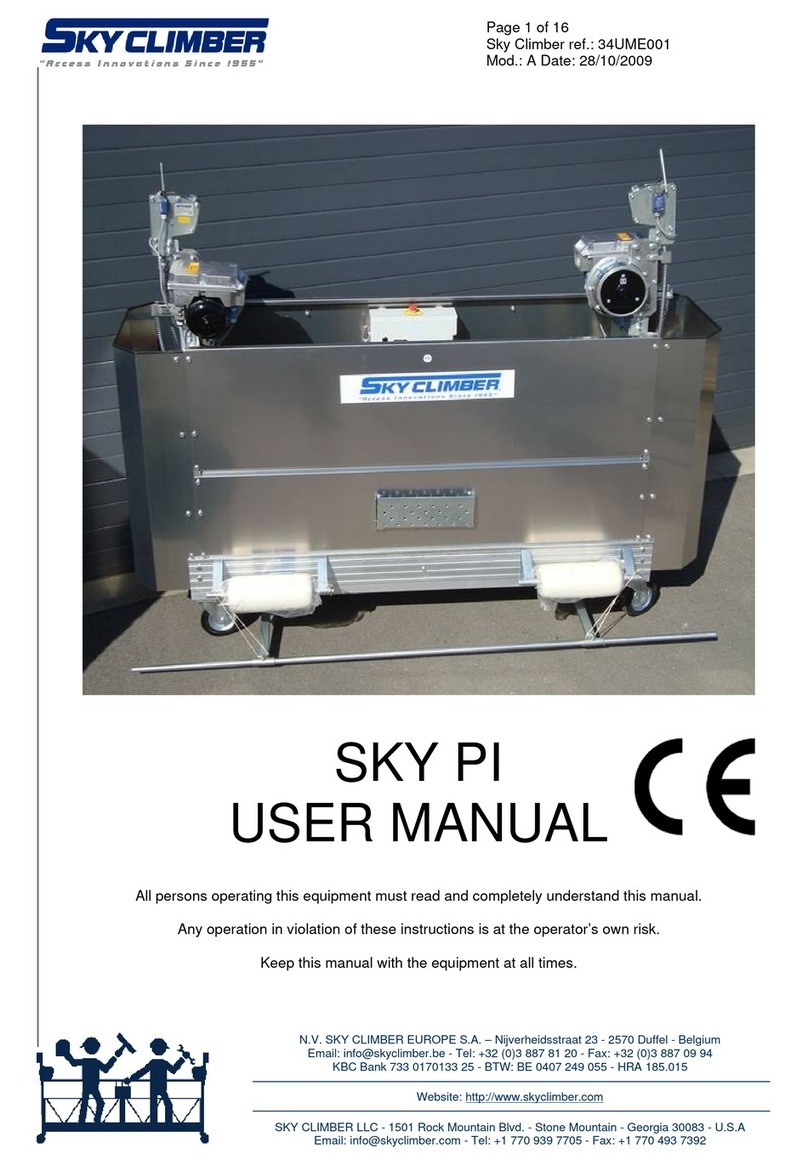

Sky Climber Alpha 800 User manual

Edited by ZEABRON SHIP MANAGEMENT SINGAPORE PTE LTD.

(Document Reference SkyclimberUser Manual Version 2.0)

User Manual

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

MANGEMNT

- Page 2 -

TABLE OF CONTENTS

Page

Section 1 - SAFETY : 6

1.0

Introduction……………………………………………………………………………. 6

1.1

Operator…………………………………………………………………………………6

1.2

Safety equipment……………………………………………………………………….6

1.3

General………………………………………………………………………………….7

1.4

System support………………………………………………………………………… 7

1.5

Steel wire rope…………………………………………………………………………. 7

1.6

Power Circuit…………………………………………………………………………… 8

1.6.1

General……………………………………………………………………………8

1.6.2

Electric Powered Hoist…………………………………………………………. 8

1.6.3

Air Powered Hoist………………………………………………………………. 9

1.7

Controls………………………………………………………………………………….9

1.8

Operator’s Support / Work Platform…………………………………………………. 9

1.9

Environmental Hazards………………………………………………………………. 9

1.10

Hazardous Activities:Welding...........................................................................10

1.11

Corrosive Atmosphere......................................................................................11

1.12

Safety Labels/ Instructions ...............................................................................11

Section 2 - INTRODUCTION / DESCRIPTION: 12

2.0

Introduction.........................................................................................................

12

2.1

General Features................................................................................................

12

2.2

Electric/Air Powered Hoists.................................................................................

13

2.2.1

Technical Specifications............................................................................

13

2.2.2

Controls..................................................................................……………

13

2.2.3

Crank Handle............................................................................................

14

2.2.4

Hoist Brake ………………………………………………………………………

14

2.3

Sky Lock Overspeed Sensitive FallArrest Device..................................................

15

2.4

Overload & Underload Device...............................................................................

15

Section 3 - OPERATION / INSTALLATION &REEVING: 16

3.0

General...............................................................................................................

16

3.1

Sky Lock Overspeed Brake.................................................................................

16

3.1.1

Installation……………………………….….…………….…………………………16

3.1.2

Operation……………………………………………………………………………

17

3.2

Emergency operation -Power Failure..................................................................

17

3.2.1

Ascent - OptionalHand Crank ....................................................................

18

3.2.2

Descent - ControlledLowering Lever..........................................................

18

3.3

Electric Powered Hoist........................................................................................

18

3.3.1

General .....................................................................................................

18

3.3.2

Power Supply.............................................................................................

19

3.3.3

Low Voltage Operation...............................................................................

19

3.3.4

Power Cords..............................................................................................

19

3.3.5

Thermal Overload.......................................................................................

19

3.4

Hoist operation....................................................................................................

19

3.5

Hoist Installation and Reeving.............................................................................

20

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

MANGEMNT

- Page 3 -

TABLE OF CONTENTS (Continued)

Section 4 - STEEL WIRE ROPE : 22

4.0

Wire Rope ..........................................................................................................

22

4.1

Specifications and preparation ............................................................................

22

4.1.1

Specifications.............................................................................................

22

4.1.2 Preparation……………………………………………………………… ………

22

4.2

Handling / Use / Storage.....................................................................................

23

4.2.1

General......................................................................................................

23

4.3

Inspection / Replacement Criteria........................................................................

24

4.3.1

Fittings.......................................................................................................

25

4.4

Sky Climber Wire-Winder....................................................................................

26

Section 5 - INSPECTION ANDMAINTENANCE : 27

5.0

General Information............................................................................................

27

5.1

Types of Inspection.............................................................................................

27

5.1.1

Factory Inspection......................................................................................

27

5.1.2

Field Inspection..........................................................................................

27

5.2

Frequency of Inspections ....................................................................................

27

5.3

Operators SafetyEquipment Inspection...............................................................

29

5.4

Sky Lock Overspeed Brake Inspection /Functional checks..................................

30

5.4.1

Work environment......................................................................................30

5.4.1.1

Group 1 - Normal....................................................................................30

5.4.1.2

Group 2 - Contaminated..........................................................................30

5.4.1.3

Group 3 - Freezing..................................................................................30

5.4.2

Inspecting the Sky LockOverspeed Brake..................................................

31

5.4.2.1

Inspecting Trip Performance of MountedSky Lock...................................

31

5.4.2.2

Inspecting Load Supporting Performance.................................................

31

5.5

Over- Underload Calibrationand Inspection.........................................................

33

5.6

Hoist Components Inspection and Maintenance..................................................

33

Section 6 - TROUBLESHOOTING 35

Section 7 - PLATFORMTRANSFER INSTRUCTIONS 37

Section 8 - SAFETY CHECKLISTS 38

8.1

Daily Checklist Form............................................................................................38

8.2

Set-up Checklist Form.........................................................................................39

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

MANGEMNT

- Page 4 -

TO THE EXPERIENCED SKY CLIMBER OPERATOR :

The typical first reaction of the experienced operator to an instruction manual is “Why should I read it?

I’ve had enough experience with Sky Climber hoists to write the Manual !” You may be right, but before

you put this Manual aside, please hear us out.

The new European Safety Standard EN1808 prescribes the supply of a manual with the equipment. In

addition, this manual is intended to remind experienced operators of the safe operating practices they

should consistently follow. Are you operating the system according to the book, or have short cuts and

omissions crept in ?

Have we omitted anything important?

Do you disagree with anything in this Manual?

If so, please let us know Zeaborn QHSE team by any possible means.

TO THE NEW SKY CLIMBER OPERATOR :

Sky Climber hoist can be operated safely. Properly operated and maintained.

This manual will guide you through the features of the Sky Climber hoist and will help you to start

operating it a safe way.

Throughout this Manual the words WARNING, CAUTION and NOTE appear in bold face font.

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

MANGEMNT

- Page 5 -

“WARNING” is preceded by the safety alert symbol and, with its corresponding message, is

underlined. This indicates that injury to personnel could occur if the proper procedures are not followed

during operation or maintenance. Always read and fully understand and act according to theWARNING

extremely carefully.

“CAUTION” indicates a possible hazard to the product or its components if the proper procedures are

not followed. Whenever the word CAUTION appears, special attention should be given to prevent

possible equipment damage.

“NOTE” is used to stress a point or to give additional information concerning the procedures being

discussed.

These WARNINGS and CAUTIONS are not all inclusive. It is impossible for Sky Climber Europe, to

know, evaluate and advise on every conceivable way in which our products may be used or serviced,

and of all possible resulting hazardous consequences. It is therefore extremely important for anyone

who uses a procedure about which this manual is silent to first satisfy himself that it will not jeopardize

his own safety, the safety of others, or cause product or component damage.

Every effort has been taken to make this Manual as complete and accurate as possible at the time of

publication. Sky Climber Europe, however, reserves the right to continually improve its products. For

this reason, changes may have been made to the Sky Climber hoist or its accessories which are not

detailed in this Manual.

WARNING: Failure to inspect, maintain and operation of Hoist, Sky Lock, and

accessories as described in this manual, could result in serious injury or death.

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

MANGEMNT

- Page 6 -

P R E V E N T A C C I D E N T S!

Read and follow this safety check list. It includes all safety requirements of State and National codes as

well as the recommendations of Sky Climber Europe. Follow all applicable company procedures and

guidelines pertaining to safety; they are minimum standards for the safe operation of Sky Climber

equipment.

1.0

INTRODUCTION

Sky Climber Hoists and accessories are designed and manufactured to the highest standards in the

industry for your safety. ACCIDENTS WILL BE AVOIDED IF YOU FOLLOW THE INSTRUCTIONS IN

THIS MANUAL. It is the operator’s responsibility to be sure that he and his co-workers are fully familiar

with this Manual before using the Sky Climber hoist and related equipment.

1.1

OPERATOR

1.1.1

People who operate suspended equipment must be:

Emotionally and physically able to withstand the stress of working at elevations

Able to read and understand this Manual and follow itsinstructions.

1.1.2

If an operator is subject to seizures or loss of physical control, he shall not work at elevations

1.1.3

Operators must be safety conscious, responsible, and not under the influence of alcohol, drugs

or other substances.

1.2

SAFETY EQUIPMENT

1.2.1

All persons using suspended access equipment must always wear safety harnesses attached

by lanyards and rope grabs to independently hung lifelines. Do not disconnect/remove safety

belts, harnesses, or lanyards until you are safely on the ground or until completely disembarked

from suspended devices to a safe location.

1.2.2

Use a short lanyard, and maintain the rope grabs high on the lifeline aspractical.

1.3

GENERAL

1.3.1

Know and understand the operation of this equipment. Be sure that all persons who service,

erect, dismantle or use thisequipment are thoroughly familiar with, andfollow all the safety rules

in this Manual.

1.3.2

Training in the use of Sky Climber equipment is important and must be carried out prior use.

1.3.3

Safety Helmets shall be worn at all times when servicing, erecting, disassembling, or using this

equipment.

1.3.4

Provide protection for operators from collision with overhead obstacles and fallingobjects.

1.3.5

Provide protection below the suspended equipment to prevent injury to personnel from falling

objects.

1.3.6

Keep all persons from beneath suspended equipment.

1.3.7

Never work alone on a suspended platform or where aid is not immediately available in case of

an emergency.

1.3.8

Do not overload the hoist. The working load limit (W.L.L.) of the hoistis always listed on the data

plate. This rating includes wire rope, power cord, platform, men tools and other associated

equipment.

1.3.9

Do not exceed the rated capacity of the platform. Different platform compositions have different

load ratings. (please refer to the corresponding platform load table as indicated in the platform

manual).

1.3.10

Check the operation of the Sky Lock overspeed brake at the beginning of each work shift or as

adverse environments require.

SECTION 1

SAFETY

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

MANGEMNT

- Page 7 -

1.3.11

Thoroughly inspect all equipment before use to make sure that it is maintained in a safe,

workable condition. The supervisor should assign a responsible person to do this at regular

intervals.

1.3.12

In the case of apparent difficultyinthe machine, steel wire rope, platform etc., notify your nearest

authorized Sky Climber representative through Technical managers, and do not use the

equipment until it is repaired or replaced.

1.3.13

In anemergency,press the red emergency stop button. Thiswill cut allpower, stopthe operation

and will allow the brake of the hoists to set. Do not turn the emergency switch until the cause

has been corrected.

1.3.14

All suspended access equipment must be handled with care. Impose loads on the platform

gently. Do not drop the hoists on the platform whenhandling.

1.3.15

Use only Sky Climber genuine spare partsfor your SkyClimber equipment. Do not alter any Sky

Climber Hoists or accessories.

1.4

SYSTEM SUPPORT

1.4.1

Make sure the platform is suspended from a strong structure and is able to support the load

imposed by the suspended platform. Do not secure to a weak or questionable structure. When

in doubt, consult office for further guidance.

1.4.2

Make sure that Aluminum Brackets used, will support the suspended platform load with a

minimum of 3:1 safety factor. In case of doubt, consult a professional rigger/engineer.

1.4.3

Tiebacks (additional support, Wire sling or canvas sling) of sufficient SWL (Min 4 Tons) must be

used on all supporting devices. Tiebacks must be kept tight and attachedto a structuralmember

being capable of supporting the entire suspended load as well as the support system. Note:

Professionally designed Davit systems do not usually require tiebacks.

1.4.4

Always use the correct type and size of rope clamps. Steel wire rope will slip through oversize

clamps. Undersize clamps will damage the steel wire rope.

1.4.5

The nut-type used for assembling suspension systems shall be of the self-lockingtype.

1.4.6

Never move a suspension support with the platform being suspended. The platform shall be

lowered onto a solid surface and the suspension wires shall be slack before the suspension

supports are to be moved.

1.5

STEEL WIRE ROPE

1.5.1

Comply with codes, regulations and industrial standards which forbid or warn against the use of

kinked, bird-caged or damaged steel wire rope. Inspect the steel wire ropefor wear and damage

prior to use and during operation. Steel wire rope is susceptible toserious damageif not handled

in accordance with these and other instructions in this Manual. Exposure to concentrated acids,

caustic material, corrosion, fire, electricity, undue heat or abuse damages the steel wire rope.

When such an exposure has occurred, replace the steel wire rope immediately.

WARNING : The use of kinked, birdcaged or excessively worn or damaged steel wire rope

is unlawful. Such use may result in injury or death to yourself orothers.

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

MANGEMNT

- Page 8 -

1.5.2

Use Sky Climber specified steel wire rope, clamps, thimbles, and other work associated

components. See section 4 for more information.

1.5.3

Rig from top of structure allowing approximately 3 meter of extra steel wire rope at the bottom

to reeve hoist. Sky Climber strongly recommends that all rope drops be of sufficient length to

reach a safe surface level when reeved.

WARNING : If it is necessary to rig with less steel wire rope than specified above, it is

mandatory that the bitter end of the steel wire rope be looped back on itself and secured with

a “J”-clamp. See figure 4.4.

1.5.4

Steel wire rope must be rigged to remainvertical, with suspension pointsdirectly abovethe hoist

entry guide or lead-in device at alltimes.

1.5.5

A double wire suspension (primary and secondary safety steel wire rope) system hasto be used

at all times in order to comply with company safety requirements. Make certain that each steel

wire rope is attached to its own suspension point on the suspensiondevice.

1.5.6

Special precautions must be taken to protect the steel wire rope when welding. See section

1.10 for list of precautions.

1.5.7

Steel wire rope fittings (J-clamps, shackles and Talurit clamps) must be checked for tightness

at first loading and then at the beginning of each shift.

1.6

POWER CIRCUIT

1.6.1

General

1.6.1.1.

Do not remove the motor from the hoist unless the platform is safelysupported.

1.6.1.2.

Optional manual crank handle can be used to raise the suspended equipment if power fails

and in order to get the load back on the primary steel wire rope in case of a power failure. This

will enable you to reset the tripped Sky Lock. Refer to section 2.2.3 on how to use the crank

handle. If Sky Lock has tripped due to overspeed do NOT crank the hoist up in order to try re-

setting the sky lock.

1.6.1.3.

Emergency brake release may be used for controlled lowering of the suspended equipment

in case of power failure. See section 3.2.2.

1.6.1.4.

Do not allow the electrical power supply cable / air hose to become tangled with any

obstruction or the suspension ropes when raising or lowering the suspended equipment.

Make certain the electrical cord is of sufficient length to allow full travel of the suspended equipment.

1.6.2

Electric Powered Hoists

1.6.2.1

Before using electric powered hoists, have a qualified person check the voltage while hoisting

with your maximum allowable load. The voltage should vary with no more than 10 % of the

nominal power supply voltage indicated on the electromotor dataplate.

1.6.2.2

Make sure that the electrical power source is “earthed” to a point of sufficient low resistance.

1.6.2.3

Use only approved connector plugs and power supply cords with strain relief, correctly

assembled from hoist to power supply. Verify ground continuity and use a ground fault

interrupter (as required by code in your location). Consult local safety authorities for further

information.

1.6.2.4

Ensure that all metal parts, outlets, junction boxes and other components that might come in

contact with live conductors are properly earthed.

1.6.2.5

Always use a power cable cord with earth conductor when using electrically driven hand tools

on a suspended platform. Verify that the hand tools are properly earthed. (or use hand tools

of the double insulated type)

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

MANGEMNT

- Page 9 -

1.6.3

Air Powered Hoists

1.6.3.1

Before using air powered hoists, check the pressure setting of the pressure regulator. The

pressure setting should be equal to the working pressure indicated on the air motor data plate.

1.6.3.2

Use only approved connector plugs and air hoses with strain relief, correctly assembled from

hoist to air distribution yoke.

1.6.3.3

Use an air hose off sufficient cross-section.

1.6.3.4

Use air hoses that are in good condition.

1.6.3.5

In case the permissible noise level of 79dB is exceeded ear protection isnecessary.

1.7

CONTROLS

1.7.1

Before switching on the main power: check all hoist controls and verify that they are in the

“neutral” or “off” position.

1.7.2

Before moving the platform: verify that all the persons on or close to the platform are standing

clear and are aware you are going to raise or lower the platform before moving.

1.7.3

Before raising or lowering the platform: check that the controls are operating as indicated on

the control panel. Activating the “UP” button / lever has to initiate the upward movement. If this

is not the case: call for a servicemechanic.

WARNING: Always wait for the hoist to come to a complete stop before changing direction

of movement, otherwise this may result in loss of control.

1.7.4

Activate the control buttons / levers only by manual action. It is not allowed to block the

control push buttons by any othermeans.

1.8

OPERATOR’S SUPPORT/WORK PLATFORM

1.8.1

Check stirrup bolts daily and verify that the bolts are still in position and tightened firmly.

1.8.2

Never operate a suspended work cage or platform without having the guard-rails, toe boards,

bumpers, lifelines, lanyards and safety harnesses in position.

1.8.3

When operating the platform: keep it as level as possible. If necessary: operate one hoist in

order to re-establish the level position.

1.8.4

When suspended: do not climb or stand on : guard-rails,toe boards, platform supported objects.

Do not reach over the ends or sides of the platform. Do not use ladders or scaffolding that are

put on the platform deck for reaching out to higher levels.

1.8.5

The Bosun chair shall only carry the operator. It is not allowed to suspend or mount any other

items on or from the chair.

1.8.6

Do not attempt to bridge from one platform to another, nor to any other structure or other

equipment. Embarking/disembarking of the platform is only allowed at ground or top level.

1.8.7

Do not attempt to transfer a work platform to another “drop” while suspended. Only transfer the

platform from one suspension location to another when it is lowered and standing on a level and

solid surface.

1.8.8

In order toprevent damage tothe aluminum structureevery contact with causticmaterials, acids

fluids and fumes is strictly prohibited. Select wooden or fiberglass-made platforms for working

in a caustic environment.

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 10

-

1.9

ENVIRONMENTAL HAZARDS

WARNING: Touching live powerlines may result in Death or serious injury.

1.9.1

Refer to company procedures when working in the vicinity of electrical overhead powerlines.

Consult the local power company for safe operating procedures before rigging.

1.9.2

Do use of long-handled tools when working close to electric powerlines.

1.9.3

The minimum separation between live power lines and the platform and all of its components is

3 meters.

1.9.4

Verify that there are no obstructions in the vertical travel zone of the platform. Always keep a

good look-out when raising or lowering the platform. When running into an obstruction:

immediately stop the platform and inspect the platform and obstruction for possible damage

and/or hook-up. Proceed in a safe direction to clear theobstruction.

WARNING: Take care not to overload the system or get in a slack suspension wire situation

when running into an obstacle.

1.9.5

For Temporary suspended platforms with a lifting height of over 40m and intended to be used

on locations exposed to wind speeds above 14 m/s (= 50 km/h) an adequate restraint shall be

provided.

1.9.6

Carefully follow the instructions for using and checking the Sky Lock fall arrest device in a

normal, contaminated, or freezing environment.

1.9.7

When using a hoist in or near a Marine (or corrosive/salty) environment, more frequent

inspections are required. In these applications a thorough 4-hours interval inspection of the

hoists, steel wire rope, fittings and equipment has to be executed. Make sure to replace all the

components that get degraded by corrosion or wear.

WARNING: The electric powered hoists are not rated for operating in an explosion

hazardous environment. Select an air powered hoist.

1.10

HAZARDOUS ACTIVITIES : WELDING

During welding, the electrocution hazard and the risk of the welding current passing through the

suspension steel wire ropes shall be eliminated by taking the following precautions:

1.10.1

Use an insulated thimble to attach each steel wire rope to its suspension point. Electrically

insulate the extra steel wire rope stored on the top to prevent grounding or terminate the

suspension rope at the insulated thimble.

1.10.2

Cover the steel wire rope support cable with insulating material above and below the hoist. (See

Fig. 1.1) This can be done by using a length of rubber-hose, taped in position around the cable.

Proceed as follows:

a.

Above the Sky Lock brake extending upwards for approximately 1.2 meter (more if required

by local safetyregulations).

b.

Below the hoist, extending downward sufficiently far enough to insulate the tail line from the

platform. The portion of the tail line that hangsfree belowthe platform must be guided and/or

retained so that it does not become grounded.

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 11

-

Figure 1.1

1.10.3

Cover each Hoist, Sky Lock and wire winder with protective covers made out of insulating

material.

1.10.4

Connect a ground conductor from the platform to the work piece. The size of this conductor

shall be equal to, or greater than the size of the stingerlead.

NOTE : This must be a secondary conductor and shall not be in series with the primary

conductor between the welder and the workpiece.

1.11

CORROSIVE ATMOSPHERE

When Sky Climber hoists are being used in corrosive work-associated atmospheres such as acid

washing, the hoist and its supporting steel wire rope shall be protected from direct contact with the

corrosive solutions and agents. Each day, on the final descent, the steel wire rope shall be washed with

a neutralizing solution and relubricated. Stainlesssteel wire rope, whichisfarmore resistant to corrosion

deterioration can be obtained from Sky Climber.

Daily examination of the full supporting length of wire rope is mandatory.

1.12

SAFETY LABELS / INSTRUCTIONS

The Sky Climber equipment shall be labelled as follows :

Use only 8 mm SKY CLIMBER Steel wire rope

with a min. actual breaking load of 40 kN(or better)

COMPACT CX500

Manufactured by :

SKY CLIMBER EUROPE N.V.

Boomsesteenweg 14

B-2630 Aartselaar

BELGIUM

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 12

-

2.0

INTRODUCTION

This Manual contains Sky Climber’s minimum requirements for safety, operation, and maintenance.

Follow all company procedures pertaining to the safe use and maintenance of this equipment.

WARNING : Failure to inspect, maintain and operation of hoist, Sky Lock, and accessories

as described in this manual, could result in serious injury or death.

2.1

GENERAL FEATURES

Sky Climber hoists are is rated for man lifting, of the traction sheave type, and portable hoist. The

hoist is certified by CE, Underwriters Laboratory (UL) and the Canadian Standards Association.

They climb up- and down on a 8 or 9mm steel wire rope and carries men and materials to their

workstations.

Sky Climber hoists are used to lift suspended platforms, work cages, Bosun chairs and other approved

devices in suspended access operations.

All hoists are available in 4 different models :

Single Phase, 220-240V/50 Hz , 24V Control Voltage

Single Phase, 220-240V/60 Hz , 24V Control Voltage

Three Phase, 380-415V/50 Hz , 24V Control Voltage

Three Phase, 380-415V/60 Hz , 24V Control Voltage

Air

WARNING : A Sky Lock overspeed sensitive fall arrest device shall be used AT ALL TIMES

with each type of hoist.

2.2

ELECTRIC / AIR POWERED HOIST

The Sky Climber hoist consists out of :

Traction sheave / Gearbox unit

Drive Motor Unit (electric / air)

with built-on Motor control unit

Brake Unit (electromagnetic or pneumatic, spring actuated)

built-in for Compact & CX

built-on for Alpha

Central Control Unit (central control box (CE) or hoist-mounted control box(UL))

Sky Lock Overspeed sensitive Fall arrest device

SECTION 2

INTRODUCTION / DESCRIPTION

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 13

-

2.2.1

Technical specifications

Compact 400

Motor

50Hz / 1~

60Hz / 1~

50Hz / 3~

60Hz / 3~

Air

Voltage / Press.

220-240V

220-240V

380-415V

380-415V

6 bar

Current / Flow

3.6 A

5.4 A

2.4 A

1.8 A

1.7 m³/min

Power

0.55 kW

0.74 kW

0.55 kW

0.88 kW

1.25 kW

Motor speed

1420 rpm

1700 rpm

1400 rpm

1690 rpm

1500 rpm

Weight

35 kg

36 kg

35 kg

36 kg

30 kg

Capacity

400 kg

400 kg

400 kg

400 kg

400 kg

Steel Wire Rope

8mm

8mm

8mm

8mm

8mm

Actual Breaking Load

44,63kN

44,63kN

44,63kN

44,63kN

44,63kN

Climbing Speed

8.5 m/min

10.6 m/min

8.4 m/min

10.6 m/min

8.5 m/min

Sky Lock

III (8mm)

III (8mm)

III (8mm)

III (8mm)

III (8mm)

CX 500

Motor

50Hz / 1~

60Hz / 1~

50Hz / 3~

60Hz / 3~

Air

Voltage / Press.

220-240V

220-240V

380-415V

380-415V

6 bar

Current / Flow

7 A

7.5 A

3.2

2.1

1.7 m³/min

Power

0.88 kW

1.1 kW

0.88

1.1

1.25 kW

Motor speed

1420 rpm

1710 rpm

1400

1700

1500 rpm

Weight

41 kg

43 kg

41 kg

43 kg

30kg

Capacity

500 kg

500 kg

500 kg

500 kg

500 kg

Steel Wire Rope

8mm

8mm

8mm

8mm

8mm

Actual Breaking Load

44,63kN

44,63kN

44,63kN

44,63kN

44,63kN

Climbing Speed

8.5 m/min

9.7 m/min

8.5 m/min

9.7 m/min

8.5 m/min

Sky Lock

III (8mm)

III (8mm)

III (8mm)

III (8mm)

III (8mm)

Alpha 500

Motor

50Hz / 1~

60Hz / 1~

50Hz / 3~

60Hz / 3~

Air

Voltage / Press.

220-240V

220-240V

380-415V

380-415V

6 bar

Current / Flow

6.8

5.7 A

3.3 A

2.1 A

2 m³/min

Power

0.88

0.88 kW

0.88 kW

1.1 kW

0.96 kW

Motor speed

1420

1700 rpm

1400 rpm

1700

2800 rpm

Weight

62 kg

63 kg

62 kg

63 kg

60 kg

Capacity

500 kg

500 kg

500 kg

500 kg

500 kg

Steel Wire Rope

9mm

9mm

9mm

8mm

9mm

Actual Breaking Load

66,1kN

66,1kN

66,1kN

66,1kN

66,1kN

Climbing Speed

8.5 m/min

9.7 m/min

8.5 m/min

9.7 m/min

8.5 m/min

Sky Lock

III (9mm)

III (9mm)

III (9mm)

III (9mm)

III (9mm)

Alpha 800

Motor

50Hz / 1~

60Hz / 1~

50Hz / 3~

60Hz / 3~

Air

Voltage / Press.

220-240V

220-240V

380-415V

380-415V

6 bar

Current / Flow

9.4 A

11 A

4.3 A

3.7 A

2 m³/min

Power

1.33 kW

1.5 kW

1.1 kW

1.5 kW

0.96 kW

Motor speed

1370 rpm

1720 rpm

1410 rpm

1660 rpm

2800 rpm

Weight

65 kg

67 kg

66 kg

67 kg

65kg

Capacity

800 kg

800 kg

800 kg

800 kg

800 kg

Steel Wire Rope

9mm

9mm

9mm

9mm

9mm

Actual Breaking Load

66,1kN

66,1kN

66,1kN

66,1kN

66,1kN

Climbing Speed

8.5 m/min

9.7 m/min

8.5 m/min

9.7 m/min

8.5 m/min

Sky Lock

II (9mm)

II (9mm)

II (9mm)

II (9mm)

II (9mm)

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 14

-

2.2.2

Controls

Refer to the central controlbox manual for a detailed description of the central control unit.

2.2.2.1

UP and DOWN SWITCH/LEVER:

2.2.2.2

SELECTOR SWITCH: (only electric poweredhoist)

2.2.2.3

EMERGENCY STOP Button:

2.2.2.4

CONTROLLED DESCENT LEVER:

In the event of a power failure, the controlled descent lever, located on the end-side of the hoist can be

activated to manually release the hoist brake. This is done by pushing it towards the hoist-end.

(See Figure 2.1 & 2.2). The hoist will lower at a controlled speed of +/- 8.5m/min. The controlled

descent lever shall only be activated when the power supply has been disconnected.

WARNING: Always disconnect power to the platform before activating the controlled

descent lever, otherwise serious injury or death may result.

2.2.3

CRANK HANDLE:

A crank handle is supplied with every hoist for raising the hoist and its load when there is a power failure

and upward travel of the Sky Climber hoist is required. Most of the time the distance over which

the hoist is to be raised is very limited : the main goal is to get the load back on the primary

suspension steel wire rope in order to un-load and re-set the Sky Lock.

How to use the crank handle:

Disconnect power supply plug (to central control box / air distributionyoke)

Remove the plastic safety plug in the center hole of the drive motor or brakeunit.

Insert the crank handle on the shear pin of the shaftrear-end.

Hold the crank handle firmly whit one hand while lifting the brakemanually.

Rotate the handle in the counter-clockwise direction toclimb.

When stopping, release the controlled lowering lever before releasing thecrank.

Figure 2.1 Figure 2.2

2.2.4

HOIST BRAKE:

The hoist brake is spring-loaded, with electro-magnetic or pneumatic release and manual override. To

use manual override, pull Controlled Lowering Lever toward outer end of hoist. See Figure 2.1 & 2.2

NOTE: This brake may not be serviced in the field.

NOTE: Never manually release the Hoist brake for normal lowering operations.

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 15

-

2.3

SKY LOCK OVERSPEED SENSITIVE FALL ARREST DEVICE

The Sky Lock overspeed brake provides additional backup to the safety devices built into the Sky

Climber hoist. The Sky Lock is a device which senses the dynamic speed of the wire rope as it passes

through the Sky Lock mechanism. If, as the Sky Lock brake is travelling down the wire rope, the factory

pre-set speed is exceeded, the Sky Lock brake will lock onto the wire rope and support the load. The

secondary steel wire rope cannot be released until the load on the Sky Lock brake is relieved.

The right type of Sky Lock (See Figure 2.3) should be used with the right type of hoist (see 2.2.1). These

models provide a manual trip lever for manual activation or functional checking. Installation, operating

procedures and functional checking procedures are defined in Section 5.4.2

Figure 2.3

2.4

OVERLOAD & UNDERLOAD DEVICE

The over-/underload device is a combined device which detects an overload or underload situation to

avoid danger to persons and damage to machines. It is mounted for each hoist on the end stirrup or on

the walk true stirrup. Refer to the “Safety Devices Assembly Manual” for more detaileddrawings.

The overload device prevents the hoist from moving upwards in an overload situation. The underload

device prevents the hoist from moving downwards in an underload situation. In both situations an audio

alarm will occur to warn the operators.

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 16

-

3.0

GENERAL

Users are responsible for reading, understanding and following the instructions in this manual. Do not

operate SkyClimber equipment until you have read andunderstood this manual, and are willing tofollow

its instructions. Consult your supervisor or nearest Sky Climber Office if you have any questions

concerning these instructions, or if training is required.

3.1

SKY LOCK OVERSPEED BRAKE

The Sky Lock overspeed brake is a safety device which senses the speed of the rope passing through

its mechanism. If the factory pre-set actuation speed is exceeded as the Sky Lock is travelling down the

wire rope, the Sky Lock brake will lock onto the wire rope and support the descending load. The wire

rope cannot be released until the load on the Sky Lock brake is relieved.

NOTE: Use always the right type of Sky Lock for the right type of Hoist. (See 2.2.1)

3.1.1

Installation

The Sky Lock brake is installed above and attached to the Sky Climber hoist with a coupling link. The

Sky Lock brake may also be attached to platforms as part of a secondary wire rope installation, or to

other equipment which may require the use of a dynamic braking device. Consult Sky Climber Europe

for use of the Sky Lock brake in other than Sky Climber hoist applications.

Before passing the wire rope through the Sky Lock brake, the reset handle must be placed in the reset

position. See Figure 3.1. Afterthe wire rope has been passed through the Sky Lock brake, the operation

of the brake must be inspected according to procedures in Section 5.4.2 of this manual.

Figure 3.1

SECTION 3

OPERATION / INSTALLATION & REEVING

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 17

-

3.1.2

Operation

Should the SKY LOCK brake engage due to an overspeed condition, do not attempt to release or reset

it. Instead, remove men from suspended equipment, and lower it to ground or raise it to top by means

other than the hoist. Then contact your nearest Sky Climberrepresentative.

