SLC SG1D-1 User manual

Manual

300.000.123 I Version 02.2019

Progressive safety gear SG

braking downwards

Safety gear

SG1D-1

Progressive safety gear SG Manual

SG braking downwards

Published by

Sautter Lift Components GmbH

Remsstraße 2

70806 Kornwestheim I Germany

Phone: +49 (0) 7154.9996 - 0

Email: [email protected]m

Home: www.slc-liftco.com

Copyright © 2019 Sautter Lift Components GmbH

This manual is protected by copyright for the publisher and all rights are reserved.

This manual may not be reproduced in any way or copied by means of electronical copying methods, either as a whole or in

part, without written permission of the publisher. Translating the material also comes under the definition of copying.

Copyright as per DIN ISO 16016. Subject to modification.

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 2

Table of content

1. Safety instructions ...................................................................................................................... 3

1.1 Designations and signs ................................................................................................................ 3

1.2 Principle / intended use of the safety gear................................................................................... 3

1.3 Selection and qualification of personnel / basic responsibilities .................................................. 4

1.4 Safety instructions governing assembly and specific operational phases ................................... 4

2. General notes ............................................................................................................................... 5

2.1 Designation .................................................................................................................................. 5

2.2 Criteria for the selection of safety gears ...................................................................................... 5

2.3 EC type-examination certificate ................................................................................................... 5

2.4 Manufacturer of the safety gear ................................................................................................... 5

3. Technical Data ............................................................................................................................. 6

3.1 Range of application .................................................................................................................... 6

3.2 Tripping ........................................................................................................................................ 6

3.3 State of delivery ........................................................................................................................... 7

4. Mounting and dimensions .......................................................................................................... 8

5. Specification and function ....................................................................................................... 10

5.1 Specification of the safety gear .................................................................................................. 10

5.2 Function of the safety gear ........................................................................................................ 10

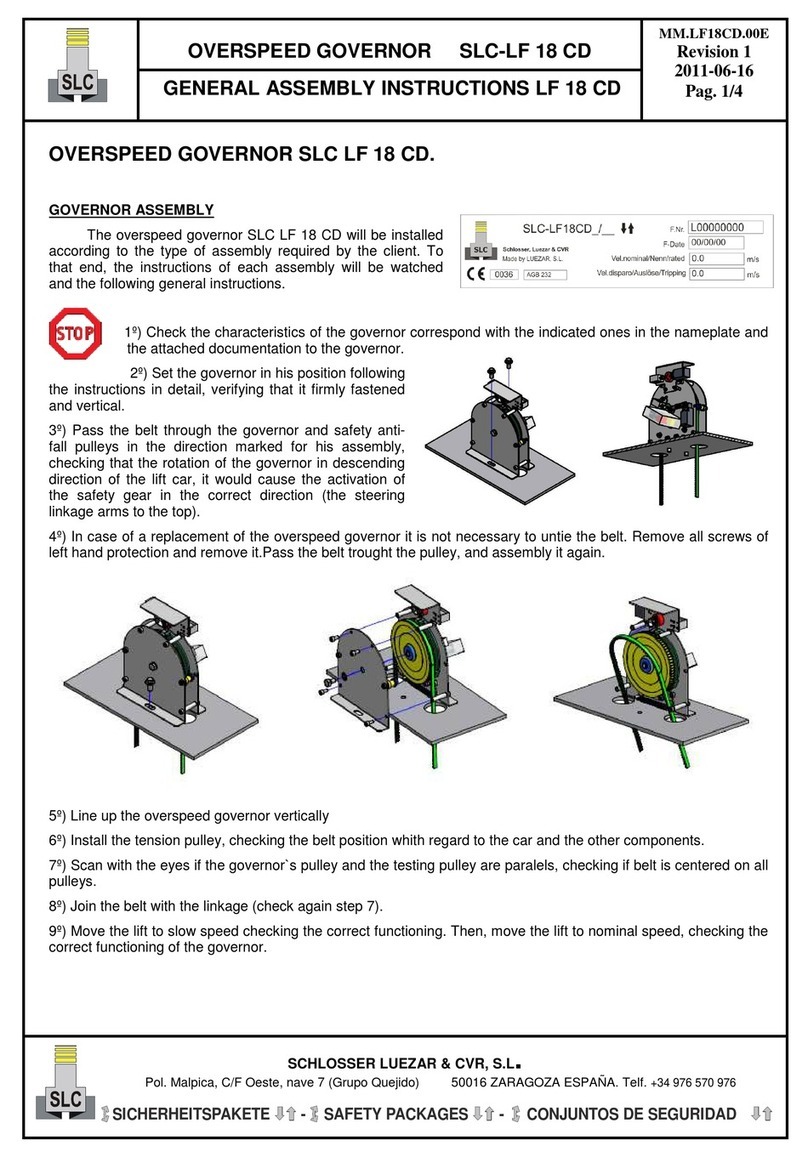

6. Assembly .................................................................................................................................... 11

6.1 Assembly of the safety gear at the lift car .................................................................................. 11

7. Commissioning .......................................................................................................................... 13

7.1 Functional check ........................................................................................................................ 13

7.2 Commissioning at the lift ............................................................................................................ 13

7.3 Acceptance test or commissioning of the lift.............................................................................. 13

7.4 Check after braking .................................................................................................................... 13

8. Content of QR-Code .................................................................................................................. 14

9. Maintenance ............................................................................................................................... 15

10. Transport .................................................................................................................................... 15

11. Annexe ........................................................................................................................................ 15

Progressive safety gear SG Manual

SG braking downwards Safety instructions

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 3

1. Safety instructions

This product information refers to the progressive safety gear type SG1D-1 braking downwards and

contains important information on correct and safe installation, putting into service, use and

maintenance of the safety gear. Observing these instructions helps to avoid danger, to reduce repair

costs and downtimes and to increase the reliability and life of the safety gear.

The product information has to be supplemented by instructions based on national rules and

regulations concerning accident prevention.

The product information must always be available wherever the safety gear is in use. The manual

must be read and applied by any person in charge of carrying out work with and on the safety gear.

In addition to the product information and to the mandatory rules and regulations for accident

prevention in the country and place of use of the safety gear the generally recognized technical rules

for safe and proper working must also be observed.

