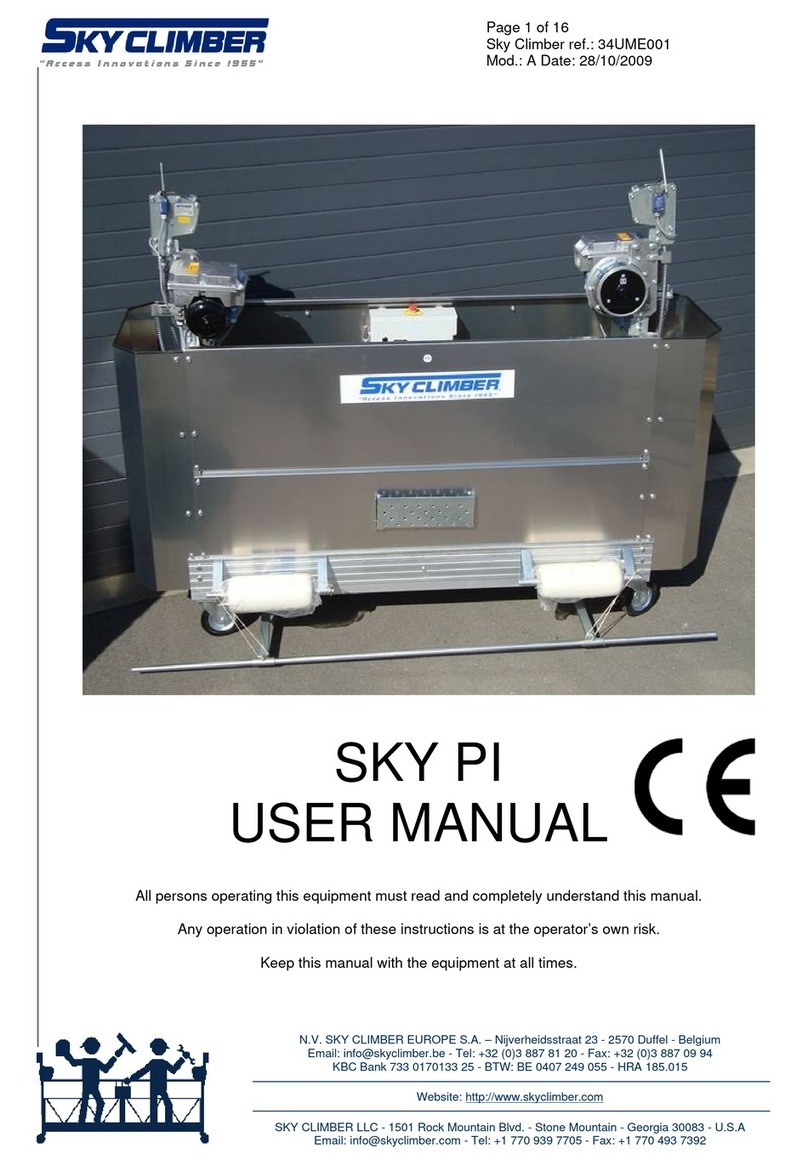

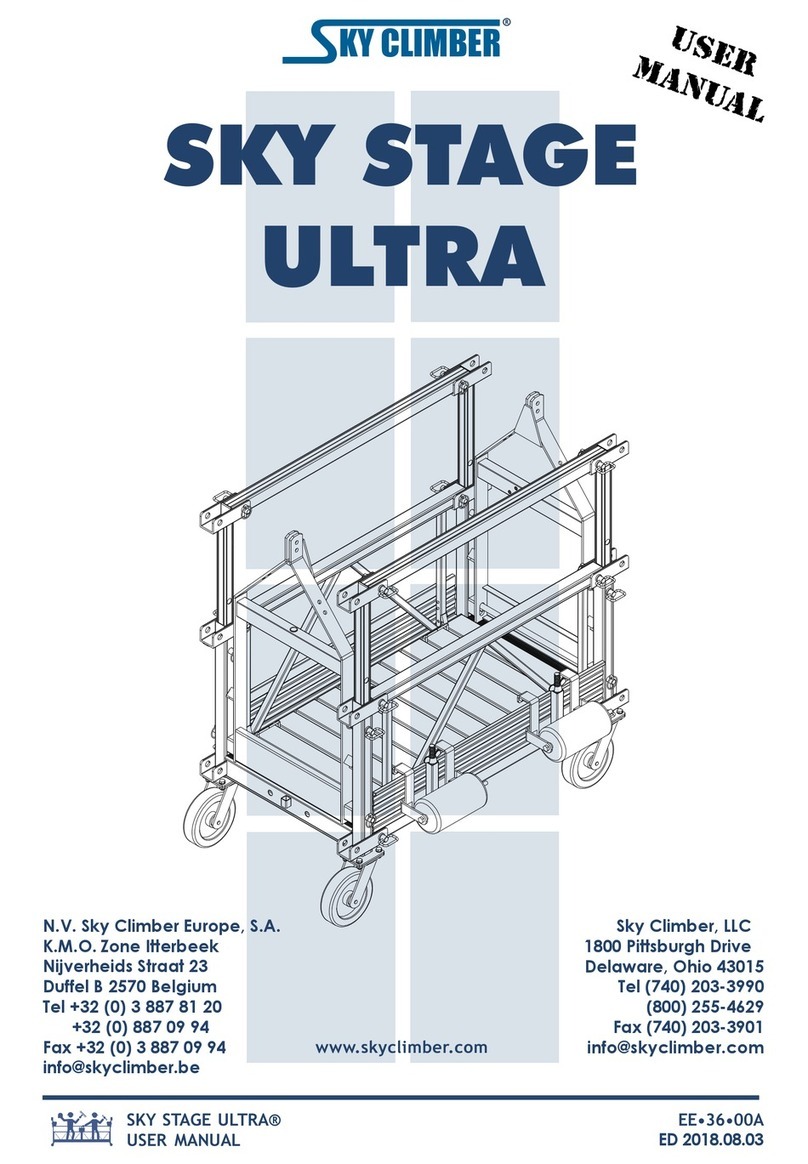

Sky Climber SKY STAGE ULTRA User manual

®

K

Y

CLIMBER

SKY S

T

A

GE

TRA

N.

V

. Sky Climbe

r

Europe S.A.