SKY LOCK brakes may also be engaged by:

Turning manual trip lever

Sudden movement of men on platform or repeatedvibration

In the event the Sky Lock brake engages for reasons other than overspeed, check condition of

equipment and wire rope below the Sky Lock brake. If satisfactory, operate hoist in up direction 5 to

10cm to relieve load on the Sky Lock brake, then turn reset handle as indicated on the Sky Lock brake

decal, until the Sky Lock brake resets. (See Figure 3.2)

Figure 3.2

WARNING: Failure to inspect and functionally check Sky Lock brake operation at the

beginning of each work shift in accordance with Section 5.4.2 could result in serious injury or

death.

3.2

EMERGENCY OPERATION - POWER FAILURE

In the event of loss of power, the hoist may be raised by using the option of hand crank, or lowered

using the Controlled Lowering Lever.

WARNING: Always Disconnect power at the pigtail connection before using the manual

crank or Controlled Lowering Lever, otherwise serious injury or death may result.

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 18

-

3.2.1

Ascent - Optional Hand Crank

If power fails and you desire to raise suspended equipment:

Disconnect power supply.

Remove protective cover and insert the hand crank

While tightly holding crank with one hand, pull Controlled Lowering Lever as far as it will go

with the other hand (thus brake), and begin cranking in a counter-clockwisedirection.

WARNING: Release Controlled Lowering Lever to set Hoist brake before releasing crank,

otherwise serious injury could result.

3.2.2

Descent - Controlled Lowering Lever

If power fails and you desire to lower the hoist and its load:

Disconnect power at the pigtail connector.

Release Hoist brake by gently pulling Controlled Lowering Lever as far as it will go. (See

Figure 3.3 & 3.4)

CAUTION : Partial release of Hoist brake may result in overheating and premature brake wear.

WARNING: Before descending, be sure that optional hand crank is removed from hoist,

otherwise, serious injury or death could result.

Figure 3.3 Figure 3.4

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 19

-

3.3

ELECTRIC POWERED HOIST

3.3.1

General

For typical installation on a scaffold and for reeving instructions, see Section 3.5

WARNING: An electric powered Sky Climber hoist shall NOT be used in an explosive

atmosphere.

An explosive atmosphere is one in which flammable gases or vapors or small particles are or may be

present in the air in quantities sufficient to produce an explosive or ignitable mixture.

3.3.2

Power Supply

Check technical specifications for minimum power requirements (see 2.2.1).

CAUTION: The motor may overheat if the measured voltage at the motor during operation is less than

90% or more than 110% of the voltages shown on the motor data plate.

On exceptionally long drops, locate the power source in the middle of the drop, thereby reducing the

amount of power cord required.

3.3.3

Low Voltage Operation

If a problem in motor performance exists when operating two hoists due to low voltage, the use of a

booster transformer or of a separate power cord for each hoist is recommended.

3.3.4

Power Cords

Because of varying platform load, source voltage and electrical system impedance, it is impossible to

recommend optimum electric cord wire sizes, but Sky Climber recommended supply cable will be

satisfactory in nearly all cases. Extremely long drops may necessitate the use of a voltage booster

transformer or location of the power source in the middle of the drop, thereby reducing the required

power cord length.

IF A BOOSTER TRANSFORMER IS NEEDED, CALL YOUR SKY CLIMBER REPRESENTATIVE.

The power cord must be secured to the swing stage by strain relief devices or other means to prevent

the connector from pulling apart.When two power cords are used in series, include strain relief devices.

Make sure the power cord length is sufficient to permitfree travel of the platform without applying undue

strain to the cord strain relief.

When finished for the day, make certain the power cord is disconnected at the main outlets. Protect

power cords from rain and water at all times.

Do not attempt to alter any connectors to fit power outlets. Do not use deteriorated or contaminated

components.

Sky Climber

ZEABORN GUIDELINES

18.11.2020 Version 1

- Page 20

-

3.3.5

Thermal Overload

When the motor is overheated because of excessive current draw or prolonged use in hot weather, a

thermal overload switch will cut power to the motor windings. Determine the cause of overheating and

make necessary corrections. Allow the motor to cool approximately 20 minutes. During this time, the

thermal overload switch will automatically reset.

3.4

HOIST OPERATION

The electric hoist is activated by movement of the directional switch in the desired direction of travel.

Travel may be stopped by releasing the directional switch, which cuts power to the motor and sets the

hoist brake.

WARNING: Allow Hoist to come to a full stop before changing direction of travel. Rapidly

changing position of directional switch may result in loss of control.

3.5

HOIST INSTALLATION AND REEVING

These mounting and reeving instructions are directed to the reeving of a hoist mounted on the stirrup of

a stage. These same instructions are generally applicable to the reeving of Compact CX 500 Hoist

mounted on work cages, bosun chairs and other work platforms.

Read and understand the paragraphs describing operation of the hoist before attempting reeving. Prior

to reeving, test the Sky Lock in accordance with Pre-reeving Inspection, Section 5.4.2.1; and inspect the

Hoist in accord with Section 5.6. Figure 3.5 illustrates a typical assembly with safety equipment.

Figure 3.5

STEP 1: Rigging

Install rigging as described in Section 7.0, or arrange for rigging to be installed by your local Sky

Climber Office.

This manual suits for next models

3

Table of contents

Other Sky Climber Construction Equipment manuals