each season to make sure

the gears are still coated with a lm of grease. If

additional grease is needed, use several ounc-

es of NLGI #0 gear grease.

All of the pivot points have a grease

tting and a bronze bushing. This

should always be visibly wet with

grease. Grease as needed.

General Lubrication

When a grease point has specic hourly frequency, 1 full pump each time should

be sucient lubrication. Always use a NLGI#2 grease that is rated for high tem-

peratures commonly found in a bearing.

The cylinder nut should always be vi-

sually wet with grease. Grease as

needed.

Figure 20

Figure 21

LUBRICATION AND MAINTENANCE

17

The radial pin clutch on the primary

driveline should be greased every 50

hours. Do not overgrease the radial

pin clutch.

PTO Shaft Lubrication

Figure 22

Figure 23

Grease the CV Joint (part

that connects at tractor)

every 50 Hours (3 loca-

tions)

18

The plastic PTO shielding

should be lubricated at all times.

If the shield feels tight when it is

extended and retracted then lu-

bricate as necessary.

The center cross in all of the

PTO yokes should be greased

every 50 hours.

Figure 24

Figure 25

LUBRICATION AND MAINTENANCE

Table of contents

Other Skibo Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions