Sky Climber SKY PI User manual

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 1 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

SKY PI

USER MANUAL

All persons operating this equipment must read and completely understand this manual.

Any operation in violation of these instructions is at the operator’s own risk.

Keep this manual with the equipment at all times.

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 2 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

Table of contents

1.

Purpose, limitations and condition of use. ......................................................................................... 3

2.

General view of the basket ................................................................................................................ 3

3.

Nameplate basket.............................................................................................................................. 5

4.

Basket specifications ......................................................................................................................... 5

4.1.

Basket ................................................................................................................................................ 5

4.2.

Hoist: Compact S............................................................................................................................... 5

4.3.

Safety device: Sky grip ...................................................................................................................... 5

5.

Central control box............................................................................................................................. 6

5.1.

installation of the CCB ....................................................................................................................... 6

5.2.

Maintenance of the CCB.................................................................................................................... 7

6.

Movements of basket, control functions. ........................................................................................... 8

7.

SKY GRIP particularities.................................................................................................................... 9

8.

No power control descent .................................................................................................................. 9

9.

Overload/Underload safety device .................................................................................................. 10

10.

Top limit and ultimate top limit ......................................................................................................... 11

11.

Bottom limit ...................................................................................................................................... 12

12.

Twin drum wire winders ................................................................................................................... 13

12.1.

Installation of the twin drum wire winders........................................................................................ 13

12.2.

Maintenance of the twin drum wire winders .................................................................................... 14

13.

Additional Safety guidelines ............................................................................................................ 15

14.

Hoist................................................................................................................................................. 15

15.

Daily Check list ................................................................................................................................ 15

16.

Maintenance of the BMU ................................................................................................................. 15

16.1.

Routine maintenance....................................................................................................................... 15

16.2.

Annual maintenance or every 50 running hours:............................................................................. 15

Appendix

A.

SKY CLIMBER general users manual V2.0 .................................................................................... 15

B.

SKY CLIMBER SKY GRIP assembly manual ................................................................................. 15

C.

SKY CLIMBER SKY GRIP users manual........................................................................................ 15

D.

SKY CLIMBER Assembly manual compact S ................................................................................. 15

E.

SKY CLIMBER Wiring Diagram - Central Control Unit.................................................................... 15

F.

SKY CLIMBER Assembly manual safety devices for Compact / CX .............................................. 15

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 3 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

1. Purpose, limitations and condition of use.

This SAE (Suspended Access Equipment) is a BMU (Building maintenance Unit) to be permanently installed

and dedicated to a specific building or structure and to be used for planned for routine inspection, cleaning and

maintenance of the particular building.

The power for the Permanent Installation ( PI ) is provided with a power supply cable.

The power in the PI is fused and has an earth leakage detection of 30mA.

Wind conditions: Max 12m/s – Rated load: Max 240 kg

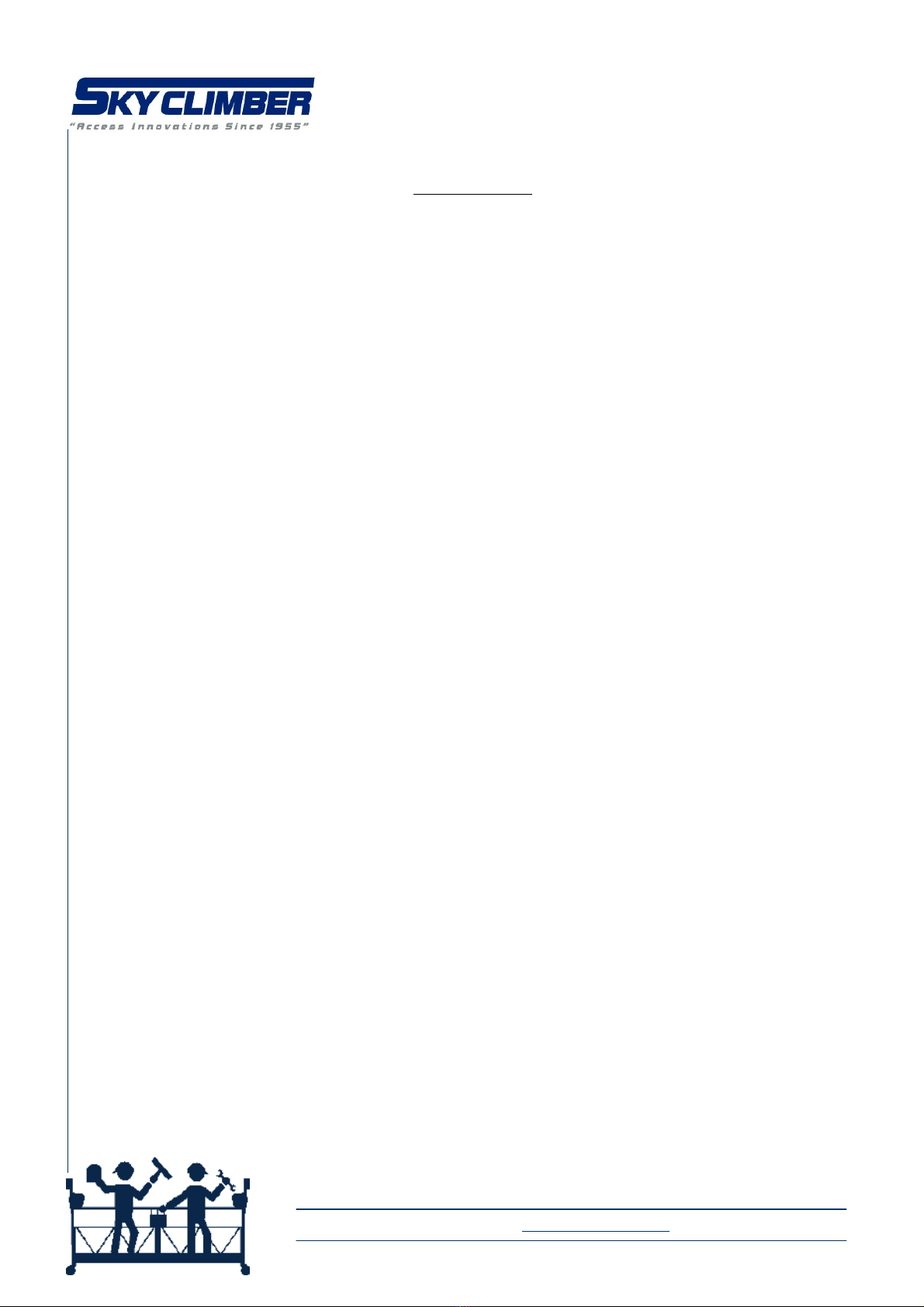

2. General view of the basket

Figure 1: General view of the PI

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 4 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

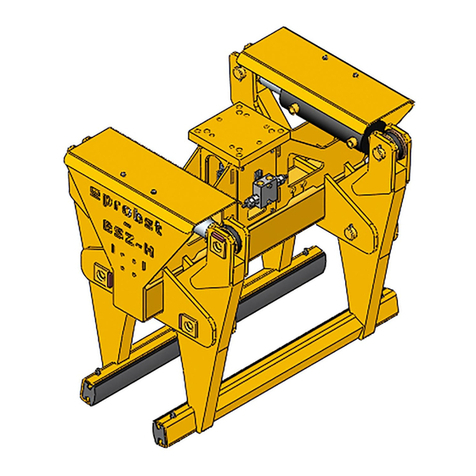

Figure 2: General dimensions and description of main parts of the PI

1 Safety rope 11 Overload/underload safety device

2 Suspension rope 12 Eye bolt

3 Sky Grip, See Sky Grip Manual, appendix C 13 Electric supply cable collection bin

4 Compact Hoist, see appendix D 14 Twin drum Wire Winder

5 Wire winder protection 15 Castor wheel

6 Central Control Box 16 Striker plate

7 Cradle 17 Handwheel

8 Bottom limit trip bar 18 No power descent lever

9 Top limit switch and ultimate top limit switch 19 Foot step

10

Steel Stirrup 20 Wall roller

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 5 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