Sky Climber Inc

Boomsesteenweg

2630 Aartselaar

Belgium

14

1501 Rock Mountain Blvd.

Stone Mountain

Georgia 30083, USA

Tel +1 (770) 939-7705

Fax +1 (770) 493-7392

info®skyclimber.com

T

el +32 (0)3 887 81 20

Fax +32 (0)3 887 09 94

info®skyclimber.be limbe

r

.com

SKY STAGE U

L

TRA®

USER MANUAL

UM•36•00

A

ED•2019-12-04

www.skyc

UL

®

KY CLIMBER

FOREWORD

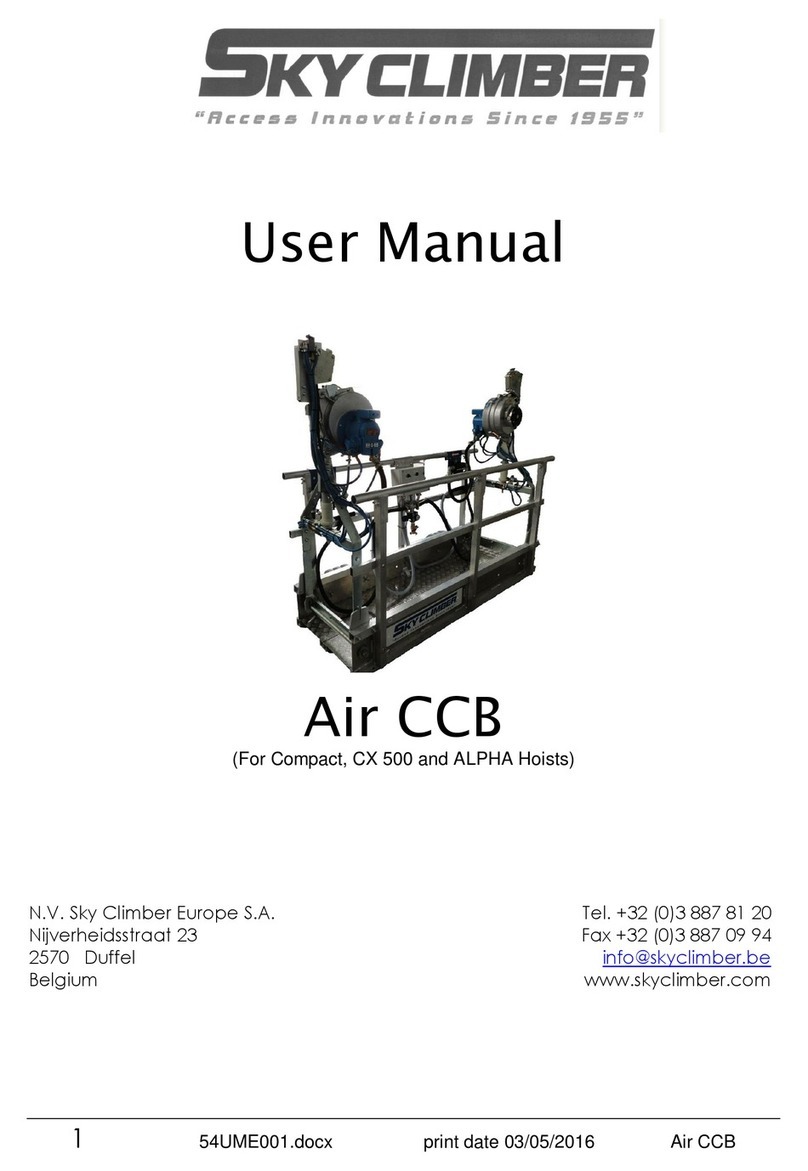

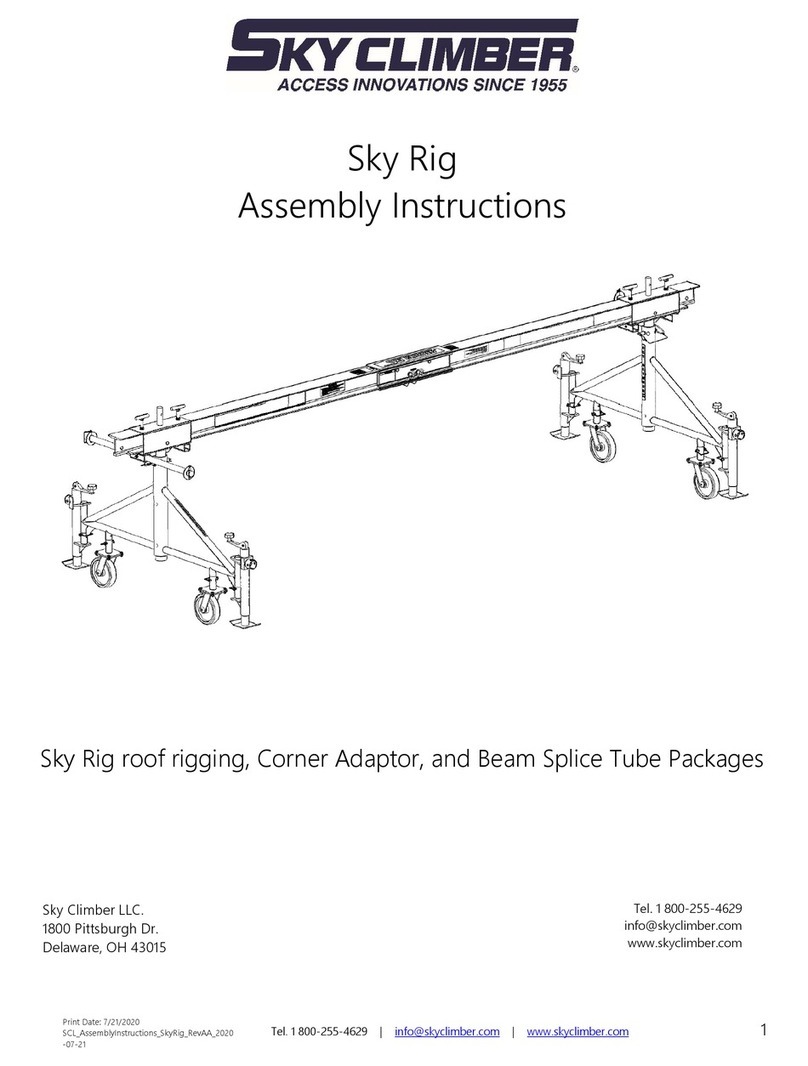

Welcome to Sky Climber®.

Congratulations on you

r

new Sky Climber® product.

A

ll Sky Climber® products are designed

and certified to the highest worldwide industry standards. Our continuous quality control ensures

this product is manufactured to the relevant codes. Nonetheless, all of this work and effort can

be and is nullified by improper use.

It is vitally important that you and each and every person who is to utilize the Sky Climber

®

product, take the time to learn the proper and safe methods relating to utilization of the Sky

Climber® product. Safety begins with a familiarization with the functions and limitations of the

Sky Climber® equipment. It is your responsibility to READ AND UNDERSTAND the contents of

this manual. If you have any questions whatsoever, contact your dealer or Sky Climber® cus-

tomer service. It is our desire and intention to provide answers to your question regarding the

proper use of Sky Climber® products. Sky Climber® cannot and will not under any circum-

stances be responsible in any way for injuries or damage sustained as a result of misuse or

misapplication of the product. Please consult your sales materials to determine other applicable

limitations of liability.

Sky Climber®'s 'use

r

manual' will guide you through installation and operation procedures.

Sky Climber® reserves the right to continually improve its products. Every effort has been made

to make this manual as accurate as possible at the time of publication; however, there may be

product changes which are not detailed in the manual. Please contact your dealer or Sky

Climber® customer service on a regular basis to obtain follow up information and materials.

Each manual is also available as a PDF (portable document format).

A

PDF 'user manual' can

be used to look up the correct spare part on a computer screen. With the use of the 'Contents',

you can quickly jump to the correct page by clicking on the contents line or bookmark. You can

recognize other links by blue markings.

We remind you to always wear personal fall protection equipment and to make sure that all

persons utilizing the product are fully familiar with its features, including safety features and

limitations, such as weight limitations.

© Sky Climber®, 2002

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of the publisher.

SKY STAGE U

L

TRA®

USER MANUAL

UM•36•00

A

ED•2019-12-04

2

®

KY CLIMBER

CONTENTS SKY STAGE ULTRA

SKY ST

A

GE U

L

TR

A

.................................................................................................................. 1

FOREWORD ......................................................................................................................... 2

CONTENTS ........................................................................................................................... 3

Safety Guidelines ................................................................................................................... 4

Operator's Safety ....................................................................................................................... 4

Operation Safety .......................................................................................................................4

Environment ............................................................................................................................... 5

Sky Stage Ultra® with End Stirrup configurations ..................................................................... 6

Overview ................................................................................................................................... 6

Dimensions ................................................................................................................................ 7

Transport & Handling Weights .....................................................................................................7

Standard Configurations & Assembly Parts ................................................................................... 8

Standard Configurations & Load Ratings per UL .......................................................................... 9

Standard Configurations & Load Ratings per EN1808 ................................................................ 10

Installation Instructions ........................................................................................................ 11

Assemble platform .................................................................................................................... 11

Dis-assemble platform ..............................................................................................................14

Use-operation...................................................................................................................14

Wall-rollers .............................................................................................................................. 14

Repositioning platform .............................................................................................................14

Check Lists .......................................................................................................................... 15

Inspection prior to installation ...................................................................................................15

Check components prior to shipment ......................................................................................... 15

Inspection after installation ....................................................................................................... 15

Logbook .............................................................................................................................. 16

Instruction to the owner .............................................................................................................16

SKY STAGE U

L

TRA®

USER MANUAL

UM•36•00

A

ED•2019-12-04

3

®

KY CLIMBER

Safety Guidelines

•

A

ll persons who service, install, dismantle or use

suspendedaccessequipmentmust fullycomprehend and

act in accordance with this manual and all appropriate

regulations. A competent person is a designated person,

suitably trained, qualified by knowledge and practical

experience to carry out the required task safely.

Training, manuals and other documentation are available

at Sky Climber®. Do not hesitate to contact us for more

details.

•

Operators must be emotionally and physically able to

withstand the stress of working at elevations. Do not work

at elevations if subject to seizures or loss of physical

control. Operators must be safety conscious, responsible

and not under the influence of alcohol, drugs or other

substances.

•

All persons using suspended access systems must at

all times wear safety harnesses attached by lanyards and

rope grabs to independent lifelines. Use short lanyards

and attach the rope grabs as high on the lifeline as

practically possible. Lifelines shall be fastened to a fixed

anchorage other than the rigging systems. Do not

disconnect or remove harnesses or lanyards until safely

on the ground or until completely disembarked from

suspensionsystemtoasafelocation.

•

Safety helmets should be worn at all times when

servicing, (dis-) assembling or using the equipment.

•

Provide protection for operators from collision with

overhead obstacles and falling objects.

•

Provideadequateprotectionbelowthesuspended

system to prevent injury to persons from falling objects.

Keep all persons from beneath suspended platforms.

•

Maintain contact with your supervisor at all times.

•

Make a copy of this manual available to every person

using, erecting and assembling this equipment.

•

•

Never work alone on suspended access systems

Do not over load the equipment

•

All suspended access equipment must be handled

with care: during handling of equipment, installation and

use (place loads gently on platform).

•

Inspect and test the equipment before use, rigging,

re-

rigging, after de-rigging and at regular intervals to

make

sure that it is maintained in a safe workable

condition. The

supervisor should assign a competent

person for

inspection purposes. In case of equipment

failures or

difficulties noticed during testing and inspec-

tion prior to

use, contact your nearest Sky Climber®

representative

and do not use the equipment until it is

repaired or

replaced. Only use Sky Climber® spare

parts. Do not

alter any equipment. Maintenance may

only be carried

out by Sky Climber® representatives.

•

Verify if all decals and nameplates are properly

affixed and legible. If they are obscured or missing,

replacements are available from Sky Climber®.

•

Always verify if a platform is properly counter-

weighted: check the rigging systems prior to each shift.

•

Never load the platform above the indicated safe

working load.

•

In case of an emergency during operation press the

red

emergency stop button on the hoist or control unit. The

platform will halt immediately (power is cut off,

brakes are

activated). Solve the problem first, prior to

furtheruse.

•

Never use suspended access systems for

transportation of passengers from one level to another.

•

Where an object falling from a platform could pose a

hazard to persons below, a screen or other material

shall be provided around the periphery of the platform

to prevent objects 25mm (1”) in diameter from falling

through.

•

Keep the vertical travel zone of the platform free of

obstructions. If contacting an obstruction immediately stop

the platform. Inspect the platform and the obstruction for

possible damage and/or hang-up. Proceed in a safe

direction. Take care not to overload the system or get in

slack rope situation when running into

an obstacle.

•

Beware of obstacles when there is too small of a

clearance between platform and facade. Use long-

handled tools when working at large distances between

platform and facade.

•

Do not handle suspended loads in conjunction with

suspended platforms.

•

When leaving a suspended platform (in mid-air), in

order

to k eep it from m oving away from the building, s ecure the

platform to the face of the structure. Do not forget to

disconnect the platform from the structure before moving

otherwise serious injuries and/or damage can occur.

•

Hazardous situations occur when it is not possible to

lower platform to a safe position (i.e. over water or roads).

•

Never alter equipment once the platform is sus-

pended. Keep all equipment out of reach of

unauthorized persons.

•

Rejected equipment must be destroyed prior to

disposal so that it cannot be misused, reused, or other-

wise returnedtoservice.

•

The guardrail on the front portion of the platform (i.e.

side adjacent to the building or structure) is adjustable/

removable. This guardrail should be lowered to its

down position or removed only when the platform is not

moving (being raised or lowered) and when the platform

is restrained to within 0.30m (12”) or less of the face of

the building or structure.

