Skytron STELLAR LFS Series User manual

Page 27

OWNERS MANUA

L

LFS SERIES

REV 7-05

Page 1

TITLE PAGE

EQUIPMENT LABELS AND SPECIFICATIONS ................................................................................. 2

Special User Attention.............................................................................................................................. 3

Introduction .............................................................................................................................................. 4

Basic Lighthead Operation....................................................................................................................... 6

LightheadPositioning ............................................................................................................................... 8

IlluminationTechnique............................................................................................................................ 10

Maintenance........................................................................................................................................... 14

Repair Parts ........................................................................................................................................... 18

Hub and Radial Arm Assembly ........................................................................................................ 18

Flatscreen Bracket Assembly.......................................................................................................... 20

Height Adjustable Arm Assembly..................................................................................................... 22

TABLE OF CONTENTS

Although current at the time of publication, SKYTRON'S policy of continuous development makes this

manual subject to change without notice.

REV 7/05

Page 2

FUSE TYPE 5 AMP, SLOW BLOW TYPE

FOR DRY LOCATIONS

UNIT TO BE USED ONLY IN SPECIFIED ENVIRONMENTAL CONDITIONS

TEMPERATURE: 15 - 30 C (60 -85 F)

ATTENTION, CONSULT MANUAL FOR FURTHER INSTRUCTIONS.

INDICATES SPECIAL USER ATTENTION.

AC VOLTAGE

HUMIDITY: 30% - 60% RELATIVE HUMIDITY, NON CONDENSING

EQUIPMENT LABELS AND SPECIFICATIONS

5A

ENTELA CERTIFIED

TO UL2601-1

CAN/CSA601.1, IEC 60601-2-46

FUSE TYPE 3 AMP, SLOW BLOW TYPE

3A

CLASS I DEFIBRILLATION PROOF, TYPE B EQUIPMENT- IPX4 RATED.

INTERNALLY POWERED EQUIPMENT

TYPE B

EQUIPMENT

- GRAND RAPIDS, MI

ELECTRIC RATING CAT. NO.

SAFETY FUSE

IPXO CLASS 1

TYPE B

BULBSTYPE

24V 50W

INPUT 120V H24501

60Hz

DAI-ICHI SHOMEI CO., LTD. TOKYO, JAPAN

SERIAL NO.

MODEL

(CAT. NO.)

FUSE

TYPE

SERIAL NO.

The lighthead Data Label contains the lighthead

model number, bulb type, fuse type, electrical specifications

and product serial number.

Page 3

SPECIAL USER ATTENTION

To help assure the highest degree of operating

safety for user and patient, SKYTRON has pro-

vided precautionary instructions throughout this

manual.

As with the operation of any surgical light, all

hospital personnel should be aware that a certain

amount of care must be exercised to maintain

patient safety and to keep your SKYTRON light

fixture performing at peak efficiency.

The following is a summary of the important pre-

cautionary instructions:

WARNING

Indicatesapossibilityofpersonalinjury.

CAUTION

Indicates a possibility of damage to

equipment.

NOTE

Indicatesimportantfactsorhelpfulhints.

NOTE

To prolong bulb life, the sof-start bulb

protectioncircuitwillcauseaslightdelay

before the bubs will illuminate.

NOTE

Always make sure that the handle is

properly engaged. Failure to perform

this procedure could result in the

inadvertent release of the center focus

handle.

NOTE

SKYTRON products are guaranteed

for proper performance with the use of

genuine SKYTRON CENTER FOCUS

HANDLES. After market competitive

handles and other disposable handles

will have varying results that could

ultimatelyaffecttheproperperformance

and secure engagement of the center

focus handle. Such applications are at

the discretion of the user to ensure

patient safety.

To ensure product performance,

product longevity, and patient/staff

safety, always take caution to avoid

impact to the fixture when positioning.

NOTE

ForLFSLFSpositionthesecondarm in

the same way on the opposite side of

thetable.

NOTE

All repairs should be made using only

authorized SKYTRON replacement

parts.

WARNING

Be sure the power is turned "OFF" and

thebulbshavecooledbeforechanging.

WARNING

DO NOT attempt to remove a bulb by

pullingon the glasssurfaceor end cap.

This may cause the bulb to break off in

your hand.

NOTE

Halogen bulbs are sensitive to body

oils. DO NOT handle glass surface of

bulbasbodyoilfromfingers can create

a "hot spot" and may cause the bulb to

burn out prematurely.

NOTE

To extend the life of the bulb reflector

surface, it should not be included in

normal cleaning. It should be cleaned

only if absolutely necessary. Clean

gentlywithaclean,damp,softclothand

a mild soap solution. NO abrasives.

NOTE

The system can support and balance a

monitor weight up to 22 lbs. Exceeding

theweightwillresultinpoorbalanceand

performance.

NOTE

Refer to applicable light model

maintenanceandpartsmanualsforlight

fixture components.