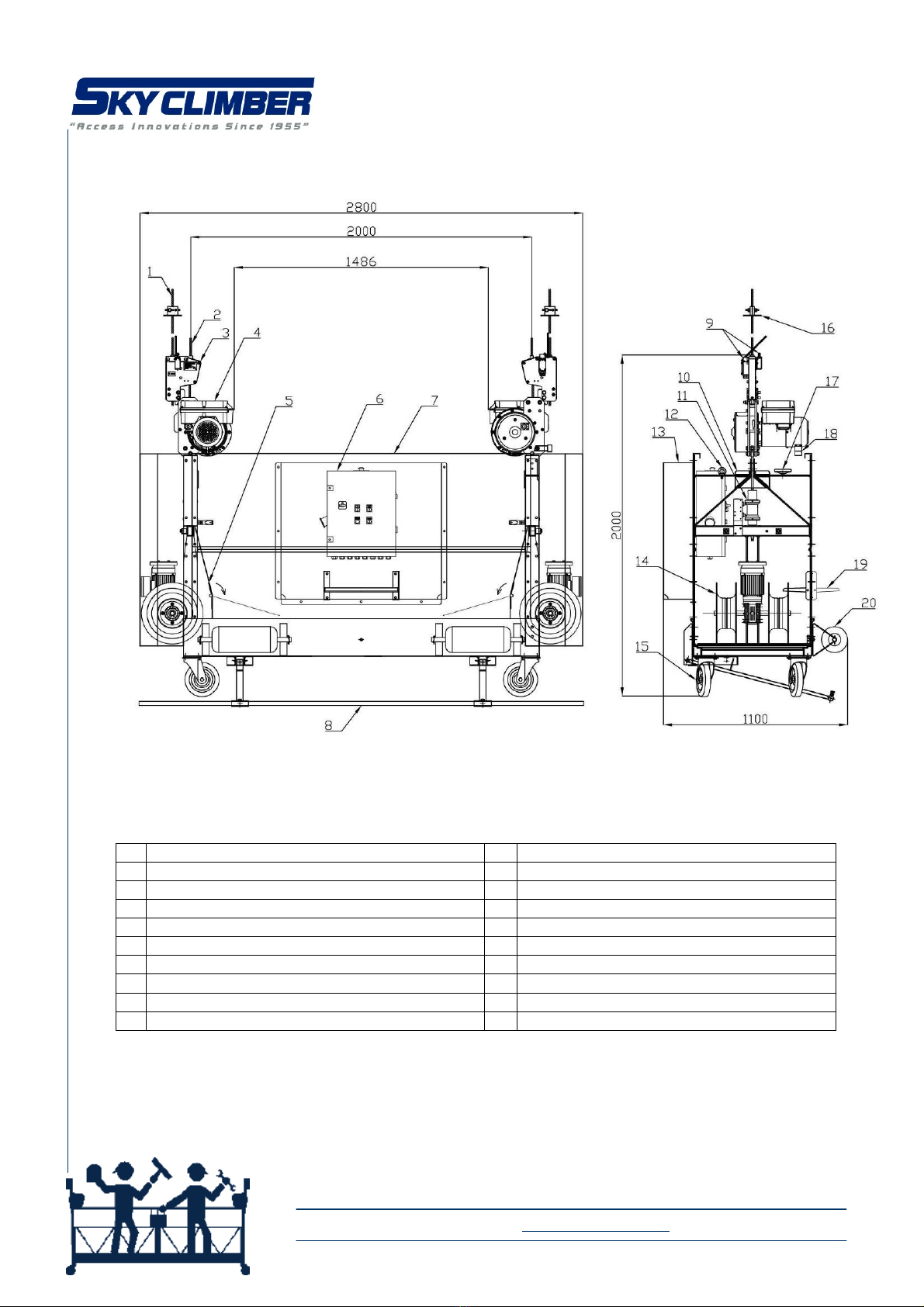

3. Nameplate basket

The next figure shows an example of the nameplate for the PI.

Figure 3: Example of the nameplate for the PI

4. Basket specifications

4.1. Basket

The rated load of the Sky PI is 240 kg

4.2. Hoist: Compact S Optional

oMotor: 50Hz / 3 ~ 60Hz / 3 ~ 50Hz / 1~ 60Hz / 1~

oVoltage: 380-415 V 380-415V 220-240V 220-240V

oCurrent: 2,4 A 1,8A 3,6 A 5,4 A

oPower: 0,55 kW 0,88 kW 0,55 kW 0,74 kW

oMotor speed: 1400 rpm 1690 rpm 1420 rpm 1700 rpm

oWeight: 35 kg 36 kg 35 kg 36 kg

oWorking load limit: 400 kg 400 kg 400 kg 400 kg

oSteel Wire Rope: 8 mm 8mm 8mm 8mm

oClimbing speed: 8,4 m/min 10,6m/min 8,5 m/min 10,6 m/min

4.3. Safety device: Sky grip Optional: Sky lock (not CE)

oSteel Wire Rope: 8 mm 8 mm

oActivation: 10°inclination see also: SKY LOCK manual 56PMM003

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 6 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

5. Central control box

oSupply voltage: 400V / 50Hz / 3 phase

oControl voltage: 24V

CCB Optional:

oSupply voltage: 220V – 380V / 50Hz – 60Hz / 3 phase – 1 phase

oControl voltage: 24V – (220V not CE)

oTrolleys control

5.1. installation of the CCB

The installation needs to be done by a competent electrician.

oThe central control box is installed in the middle of the PI at the factory.

oRecheck that ale leads are positioned so that leads cannot be damage by normal use. Specially

take attention close to steel wire rope and wire winder.

oConnect the supply cable and make sure that the supply cable is in the compartment next to the

central control box.

oSwitch the emergency push button on top of the control box OFF by turning it (rotate red button to

the right).

oCheck that the general contactor is activated, if not you must do the following:

Check that the plugs of the hoists are connected

Check the emergency button, you can reset it by turning it.

Check the plugs of the UTL and OL/UL device

Check if the phase sequence is wrong: switch two phases in your power supply.

oTest Emergency Push Button: Operate the basket in both directions, make sure the basket goes

UP when pushing the "UP" button, and hit the emergency push button in each direction. The PI

stops moving. To regain movement you need to reset the emergency push button by turning it.

oTest Selector Switch: The Selector Switch has 3 positions. It operates the first hoist (I), both hoists

(I+II) or the second hoist (II). Try out each position and check the reaction.

oTest anti-tilting device: when suspended operate one side with the selector switch and tilt the PI 5°

at the left side, when operating both of the hoists "UP": the 'left' hoist should stop moving up.

Repeat test for the opposite side and also in the "DOWN" mode.

oAnti-Tilting Device. The central control box is also fitted with an ANTI TILTING DEVICE. The

purpose of this device is to avoid the cradle going out of level. For instance when the cradle is

being lowered it if tilts by more than 5 degrees the lower hoist will stop allowing the other which

continues to operate and return the cradle to its correct position. When the cradle is being

operated in the up direction if it goes out of level by more than 5 degrees the upper hoist will stop

allowing the lower hoist to continue operating and return the cradle to its correct position. It is

therefore important to have the central control box mounted correctly on the cradle. If this has not

been done right, the anti-tilting device will not work properly.

oThe CCB is now ready to use.

The wiring diagram of central control box is included inside and should always remain there.

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 7 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

After everything has been connected and tested correctly

by a competent person, the central control box must be used as follows:

RAISING AND LOWERING

On the front panel there are two push buttons: a button to raise and a button to lower the basket. For

instance, to lower the basket one has to push the down button until the basket reaches the required height.

The buttons may never be blocked in an active (pushed inwards) position.

The selector switch has to point to the middle option: I+II. Both hoists will then be operated at the same

time.

EMERGENCY SITUATION

The emergency push button on top of the control box is useful to switch the complete installation off in case

of an EMERGENCY. The emergency push button can be reset by turning it.

On the front panel the selector switch can be used to operate either the left or right hoist only. When

dereeving the hoist the selector switch must be turned to I (first hoist) or II (second hoist) depending on the

hoist being dereeved. Use the push button (DOWN) to activate the dereeving.

5.2. Maintenance of the CCB

PERIODIC INSPECTIONS:

Only a competent person may carry out the maintenance.

oPull out the main power supply before touching the wiring. The wiring up to the emergency button

can still be under tension.

oEach central control box and hoist is delivered with a wiring diagram (in a plastic bag) (appendix

E). Preserve this in the central control box and hoist in order to avoid needless searching.

oThe box: check on water penetration and possible corrosion on the contacts.

oThe emergency push button: check if the screws connecting the emergency button on the box are

still fixed.

oThe labels: check if all labels and indications are present and legible.

oThe cables: check if there are no external damages on the outer jacket and/or isolation in order to

avoid short-circuit.