1.1 Designations and signs

The following designations and signs are used in this product information to designate instructions of

particular importance:

DANGER

In this manual refers to the risk of death, heavy injuries and extensive damage if the required

prevention measures are not taken.

WARNING

In this manual refers to light injuries or damage if the required prevention measures are not taken.

IMPORTANT

In this manual refers to important information about the product or is meant to attract the readers’

attention to important parts of the product information.

1.2 Principle / intended use of the safety gear

The safety gear has been built in accordance with current standards and the recognized safety rules.

Nevertheless, its use may constitute a risk to life and limb of the user or cause damage to the safety

gear and to other material property.

The safety gear must be operated in technically perfect condition only, in accordance with its

intended use and with the instructions set out in this product information.

Any functional disorders, especially those affecting the safety of the safety gear should therefore be

rectified immediately!

The safety gear SG braking downwards is designed exclusively for preventing the fall of the lift car

(see EN81-20:2014-11, chapter 5:6:2:1 and EN81-1/2:1998 +A3: 2009, chapter 9.8)

Using the safety gear for purposes other than those mentioned above is considered contrary to its

designated use. The manufacturer cannot be held liable for any damage resulting from such use.

The risk of any misuse lies entirely with the user.

Operating the safety gear within the limits of its designated use also involves observing the

instructions set out in this manual and complying with the inspection and maintenance directives.

Progressive safety gear SG Manual

SG braking downwards Safety instructions

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 4

Never make any modifications, additions or conversions that might affect safety without the supplier’s

approval!

Spare parts must comply with the technical requirements specified by the manufacturer. Spare parts

from original equipment manufacturers can be relied to do so.

Adhere to prescribed intervals for routine checks and inspections!

For the execution of maintenance work tools and workshop equipment adapted to the task on hand

are absolutely indispensable.

1.3 Selection and qualification of personnel / basic responsibilities

Any work on and with the safety gear must be executed by reliable personnel only. Statutory

minimum age limits must be observed!

Employ only trained and instructed staff and set out clearly the individual responsibilities of the

personnel for operation, set-up, maintenance and repair!

Make sure that only authorized personnel works on or with the safety gear!

1.4 Safety instructions governing assembly and specific operational phases

Assembly Always wear personal protective equipment during assembly work.

Standard

Operation Avoid any operational mode that might be prejudicial to safety!

Take the necessary precautions to ensure that the safety gear is used only when in a safe and

reliable state!

Main-

tenance Ensure that the maintenance area is adequately secured!

For carrying out overhead assembly work always use specially designed or otherwise safety-

oriented ladders and working platforms. Wear a safety harness when carrying out maintenance

work at greater heights!

Before cleaning with water or detergents cover or tape up all openings which - for safety and

functional reasons - must be protected against water or detergent penetration.

After cleaning remove all covers and tapes applied for that purpose!

Always tighten any screwed connections that have been loosened during maintenance and repair!

Ensure that all consumables and replaced parts are disposed safely and with minimum

environmental impact!

Gas

Dust

Steam

Smoke

Carry out welding or grinding work on the safety gear only if this has been expressly authorized, as

there may be a risk of explosion and fire!

Before carrying out welding or grinding operation, clean the safety gear and its surroundings from

dust and other inflammable substances and make sure that the premises are adequately ventilated

(risk of explosion)! When there is little space for working observe the national rules and regulations!

Oil

Grease

etc.

When handling oil, grease and other chemical substances, observe the product-related safety

regulations!

Be careful when handling hot consumables (risk of burning or scalding)!

Progressive safety gear SG Manual

SG braking downwards General notes

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 5

2. General notes

2.1 Designation

SG.. - . Safety Gear

1D braking in 1 Direction

2D braking in 2 Directions (see manual 300.000.155)

- 1 Type 1

Example SG1D-1 = Safety gear SG braking downwards, type 1

2.2 Criteria for the selection of safety gears

Rail head width

Load of safety operation P+Q

Counterweight mass

Car speed

Guide rail machined dry

oiled

drawn dry

oiled

2.3 EC type-examination certificate

Certification number of the EC type-examination certificate:

Type Certification no.

SG1D-1 EC-SG 802/1

Please note:

Type-examination certificates according to 95/16/EC

can be downloaded at SLC homepage:

http://www.slc-liftco.com/en/12/downloads.html

2.4 Manufacturer of the safety gear

Manufacturer of the safety gear and holder of the type-examination certificate:

Sautter Lift Components GmbH

Remsstraße 26

70806 Kornwestheim I Germany

Progressive safety gear SG Manual

SG braking downwards Technical data

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 6

3. Technical Data

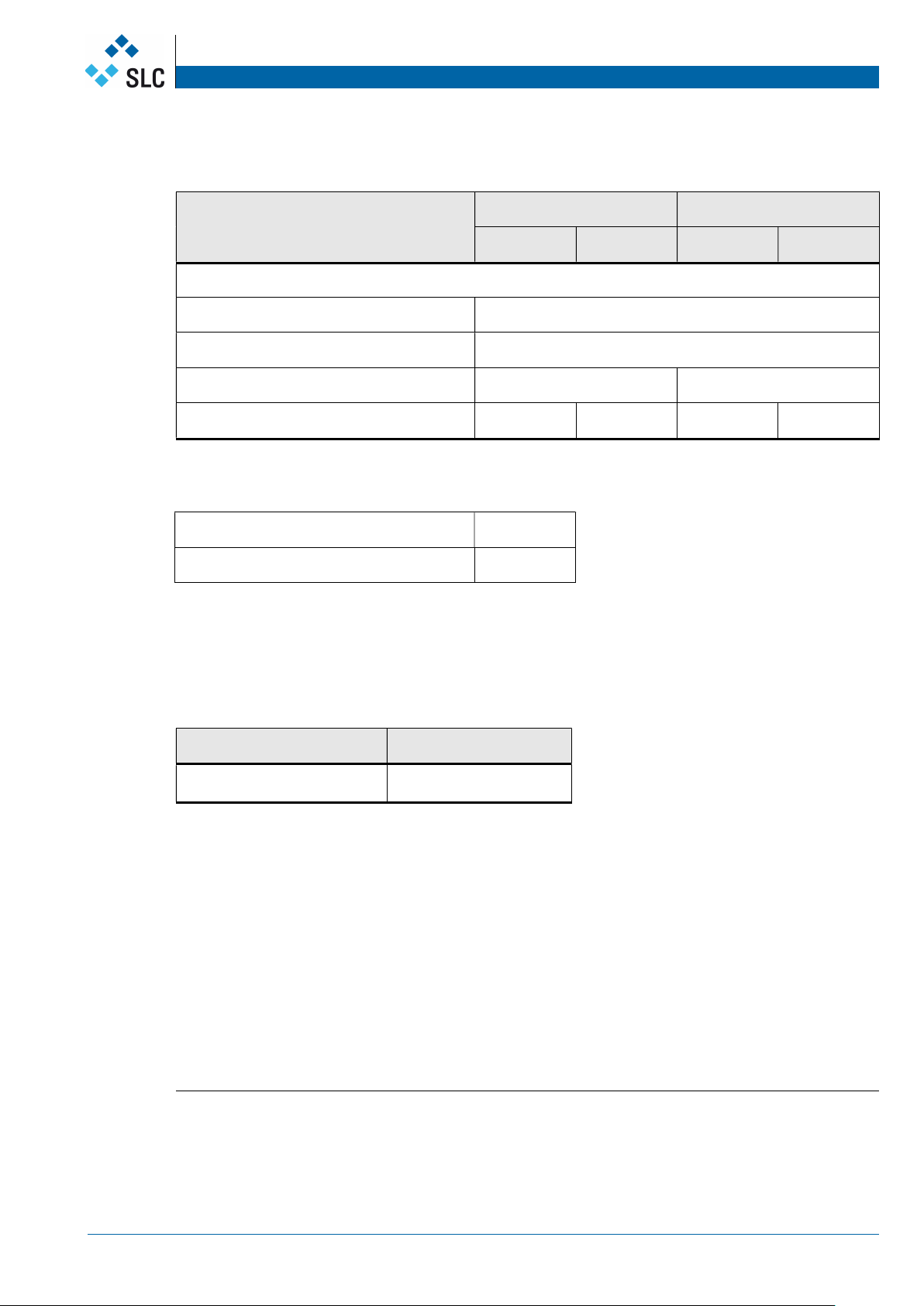

Range of application

Machined rails Drawn rails

dry oiled1 dry oiled1

SG1D-1

Min. width of running surface 19 mm

Rail head width 5 – 16 mm

Max. rated speed [m/s] 3.23 3.23

Total mass min.-max. [kg] 543 – 3’095 523 – 2’935 305 – 2’605 299 – 2’547

Maximum tripping speed of the overspeed governor and range of maximum rated speed:

Max. tripping speed [m/s] 3.23

Max. rated speed [m/s] 2.50 – 2.80

3.1 Tripping

Below the minimum tripping force (without tripping device) required to trip the safety gear

Type Braking downwards

SG1D-1 120 N

The maximum admissible tripping force required at the safety gear shall not exceed 1600 N.

The individually needed tripping force has to be ascertained at the lift, considering all components.

Standard EN81-20:2014-11 rules that for the tripping of safety gears twice the required tripping

force has to be available – at least 300 N!

1

the indications for oiled guide rail refer to use of mineral oils without additive

(for example lubricant C according to DIN 51517, Part 1).

Progressive safety gear SG Manual

SG braking downwards Technical data

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 7

3.2 State of delivery

The safety gear is adjusted in the factory to the following lift specific characteristics:

Mass of lift car (P)

Mass of payload (Q)

Mass of compensation ropes

Rated speed of the lift car

Rail head width (5 – 16 mm)

Manufacturing mode of rails (machined, drawn)

Surface condition of rails (dry, oiled)

The setting is secured against alterations by the manufacturer by means of a seal.

DANGER

Wrong setting of the safety gear can result in falling-down of the lift.

The safety gear is adjusted by the manufacturer. As the deceleration depends on different, partially

lift-specific factors (material of guide rail, surface hardness of the rail, …) a precise pre-adjustment

cannot be guaranteed.

If a setting correction is exceptionally required, the setting has to be carried out only by specially

trained personnel after consultation with the manufacturer. The new setting has to be secured

against unauthorized alterations by means of a seal.

WARNING

The manufacturer cannot be held liable for damages caused by unauthorized setting alterations.

ACHTUNG

WARNING

Before installing the safety gear on the lift car its type plate characteristics have to be compared with

the lift characteristics. The type plate is mounted on the safety gear.

The safety gear must only be applied within the permission scope of application: see EC type-

examination certificate “Scope of application”, certificate no. see chapter 2.3.

IMPORTANT

The safety gear is set at work according to values specified in the order form for safety gears to

obtain the required braking force.

The order form can be downloaded on the homepage of SLC

http://www.slc-liftco.com/en/12/downloads.html

Progressive safety gear SG Manual

SG braking downwards Mounting and dimensions

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 8

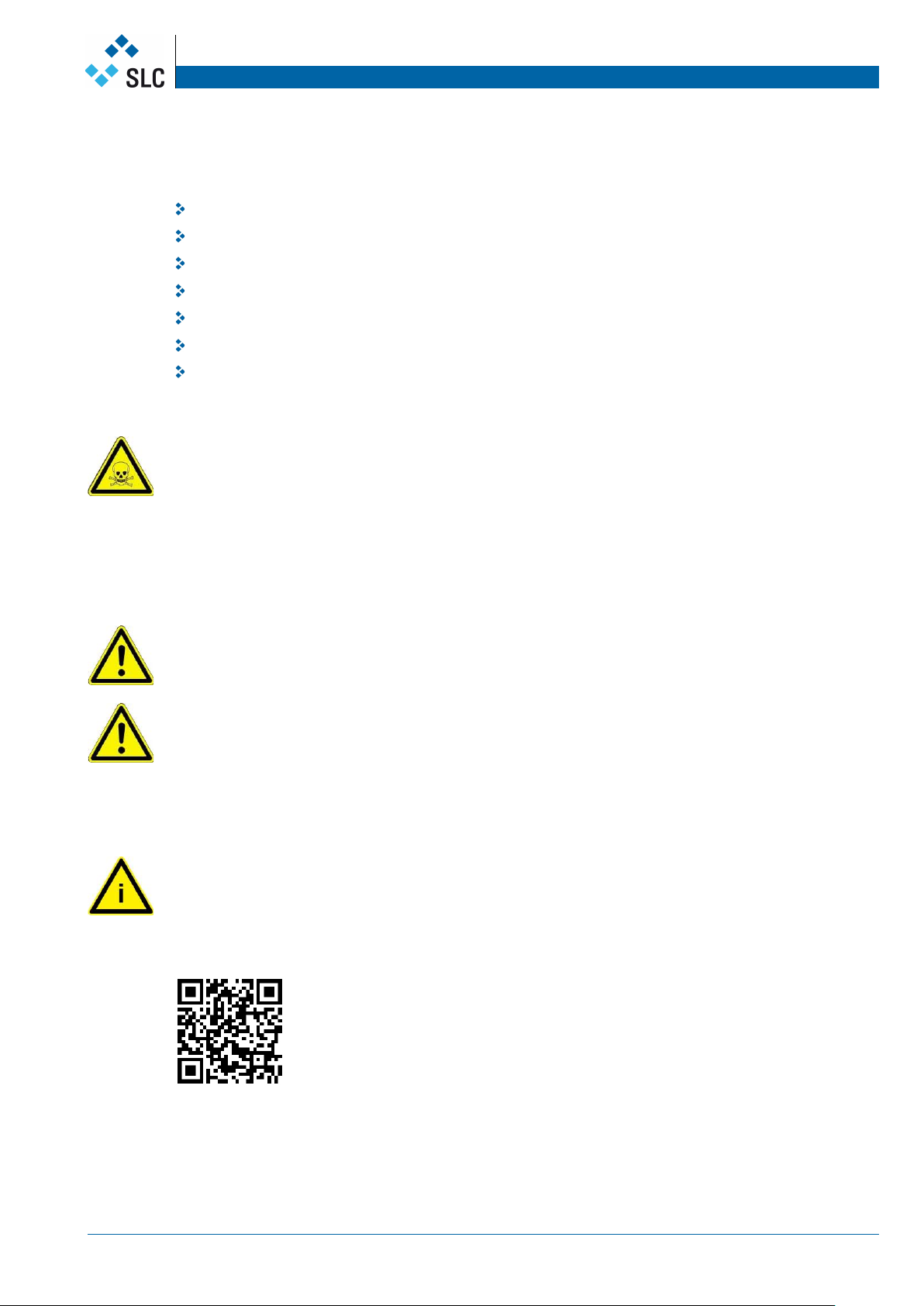

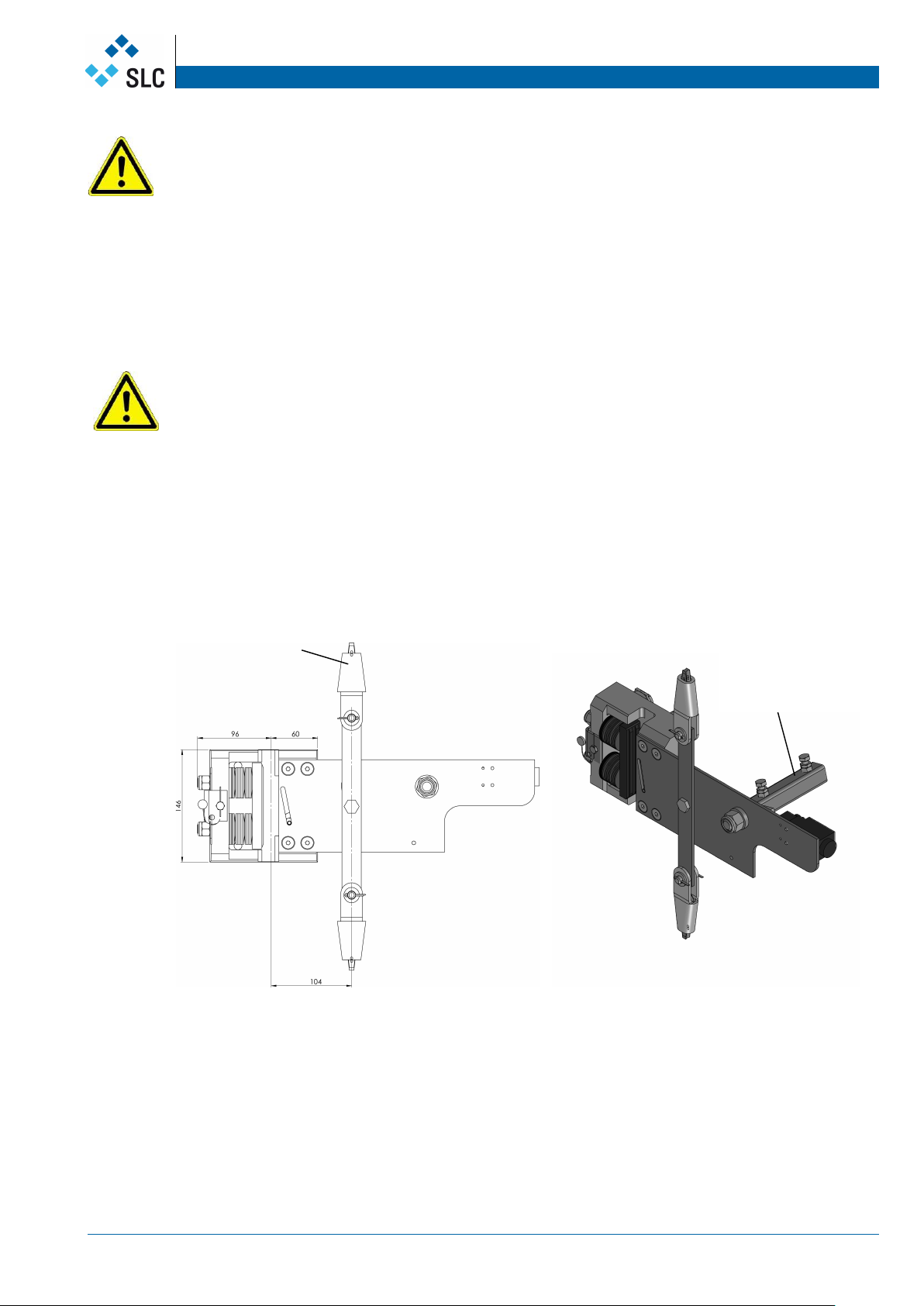

4. Mounting and dimensions

Installation dimensions

Type Weight

(Pair) Height Width Depth

SG1D-1 18 kg 144 mm 417 mm 55 mm

SG1D-1

* When brake is activated, the measure increases by approximately 5 mm.

Trigging of the

release force

Resetting

spring

Progressive safety gear SG Manual

SG braking downwards Mounting and dimensions

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 9

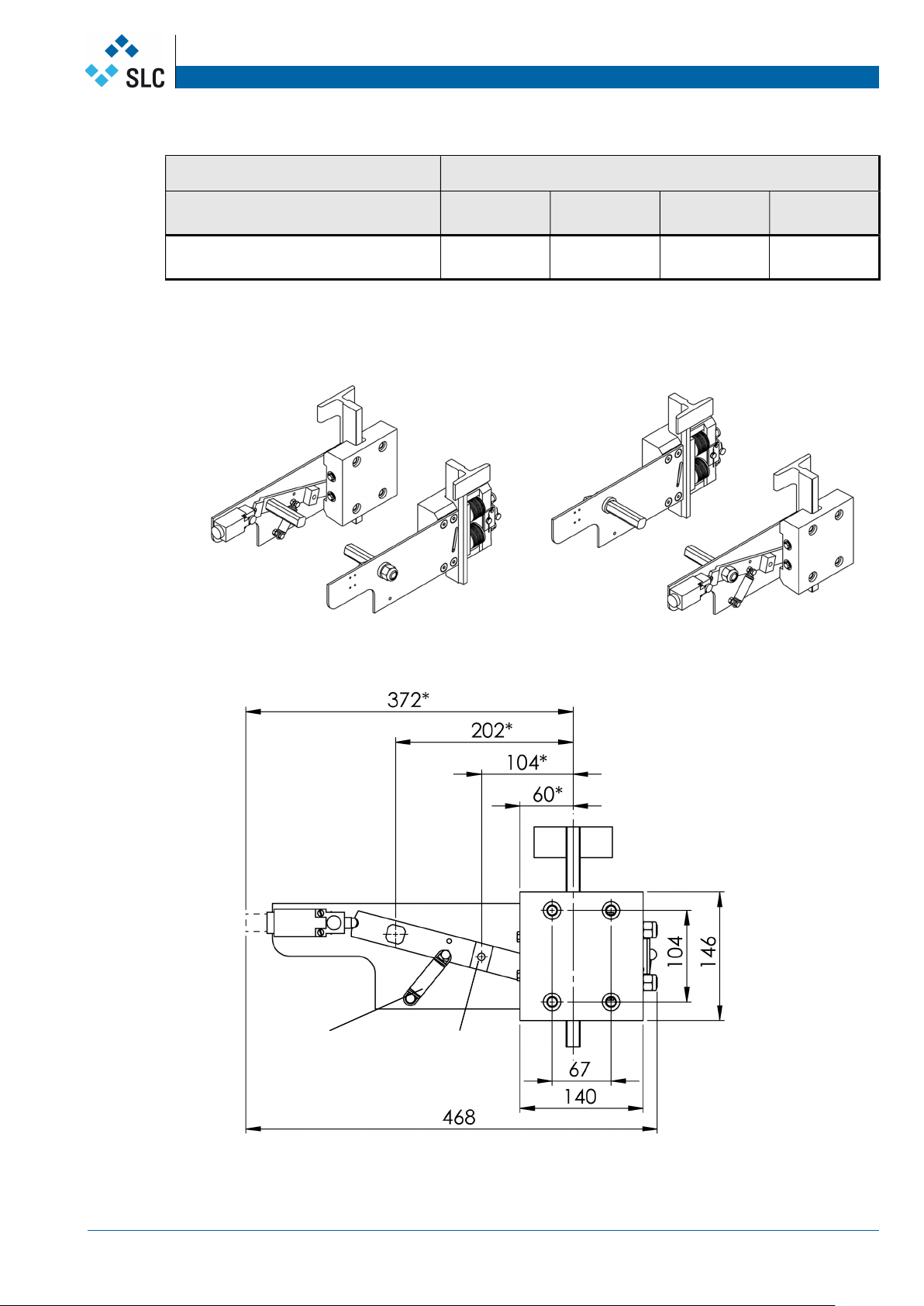

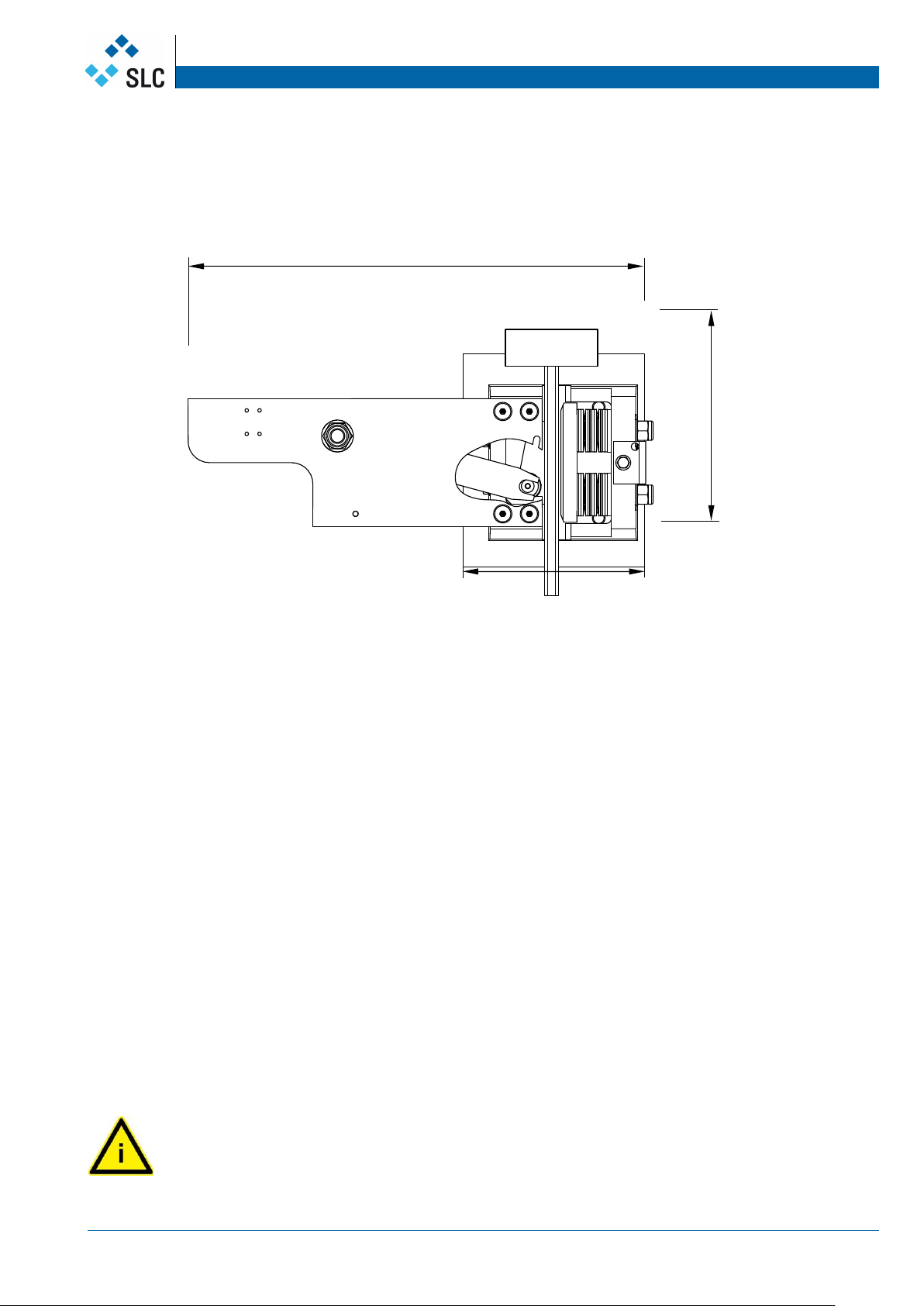

SG1D-1 with mounting brackets

Safety contact

Neutr

al

position

Progressive safety gear SG Manual

SG braking downwards Description and function

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 10

5. Specification and function

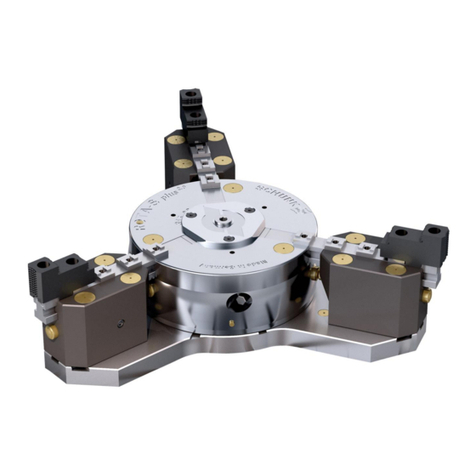

5.1 Specification of the safety gear

safety gear roller

roller guide

lever

brake shoe

rail

disk spring

distance plates

safety plate

internal housing

fishplate

5.2 Function of the safety gear

Upon tripping the overspeed governor both levers synchronised by the actuating shaft are turned

by 15°.

In doing so the safety gear roller moved by the lever makes contact with the rail surface.

The safety gear roller is pressed into the wedge-shaped gap between rail and roller guide . Owing

to the wedge effect of the roller guide the full floating beared safety gear is moved until the brake

shoe rests against the rail .

The disc spring transmits the braking force to the internal housing. To adapt to different widths of

guide blades distance plates of various thickness are placed under the disc.

The spring pressure is preset and secured by a safety plate and a led-sealing to prevent

unauthorized adjustment.

In the braking process the brake shoe fixed on the bracket cuts into the rail surface. The braking

effect is caused by metal cutting in the rail surface, friction and spring tensioning work.

Moving the lift car upwards releases the brakes and lever and the safety gear rollers return to neutral

position.

The safety gear is ready for action again.

IMPORTANT

The safety gear transmits the braking force to the car. This braking force must be taken into account

in the construction of the interface between safety gear and car.

139

144

420

Progressive safety gear SG Manual

SG braking downwards Assembly

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 11

6. Assembly

6.1 Assembly of the safety gear at the lift car

The safety gear is fixed to the lift car with four screws of type M12 and bushes.

Pay attention to the full floating bearing the safety gear as this is the key to the safety gear sliding

