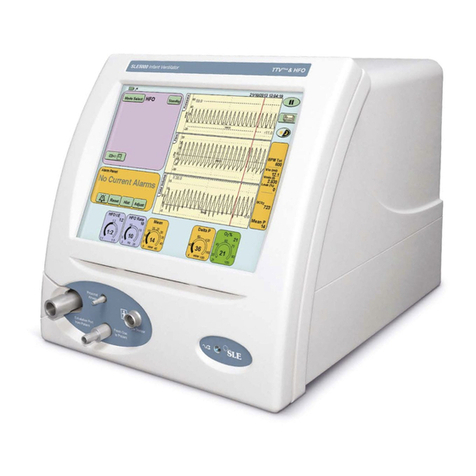

SLE SLE2000 HFO User manual

SLE2000

Service manual

Page 2 (SLE2000)

Contact Information:

All rights reserved. No part of this publication may be reproduced, stored in any retrieval system, or transmitted

in any form or by any means, electronic, mechanical, photocopy, recording or otherwise, without prior

permission of SLE. © Copyright SLE 19/03/2012.

Manual : SM7 Issue 12

SLE Part Nº: N2000/00

SLE Limited

Twin Bridges Business Park

232 Selsdon Road

South Croydon

Surrey CR2 6PL

Telephone: +44 (0)20 8681 1414

Fax: +44 (0)20 8649 8570

Web site: www.sle.co.uk

(SLE2000) Page 3

Contents

1. Introduction ............................................................................................................... 8

2. Principles of operation SLE2000 valveless system ................................................... 8

3. User/owner responsibility .......................................................................................... 10

4. Warnings ................................................................................................................... 11

5. Symbols used on or in the equipment ....................................................................... 12

6. Glossary of abbreviations ......................................................................................... 13

7. Ventilator control description ..................................................................................... 16

7.1. Front Panel..................................................................................................... 16

7.2. Function of front panel controls and indicators............................................... 17

7.3. Rear panel...................................................................................................... 19

7.4. Side panel ...................................................................................................... 20

8. Accessing the SLE2000 internal components. ......................................................... 22

8.1. Electronic module........................................................................................... 22

8.2. Pneumatic module.......................................................................................... 22

8.2.1. To Remove the A0702/01 PCB (Runner mounted) ................................. 23

8.2.2. To Remove the A0702/01 PCB (Pillar mounted) ..................................... 24

8.3. To Separate The Two Modules ...................................................................... 25

8.4. Removal Of The Oxygen Blender................................................................... 26

8.5. Removal of the Oxygen cell............................................................................ 27

8.5.1. Oxygen Cell Mounting ............................................................................. 27

9. Maintenance ............................................................................................................. 30

9.1. Cleaning, disinfection and sterilization ........................................................... 30

9.1.1. Preparation of a new ventilator ................................................................ 30

9.1.2. Cleaning and disinfection of an in-service ventilator................................ 30

9.1.3. Cleaning, Disinfection & Sterilization chart .............................................. 31

9.1.4. Cleaning method...................................................................................... 31

9.1.5. Disinfection method ................................................................................. 32

9.1.6. Sterilization method ................................................................................. 32

9.2. Filter systems ................................................................................................. 33

9.2.1. Bacterial filter, SLE Part Nº:N2029 (Autoclavable) .................................. 33

9.3. Bacterial filter, SLE Part Nº:N2587 (Single use)............................................. 33

9.3.1. Precautions when using bacterial filter N2587......................................... 33

9.4. Monthly operational checks............................................................................ 34

9.4.1. Battery condition and LED display test. ................................................... 34

9.4.2. Air and oxygen supply failure alarm test.................................................. 34

9.4.3. Condition of O2cell.................................................................................. 34

9.4.4. Proximal airway pressure gauge accuracy .............................................. 34

9.4.5. Inspiratory nozzle..................................................................................... 34

9.5. Preventative maintenance.............................................................................. 35

9.6. Overhaul......................................................................................................... 35

9.6.1. Service parts list ...................................................................................... 36

Page 4 (SLE2000)

10. Electronic module description .................................................................................38

10.1. Description of operation ................................................................................38

11. Pneumatic module description ...............................................................................40

11.1. Description of operation ................................................................................40

11.2. Fresh Gas System ........................................................................................42

11.3. CPAP System ...............................................................................................43

11.4. Inspiratory System ........................................................................................44

11.5. Pneumatic Circuit Diagram ...........................................................................45

11.6. Pneumatic Module Parts List ........................................................................46

12. Test Equipment Required ........................................................................................50

13. SLE2000 Calibration Procedure ..............................................................................51

13.1. Electronic unit preliminary checks and adjustment .......................................51

13.1.1. System Watchdog ..................................................................................52

13.1.2. Pressure Transducer, PTR1 Calibration. ...............................................52

13.1.3. Pressure Transducer Buffered Output ...................................................52

13.1.4. CPAP alarm threshold control. ...............................................................52

13.1.5. PIP alarm threshold control. ...................................................................53

13.1.6. Inspiration Time Control .........................................................................53

13.1.7. Alarm Volume Control ............................................................................53

13.1.8. Airway Trigger Calibration (Part 1) .........................................................53

13.2. Pneumatic module setup and calibration ......................................................54

13.2.1. Fresh Gas Pressure Regulator (REG3) Adjustment ..............................54

13.2.1. Minimum blender flow needle valve (NV2) adjustment .........................54

13.2.2. Fresh gas flow needle valve (NV1) adjustment......................................54

13.2.3. Fresh Gas Block and Leak Alarm...........................................................55

13.2.4. FiO2 Digital Display................................................................................55

13.2.5. Airway Trigger Calibration (Part 2) ........................................................56

13.3. Soak Test......................................................................................................57

13.4. CMV mode soak test 50 hours .....................................................................57

13.5. Functional testing (Post soak).......................................................................58

13.5.1. Perform Electrical Safety Test................................................................58

4.0.1. Basic Operation........................................................................................58

4.0.2. Mains Voltage tolerance test. ...................................................................60

4.1. SLE 2000 Electrical Troubleshooting Chart ....................................................62

4.2. SLE 2000 Pneumatic Troubleshooting Chart..................................................63

5. Technical Specification ..............................................................................................66

5.1. Conventional Ventilation .................................................................................66

5.2. Displays ..........................................................................................................66

5.3. Controls...........................................................................................................67

5.4. Alarms.............................................................................................................67

5.5. Power , Dimensions etc. .................................................................................68

6. Electronic Circuit Details ...........................................................................................70

6.1. Display Board A0700/01 .................................................................................70

6.1.1. Display Board Circuit Diagram A0700/01.................................................71

(SLE2000) Page 5

6.2. LED Board A0701/01 ..................................................................................... 73

6.2.1. LED Circuit Board Diagram CD/A0701/01............................................... 74

6.3. Ventilator CPU Board AS/A0702/01 Issue 4 ................................................. 77

6.3.1. Ventilator CPU Board CD/A0702/01 Issue 2 Sheet 1 of 3....................... 78

6.3.2. Airway Trigger Circuit Diagram CD/A0702/01 Sheet 2 of 3..................... 79

6.3.3. Window Pressure Alarm A0702/01 Sheet 3 of 3 ..................................... 80

6.4. Ventilator CPU Board AS/A0702/01 Issue 5 ................................................. 84

6.4.1. Ventilator CPU Board CD/A0702/01 Issue 6 ........................................... 85

6.5. Ventilator CPU Board AS/A0702/01 Issue 5 ................................................. 89

6.5.1. Ventilator CPU Board (Detail A) .............................................................. 90

6.5.2. Ventilator CPU Board CD/A0702/01 Issue 7 ........................................... 91

6.6. RS232/423 Option.......................................................................................... 96

6.7. PSU PCB AS/A0703/01 issue 3 ..................................................................... 99

6.7.1. Power Supply Circuit Diagram CD/A0703/01 issue 4.............................. 100

6.8. PSU PCB AS/A0703/01 issue 7 ..................................................................... 103

6.8.1. Power Supply Circuit Diagram CD/A0703/01 issue 5.............................. 104

6.9. PSU PCB AS/A0703/01 issue 8 ..................................................................... 107

6.9.1. Power Supply Circuit Diagram CD/A0703/01 issue 6.............................. 108

6.10. Back-up alarm sounder AS/A0703/03 issue 1.............................................. 111

6.10.1. Back-up alarm sounder circuit diagram CD/A0703/03 issue 1 .............. 112

6.11. A0704 P.S.U. PCB assembly ....................................................................... 114

6.12. CD/W0288 Wireloom issue 1 ....................................................................... 117

6.13. CD/W0288 Wireloom issue 3 ....................................................................... 118

6.14. Electronic Chassis Stage 1 AS/L0105 issue 8 ............................................. 120

6.15. Electronic Chassis Stage 2 AS/L0104 issue 4 ............................................. 125

6.15.1. Electronic Chassis AS/L0104 issue 4 .................................................... 126

6.16. Electronic Chassis Stage 2 AS/L0104 issue 8 ............................................. 129

6.16.1. Electronic Chassis AS/L0104 issue 8 .................................................... 130

6.17. Electronic Chassis Stage 1 AS/L0105 issue 9 ............................................. 133

6.18. Electronic Chassis Stage 2 AS/L0104 issue 9 ............................................. 138

6.18.1. Electronic Chassis AS/L0104 issue 9 .................................................... 139

7. Service Information and Technical bulletins ............................................................. 156

7.1. Service Information ........................................................................................ 157

7.1.1. SI 980301 Ventilator Alarms &INOSYS Nitric Oxide Delivery System .... 157

7.1.2. SI 980302 Ventilator oxygen cells (N2191) ............................................. 159

7.1.3. SI 990302 Possible inadvertant solenoid failure messages .................... 160

7.1.4. SI 000201 Leak Alarm Trigger Threshold................................................ 162

7.1.5. SI 020901 Cleaning, Disinfection and Sterilisation of SLE ventilators..... 164

7.1.6. SI 031101 N2183 0-4 bar pressure gauge .............................................. 165

7.1.7. SI 050301Maximum Mean & Min Pressure Selection Switch.................. 166

7.1.8. SI 050701 Activation of watchdog secondary alarm sounder in case of

primary alarm sounder failure. ............................................................................ 167