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 8 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

6. Movements of basket, control functions.

In the next figure all the movements of the basket are indicated with the arrows. So there can be moved UP

and DOWN.

Figure 4: Movements of the basket and front view of central control box

CCB Functions:

-Main power switch

-To stop the basket in case of emergency: Press the emergency button

-To go UP: Push the up arrow button

-To go DOWN: Push the down arrow button

-To power the left hoist: turn the selector switch left

-To power the right hoist: turn the selector switch right

-Bottom limit override: to travel downwards while the trip bar is activated

-Test button: to test if the safety circuit still works (signal by buzzer)

-Buzzer: sounds when the PI goes in to OL/UL, when the UTL is switched, or when there is a plug

disconnected

-Inside: hour counter

Important instructions:

-Make sure during travelling that there are no obstacles.

-Constantly take special attention at the supply cable! Check that the supply cable is always free

hanging and does not hook anywhere, also underneath the basket while going down.

-When the basket is stationary to perform tasks the main power switch should be OFF.

The basket is electrically automatic levelled at 5°. No separate control of the hoist is needed

In order to be able to reeve the ropes into the wire winders, the hoists can be controlled independently. Here

for turn the selector switch left or right to control the corresponding hoist.

If the SKY GRIPS safety device blocks the down movement of the lower hoist. Just push to UP button for a

while, the basket will level automatically and the SKY GRIP will be reset automatically.

The hour counter indicates the downward movement only. For maintenance purposes multiply the hours on

the counter with 2 to have the total runtime for the hoists.

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 9 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

7. SKY GRIP particularities

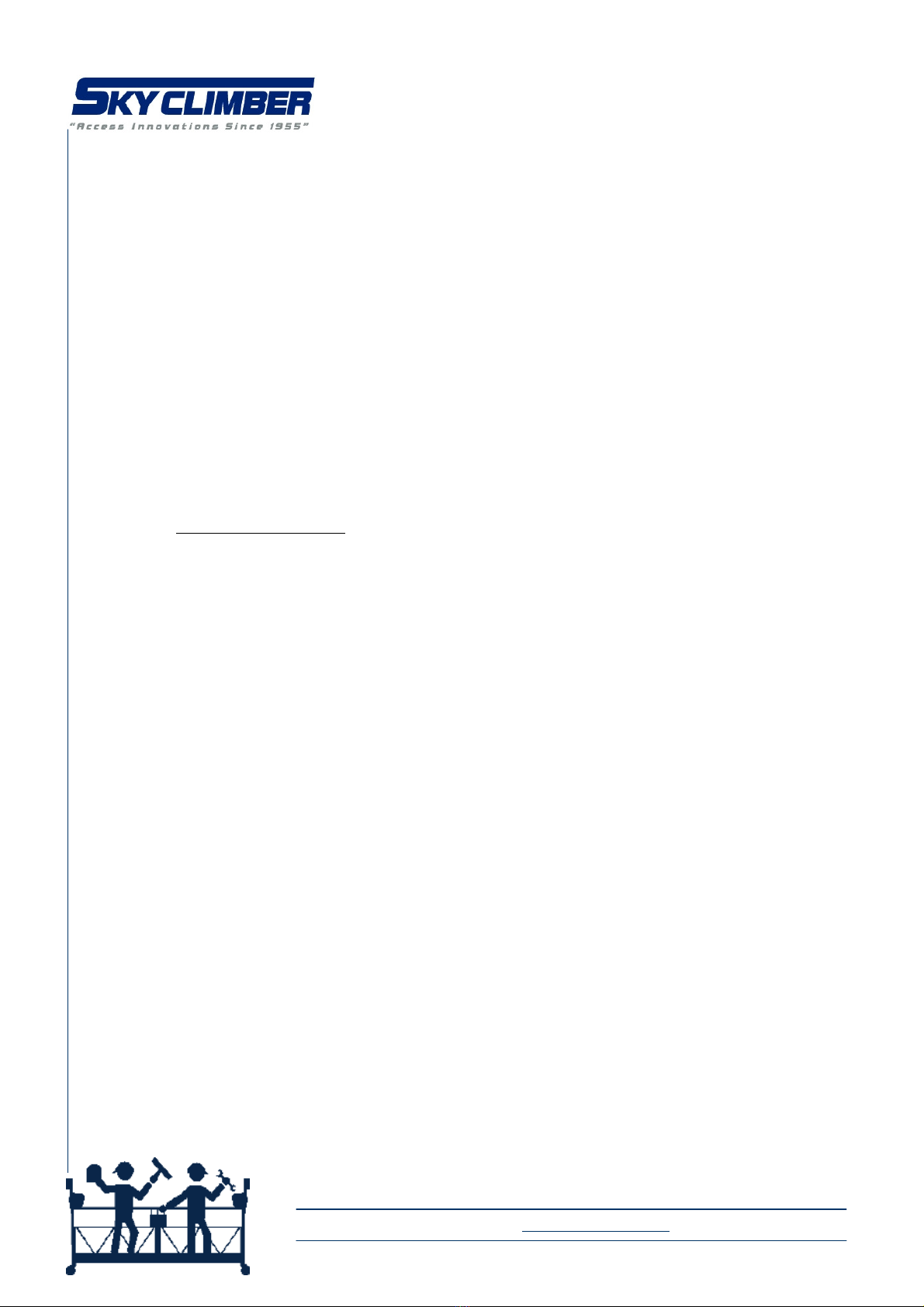

Figure 5: SKY GRIP mounted

The SKY GRIP mechanical safety device prevents the basket going down in case of inclined basket. The SKY

GRIP acts on the safety rope.