CAUTION

Page 4

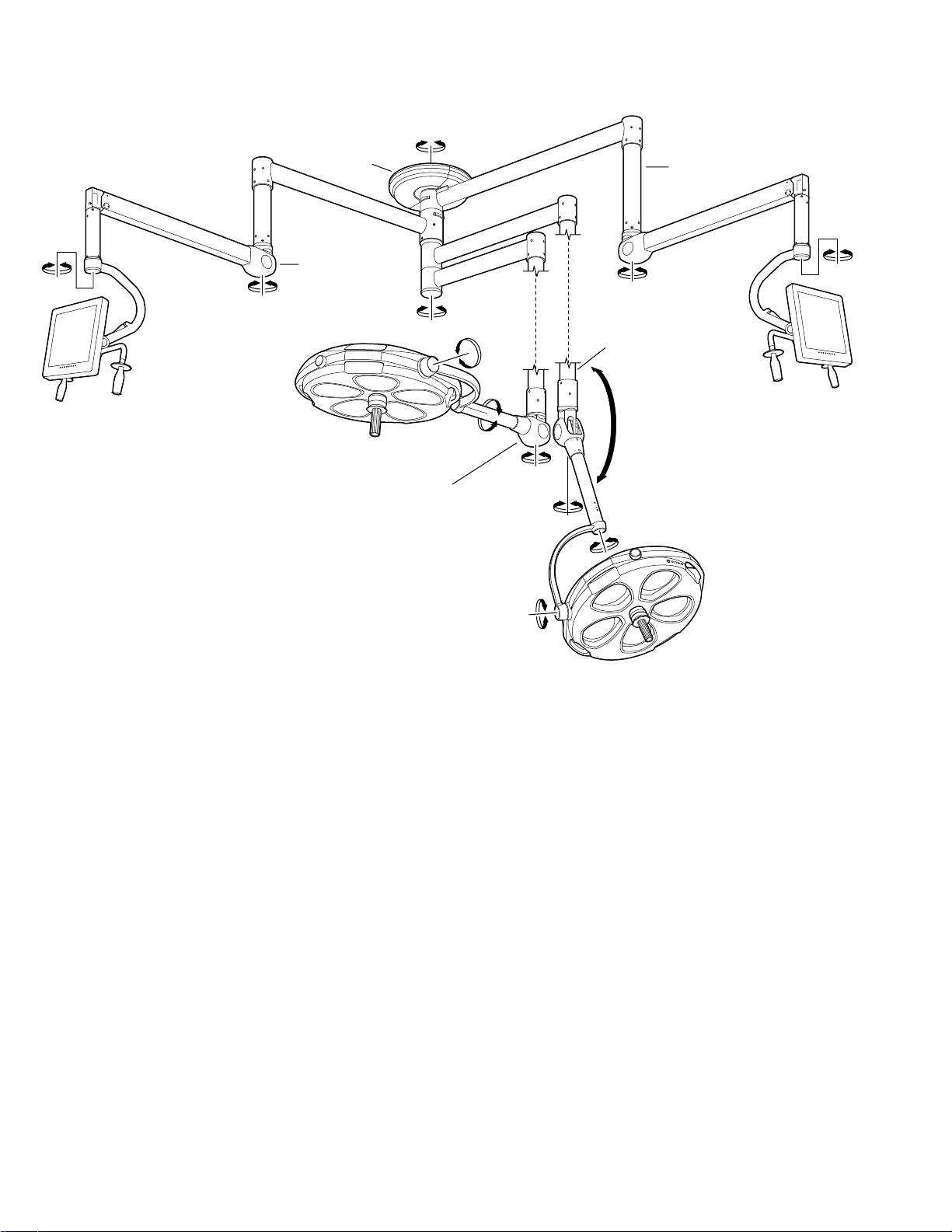

Figure 1. Light Fixture Rotation Capabilities

INTRODUCTION

The Stellar LFS series combines flatscreen moni-

tor mounting with a surgical lighting system from a

single ceiling mount.

The LFS model allows a single flatscreen monitor

mount to be combined with up to 3 separate

lightheads. The LFSLFS model combines 2

flatscreen monitor mounts with up to 2 separate

lightheads.

The LFS radial arm assembly allows up to 90" of

reachfortheflatscreenmonitorwith345°ofrotation

capability at the ceiling mount. Vertical travel of up

to 45.5" is provided.

The lighthead models available for use with the

LFS system include ST19WC, ST23, ST23TV,

ST29 and ST29TV. The ST19WC model is fixed

focus, the remaining models are all focusable.

345˚

PITCH

360˚

CEILING

COVER

360˚ ROLL

360˚

ROLL

360˚

110˚

VERTICAL

TRAVEL

PITCH

360˚

VERTICAL

SUPPORT

TUBE

VERTICAL

SUPPORT

TUBE

BALANCE

MECHANISM

BALANCE

MECHANISM

340˚

340˚

360˚

540˚ 540˚

360˚

Page 5

STERILIZABLE

FOCUS/POSITIONING

HANDLE

NON-STERILE

SIDE FOCUS KNOB

The Stellar series surgical lighting system from

SKYTRON features fully adjustable positioning

and focus control for its cool, color-corrected,

multiplebulb,lightsource.Combinationsofvertical

positioningandmultiplerotationalcapabilitiesallow

the single, dual or triple lighthead models virtually

limitlesspositioning.

Thefixturesaresinglepointceilingmountedwitha

continuous 360 degree rotation capability at the

ceiling mount end of the radial support arm. See

figure 1. The balance mechanism which is at-

tached to the radial arm by a vertical support tube,

providesthelightheadanadditionalcontinuous360

degree rotation point. The balance mechanism is

an enclosed spring tension system. This allows

verticalmovementofthe lighthead while maintain-

ingthelightheadpositionwithoutdrifting.Theyoke

provides additional 360 degree rotation points for

lighthead pitch and roll.

The Stellar fixtures have a lighthead vertical travel

capability of 110°.

The adjustable focus mechanism which optimizes

thelightoutputbysuperimposingallthelightbeams

into a single spot can be operated by non-sterile

personnelusingthelightheadmountedfocusknob.

All lightheads also have a removable, sterilizable,

focus/positioning handle. This allows all final posi-

tioning and focus adjustments or changes to be

precisely done by the surgeon. See figure 2.

Figure 2. Focus Adjustments

Page 6

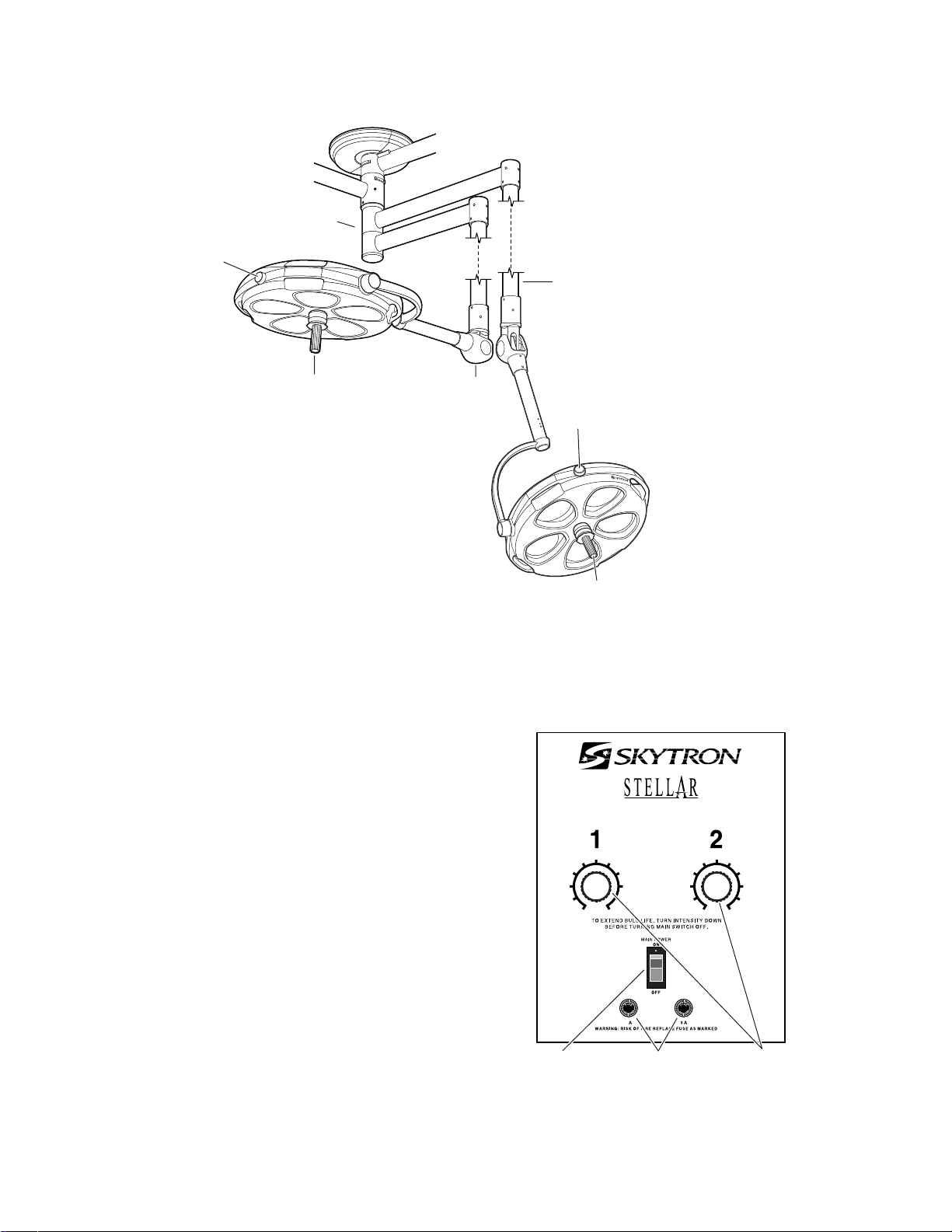

BASIC LIGHTHEAD OPERATION

Use the following instructions to operate the light

fixture:

1.Positionthelightheadsasrequiredbygrasp-

ing the lighthead positioning handles and moving

the lighthead to the desired position. See figure 3.

2.Turnthelightfixturemainpowerswitch"ON"

at the wall mounted control box and select the

desired intensity for each lighthead as required.

See figure 4. The mid-range position will provide

adequate illumination for most procedures. Full

intensity will usually only be required for extreme

deep cavity cases.

NOTE

To prolong bulb life, the sof-start bulb

protectioncircuitwillcauseaslightdelay

before the bulbs will illuminate.

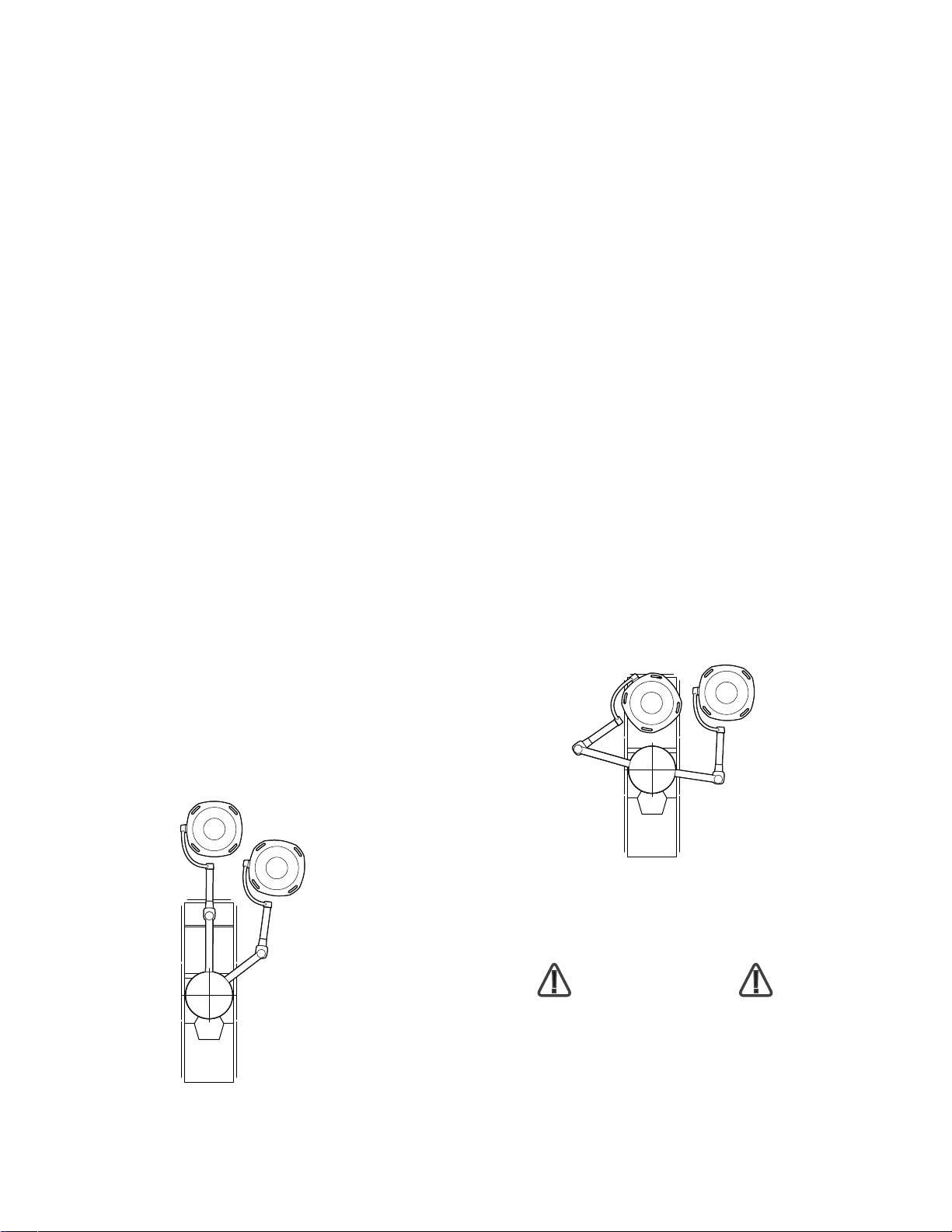

Figure 3. Dual Lighthead Fixture

Figure 4. Wall Mounted Control Box

SAFETY

FUSES

MAIN

POWER

SWITCH

6

010

19

28

37

456

010

19

28

37

45

INTENSITY

CONTROL

KNOBS

5

RADIAL ARM

ASSEMBLY

STERILIZABLE

FOCUS/POSITIONING

HANDLE FOCUS

KNOB

FOCUS

KNOB VERTICAL

SUPPORT

TUBE

BALANCE

MECHANISM

STERILIZABLE

FOCUS/POSITIONING

HANDLE

Page 7

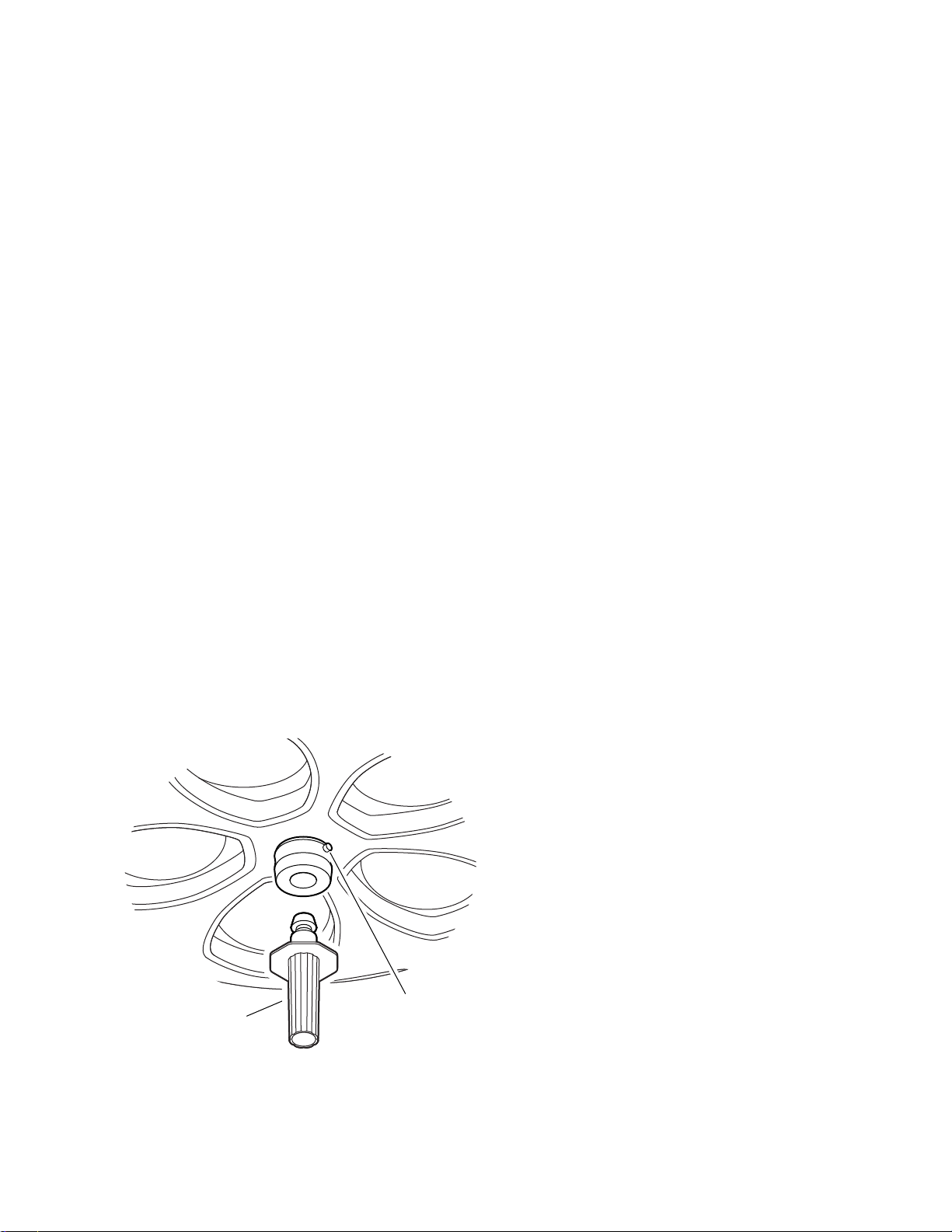

3. When the surgeon is ready to use the light,

installthesterilizedcenterfocus/positioninghandle

using the following procedure. See figure 5. Be

sure handle is properly secured before using the

lighthead. Possible injury to patient or staff could

result if a handle is not installed properly.

a. Insert the handle into the lighthead at-

tachment ring.

NOTE

Always make sure that the handle is

properly engaged. Failure to perform

this procedure could result in the

inadvertent release of the center focus

handle.

b. Push the handle in, turn it right and left, and pull

thehandleouttobecertainthatitislocked(PUSH-

TWIST-PULL). A distinct click can be heard when

the handle is properly engaged.

c. To remove the handle, push the release

button and pull the handle out.

Figure 5. Center Focus/Positioning Handle

Installation

STERILIZABLE

HANDLE

HANDLE

RELEASE

BUTTON

4. Adjust the focus by moving either the non-

sterile focus knob or the (sterilized) center focus

handle until all of the light beams converge on the

surgical site forming a single bright spot of light.

5.Forlowanglelightingapproach,thelighthead

will move 90° below horizontal. Pull the lighthead

down by the positioning handles or the (sterile)

positioning/focushandle.

In the presence of flammable anesthetics, DO

NOT allow the lighthead to travel below 60 inches

from the floor.

6. When the light is no longer required, return

the lighthead to its full up position. Decrease the

intensityatthewallcontrol,andturnthemainpower

switch "OFF".

NOTE

SKYTRON products are guaranteed

for proper performance with the use of

genuine SKYTRON CENTER FOCUS

HANDLES. After market competitive

handles and other disposable handles

will have varying results that could

ultimatelyaffecttheproperperformance

and secure engagement of the center

focus handle. Such applications are at

the discretion of the user to ensure

patient safety.

Page 8 LIGHTHEAD POSITIONING

CAUTION

To ensure product performance,

product longevity, and patient/staff

safety, always take caution to avoid

impact to the fixture when positioning.

The lightheads can be most effectively positioned

by using the following procedures:

1.Graspthepositioninghandlesonthelighthead

and pull the lighthead down to shoulder height.

Keepthe lightheadatapproximatelya45°angleto

easily position the support yoke. See figure 6.

General

To obtain the maximum benefit from your

SKYTRON surgical lighting system, the following

suggestions are offered as a guide for lighthead

positioning. Personnel who are trained in proper

lightingtechniques canplanandsetupthe lighting

arrangements prior to the arrival of the patient.

Factors which should be considered when

prepositioning surgical lights are:

-Specific procedure to be done

-Patient position during procedure

-Position of surgical team

-Location of instrument trays or tables

-Location of IV stands

-X-ray equipment and personnel

-Anesthesia equipment and personnel

-Angulation and size of surgical cavity

Surgical Table Placement

For most procedures the surgical table should be

located with its center point directly under the light

fixture’s ceiling mount.

Pre-Positioning The Lighthead

Surgicallightpositioningrequirementschangenot

onlyfromproceduretoprocedure,theyalsochange

from surgeon to surgeon. Final light positioning

and adjustment will be directed or done directly by

the surgeon. The objective of prepositioning is to

requireaminimumoffinaladjustmentsafterarrival

of the patient. The non-sterile focus control should

be located where it can be reached by non-sterile

personnel and the sterile positioning/focus handle

where they can be reached by the surgeon. Use

extreme care when prepositioning lightheads.

Bumpinglightheadsintooneanother,intowalls,or

other equipment may alter bulb alignment which

affects proper focus adjustment.

90˚

RADIAL ARM

Figure 7.

Figure 6.

2. Using the positioning handles, rotate the

lighthead around the vertical support until the

lighthead is at an approximate 90° angle to the

radial arm. See figure 7.

POSITIONING

HANDLE

SUPPORT

YOKE

Page 9

Figure 8. Main Lighthead Radial Arm

Positioning

5. With the radial arm in proper position, rotate

the lighthead to the desired position and install the

sterile positioning/focus handle. Refer to sterile

handleinstallationprocedure.

6. Grasp the positioning handles, place the

lightheadat anangle andmovethe lighthead toits

full up position.

90˚

ABDOMINAL

CHEST

PELVIC

HIP

ORTHO

OB/GYN NEURO

EENT

DOCTOR SIDE OFTABLE

45˚ 45˚

180˚ 180˚

3.Placetheradialarminthedesiredpositionby

pushing or pulling the lighthead by the positioning

handles as you walk around the surgical table.

4. Refertofigure8toapproximatethedesired

radial arm position for locating the lighthead over

thepatient.

