4

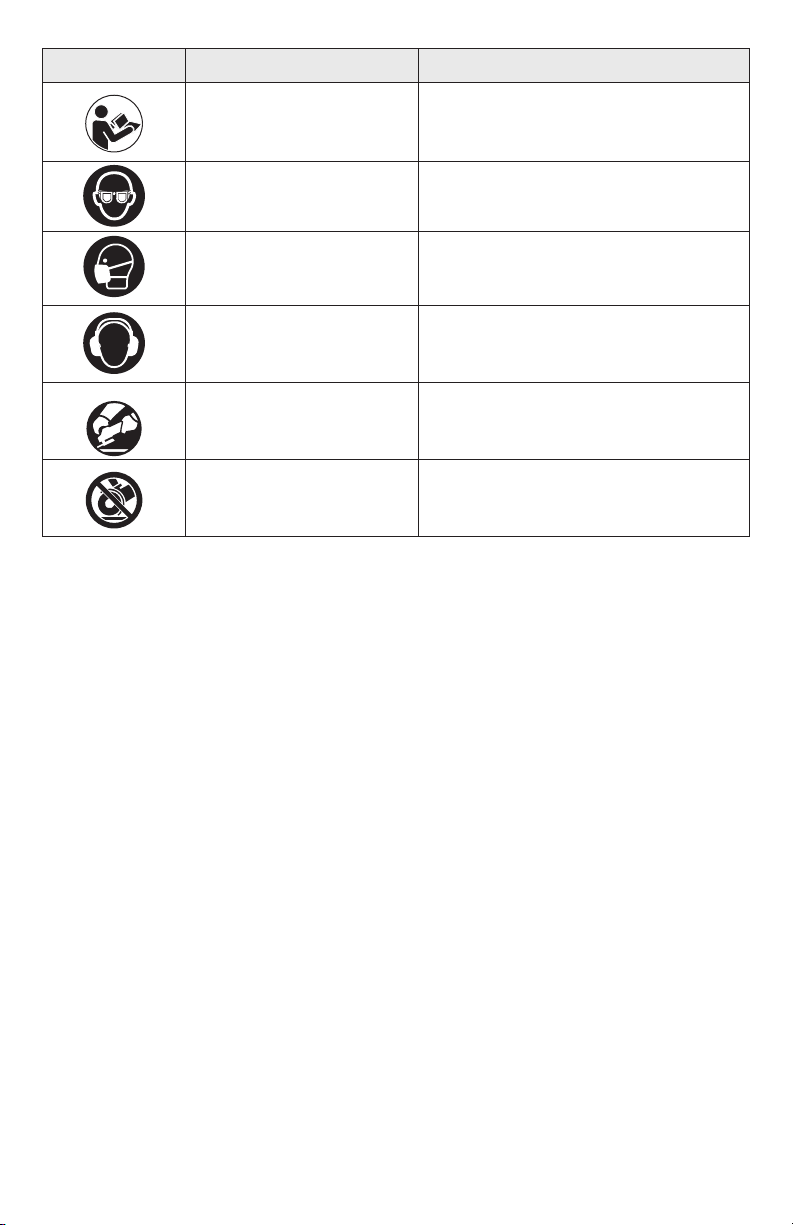

Protect your lungs. Wear a face or dust mask if the cutting operation is dusty.

Protect your hearing. Wear hearing protection during extended periods of operation.

Blade coasts after being turned off. Be mindful of the time it takes for the blade to come to

a complete stop.

Never use in an explosive atmosphere. Normal sparking of the motor could ignite fumes.

Inspect tool cords periodically. If damaged, have them repaired by a qualied service

technician at an authorized service facility.

Inspect extension cords periodically and replace if damaged.

Ground all tools. If tool is equipped with three-prong plug, it should be plugged into a

three-hole electrical receptacle. Check with a qualied electrician or service personnel if the

grounding instructions are not completely understood or if in doubt as to whether the tool is

properly grounded.

Use only correct electrical devices: 3-wire extension cords that have 3-prong grounding

plugs and 3-pole receptacles that accept the tool’s plug.

Do not modify the plug provided. If it will not t the outlet, have the proper outlet installed by

a qualied electrician.

Keep tool dry, clean, and free from oil and grease. Always use a clean cloth when cleaning.

Never use brake uids, gasoline, petroleum-based products, or any solvents to clean tool.

Stay alert and exercise control. Watch what you are doing and use common sense. Do not

operate tool when you are tired. Do not rush.

Do not use tool if switch does not turn on and off. Have defective switches replaced by an

authorized service center.

Before making a cut, be sure all adjustments are secure.

Be sure blade path is free of nails. Inspect and remove all nails from lumber before cutting.

Never touch blade or other moving parts during use.

Never start a tool when any rotating component is in contact with the workpiece.

Do not operate a tool while under the influence of drugs, alcohol, or any medication.

When servicing use only identical replacement parts. Use of any other parts may create a

hazard or cause product damage.

Use only recommended accessories listed in this manual. Use of accessories that are not

listed may cause the risk of personal injury.

Double check all setups. Make sure blade is tight and not making contact with saw or

workpiece before connecting to power supply.

SPECIFIC SAFETY RULES

To avoid injury from unexpected movement, make sure the saw is on a rm, level surface,

properly secured to prevent rocking. Make sure there is adequate space for operations. Bolt

the saw to a support surface to prevent slipping or sliding during operation.

Turn off and unplug the saw before moving it.

Use the correct size and style of blade.

Make sure the blade teeth point down and toward the table.

Blade guide, supports, bearings, and blade tension must be properly adjusted to avoid

accidental blade contact and to minimize blade breakage. To maximize blade support, always

adjust the upper blade guide and blade guard so that it barely clears the workpiece.

Use extra caution with very large, very small, or awkward workpieces.

Use extra supports to prevent workpieces from sliding off the table top.