02

WARNINGTOPROPRIETORSANDOPERATORS

The Food Processor has been designed to process foods with efficiency and safety .

However , as much well trained should be an operator, the possibility of a serious accident

exists.Itistheproprietorresponsibilitytoassureasafeandcorrectoperation,followingthe

instructionsofthepresentManualandthelocallaws.

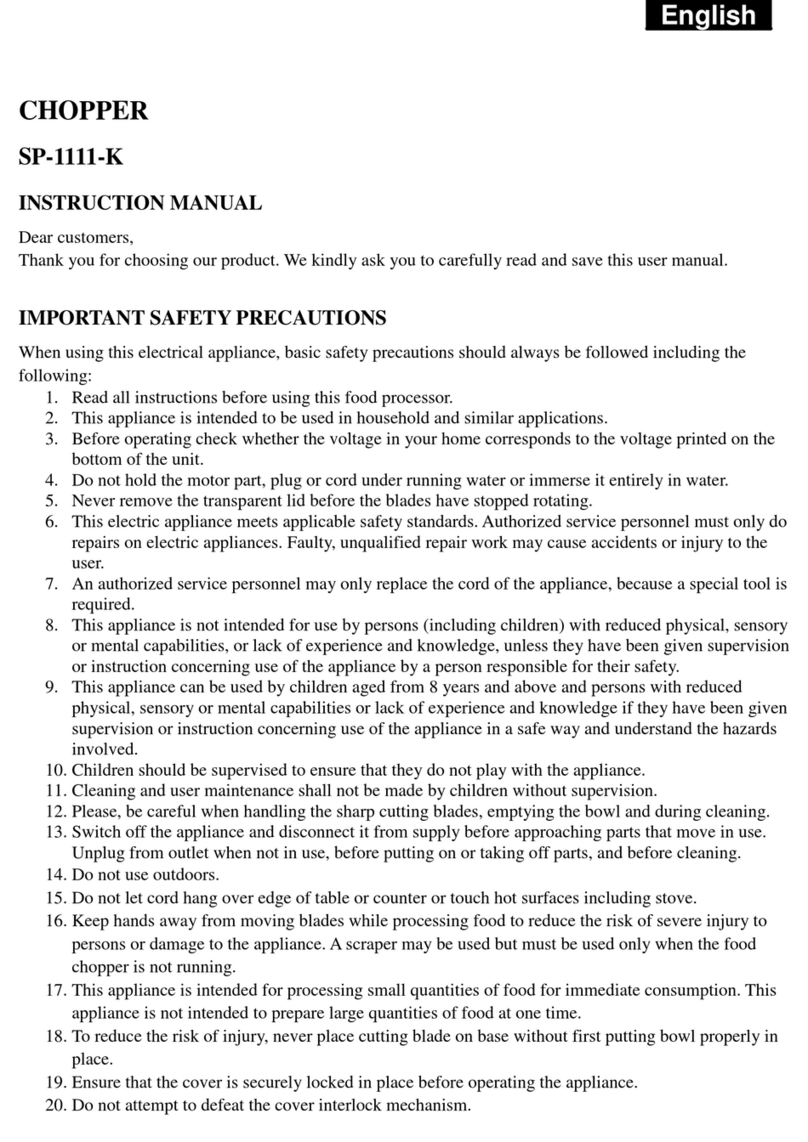

01- MAINPRECAUTIONS

The Food Processor may be a dangerous machine when incorrectly used. Cleaning and

maintenance shall be made only by skilled operators. Therefore to avoid accidents read

carefullyallthefollowinginstructions:

TOBEUSEDonlybyskilledoperators.

BEFOREcleaningormaintenanceunplugthemachinefromelectricpowersource.

NEVERusetoolsnotbelongingtothemachinetohelpoperation.

BEFORE to switch ON the machine check if the Disc No. 01 (Pic.03)and the Lid No. 02

(Pic.01)aredulyheldontheirposition.

NEVERremovetheLidbeforethemachineiscompletelystill.

NEVER put the hand inside the feeding throat , nor inside the processed food exit opening.

Keephandsawayfromanymovingparts.

NEVERswitchONthemachinewithwethandsorclothes.

NEVER throw water or other liquids directly on the motor , electric switch , or any other

electricalcomponent.

ALWAYSinstall the machineina wide andclearworking area ,farfrom the reachofchildren

andvisitors.

NEVER operate the machine without its warning labels and the Instruction Manual out of

reach.

NEVERletthemachinealoneduringoperation.

ALWAYSgroundthemachineinaccordancewithlocalrules.

STOPthemachine immediatelyifunusualnoises are heard,orwhenhaving the feeling that

somekindofaccidentmightoccur.

CONTACTyourdealer,ifanyproblemariseswheninstallingoroperatingthemachine.

09

12. ELECTRICAL DIAGRAM MODELS PA-7S and PA-7L

ON/OFF switch

Voltage Selector Switch

11 GENERAL WARNINGS

ALWAYSswitchOFFthemachinebeforemaintenanceorcleaning.

CLEARenoughspacearoundthemachineto avoidaccidents.

KEEPFLOORSdry.Wetfloorsmaycausetoslip.

ALWAYSswitchOFFthemachinewhenelectricityiscutout.

NEVER allow dirt or water get inside electrical or mechanical

components.

DONOTchangetheoriginalcharacteristicsofthemachine.

DONOTremovesafetyandidentificationlabels.

DONOTwearloosefittingclotheswhileoperatingtheunit.

DONOTusebraceletsoranyotherpieceofjewerly.

HaveyourhairALWAYSshortenedandheldup(usehairfishnetsif

necessary)inawayitcannotreachanypartofthemachine.Rollupanyloose

sleeves.

SKYMSENISNOTresponsible forANYharmorinjurycausedbythe

negligentorinappropriateuseofthisequipmentbyanyoperator.

ThisequipmentMUSTBEoperatedonlybypersonswhoseageequals

orexceeds18yearsold,inasafeandsoundstateofmind,freefromthe

influenceofanykindofdrugsandalcohol,thatreceivedpropertraining

andinstructionsregardingthecorrectoperationofthismachine,thatare

wearingcorrectandauthorizedsafetyclothes.

Allandanykindofmodificationscarriedonandappliedtothismachine

IMMEDIATELYNULLIFIESANYKINDOFWARRANTYandmayresultinharm

andinjuriestotheindividualsoperatingthismachineandtoindividualsthatare