into braking position after being tripped by the overspeed governor.

WARNING

When the safety gear is in neutral position it can be adjusted using the adjustment mechanism.

The following points must be observed:

The rail running guide must cover the brake shoes completely. The air gap between the rail running

surface and the brake shoe must be adjusted to 2 mm.

The safety gear must be installed so that the spring mounted brake shoe is parallel to the rail and in

direction of travel.

width of rail

5-16 mm

Setting of elastic

force secured with

seal

air gap 2 mm

Washer with variable

thickness for adjusting

various widths of rail blades

Progressive safety gear SG Manual

SG braking downwards Assembly

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 12

WARNING

Ensure that the mounting screws in the long slots of the external housing have enough play in both

directions in neutral positions.

Correct position of the safety gear

During assembly the safety gear on the car take care for the correct position of the safety gear.

Firstly there is an advice on the type plate of the safety gear, secondly the following characteristics of

the safety gear roller is only given if the safety gear is mounted correctly:

By pulling the lever upwards the gap between safety gear roller and rail gets smaller until the safety

gear roller rests against the rail.

WARNING

Incorrect installation of the braking device causes a functional disorder of the safety gear.

Linkage of the braking units

Both safety gear units are linked with an actuating shaft.

The actuating shaft is fixed to the lever of the safety gear with attachment screws or spring type

straight pins. The actuating shaft is connected by mean of two square-type tubes 20x20 mm.

Coupling to connect with

other safety housing

through linkage tube

Linked to OSG-rope

(Overspeed governor)

Progressive safety gear SG Manual

SG braking downwards Commissioning

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 13

7. Commissioning

7.1 Functional check

WARNING

Before commissioning the safety gear

make sure that the overspeed governor works correctly, that the safety gear is attached to the

overspeed governor and that the produced tractive force is two times the force required for

engaging the safety gear.

the guide rail must be cleaned of dirt. Most suitable for cleaning is cold solvent.