SAFETY GUIDELINES

GENERAL

UM•36•001

ED•2019-12-04

Operation Safety

Operator's Safety

4

®

KY CLIMBER

Consider and control the specific ris

k

s related

t

o certain environments and nature of the job. Increase inspection accord-

ingly.

Hazards

•

Do not use suspended access equipment in severe

conditions: extreme environmental conditions, corrosive

environment, strong magnetic fields, explosive

atmospheres.

•

Do not use suspended access equipment when

handling loads could lead to dangerous situations: molten

metal, acids/bases, radioactive materials, brittle loads.

•

When high winds are encountered the platform should

be lowered to the ground or raised to the roof top

andsecured.

•

Do not use suspended access equipment when wind

speed

exceeds 40km/hour

•

Enclosures or other items that may increase wind

loadings shall not be fitted to the platform unless authorized

by the manufacturer or done per the design of a qualified

engineer.

High voltage powe

r

-lines

•

Refer to regulations, federal, state and local codes

when working in the vicinity of electrical overhead

power-

lines. Consult the local power company for safe

operating

procedures.

•

The minimum separation between live power lines

and platform is 3m (10').

•

Touching live power-lines may result in

serious

injury or death.

Wind Speeds

•

Use adequate restraints when lifting height exceeds

40m (131') with wind speeds above 40km/h

=

11m/s

(25mph).

•

Do not use suspended access equipment when

hazards could arise from wind pressure acting on loads

having a surface area in excess of 2m2 (21.5 SQFT).

Welding

During welding, the electrocution hazard and the risk of the welding current passing through the steel wire ropes shall be

eliminated by taking the following precautions:

•

Use insulated thimbles at each suspension point.

Insulate surplus steel wire rope stored on roof to prevent

grounding or, terminate steel wire rope at insulated

thimble.

•

Cover steel wire rope above hoist and Sky Lock for a

distance of

±

1.2m (4') with insulating material: rubber

hose taped in place. Insulate tail line below hoist: extend

downward sufficiently to prevent contact with platform.

The portion of tail line hanging free below platform must

be guided and/o

r

r

etained so that it does not become

grounded.

•

Cover each hoist, Sky Lock and wire winder with

protective covers made out of insulating material.

•

Connect a ground conductor from platform to work

piece. The size of this conductor shall be equal to or

greater than the size of the stinger lead. It must be a

secondary conductor and shall not be in series with the

primary conductor between welder and work piece.

Marine environment

Salty environments may deteriorate aluminum & steel

components. Frequently inspect equipment.

Excess material accumulation

Make sure that excess material does not clutter up the

hoist, Sky Lock or platform.

SAFETY GUIDELINES

GENERAL

UM•36•001

ED•2019-12-04

Group 2B

Group 2A

Group

Category Condition Te m p . Applications Inspection

Normal

> 0°C/32 F

Inspections,light maintenance,window washing.

Prior to each workshift.

2

A

B

C

Contaminated

Contaminated

Contaminated

> 0°C/32 F

> 0°C/32 F

> 0°C/32 F

Abrasive materials: sand, grit, dust, welding.

Caustic materials: corrosive chemicals,

salty environment, acids or fumes.

Adhesive materials: cement, plaster, paint,

caulking, compound.

Prior to each workshift.

Every 4 hours.

3

Freezing

0°C/32

F

All -

Caution:Donotallowsnoworiceto

accumulateontheflooroftheplatform.

Prior to each workshift

Monitor during use.

Environment

5

®

K

Y

CLIMBER

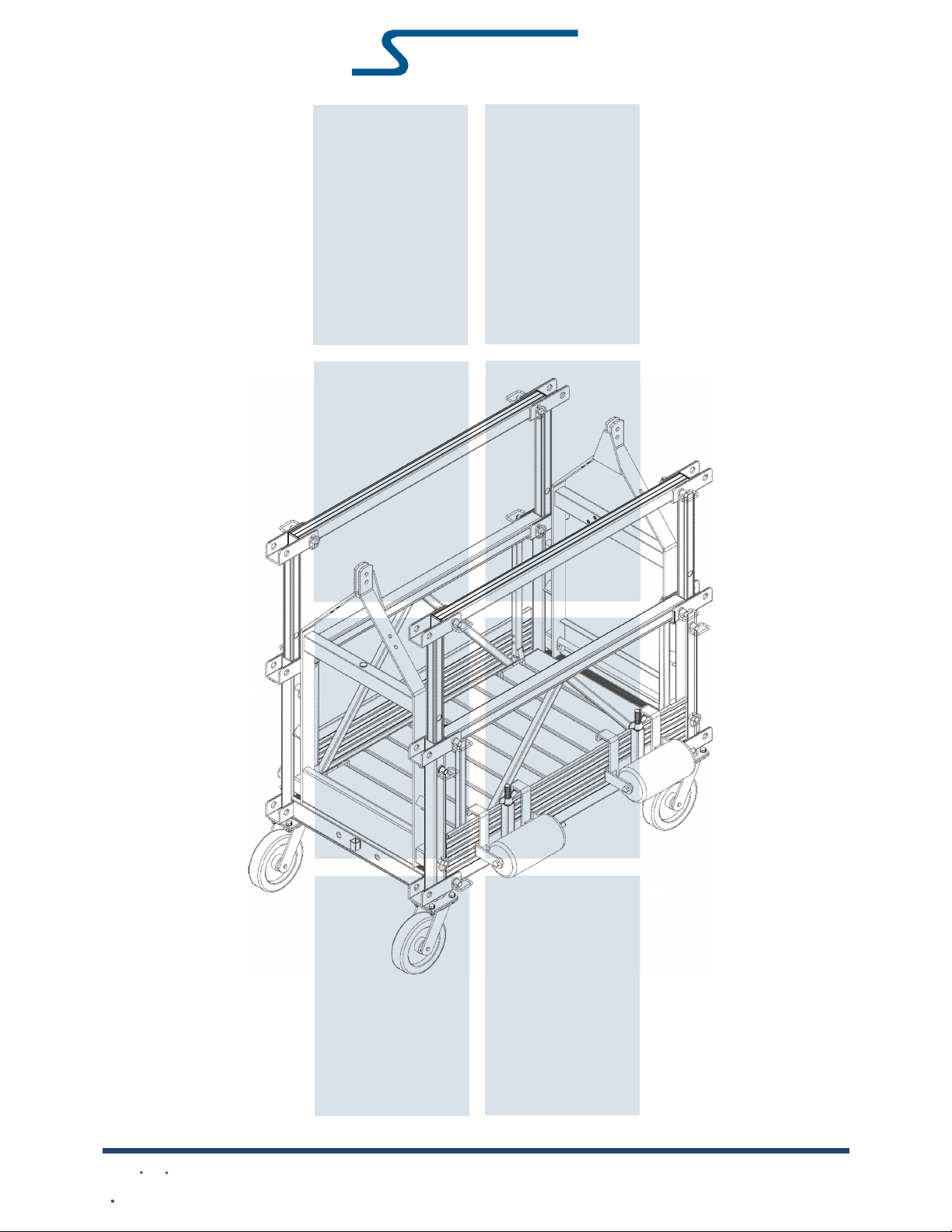

Sky Stage Ultra

®

with End Stirrup configurations

Sky Stage Ultra® is a modula

r

wo

r

k platform. All compo-

nents are welded out of high quality aluminum. The

platform lengthcanvarybetween2m andl5massem-

bled from lm, l.5m, 2m and 3m sections. A section

consistsof2 sidepanels,a floorpaneland 2toprails.

A rigid structure is formed by attaching sections to

connecting frames with connecting pins.

Top rails are telescopic on both sides of the stage.

The standard configurations are further described.

