3

1. Introducon

1.1 Safety

When incorrectly used this equipment is a potenally DANGEROUS machine.

Before using this equipment, read this Instrucons Manual carefully and keep it accessible

for future consulng.

To avoid accidents, injure or damages to the equipment, respect the following instrucons:

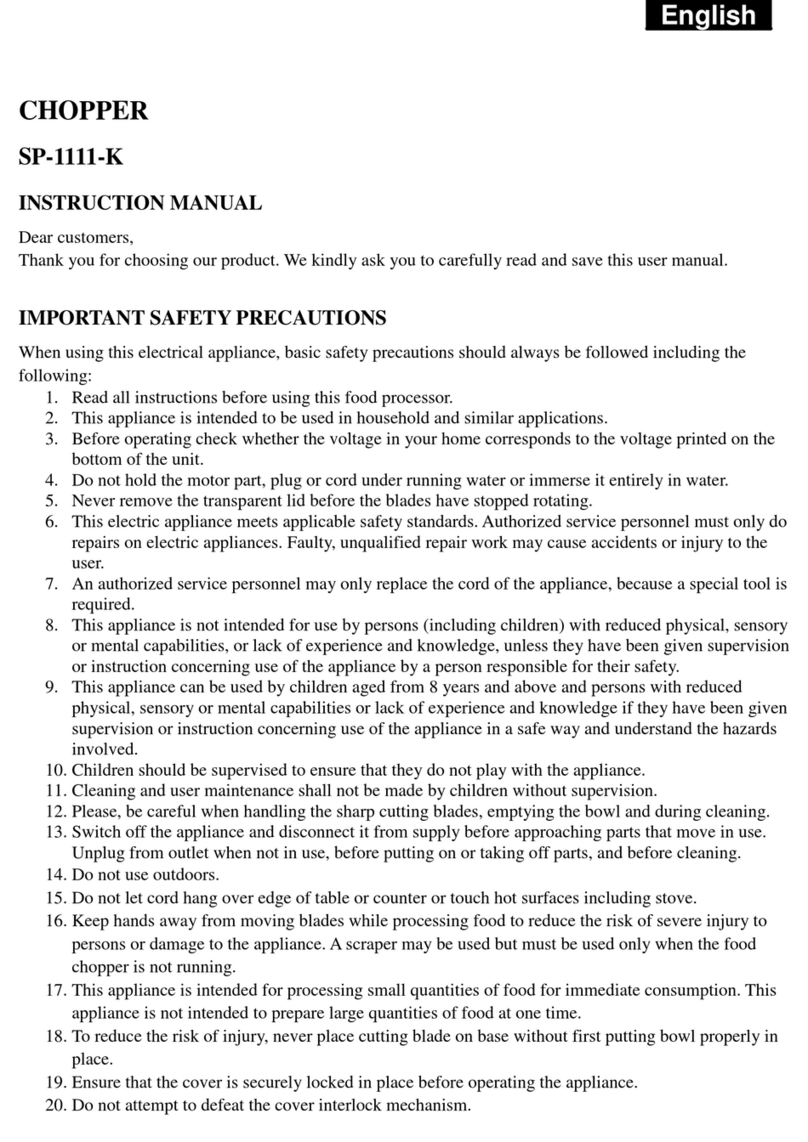

1.1.1 In order to avoid the risk of electric shocks and damage to the machine, never operate

it wearing wet clothes or shoes, install the equipment on a wet or humid surface nor dip it

in water or any other liquid, and do not spray water directly on it.

1.1.2 The use of the equipment must be always supervised specially when used next to

children.

1.1.3 Before cleaning and when not in use or before inserng or removing accessories,

maintenance, or other services, disconnect machine from power source.

1.1.4 Do not use the equipment if the cord or the plug is damaged. Do not leave the electric

cable on the edge of the table or counter nor let it touch hot surfaces.

1.1.5 Do not use the equipment if it is not working correctly, nor if it has been damaged in

any way. In case that happens, take the equipment to the nearest Technical Assistance to

check it up.

1.1.6 The use of accessories not recommended by the manufacturer may cause personal

hurt.

1.1.7 Keep your hands or any tool out of the machine while operang to avoid personal

hurt or any damage to the equipment.

1.1.8 During operaon, never wear loose clothes with wide sleeves principally around the

wrists.

1.1.9 Make sure the equipment voltage is the same as the network voltage and that the

equipment is duly grounded.

1.1.10 Before switching the equipment ON, check if the Expeller Dish, the Plate and the

Chamber Lid are correctly placed.

1.1.11 Never introduce the ngers or any other object inside the feeding opening. Always

use the Stumpers.

1.1.12 Never introduce the ngers or any other object inside the opening where processed

food comes out.

This equipment has been designed to be used in commercial kitchens, such as: restaurants,

cafeterias, hospitals, bakeries, butcheries and so on.

This equipment is not recommended to be used:

- when connuous industrial producon is necessary.

- work place has a corrosive or explosive atmosphere or it is contaminated with steam,

dust or gas.