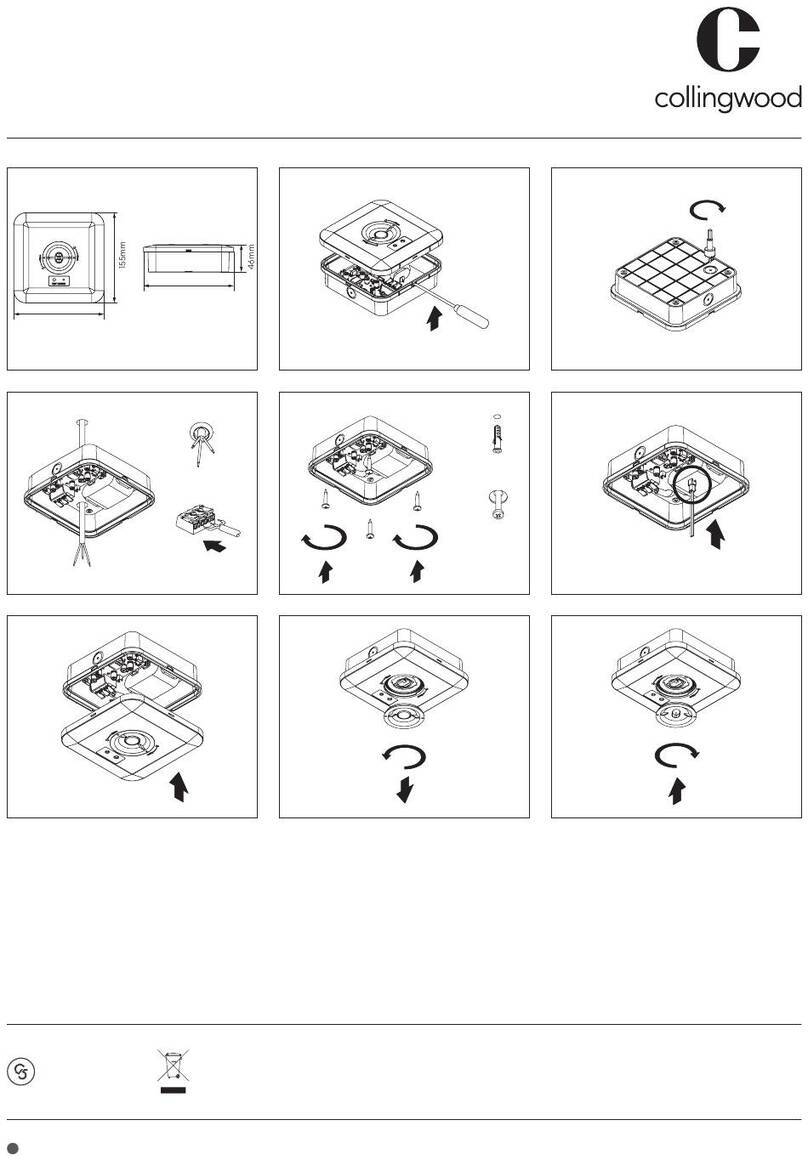

Flatscreen Monitor Positioning

The upper radial arm of the flatscreen monitor

mount should be pre-positioned on the opposite

sideofthetablefromthesurgeonatapproximately

90° from the table center line. See figure 9.

Figure 9.

The lower arm should be positioned under the

upperarm.Inthispositionthemonitorcanbeeasily

movedupordownthefulllengthofthetablewithout

interfering with the lightheads. The monitor can be

pushed up out of the way until it is needed.

Twosterilizablehandlesareprovidedforfinalmoni-

tor positioning or for changes required during the

procedure. Prior to the start of the procedure the

sterilizable handles can be installed. Insert the

sterile handles into the receptacle and turn clock-

wise until tight.

NOTE

ForLFSLFSpositionthesecondarmin

the same way on the opposite side of

thetable.

Page 10

Torso Area

For most chest and abdominal procedures, posi-

tion the large lighthead directly over the surgical

site. See figure 11. Position the radial arm on

approximately a 45° angle from the surgical table

centerline.Thispositionwilllocatethesterilefocus/

positioning handle on the lighthead where it can

easily be reached by the surgeon. The focus con-

trol will be where it can easily be reached by non-

sterile personnel. Position the satellite lighthead,

dependingonlightingneeds,toaugmentthelarger

lighthead.

Figure 11.

ILLUMINATION TECHNIQUE

Maximumillumination,shadowreduction,andpos-

sible obstruction by the surgeon or surgical staff

are also major concerns for lighthead positioning.

The following examples are offered as a basic

guide for lighthead placement for large diameter/

satellite,duallighthead,or triple lighthead fixtures.

Large Diameter/Satellite Lighthead

Positioning

The large diameter lighthead should be pre-posi-

tioned over the surgical site. The satellite can be

usedoneithersideofthesurgeonforaugmentation

and shadow control.

The large lighthead should be positioned perpen-

dicular to the bottom of the surgical cavity.

Head

To illuminate the head area, position the large

diameter lighthead radial arm parallel to the table

centerline. See figure 10. Position the lighthead

behindthesurgeon.Tiltthelightheadtothedesired

positionusing pitchaxismovement. Thiswillallow

the multiple light sources of the lighthead to pass

aroundtheheadandshouldersofthesurgeonand

at the same time permit adequate head clearance

for the surgeon.

Tilt the lighthead to position the focus control knob

where it can be easily reached by non-sterile

personnel.

Positionthesatelliteto the leftor right accordingto

surgeon preference. This allows a second light

source to come from another angle which will help

eliminate obstructions or shadows.

Figure 10.

CAUTION

To ensure product performance,

product longevity, and patient/staff

safety, always take caution to avoid

impact to the fixture when positioning.

Page 11

Some procedures, such as hip pinnings, require

bothlightheadstobeonthesamesideofthetable.

See figure 13. In this position the lightheads are

behind and adjusted to project light over the head

and shoulders of the surgeon. Both lightheads are

easily reached for adjustment by non-sterile per-

sonnel.

Figure 14.

Perineum

Thelargediameterlighthead should bepositioned

at the end of the table for perineal procedures.

Locatetheradialarmdirectlyinlinewiththecenterline

of the table. Once thesurgeonhasassumeda

seated position, the lighthead can be pulled down,

angled, and adjusted to provide the necessary

illumination over the surgeon’s head and shoul-

ders. See figure 14. The satellite lighthead radial

arm should be positioned approximately 90° from

theotherradialarm.Positionthesatellitelighthead

totherightorleftofthelargelightheadaccordingto

surgeon preference. In this position, the focus

knobsofbothlightheadsarelocatedforeasyreach

by non-sterile personnel.