END STIRRUP CONFIGUR

A

TIONS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

Overv

iew

Floor Panel

Top Rail

Connecting Pin assy

Side Panel

Wall Roller assy

Telescopic Post

Connecting Frame

Caster assy

End Stirrup assy

6

®

K

Y

CLIMBER

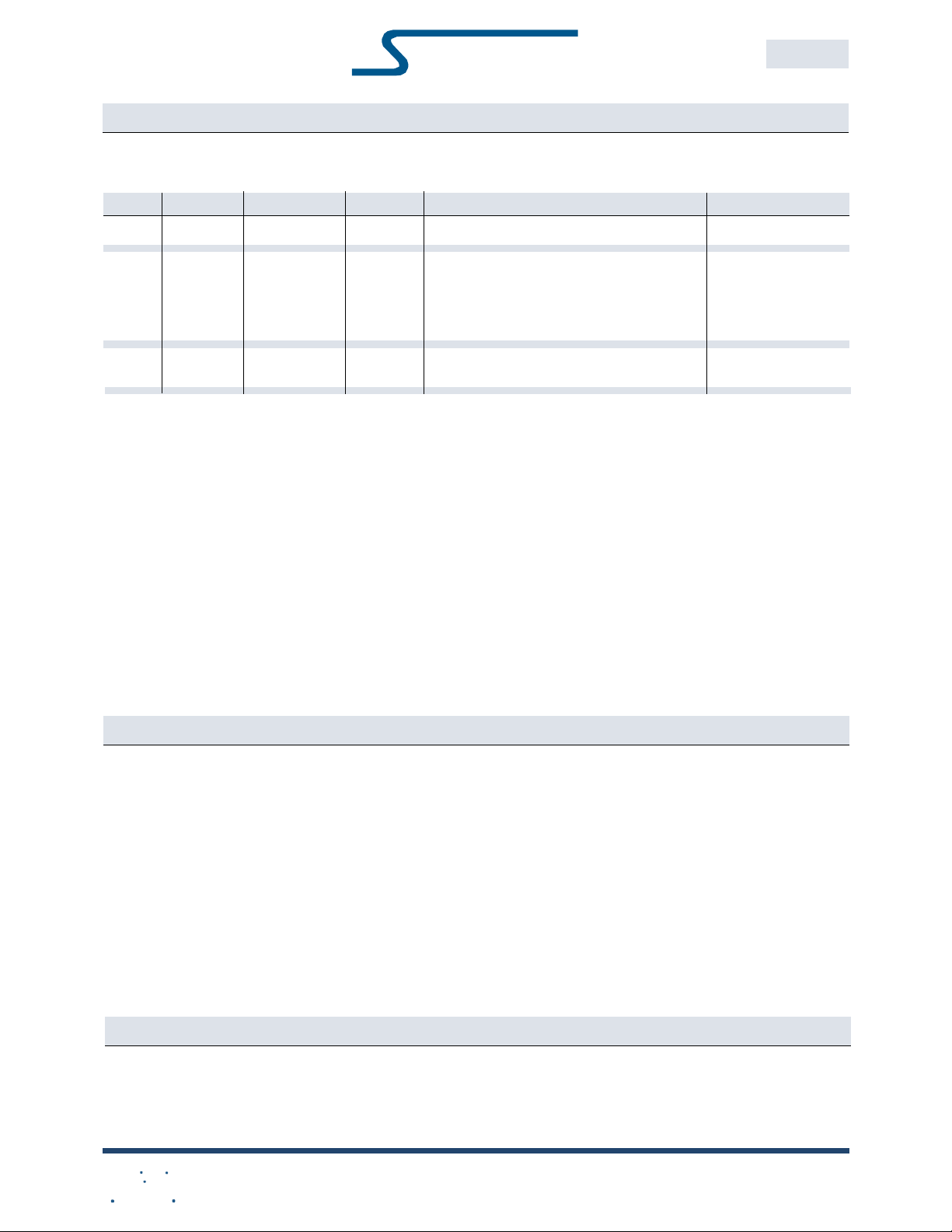

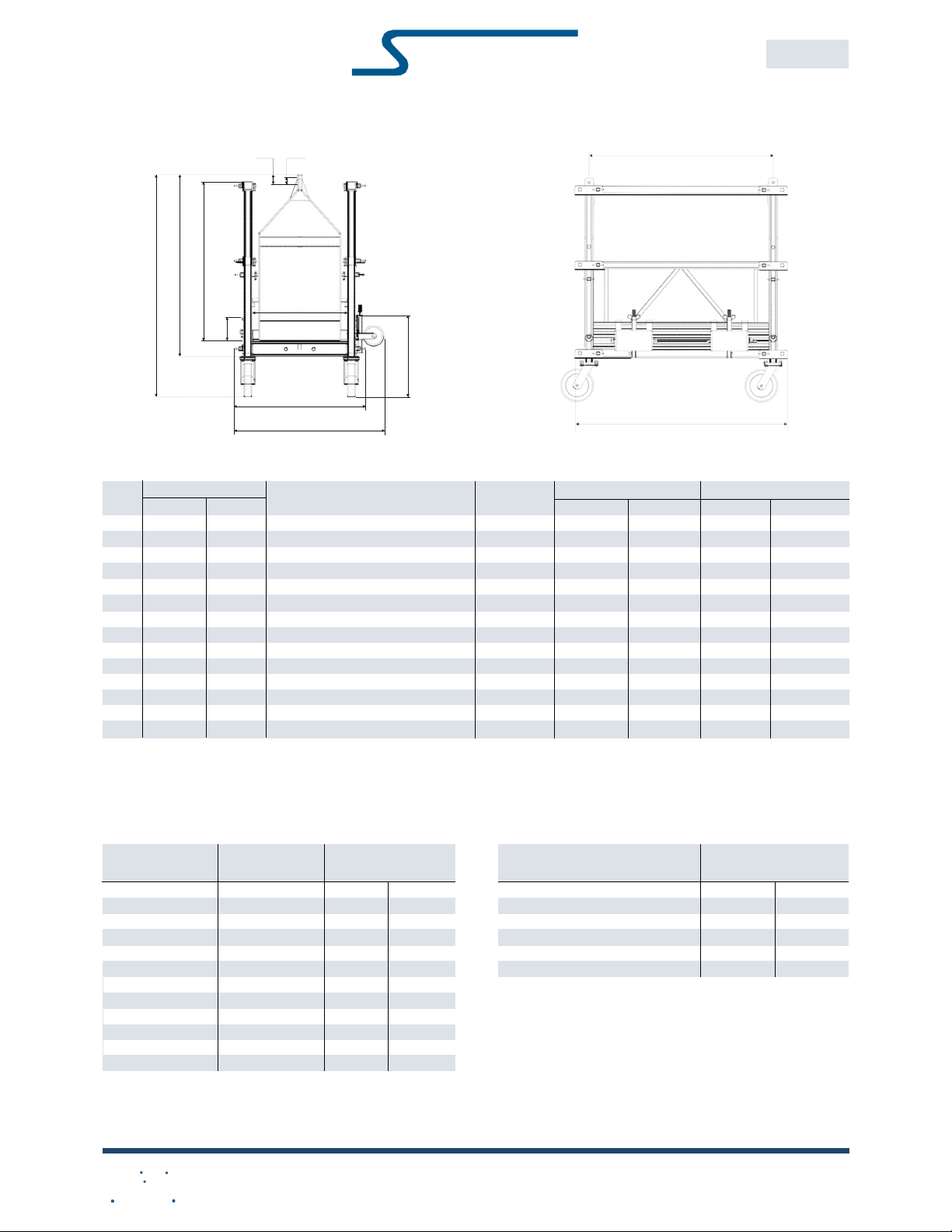

Dimensions

L

2

C

C

2

l

H

H

H

H

H

H

la

2a

3a

lb

2b

3b

W

3

4

H

5

2

L

l

l

Sky Stage Ultra® with End Stirrup: side view.

Sky Stage Ultra® with End Stirrups: front view.

1

2

Ja

Jb

2a

Ja

2b

Jb

3a

3b 3a

4

5

J

2

3

J

2

•

Platform length dimensions are only valid if standard configurations are used (see 'Configurations & Assembly

P

arts').

•

Caster wheel swings 9cm (3.5") outside total length of platform (L

1

).

Transport & Handling Weights

•

•

Handle all parts with care: do not drop o

r

thro

w

parts.

Inspect parts prior to installation and use

(see also 'Inspection Check Lists').

END STIRRUP CONFIGUR

A

TIONS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

Platform Parts

Self-weight

kg

lbs

End Stirrup assy

14. 32

Connecting Frame

4.5 10

Telescopic Post

0.9 2

Connecting pin assy

0.3 0.75

Caster assy

4.1 9

wall Roller assy

4.5 10

Platform

Parts

Options

Self-weight

kg

lbs

Side Panel

1

m

6.4

14

1.5 m

9.1

20

2

m

11.8

26

3

m

16.8

37

Top Rail

1

m

1.4

3

1.5 m

1.8

4

2

m

2.3

5

3

m

3.2

7

Floor

p

anel

1

m

6.8

1

5

1.5 m

9.5

21

2

m

12.2

27

3

m

16.8

37

Item

Dimension

Description

Platform

length

To t a l

length (L )

Suspension

dist. (L

)

Metric

Inches

Metric

Ft/Inch.

Metric

Ft/Inch.

H

1.40 m

54 .8

"

Max. height:

p

latform on surface

2

m

2.23 m

7

'

3

"

2.0

6

m

6

'

9

"

H

1.43 m

56 .2

"

Ma

x

. heigh

t

: suspende

d

p

latform

3

m

3.15 m

10

'

4

"

2.98 m

9

'

9

"

H

1.14 m

44 .8

"

Idem H but without casters

4

m

4.29 m

14

'

0

"

4.12 m

13

'

6

"

H

1.18 m

46 .2

"

Idem H but without casters

5

m

5.21 m

17

'

1

"

5.04 m

16

'

6

"

H

1.00 m

39 .4

"

T

o

p

R

a

i

l heigh

t

from floor

p

anel

6

m

6.13 m

20

'

1

"

5.9

5

m

19

'

6

"

H

1.10 m

43 .3

"

Idem H : secon

d

option

7

m

7.2

7

m

23

'

10

"

7.09 m

23

'

3

"

H

0.15 m

5

.

9

"

T

oeboar

d

height

8

m

8.19 m

26

'

10

"

8.01 m

26

'

3

"

H

0.50 m

19 .5

"

Stepping height

9

m

9.11 m

29

'

10

"

8.93 m

29

'

3

"

w

0.94 m

37 .0

"

Max. outside width with wall roller

10

m

10.25 m

33

'

7

"

10.0

7

m

33

'

0

"

w

0.83 m

3

2

.

5

"

Ma

x

. outside width with safet

y

p

in

s

11

m

11.1

6

m

36

'

7

"

10.99 m

36

'

0

"

w

0.60 m

23 .6

"

Insi

d

e width:

p

assage

12

m

12.08 m

39

'

7

"

11.91 m

39

'

0

"

C

60.00

m

m

2

.362

"

Position: hoist attachment

13

m

13.22 m

43

'

4

"

13.05 m

42

'

9

"

C

31.50

m

m

1 .240

"

Position: hoist attachment

14

m

14.14 m

46

'

4

"

13.9

7

m

4

5

'

9

"

15 m

15.0

6

m

49

'

4

"

14.89 m

48

'

9

"