If the SKY GRIP safety device blocks the down movement of the lower hoist. Just push to UP button for a

while, the basket will level automatically and the SKY GRIP will reset automatically.

The SKY GRIP also blocks the down movement in case of slack rope of the suspension rope.

In case of slack rope due to hitting an obstacle or reaching ground level, the hoist is also stopped electrically

by the under load safety device and the bottom limit trip bar.

This is a global explanation of the SKY GRIP. In appendix C you can find the detailed version of the user

manual.

8. No power control descent

Also in case of no power control descent by manual lifting the brake lever on the motor, the SKY GRIP acts

on the secondary rope in case of inclined basket. In this case lower the other hoist so that basket is levelled

again and the SKY GRIP is reset automatically. If it occurs that the SKY GRIP is not reset automatically,

the hand wheel is to be used to take away the load on the safety rope.

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 10 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

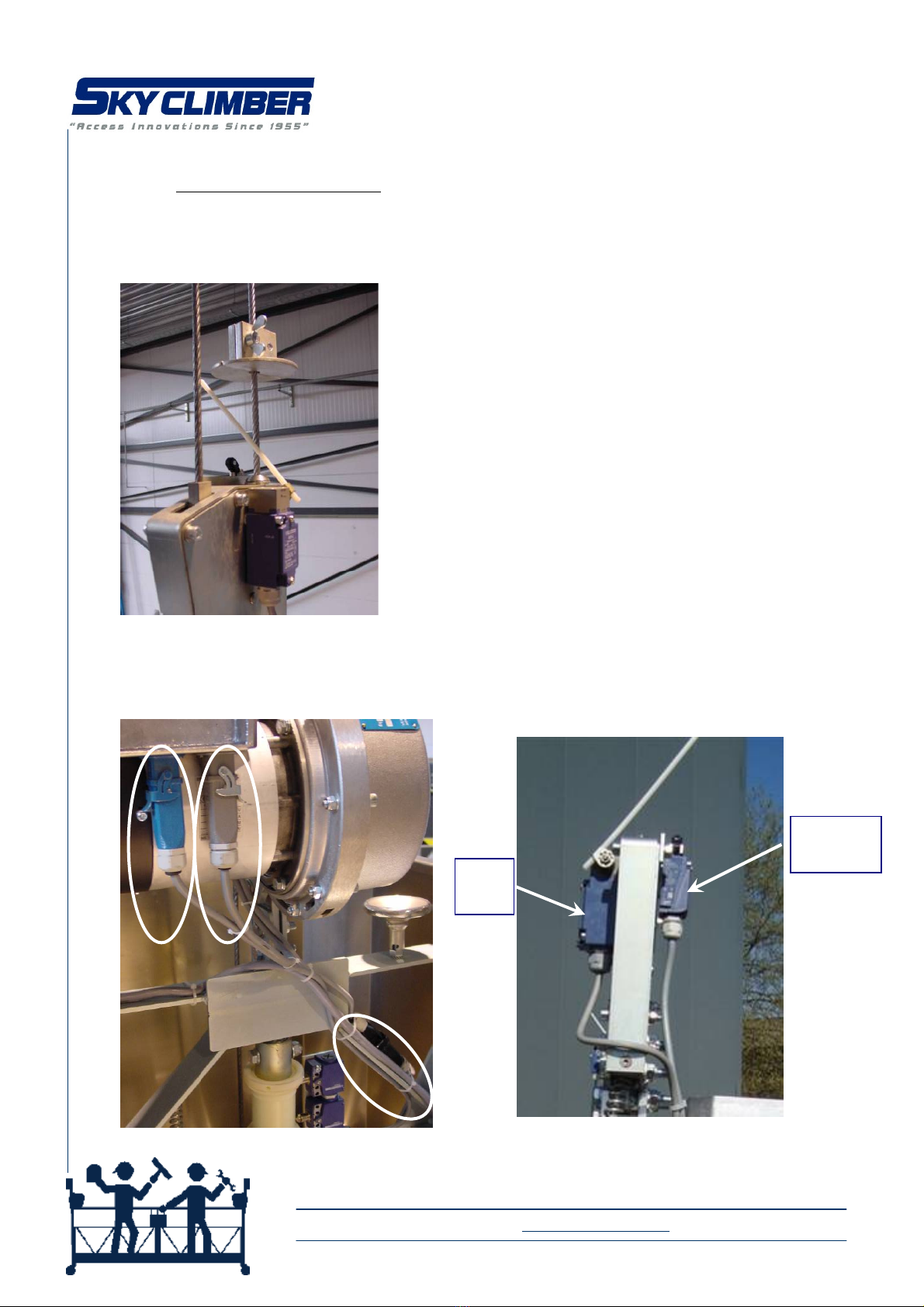

9. Overload/Underload safety device

The overload safety device detects overloaded basket and will stop up and down movement.

The overload is to be set at 125% of the rated load.

This means: 240x1.25 = 300kg.

The setting has to be done with by turning the white rings on the bus. Lock them with the socket screw.

The under load stops hoist going down when there is a no load condition. Check the adjustment by going

down up to ground level. The hoist should stop running further.