Figure 13.

Figure 12.

In some cases such as cholecystectomies and

totalabdominalhysterectomies,thesurgicalcavity

may be angled. In cases such as this, the large

lighthead should be angled so that the face of the

lighthead is perpendicular to the bottom of the

surgical cavity. See figure 12.

Page 12

Dual 23" Diameter Lighthead Positioning

Fixtures containing dual 23" diameter lightheads

require some special positioning considerations.

Thesmalldiameterofthelightheadsallowsthelight

sourcetobemoreeasilyobstructedbythesurgical

staff. It is very important that the surgical site

remain illuminated even though the head and

handsofthesurgeonandthesurgical staff may be

directly in the central light beam path. In order to

minimize shadowing, thelightheadsshouldbepo-

sitionedsothattheirlightbeamsareangledintothe

surgical cavity. Regardless of the surgical site,

these lights should be positioned to maintain an

angleofapproximately30°aboutanimaginaryline

runningperpendiculartothebottomofthesurgical

site. See figure 15.

Figure 16.

Figure 15.

Tilting the lightheads will give a larger light beam

angle. See figure 16. Final positioning and focus

adjustmentscanbedonebythesurgeonusingthe

sterile focus/positioning handles. Focus controls

shouldbepositionedwhereeasilyreachedbynon-

sterile personnel.

30˚ 30˚

30˚

CAUTION

To ensure product performance,

product longevity, and patient/staff

safety, always take caution to avoid

impact to the fixture when positioning.

Page 13

Figure 18.

Beyond the focal point, the light beams spread out

like an inverted cone and will more evenly spread

the light throughout the bell-shaped cavity.

Bell-Shaped Cavities

For most surgical procedures the lighthead will be

properlyfocusedwithallthelightbeamsconverged

in one spot at the bottom of the surgical cavity.

However, in the case of a bell-shaped cavity (for

example - total abdominal hysterectomy on an

obesepatient),focusingatthebottom of the cavity

may cause more shadow problems. The focal

point for the light beams should be above the

bottom of the cavity. See figure 18.

Triple Lighthead Positioning

Triple lighthead systems will either consist of a

large diameter lighthead with two 23" satellites or

three23"lightheads.There are twobasic position-

ing strategies that can be used to obtain the best

illumination possible. The first is to align all three

lightheads to the centerline of the table with the

largelightheaddirectlyoverthecenterofthesurgi-

cal site. The second is to cluster the lights in a

circular arrangement over the surgical site with

each lighthead about 120° away from each other.

Thewholeclustershouldbepositionedtominimize

interference with the head and shoulders of the

surgical staff. See figure 17.

Figure 17.

Whenanangledcavity is to be illuminated,atleast

one of the lightheads should be positioned to be

perpendicular to the bottom of the cavity.

For head and perineal work, the lights should be

positionedastheywouldforadualsystembutwith

a satellite on each side of the surgeon.

Other Illumination Considerations

Closeattentiontosurgicallightintensity during the

caseas wellasgoodqualitygeneralilluminationin

theroomwillhelptominimizeeyefatigueofsurgical

personnel.

Dark surgical drapes will help to reduce reflec-

tance.Whitedrapesshouldbeavoidedat all times

because of high reflectance.

The use of matte and satin finish instruments and

retractors also helps to reduce eye fatigue.

120˚ 30˚

30˚

30˚

120˚

120˚

LIGHT

BEAMS

FOCAL

POINT

BELL SHAPED

CAVITY

Page 14 MAINTENANCE

General

Toinsureproperoperationandtoextendthelifeof

your SKYTRON surgical lighting system, the fol-

lowing preventive maintenance procedures are

recommended.

NOTE

All repairs should be made using only

authorized SKYTRON replacement

parts.

Daily Maintenance

Daily or between cases, the lighthead exterior

should be wiped down with a mild cleaning agent

which will not affect the painted or acrylic parts.

•Inspect the light heads and fixture for visable

damage.TeportdamageimmediatlytoSKYTRON

representative.

•Avoid the use of cleaning solutions which contain

high concentrations of alcohol, ethelene glycol,

phenol, iodophors, or glutaraldehyde based

disinfectancts. Some degree of staining, pitting,

peeling and discoloration may occur if these are

used.

Alwaysconsultwiththemanufacturerof the clean-

ing agent for proper application and use. Always

spot test on an inconspicuous area before use.

•Avoid personal injury. Do not attempt to clean

lighthead unless power is turned off at wall control

and fixture has sufficiently cooled.

•Avoidusingexcessiveamountsofspraycleaners

near top cover vents. Leakage of fluids into the

interioroflightheadmaycausecorrosionofelectri-

cal components.

•Periodically the filter/diffuser assemblies should

be removed and dusted with a clean cloth or

washed and air dried as a complete assembly.

•DO NOT operate lights without the filter/diffuser

assemblies in place.

•Use plexiglass cleaners, DO NOT use alcohol

based cleaners on the acrylic diffusers.

Sterilization

Recommended sterilization parameters for

sterilizablehandle:

a. Prevac, 270° F, 4 minutes

b. Gravity, 250° F, 30 minutes

c. Flash, 270° F, 3 minutes

Always consult current AORN journal recommen-

dations for proper sterilization procedures.

Adjustments

As part of a regular preventive maintenance pro-

gram, it is suggested that a check of the various

positioning axes be made to verify correctness of

tensionadjustment.Ifany driftisnoticed,allthatis

usually necessary is a minor adjustment. Read-

justment should be made as per the appropriate

instructionscontainedinthe Maintenance and Ad-

justment Manual for the specific model lighthead.

