22

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

3

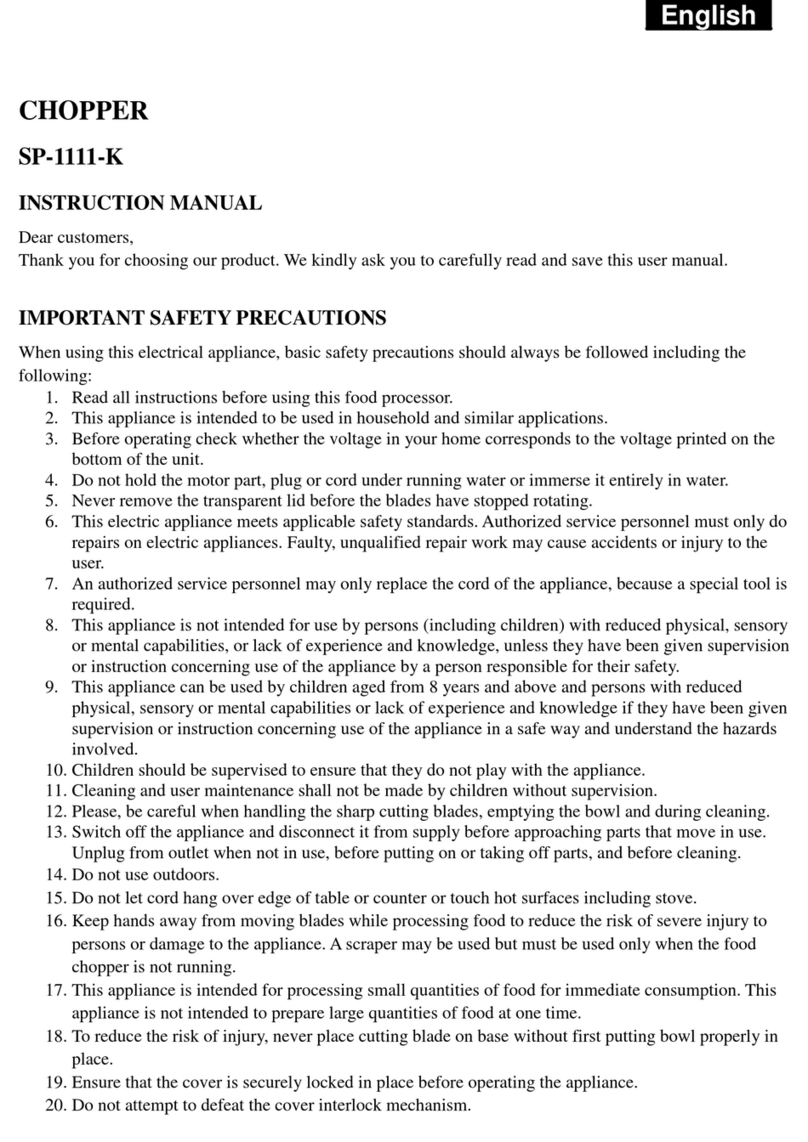

1. Introducon

1.1 Safety

When this equipment is not correctly used it may be potenally dangerous.

Before to use the equipment read carefully this Instrucon Manual and keep it accessible

for future consulng.

To avoid accidents, injures and damages to the equipment, follow the below instrucons:

1.1.1 Never use the equipment with wet clothes or wet feet, nor on a wet floor, never dip

the equipment or spray water or any other liquid on it.

1.1.2 When in use the equipment must always be watched, specially when children might

be near.

1.1.3 Unplug the equipment from electric network when not in use, before to clean it,

before to place or remove any accessory, during maintenance or any other kind of service

1.1.4 Do not use any equipment having a damaged cord or plug. Make sure the cord not to

lean on a table edge, nor to touch a hot surface.

1.1.5 If the equipment has fall, is damaged or do not switch on take it to a Technical

Assistance to be checked, repaired or adjusted.

1.1.6 Do not use accessories not recommended by the manufacturer.

1.1.7 Keep ypur hands or any tool away from the parts in movement.

1.1.8 Never use clothes with wide sleeves during operaon.

1.1.9 Make sure the equipment voltage is the same as the network voltage and that the

equipment is duly grounded.