W

W

H

7

®

K

Y

CLIMBER

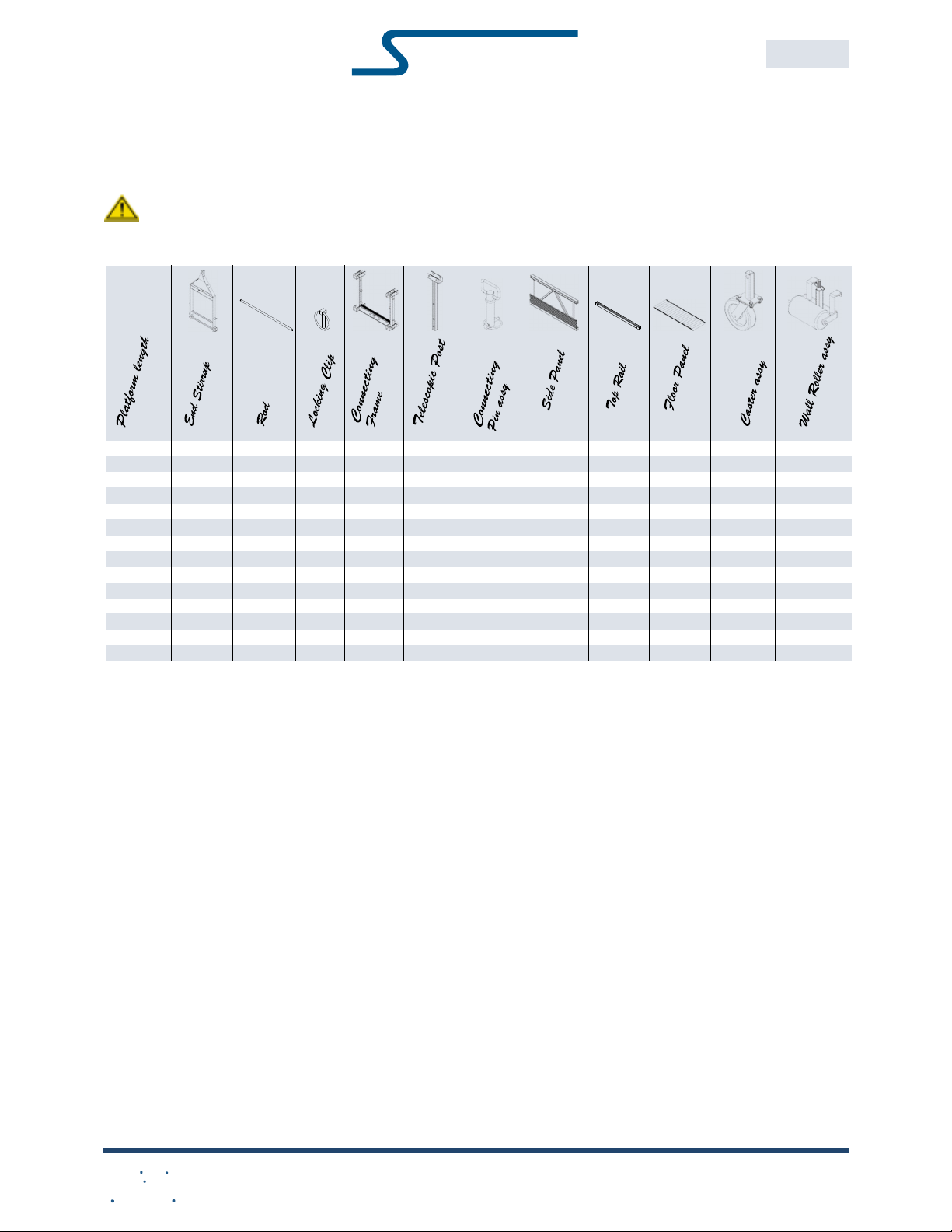

Standard Configurations & Assembly Parts

The following table can be used as check list when preparing standard configuration for transport.

Conformance to the rated load capacities & configurations as shown in these tables is critical to the safe use of Sky Stage Ultra.

Use of other configurations or greater weights could result in serious iniury.

•

lm

&

l.5m

sections are also available, providing additional versatility in platform length.

•

Contact your Sky Climber® representative for the other configurations.

Note:

Platform sections may not be used in configurations and lengths other than those shown in these tables. Contact Sky Climber®

Engineering to discuss any variations.

END STIRRUP CONFIGUR

A

TIONS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

2m

3m

2m

3m

2m

3m

2m

2

2

4

2

4

16

2

0

2

0

1

0

4

2

3m

2

2

4

2

4

16

0

2

0

2

0

1

4

2

4m

2

2

4

3

6

30

4

0

4

0

2

0

4

2

5m

2

2

4

3

6

30

2

2

2

2

1

1

4

2

6m

2

2

4

3

6

30

0

4

0

4

0

2

4

2

7m

2

2

4

4

8

44

4

2

4

2

2

1

4

2

8m

2

2

4

4

8

44

2

4

2

4

1

2

4

2

9m

2

2

4

4

8

44

6

0

6

0

3

0

4

2

10m

2

2

4

5

10

58

4

4

4

4

2

2

4

2

11m

2

2

4

5

10

58

2

6

2

6

1

3

4

2

12m

2

2

4

5

10

58

0

8

0

8

0

4

4

2

13m

2

2

4

6

12

72

4

6

4

6

2

3

4

2

14m

2

2

4

6

12

72

2

8

2

8

1

4

4

2

15m

2

2

4

6

12

72

0

10

0

10

0

5

4

2

8

®

K

Y

CLIMBER

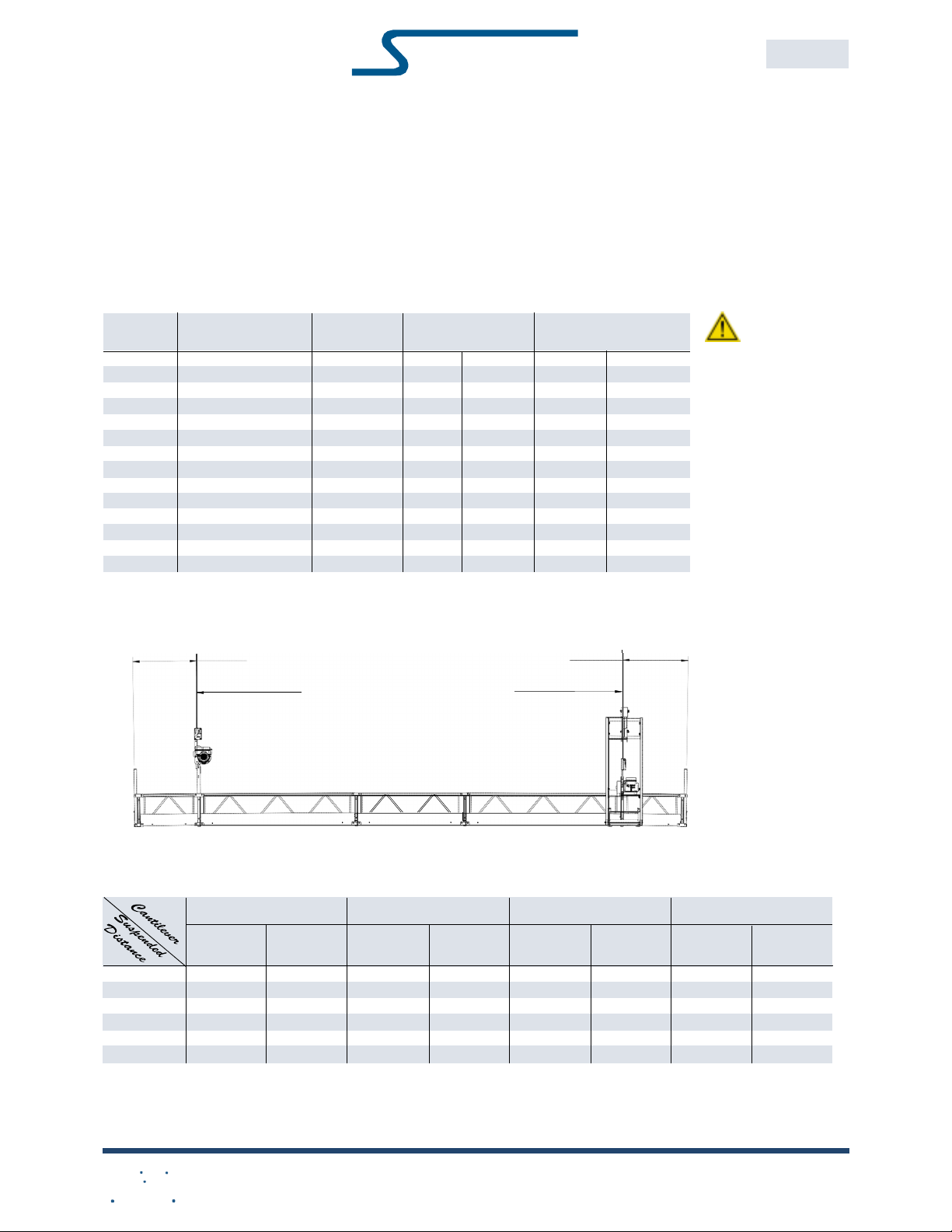

Standard Configurations

Safe Working Load

&

Load

Ratings per UL

•

Do not concentrate all loads but equally distribute over total

length of platform.

•

If loads are concentrated on one half of a platform then the

SwL equals the wLL of 1 hoist less half the self weight of the

platform (never exceed floor rating).

•

The load on the floor panels must not exceed the floor rating:

maximum 180kg per meter platform or 120lbs per foot platform.

l.

2.

3.

Determine working load limit (WLL) o

f

hoist.

Add WLL's of hoists used.

Compare total WLL of hoists less the selfweight of

platfo

r

m with load rating (L

R

) o

f

platform.

4. Use lowest value as the Safe Working Load (SWL).

Configurations fo

r

stages

w

ith End Stirrups (two point suspension systems) pe

r

ULl322.

Conformance to the

rated load capacities

& configurations as shown

in these tables is critical to

the safe use of Sky Stage

Ultra. Use of other

configurations or greater

weights could result in

serious iniury.

Note: Platform sections may not be used in configurations and lengths other than those shown in these tables. Contact Sky Climber®

Engineering to discuss any variations.

CANTILEVER

Note: Connecting frame is never to be placed outside intermediate stirrup

Note: Connecting frame is never to be placed outside intermediate stirrup.