Before commissioning the lift car

the lift car must be braked statically:

by turning the actuating shaft until both safety gear rollers contact the guide rail as well as letting

the car down slowly. It has to be checked if both safety gear rollers move to their working

position.

the lift car must be braked with low speed.

It has to be checked if both safety gear rollers move to their working position.

For checking the braking force it is possible to trip the safety gear with rated speed or overspeed.

By pulling out from braking position the lever of the safety gear roller turns back into neutral position.

WARNING

The safety gear may be operated only in combination with an overspeed governor.

7.2 Commissioning at the lift

Braking the car in down direction with 125% of payload decelerations of the car must be between

0,2g and 1g (9,81m/s2).

7.3 Acceptance test or commissioning of the lift

IMPORTANT

Engagement test downwards

Tests before commissioning the lift according to EN81-20:2014-11, chapter 6.3

(EN81-1/2:1998+A3:2009, Annexe D) resp. periodic tests according to EN81-20:2014-11, Annexe C

(EN81-1/2:1998+A3:2009, Annexe E).

7.4 Check after braking

After every braking the safety gear has to be rechecked by a qualified person.

There is to be checked visually whether any changes or dirtying at the braking elements has

occurred.

The following points have to be rechecked:

excessive wear of the brake shoes

deformations

smooth running

The rubbed-off particles have to be removed and the braking marks grinded down.

Braking again on a re-grinded braking track is not causing an essential change of the braking force.

DANGER

For guide rail lubrication oil products approved in the type examination certificate shall be used only.

Use machine oil of viscosity class ISO 68-150 without extreme pressure additive. See mineral oils

without additive (for example lubricant C according to DIN 51517, Part 1.)

Oils for hydraulic aggregates, gears and motors are not suitable for this use.