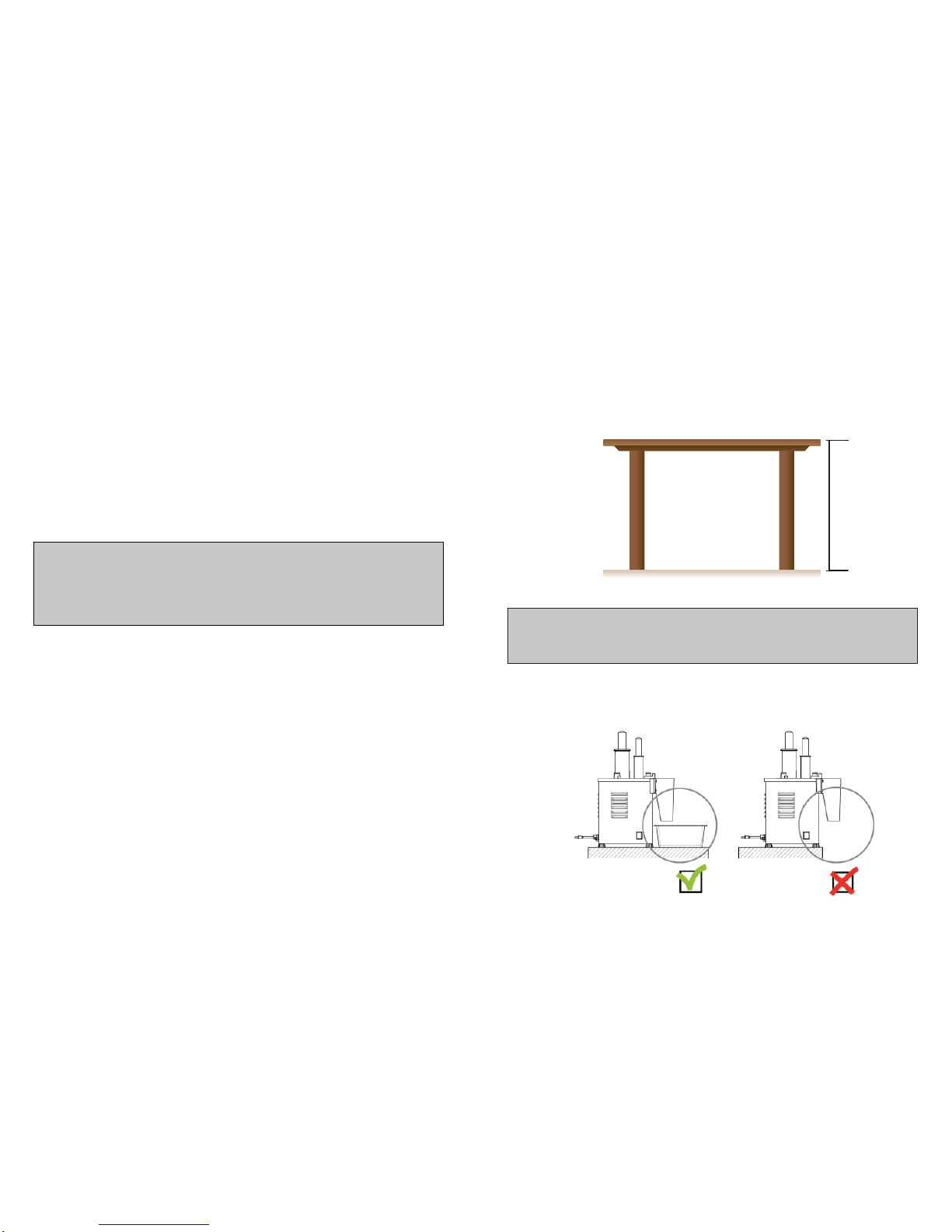

1.1.10 Before to switch ON the equipment make sure the Expeller Dish, the Plate and the

Chamber Lid are correctly placed.

1.1.11 Never introduce the fingers, or any other object inside the throats, always use the

stumpers.

1.1.12 Never introduce the fingers or any other object inside the product out load throat.

This equipment has been developed for commercial operaon, it is used for instance in

restaurants, fast foods, hospitals, bakeries, butchers and similar.

It is not recommended to use it:

- For connuous industrial producon.

- A working ambient having a corrosive or explosive atmosphere, or contaminated with

water vapour, dust or gas.