Cantilever distance is the distance from the suspension point to the end of the stage, not the distance from a part of the

intermediate stirrup to the end of stage

END STIRRUP CONFIGUR

A

TIONS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

0 - 1m

1 - 1,5m

1,5 - 2m

2 - 3m

Total Stage

Rating(lbs)

Cantilever

Rating(lbs)

Total Stage

Rating(lbs)

Cantilever

Rating(lbs)

Total Stage

Rating(lbs)

Cantilever

Rating(lbs)

Total Stage

Rating(lbs)

Cantilever

Rating(lbs)

5 - 6m

2000

500

6

- lm

1500

500

-

-

-

-

-

-

l

- Bm

1500

500

1500

500

B - 9m

1000

500

1000

500

1000

250

9 - 12m

1000

500

1000

500

1000

500

1000

250

12 - 15m

750

500

750

500

750

500

750

250

LEVER

SUSPENDED DISTANCE

CANTI

Platform

Length

Configurations

Suspension

Distance

Self-weight

kg

lbs

Load Rating

kg

lbs

2

m

2

6

'

9

"

113

249

900

2000

3m

3

9'

9"

129

28

900

2000

4m

2+2

13'

6"

164

363

900

2000

5m

2+3

16'

6"

181

399

900

2000

6m

3+3

19'

6"

197

43

900

2000

7m

2+3+2

23'

3"

232

512

680

1500

8m

3+2+3

26'

3"

249

548

680

1500

9m

3+3+3

29'

3"

265

584

450

1000

10m

2+3+3+2

33

'

0

"

300

66

2

450

1000

11m

2+3+3+3

36'

0"

316

698

450

1000

12m

3+3+3+3

39

'

0

"

333

734

450

1000

13m

2+3+3+3+2

42'

9"

368

811

340

750

14m

3+2+3+3+3

45'

9"

384

847

340

750

15m

3+3+3+3+3

48'

9"

401

883

340

750

9

®

K

Y

CLIMBER

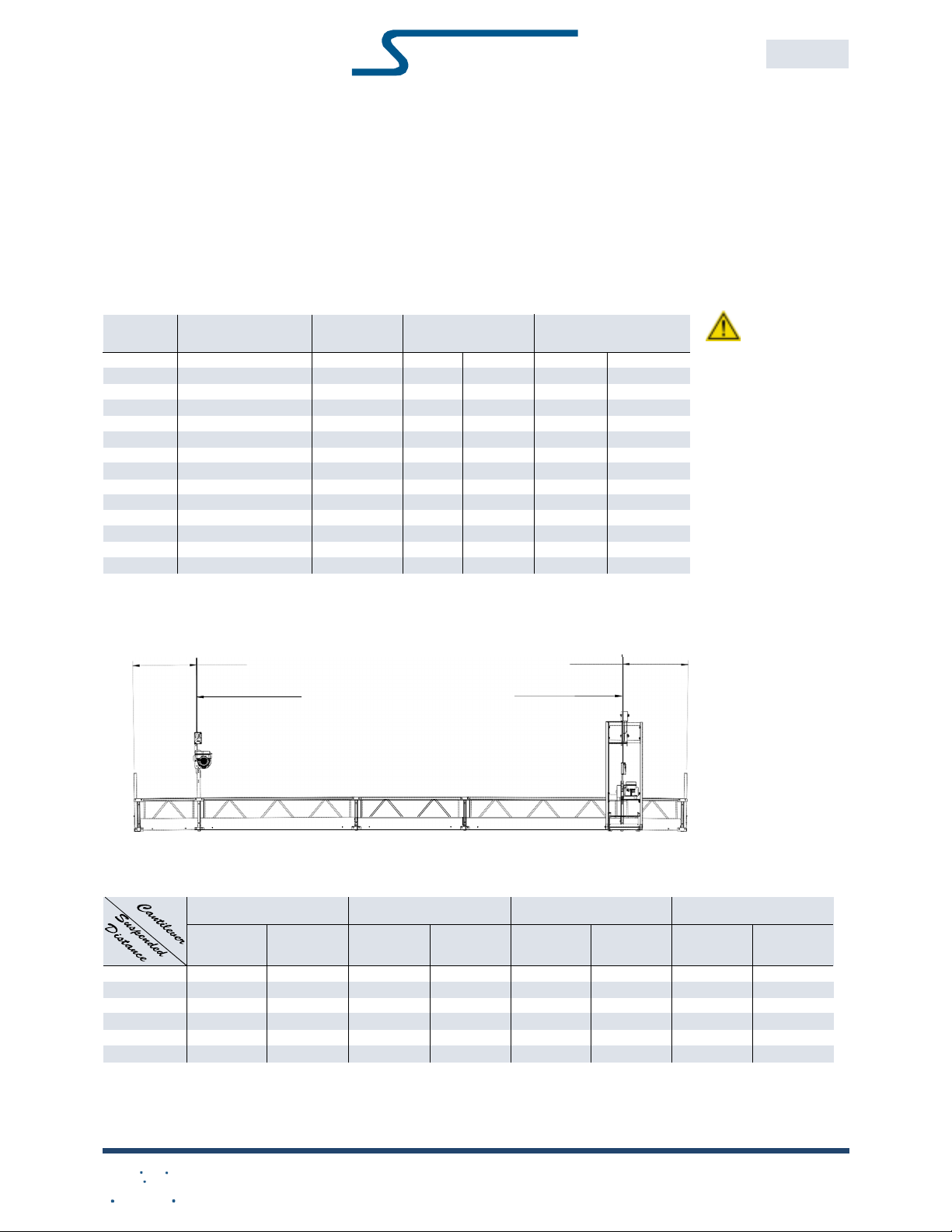

Standard Configurations

Safe Working Load

&

Load

Ratings per EN1808

•

Do not concentrate all loads but equally distribute over total

length of platform.

•

If loads are concentrated on one half of a platform then the

SwL equals the wLL of 1 hoist less half the self weight of the

platform (never exceed floor rating).

•

The load on the floor panels must not exceed the floor rating:

maximum 180kg per meter platform or 120lbs per foot platform.

l.

2.

3.

Determine working load limit (WLL) o

f

hoist.

Add WLL's of hoists used.

Compare total WLL of hoists less the selfweight of

platfo

r

m with load rating (L

R

) o

f

platform.

4. Use lowest value as the Safe Working Load (SWL).

Configurations fo

r

stages with End Stirrups (two point suspension systems) pe

r

ENl808.

Conformance to the

rated load capacities

& configurations as shown

in these tables is critical to

the safe use of Sky Stage

Ultra. Use of other

configurations or greater

weights could result in

serious iniury.

Note: Platform sections may not be used in configurations and lengths other than those shown in these tables. Contact Sky Climber®

Engineering to discuss any variations.

CANTILEVER

Note: Connecting frame is never to be placed outside intermediate stirrup

Note: Connecting frame is never to be placed outside intermediate stirrup.

Cantilever distance is the distance from the suspension point to the end of the stage, not the distance from a part of the

intermediate stirrup to the end of stage

END STIRRUP CONFIGUR

A

TIONS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

0 - 1m

1 - 1,5m

1,5 - 2m

2 - 3m

Total Stage

Rating(lbs)

Cantilever

Rating(lbs)

Total Stage

Rating(lbs)

Cantilever

Rating(lbs)

Total Stage

Rating(lbs)

Cantilever

Rating(lbs)

Total Stage

Rating(lbs)

Cantilever

Rating(lbs)

5 - 6m

6

- lm

l

- Bm

B - 9m

COMING

SOON

9 - 12m

12 - 15m

LEVER

SUSPENDED DISTANCE

CANTI

Platform

Length

Configurations

Suspension

Distance

Self-weight

kg

lbs

Load Rating

kg

lbs

2m

2

6'

9"

113

249

360

795

3m

3

9'

9"

129

285

540

1190

4m

2+2

13'

6"

164

363

720

1585

5m

2+3

16'

6"

181

399

900

1985

6m

3+3

19'

6"

197

43

1080

2380

7m

2+3+2

23'

3"

232

512

1080

2380

8m

3+2+3

26'

3"

249

548

1080

2380

9m

3+3+3

29'

3"

265

584

1080

2380

10m

2+3+3+2

33

'

0

"

300

66

2

920

2028

11m

2+3+3+3

36'

0"

316

698

750

1650

12m

3+3+3+3

39'

0"

333

734

680

1500

13m

2+3+3+3+2

42'

9"

368

811

540

1190

14m

3+2+3+3+3

45'

9"

384

847

450

990

15m

3+3+3+3+3

48'

9"