Also, during a scheduled cleaning of the lighthead

interior, lubrication of the various moving parts is

desirable.

Bulb Changing

Since SKYTRON Surgical Lights contain multiple

bulbs,itwouldnotnormallybenecessarytochange

aburnedoutbulbduringasurgicalprocedure. The

loss of one or even three bulbs in a large diameter

lightheadmaybe completelyunnoticedduringuse.

To replace a bulb, use the following procedure:

WARNING

Be sure the power is turned "OFF" and

the bulb has cooled before changing.

1. Hold the diffuser/filter assembly with one

hand, loosen the "1/4-turn" screw and lower the

diffuser/filter assembly. See figure 19.

Page 15

WARNING

DONOT attempttoremovethebulbby

pullingon theglasssurfaceorendcap.

This may cause the bulb to break off in

your hand.

2. Using caution not to touch the reflector

surface, hold the bulb by the base and pull it out.

See figure 20. Slightly working the bulb back and

forth may aid in bulb removal.

Figure 19.

Figure 20.

NOTE

Halogen bulbs are sensitive to body

oils. DONOThandletheglasssurface

ofthebulbasbodyoilfromyourfingers

can create a "hot spot" and may cause

the bulb to burn out prematurely.

3. Holding the bulb by the base, plug it directly

intothesocket.Donottouchtheglassportionofthe

bulb reflector surface with your fingers. This can

best be done by using the plastic wrapper that the

bulb is packaged in or a clean cloth wrapped

aroundthebaseofthebulbwheninstalling.Besure

bulb base is properly seated in the connector to

insure proper focus alignment.

NOTE

To extend the life of the bulb reflector

surface, it should not be included in

normal cleaning. It should be cleaned

only if absolutely necessary. Clean

gentlywithaclean,damp,softclothand

a mild soap solution. NO abrasives.

4. Replace the diffuser/filter assembly by plac-

ing the tab into the lighthead face. Place the

assembly in position and secure it with the "1/4-

turn" screw.

1/4TURN

SCREW

REFLECTOR

SURFACE

END

CAP

BASE

Page 16

LFS Height Adjustable Arm Tension

Adjustment

a. Checktheverticaltensionadjustmentofthe

Height Adjustable Arm for its capacity to support

the flatscreen monitor throughout its range of mo-

tion. The monitor should move freely yet maintain

its selected position without drifting. If an adjust-

ment is necessary, refer to figure 13 and proceed

as follows:

NOTE

TheSystemcansupportandbalancea

monitor weight up to 22 lbs. Exceeding

the weight will result in poor balance

and performance.

Figure 21

b. Remove the cover plate on the top of the

Height Adjustable Arm for access to the tension

adjustmentnut. Inserta1/8"pinpunchintoaholein

the adjustment and turn the nut as required to

achieve proper tension - clockwise to increase

tension, counterclockwise to decrease tension.

Replace access cover when adjustment is com-

plete.

c. Check the adjustment for the flatscreen

monitorpitchaxis.Themonitorshouldmovefreely

yetmaintainitsselected positionwithoutdrifting.If

an adjustment is necessary, refer to figure 14 and

proceed as follows:

Figure 22

d. Loosen set screw on trunnion nut, insert a

1/8"pinpunchintoholeoppositesetscrewlocation

and adjust trunnion nut as required - clockwise to

increase tension, counter clockwise to decrease

tension. Tighten set screw when adjustment is

complete.

e. Forfineadjustment,rotatethemonitordown-

ward until the adjustment nut is visible on the

tension spring assembly. Using a pin punch, turn

theadjustmentnutuntilpropertensionisachieved.

COVER PLATE

1/8" PIN PUNCH

ADJUSTMENT

NUT

PIN PUNCH

1/8"PIN

PUNCH

ADJUSTMENT NUT

TRUNION

NUT

SET SCREW

TENSION SPRING

Page 17

A regular program of preventive maintenance will

increase the life of your equipment and keep it

operating at peak performance.

Maintenance can be performed by authorized,

trained maintenance personnel using SKYTRON

authorized replacement parts and service tech-

niques. Service instructions and parts are avail-

able from SKYTRON.

Preventive Maintenance contracts are available

through your local SKYTRON representative.

To obtain service instructions, replacement parts,

factory service or preventive maintenance con-

tracts,contacttheSKYTRONrepresentativelisted

below.

Or contact:

SKYTRON

5000 36th Street S.E.

Grand Rapids, MI 49512

1-800-SKYTRON (1-800-759-8766)

Fax. 1-616-957-5053

Original Print Date 1/05

NOTE

Refer to applicable light model

maintenanceandpartsmanualsforlight

fixture components.

Page 18 REPAIR PARTS

1. HUB AND RADIAL ARM ASSEMBLY

1

1

24

25

1

8

8

18

19

8

8

20

20

22

23

111003.01

20

20

21

17

11

12

10

7

6

9

13

14

15

516

2

3

4

26

27

Table of contents

Other Skytron Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Collingwood Lighting

Collingwood Lighting Salvus Surface EMSBSQEM installation instructions

Elation

Elation Rayzor Q7 user manual

Cooper Crouse-Hinds

Cooper Crouse-Hinds Champ VMV High Wattage Series quick start guide

Weda

Weda B600 Service manual

Soundoff Signal

Soundoff Signal Intersector ENT3 3 Series manual

Infinity

Infinity TCYC-7 manual

GRILL MEISTER

GRILL MEISTER 360468 2007 Operation?and safety

GNC

GNC HEAVEN S Installation operating & maintenance manual

Solem

Solem WF-OL Quick installation guide

Eye Hortilux

Eye Hortilux LED 350-ES installation instructions

Lightolier

Lightolier Baselyte-BSL8 datasheet

Steren

Steren MODLED-300/RGB instruction manual