2

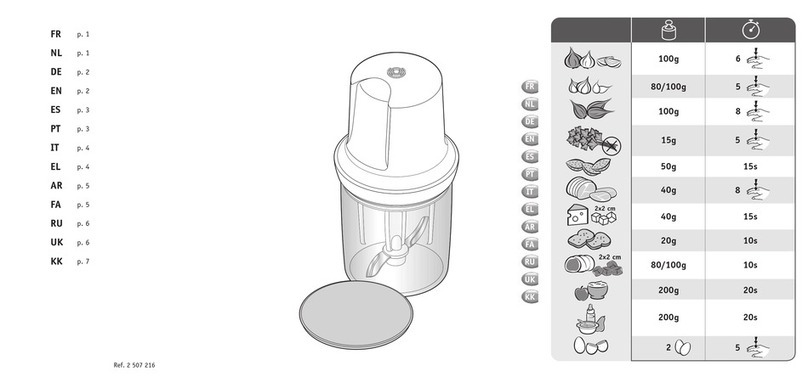

SUMMARY

1. Introducon ...................................................................................... 3

1.1 Safety .................................................................................................................... 3

1.2 Main Components ................................................................................................. 6

1.3 Technical Characteriscs ........................................................................................ 7

1.4 Available Discs ....................................................................................................... 7

2. Installaon and Pre Operaon ........................................................... 9

2.1 Installaon ............................................................................................................ 9

2.2 Pre Operaon ........................................................................................................ 9

3. Operaon ........................................................................................ 10

3.1 Starng.................................................................................................................10

3.2 Operaon Procedure ............................................................................................12

3.3 Cleaning and Sanizing .........................................................................................12

3.4 Cauons with Stainless Steel ................................................................................14

4. General Safety Pracces .................................................................. 15

4.1 Basic Operaon Procedures ..................................................................................15

4.2 Safety Procedures and Notes before Switching the Machine ON ...........................16

4.3 Roune Inspecon................................................................................................17

4.4 Operaon .............................................................................................................17

4.5 Aer Finishing The Work.......................................................................................17

4.6 Maintenance ........................................................................................................17

4.7 Warning................................................................................................................18

5. Analysis and Problem Solving .......................................................... 18

5.1 Problems, Causes and Soluons............................................................................18

6. Maintenance ................................................................................... 20

7. Electrical Diagram............................................................................ 21