401

883

360

795

10

®

K

Y

CLIMBER

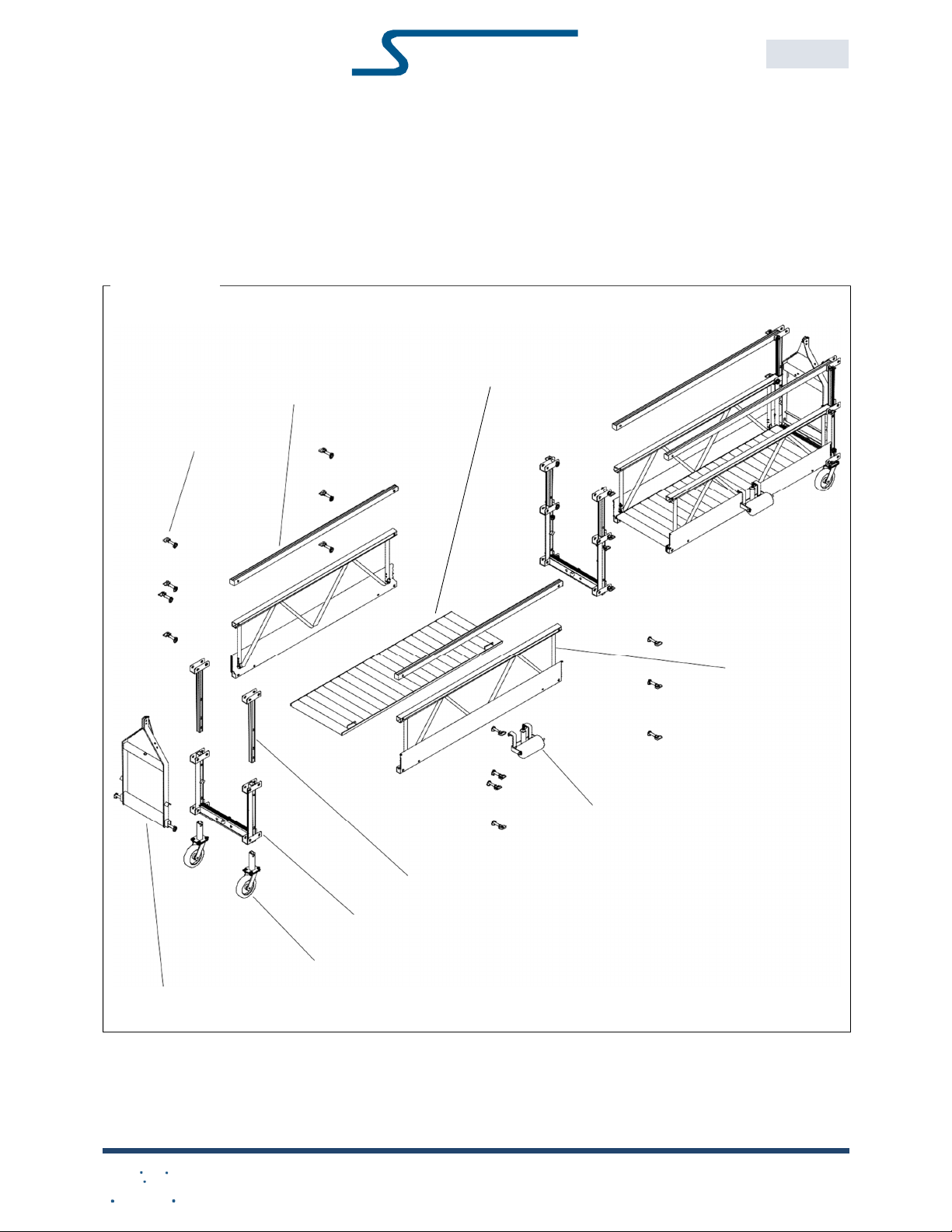

Installation Instructions

Assemble

platform

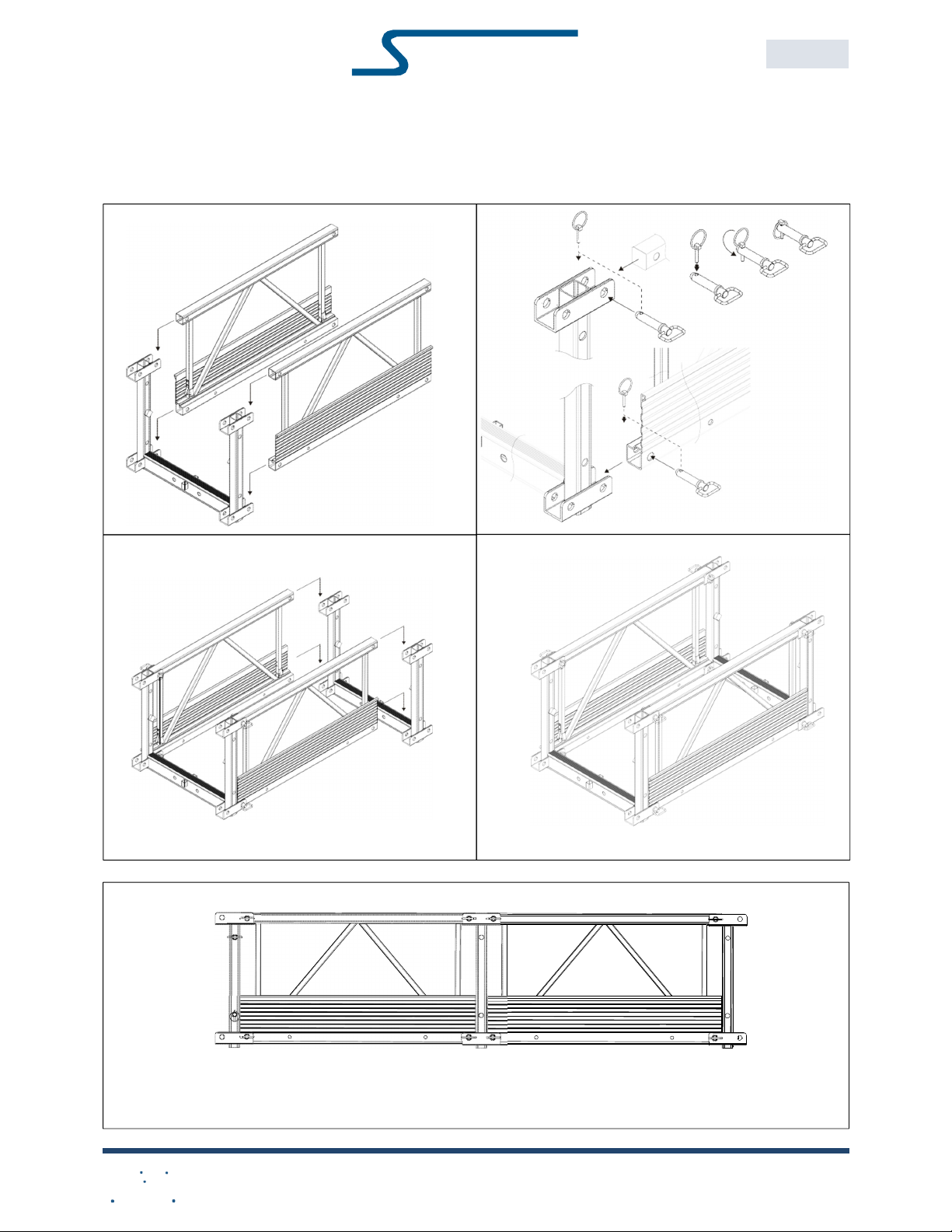

5

•

Repeat step 1-4 fo

r

longe

r

configuration.

•

To assemble multiple sections with ease:

place end of platform on blocks.

INSTALL

A

TION INSTRUCTIONS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

1

2

Secure each main pin

with a locking clip.

4 Connecting

Pin assy's per

Side Panel

3

4

11

®

K

Y

CLIMBER

INSTALL

A

TION INSTRUCTIONS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

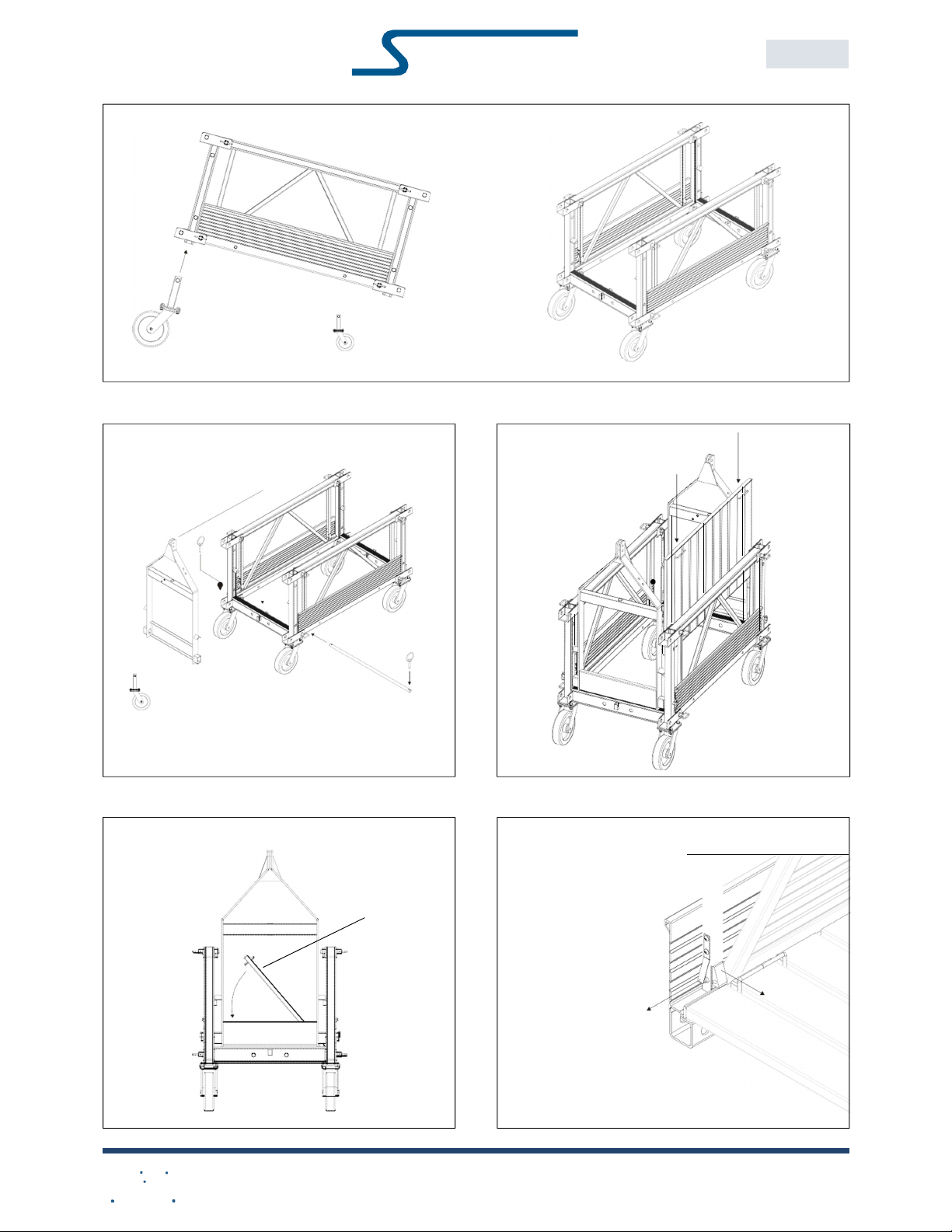

10

Floor retaining Tabs

should always be

extendedtoprevent

FloorPanel from

lifting.

9

Floor Panel

8

7

are secured with Rod of End Stirrup assy.

Note: Extra Casters (not positioned underneath an

End stirrup) can be retained by Connecting Pin assy's.