Progressive safety gear SG Manual

SG braking downwards QR-Code

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 14

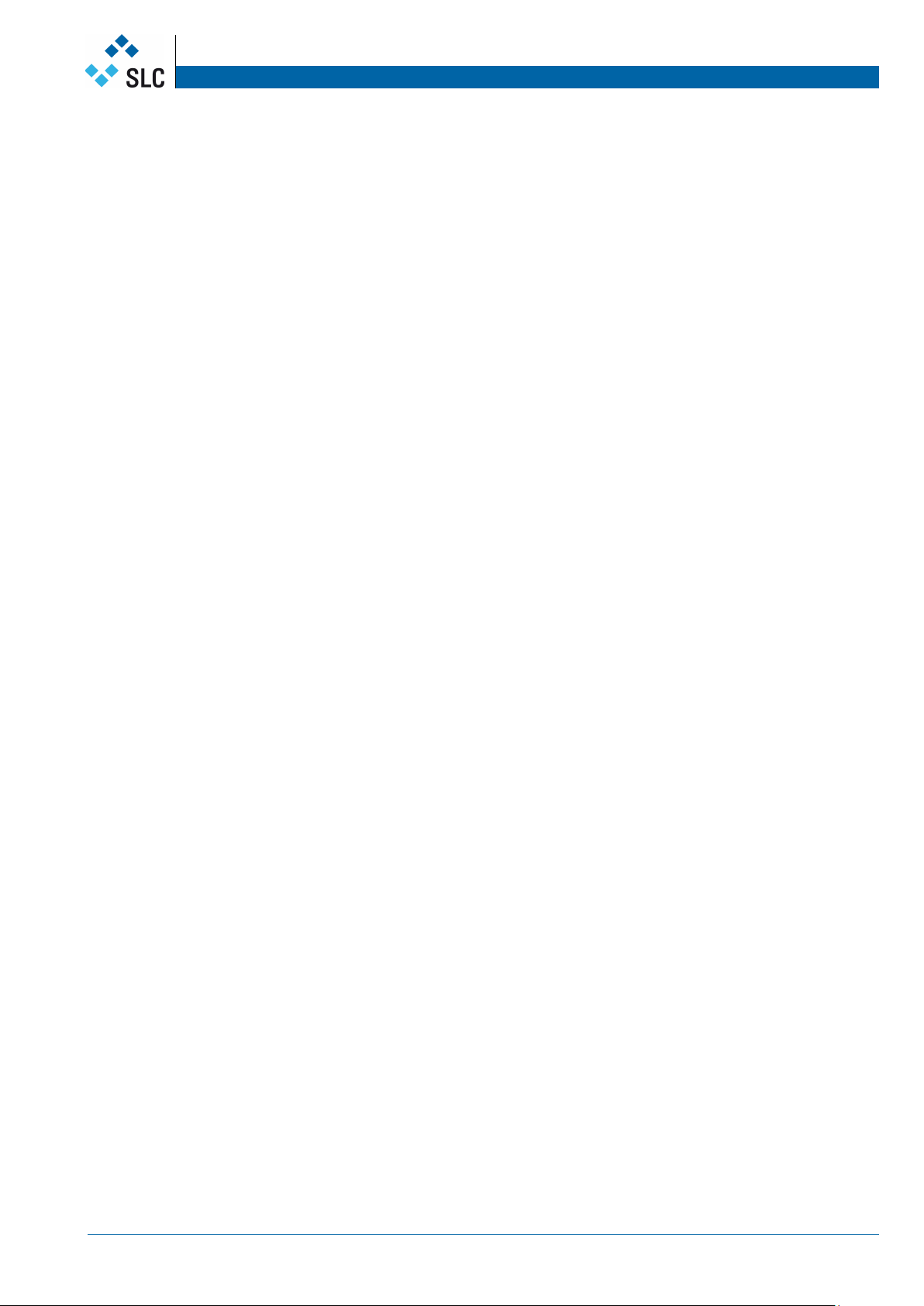

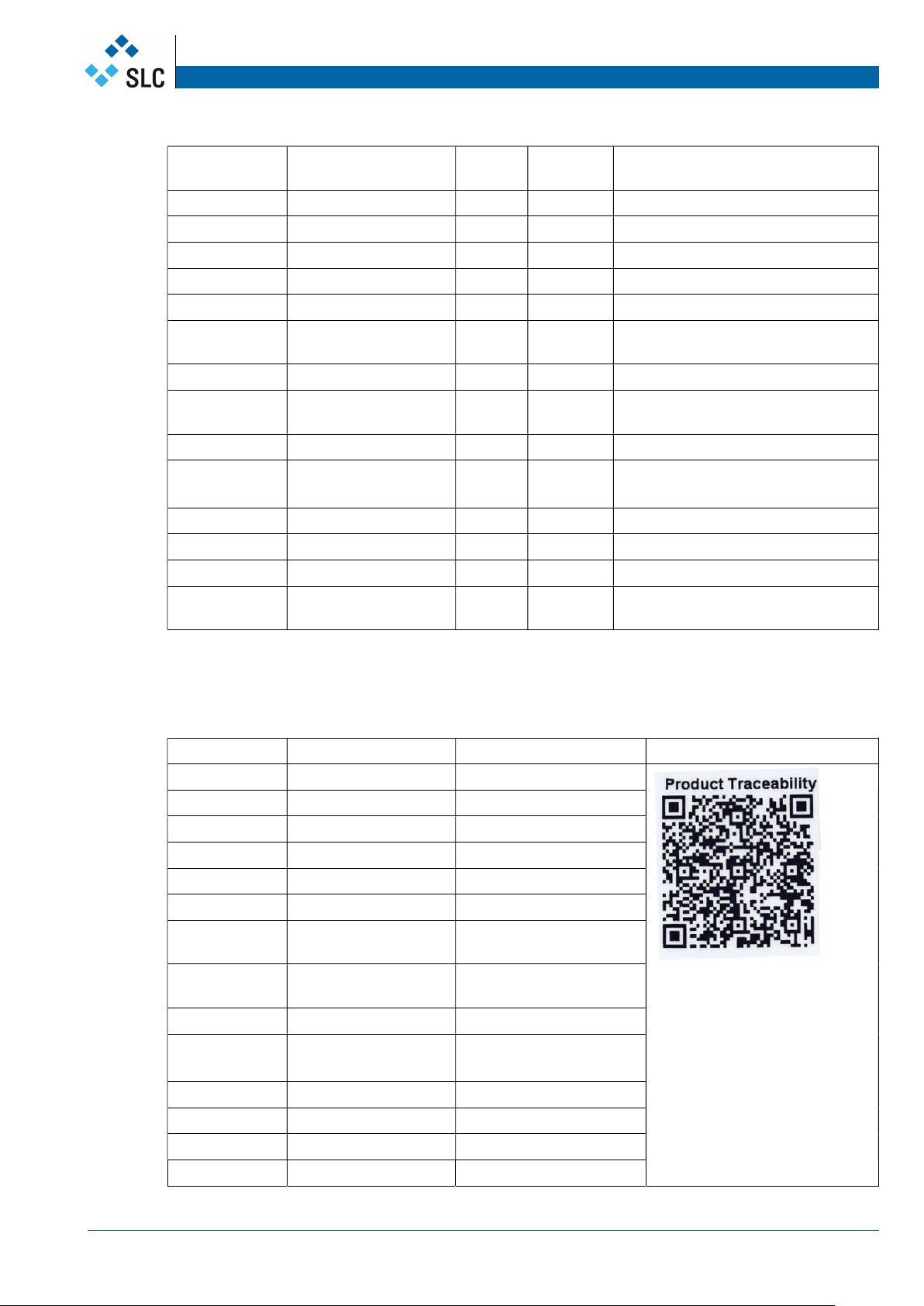

8. Content of QR-Code

Description Data field Type Length

(symbol)

Safety components from other

suppliers

1 Product name CHAR 40 Product name of safety gear

2 Release NUM 2

3 Revision NUM 2

4 Identification number CHAR 35 SL product number

5 Serial number CHAR 18

6 Batch number CHAR 10 Only when serial number is not

available

7 Manufacturer name CHAR 30 Name of manufacturer

8 Manufacturer postal

code

CHAR 10 Postal code of manufacturer

9 Manufacturer town CHAR 30 Town of manufacturer

10 Manufacturer

country code

CHAR 5 Two-character country code

according to ISO 3166-1

11 Importer name CHAR 30 Name of importer

12 Importer postal code CHAR 10 Postal code of importer

13 Importer town CHAR 30 Town of importer

14 Importer country code CHAR 5 Two-character country code

according to ISO 3166-1

Notice: Data fields without values are marked with "---". If numbers 2 and 3 (approval and

revision) are not necessary, fields remain empty.

Example of QR-code for SG1D-1 safety gear from SLC:

Description Data field Text in QR-code Sample QR-code

1 Product name SG1D-1

2 Release

3 Revision

4 Identification number 50100505

5 Serial number 16/5821

6 Batch number ---

7 Manufacturer name Sautter Lift Components

GmbH

8 Manufacturer postal

code

70806

9 Manufacturer town Kornwestheim

10 Manufacturer

country code

DE

11 Importer name SLS Sassi Lift Systems

12 Importer postal code CM7 2QJ

13 Importer town Braintree

14 Importer country code GB

Progressive safety gear SG Manual

SG braking downwards Maintenance and transport

www.slc

-liftco.com Doc. 300.000.123 I Version 02.2019 Page 15

9. Maintenance

Upon maintenance the safety gear shall be checked for:

smooth operation

synchronous operation of the two units

wear

rust

dirt

sealing

If, after a couple of braking tests, the braking rollers or the safety gear base show signs of wear they

are to be replaced by qualified persons.

Material numbers:

Brake shoe 106.930.288

Safety gear roller 106.920.120

Roller guide 106.700.191

10. Transport

Any work upon transport, storage, installation and commissioning as well as (if any) demounting and

disposal of a safety gear is to be carried out by qualified persons only.

They shall be responsible for proper assembly, transport and installation, and for putting the safety

gear into operational condition. If this is not ensured, the manufacturer shall not be held liable for any

damages that might occur.

Upon transport the safety gear must be protected against:

humidity

shock

dirt

falling-down, etc.

11. Annexe

EU type-examination certificate EU-SG 802

Certificate of conformity

IMPORTANT

Find more certificates of conformity in additional languages on our homepage:

http://www.slc-liftco.com/en12/downloads.html.

Table of contents

Other SLC Industrial Equipment manuals