Figure 6: Overload/underload safety device Figure 7: Turning of the Overload/underload safety device

In the Appendix F There is an exploded view of the overload/underload safety device.

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 11 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

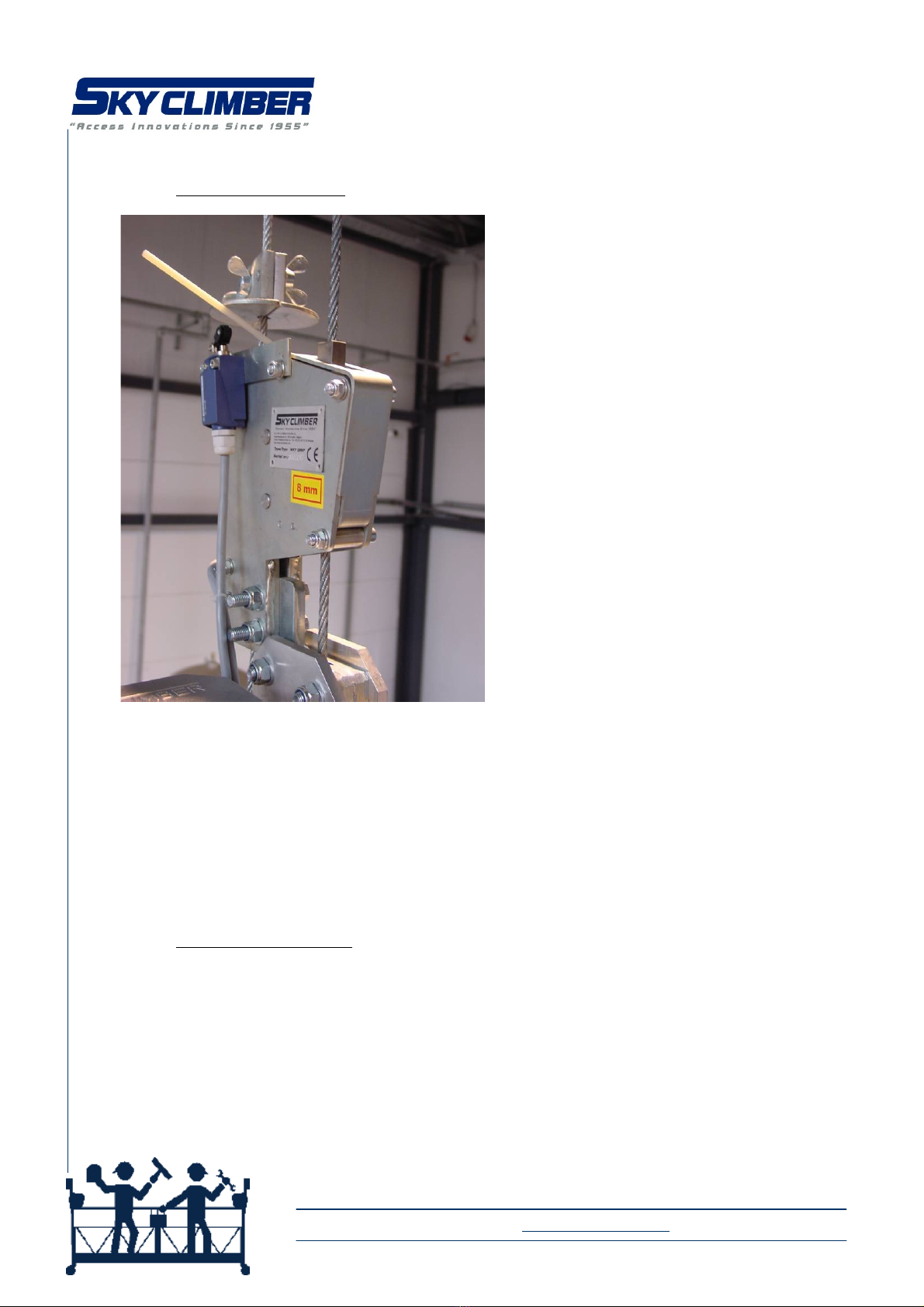

10. Top limit and ultimate top limit

The top limit stops the up movement of the both hoists on the PI. The ultimate top limit stops all movement of

the PI. To regain mobility with the PI it must be lowered with the no power control descent ( 8. ). Mount the

striker plates on both safety ropes as illustrated on the next photo.

Figure 8: striker plate

There are 3 connectors with 4 pin for each hoist. The black one is for the top limit and goes to the central

control box. The blue one is for the ultimate top limit and goes to the hoist itself. The grey one is for the OL/UL

device and goes to the hoist.

Figure 9: picture of the electrobox with plugs Figure 10: picture TL and UTL

Ultimate

Top limit

Top

Limit

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 12 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

11. Bottom limit

The PI is provided with a bottom limit that stops the downward movement when bottom trip bar hits the ground

or any object.

Figure 11: bottom limit trip bar and wall rollers

To manually override the bottom limit push the bottom limit override button on the central control box together

with the push button down.