6

Minimum4

12

®

K

Y

CLIMBER

INSTALL

A

TION INSTRUCTIONS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

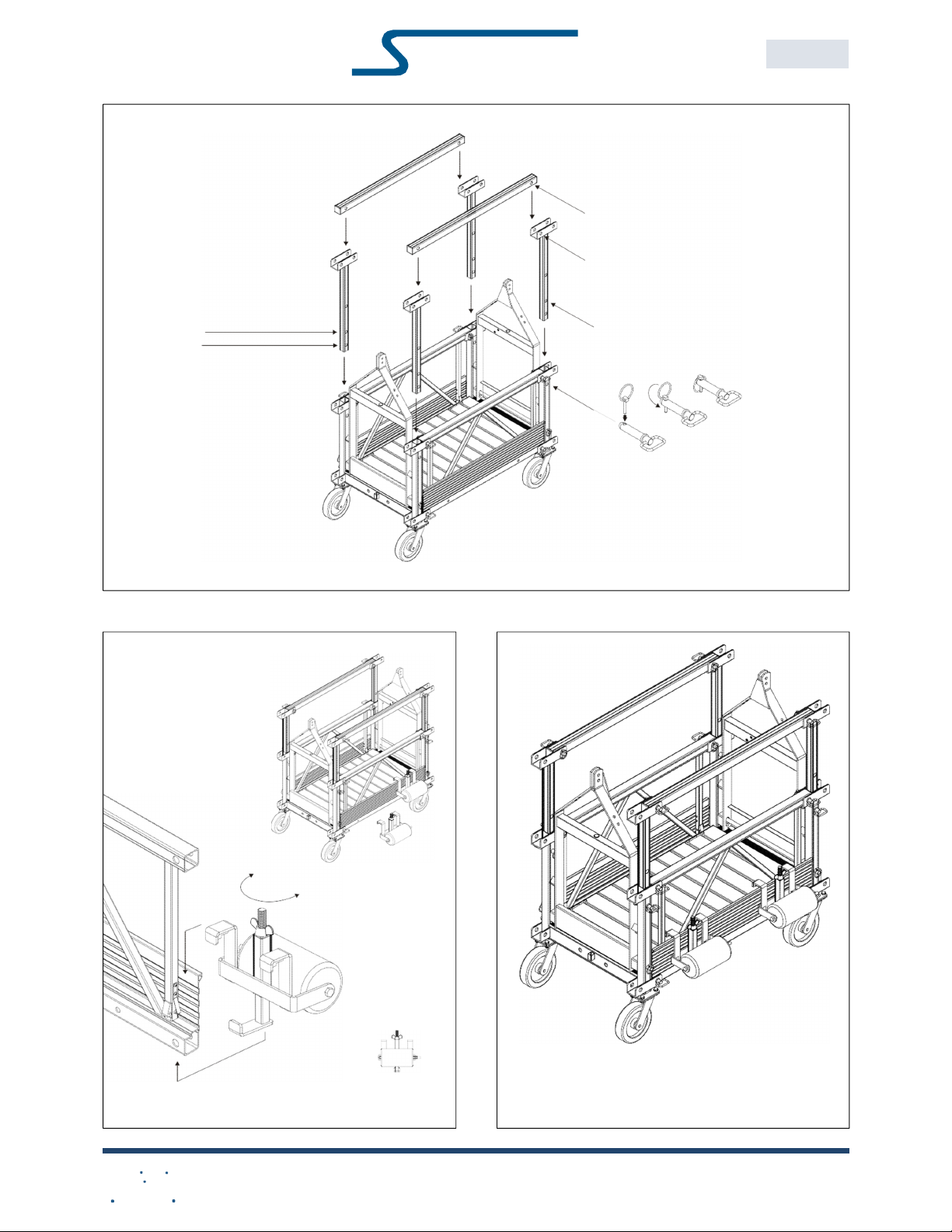

Congratulations !

•

You may now attach hoists and safety devices.

•

Installation shall be checked by a qualified person

prior to use.

12

B

C

A

B

Minimum2

Note: Once suspended wall rollers can

be repositioned from within platform.

11

1m above floor

1.1m above floor

Secure each Connecting Pin with the

Locking Clip.

2 Connecting Pin assy's per Top Rail.

1 Connecting Pin assy per Telescopic Post.

13

®

K

Y

CLIMBER

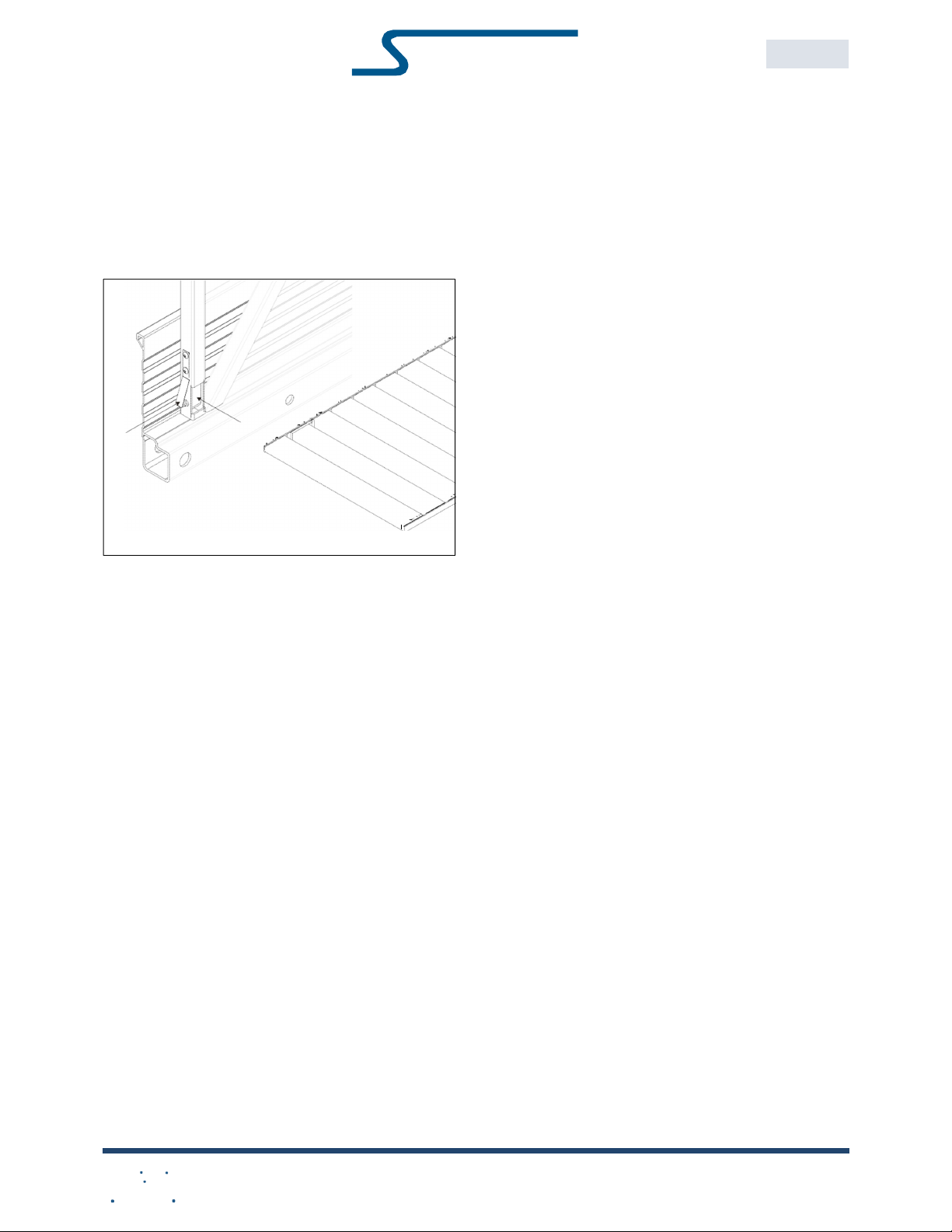

Dis-assemble platform

Use - operation

Wall-rollers

Once suspended wall rollers can be repositioned from

within platform.

Reverse'assemblingprocedure'to dis-assembleplat-

form.

Floo

r

Panels

Make sure that the floor retainer blocks are inserted (A)

into the side panel and secured by tabs (B) prior to lifting

the floor panel.

Repositioning platform

1.

2.

3.

Remove all load from platform: material and persons.

Dereeve hoists.

Reposition platform underneath new position of

rigging system.

4.

5.

Reeve hoists.

Inspect installation prior to use.

INSTALL

A

TION INSTRUCTIONS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

B A

14

®

KY CLIMBER

Check Lists

Inspection prior to installation

Operating instructions are kept with stage at all times

Reject & replace parts when the following failures are noticed:

Cracked or torn welds.

Cracked or torn material.

Deformations that could endanger the structural strength.

Deformations that would not allow normal installation.

Deformed or cracked connecting holes.

Damaged, missing or ilegible decals indicating load ratings, configurations etc.

Check components prior to shipment

Use table 'Standard configurations & Assembly Parts' in this user manual to verify to correct

amount of parts prior to shipment. Ensure all decals and/or nameplates are in place and

legible.

Inspection after installation

Inspect the platform assembly after installation and prior to each workshift:

Verify load rating pe

r

this manual or decals and verify this load will not be exceeded

Verify if all connections have a Connecting Pin assy:

Side Panel: 4 Connecting Pin assy's

Top Rail: 2 Connecting Pin assy's

Telescopic Post: 1 Connecting Pin assy

Verify if each Connecting Pin is secured with a Locking Clip.

Side Panel: 4 Connecting Pin assy's

Top Rail: 2 Connecting Pin assy's

Telescopic Post: 1 Connecting Pin assy

Verify if each End Stirrup has 2 secured Locking Clips o

r

connecting Rod.

Verify if Wall Rolle

r

assemblies are tightened.

Verify if floo

r

retaine

r

Tabs & Blocks are extended: 4 pe

r

Floor

P

anel.

Verify if all warning decals and rating labels are in place and legible

Verify if provisions are made to protect workers from falling objects above and below

equipment.

Verify if stirrups are in line with the roof supports.

CHECK LISTS

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

Always wear personal fall protection equipment.

15

®

KY CLIMBER

Logbook

Instruction to the owner

Owner must keep a logbook which contains the following:

Name of the competent person in charge.

Date and name of operator(s).

Serial numbe

r

of hoist(s) and secondary device(s).

Numbe

r

of hours equipment in service.

Specification of wire rope.

Numbe

r

of hours wire rope in use.

Record of any incident and action taken.

Dates of periodic inspection and record of outcome.

Maintenance and repai

r

records shall be kept in logbook.

LOGBOOK

SKY STAGE ULTRA®

UM•36•002

ED•2019-12-04

Always wear personal fall protection equipment.

16

Other manuals for SKY STAGE ULTRA

1

Table of contents

Other Sky Climber Construction Equipment manuals