19

SKOPE ProSpec Upright Series

Electronic Controller

Service Manual

17

Control probe failure

A critical system sensor has

failed and the cabinet can no

longer operate.

Cartridge swap is not required.

• Control probe or circuit • Either:

• Measure the probe resistance to make sure it is

within the range.

• Compare the probe’s temperature with the

known temperature, using an external trusted

thermometer.

• Replace the probe if required.

• Controller • If you have replaced the probe and it is still

reading incorrectly, replace the controller.

18

Electrical over-current

protection activated

The compressor was drawing

too much current and has shut

down to prevent permanent

damage.

• Blocked condenser • Remove and clean the condenser filter.

• Check that the condenser is free of debris.

• If the coil is dirty, clean it with a vacuum cleaner or

soft brush.

• Product blocking cabinet airflow • Check if the return air grille is covered by product.

If so, move the product from the grille and

observe.

• Compressor is overloaded from

excess door openings or

ambient temperature

• Ensure that the cabinet is operating in its climate

class.

• Compressor or gas leak • Swap the cartridge.

19

Failed to reach set

temperature

The refrigeration system has

been operating continuously for

a long period without reaching

the set temperature.

• Blocked condenser • Remove and clean the condenser filter.

• Check that the condenser is free of debris.

• If the coil is dirty, clean it with a vacuum cleaner or

soft brush.

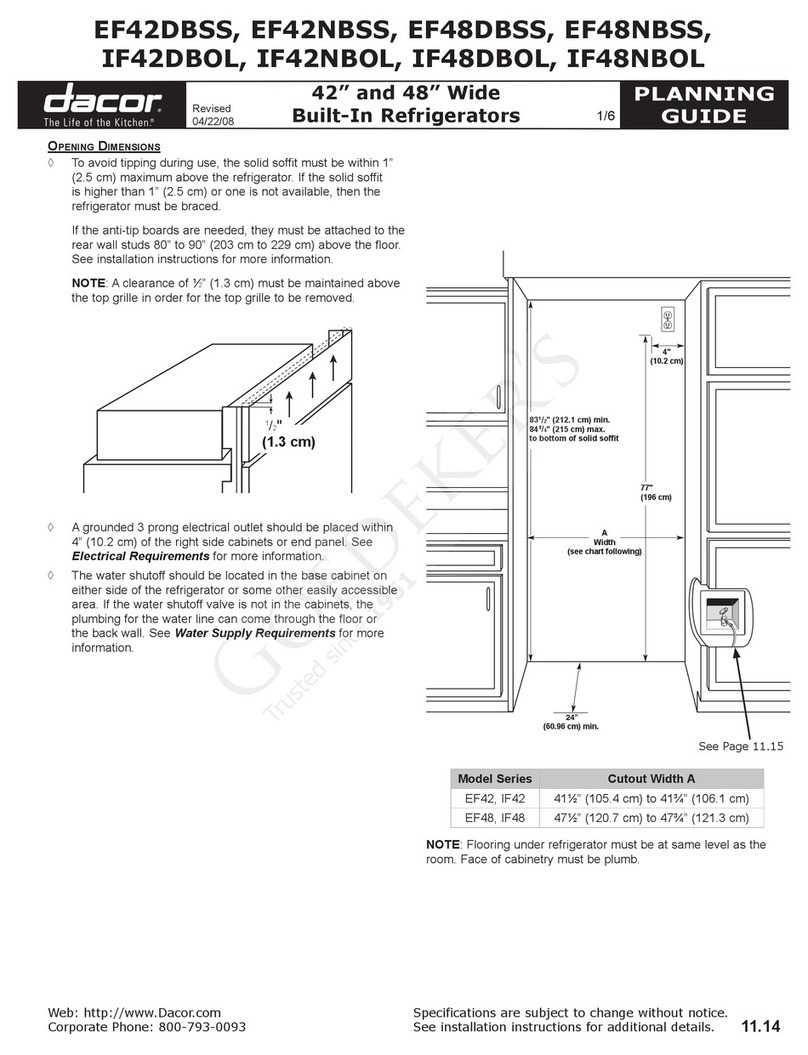

• Poor installation or ventilation • Check the installation guidelines.

• Frozen or blocked evaporator

coil

• De-ice the coil and check the that evaporator fan

motor is working.

• Check the defrost cycle and that the defrost probe

is working correctly.

• Cartridge, cabinet, or door

gasket leaking

• Check that the gasket is intact and not broken and

leaking. If required, replace the door gasket.

• Ensure the installation levers are lifting the

cartridge up onto the case correctly.

• Product blocking cabinet airflow • Check if the return air grille is covered by product.

If so, move the product from the grille and

observe.

• Compressor is overloaded from

excess door openings or

ambient temperature

• Ensure that the cabinet is operating in its climate

class.

• Condenser or evaporator fan

motor or blade

• Inspect the condenser and evaporator fans safely,

and replace if faulty.

• Controller • The controller may be reading incorrectly and

need replacing.

• Compressor or gas leak • Swap the cartridge.

20

Over-cooling product

The internal temperature is too

low. The system has temporarily

shut down until the temperature

has returned to normal.

• Set temperature has been

raised by a large amount

1. Confirm if really too cold.

2. Change parameters accordingly.

• Controller • The controller may be reading incorrectly and

need replacing.

22 Evaporator fan over-current

protection

The current supplied to the

evaporator fan motor is too high.

• Faulty fan motor • Replace the fan motor.

• Fan blade fault (imbalance,

debris, blockage)

• Visually inspect the fan blades and replace if

faulty.

23

Condenser fan over-current

protection

The current supplied to the

condenser fan motor is too high.

• Faulty fan motor • Replace fan motor.

• Fan blade fault (imbalance,

debris, blockage)

• If the fan motor is working correctly, update the

controller firmware to the latest version.

• Controller • The controller may be reading incorrectly and

need replacing.

Table 5: Alarms (continued)

Code Description Possible root cause Action