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 13 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

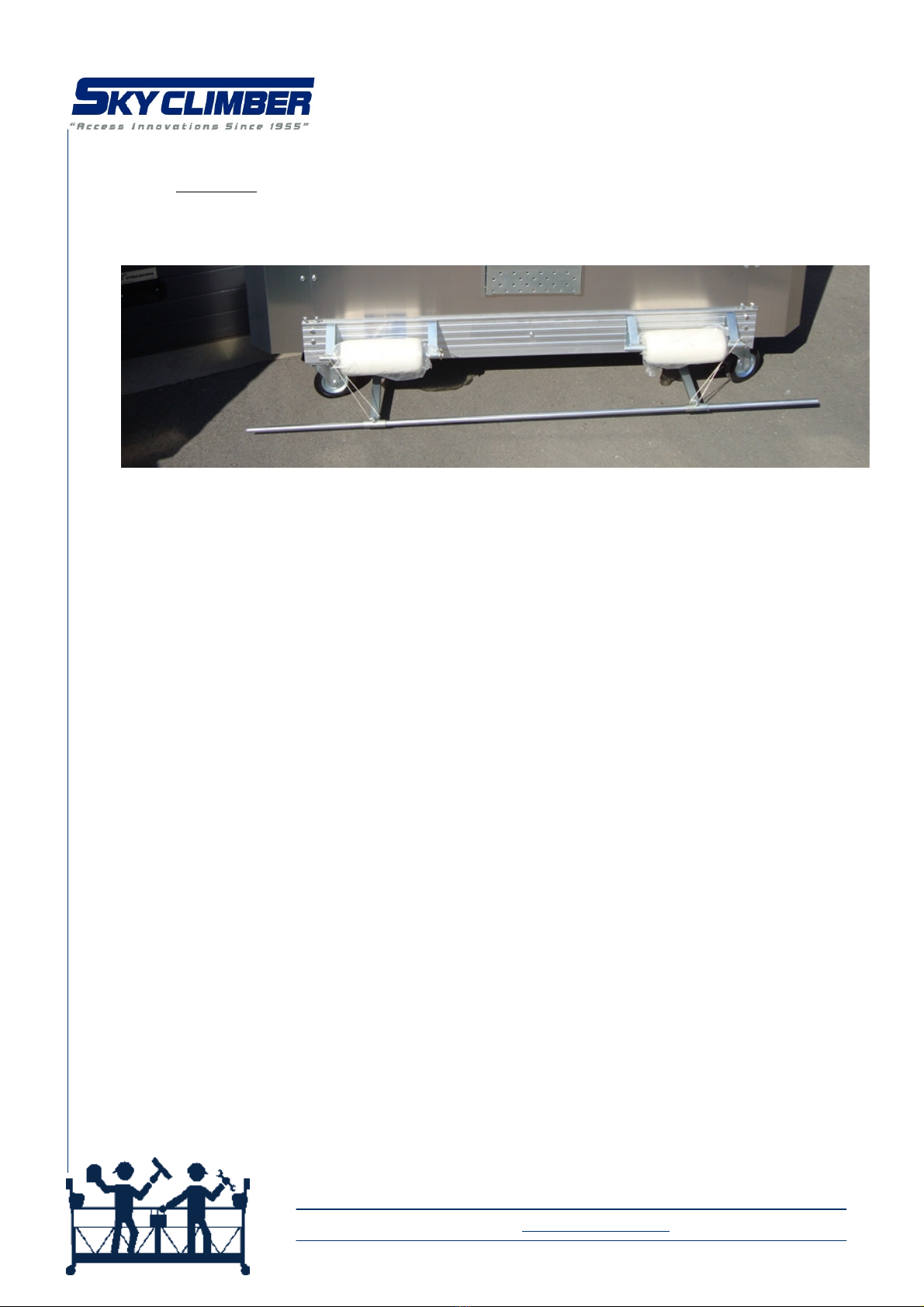

12. Twin drum wire winders

Figure 12: Picture of wire winder

Twin drum wire winders are being used to spool the primary and secondary steel wire rope on a drum. The

wire winder motor is only being activated when the basket is moved upwards. During the basket descent, the

primary and secondary steel wire ropes are un-spooled from the drums that are restraint by a friction clutch.

The Friction clutch has been pre-set at the factory. After a reasonable operation time the friction clutches may

wear out. This is indicated when the wire winder drums are not coiling the steel wire rope really tight on the

drums. During descent the steel wires ropes are being de-coiled too easily from their drums.

12.1. Installation of the twin drum wire winders

Prior to operation, the primary and secondary steel wire ropes have to be reeved onto the wire winders. In

order to do this, proceed as follows:

Figure 13: Example of wired wire winders Figure 14: Picture of empty wire winder

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 14 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

1. Prior to inserting the steel wire ropes into the drums, verify that the rotation direction of the drums is

correct so that cable will wind up as indicated on figure 13.

2. First insert the Secondary steel wire rope. (This is the rope that goes through the Sky Grip). Insert the

Steel wire rope tip approx. 15 cm (6 inches) through the cut-out hole in the drum underneath the Sky Grip

as marked in figure 14.

3. Give an "up" command and coil the secondary steel wire rope on the drum. Continue until there is no

more slack in the secondary steel wire rope.

4. Repeat the above operation on the opposite basket side (given that the basket is equipped with two wire

winders).

5. Insert the primary steel wire rope through the hoist while pushing the "UP" command button. The wire

winders will rotate while you do this, but the friction clutch will slip and thus prevent pulling on the

secondary rope that has already been inserted. As the primary steel wire rope reaches the opening in the

primary wire winder drum, stop the upward movement and insert the primary steel wire rope through the

cut-out hole of the primary wire winder drum over a distance of approx. 15 cm (6 inches).

6. Continue with the "up"-command until the primary steel wire rope is fully tensioned and almost lifts the

basket of the ground.

7. Repeat the above operation on the opposite basket side (given that the basket is equipped with two wire

winders).

12.2. Maintenance of the twin drum wire winders

Wire winders do not require any lubrication. Take care in keeping grease and oil away from the friction

clutches.

Clutch re-tightening procedure:

1. Move the basket to ground level.

2. Use a screwdriver to unlock the wire winder clutch adjustment nuts. This is done by pushing the metal lid

that locks these nuts backwards. With only two revolutions of steel wire rope around the drums, pull on the

steel wire rope. The pulling force required is approx. 8 Kg (80 N or 16 lbs).

3. Use an open-end wrench (62mm) in order to tighten the wire winder clutch adjustment nuts. Rotating the

clutch adjustment nut clockwise does this.

4. Re-check the required steel wire rope pulling force.

5. Repeat until the steel wire rope pulling force is within the above specification.

6. Once the pulling force is within the specification, use a screwdriver to lock the wire winder clutch

adjustment nuts. Pushing the metal lid that locks these nuts forward against the nut side does this.

WARNING

DO NOT set the wire winder clutch too tight. This will cause the wire winder motors to overheat and damage

them.

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 15 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

13. Additional Safety guidelines

Read and fully understand the general SKY CLIMBER users manual V2.0 in appendix A.

Read and fully understand the SKY CLIMBER SKY GRIP user’s manual in appendix C.

The steel wire ropes may not be touched while the basket is moving up and down.

While moving, arms and legs should be inside the basket at all times.

While moving the protection hinges for the wire winders should be closed

Long hair should be retained with a hair band.

The striker plates should not be moved on the steel wire rope.

When the basket is unused unplug the power supply connector.

14. Hoist

In appendix A there is a full user’s manual about the use of the Sky Climber hoists.

In appendix D there is a complete exploded view of the hoists.

15. Daily Check list:

These test must be carried out before using the platform:

Visually inspect platform for damaged, loose or missing parts.

Check the controls of the CCB. (see chapter ‘control functions’)

Double function check E-button.

Check tension of wire winder (see chapter ‘wire winder’)

Check Sky Grip. (see manual Sky Grip)

Visually inspect supply cable.

16. Maintenance of the BMU:

16.1. Routine maintenance: (every three months under normal working conditions)

Carry out daily check list.

Check the CCB as described in chapter (maintenance CCB)

Record the hour meter.

Write a report and give copy to the owner.

16.2. Annual maintenance or every 50 running hours:

Annual Maintenance may only be performed by qualified persons authorised by Sky Climber.

Appendix:

A. SKY CLIMBER general users manual V2.0

B. SKY CLIMBER SKY GRIP assembly manual

C. SKY CLIMBER SKY GRIP users manual

D. SKY CLIMBER Assembly manual compact S

E. SKY CLIMBER Wiring Diagram - Central Control Unit

F. SKY CLIMBER Assembly manual safety devices for Compact / CX

N.V. SKY CLIMBER EUROPE S.A. – Nijverheidsstraat 23 - 2570 Duffel - Belgium

Email: info@skyclimber.be - Tel: +32 (0)3 887 81 20 - Fax: +32 (0)3 887 09 94

KBC Bank 733 0170133 25 - BTW: BE 0407 249 055 - HRA 185.015

Website: http://www.skyclimber.com

SKY CLIMBER LLC - 1501 Rock Mountain Blvd. - Stone Mountain - Georgia 30083 - U.S.A

Email: info@skyclimber.com - Tel: +1 770 939 7705 - Fax: +1 770 493 7392

Page 16 of 16

Sky Climber ref.: 34UME001

Mod.: A Date: 28/10/2009

REMARKS

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

..............................................................................................................................................................

Table of contents

Other Sky Climber Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Manitowoc

Manitowoc MLC650 Service maintenance manual

Newstripe

Newstripe RollMaster 5000 product manual

Greenlee

Greenlee 6036 Triple Sheave instruction manual

Bannon

Bannon 57502 owner's manual

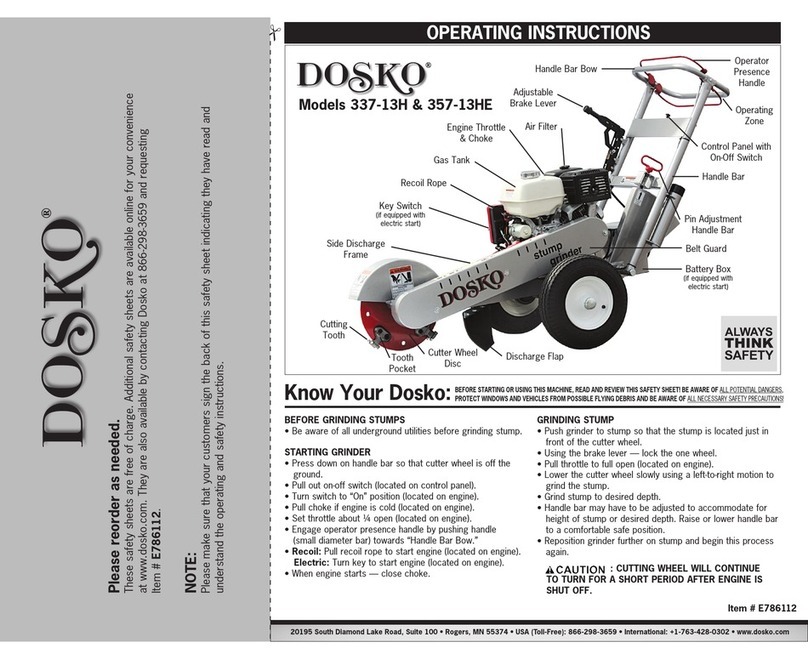

DOSKO

DOSKO 337-13H operating instructions

STEINEL PROFESSIONAL

STEINEL PROFESSIONAL HG 2120 E Translation of the original operating instructions