7.1.9. SI 060104 Replacement N2125 push button switches ............................ 168

7.1.10. SI 060201 New PCB mounting method ................................................. 170

7.1.11. SI 060301 O0408 key switch replacement ............................................ 171

7.1.12. SI 070301 Design and component change to the A0703/01 PSU PCB 173

Page 6 (SLE2000)

7.2. Technical Bulletins ..........................................................................................174

7.2.1. TB 990603 Removal of hour counter from electrical chassis. ..................174

7.2.2. TB 000201 New versions of control software...........................................175

7.2.3. TB 000801 Ventilator Firmware Status ....................................................176

7.2.4. TB 040301 SLE2000 CPU Boards ...........................................................179

7.2.5. TB 040401 V0226 Potentiometer .............................................................181

7.2.6. TB060901 Alarm sounder replacement at 10,000 hr overhaul.................182

6. Issue Revision Record ..............................................................................................185

7. Index ..........................................................................................................................186

(SLE2000) Page 7

Introduction

Page 8 (SLE2000)

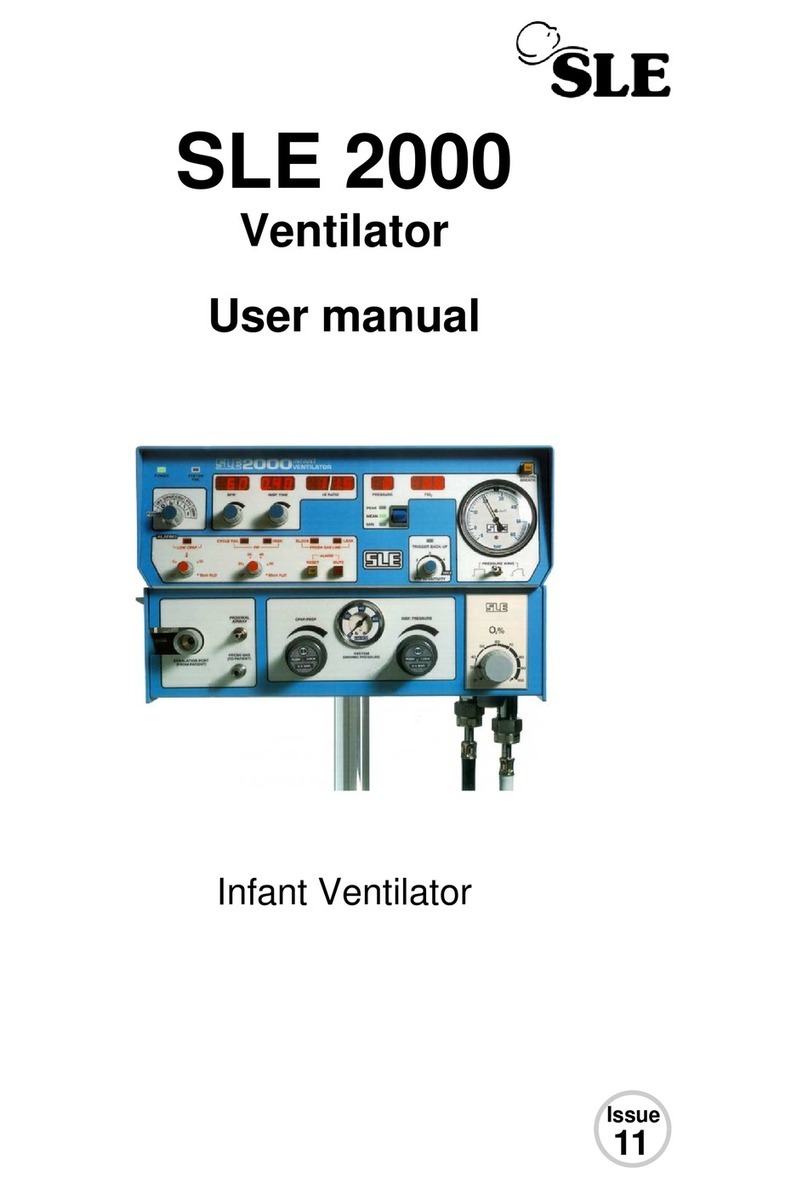

1. Introduction

The SLE2000 is a constant flow, time cycle, and pressure limited neonatal ventilator with

patient triggering.

Main features are that it has no expiratory valve but uses a reverse flow of mixed gas that is

injected from the exhaust manifold into the expiratory limb of the patient circuit. This flow of

gas has the effect of compressing 5 LPM humidified gas into the patient ET tube.

The advantage of this system is that there is no expiratory resistance due to valves or

diaphragms, therefore no inadvertent PEEP is generated.

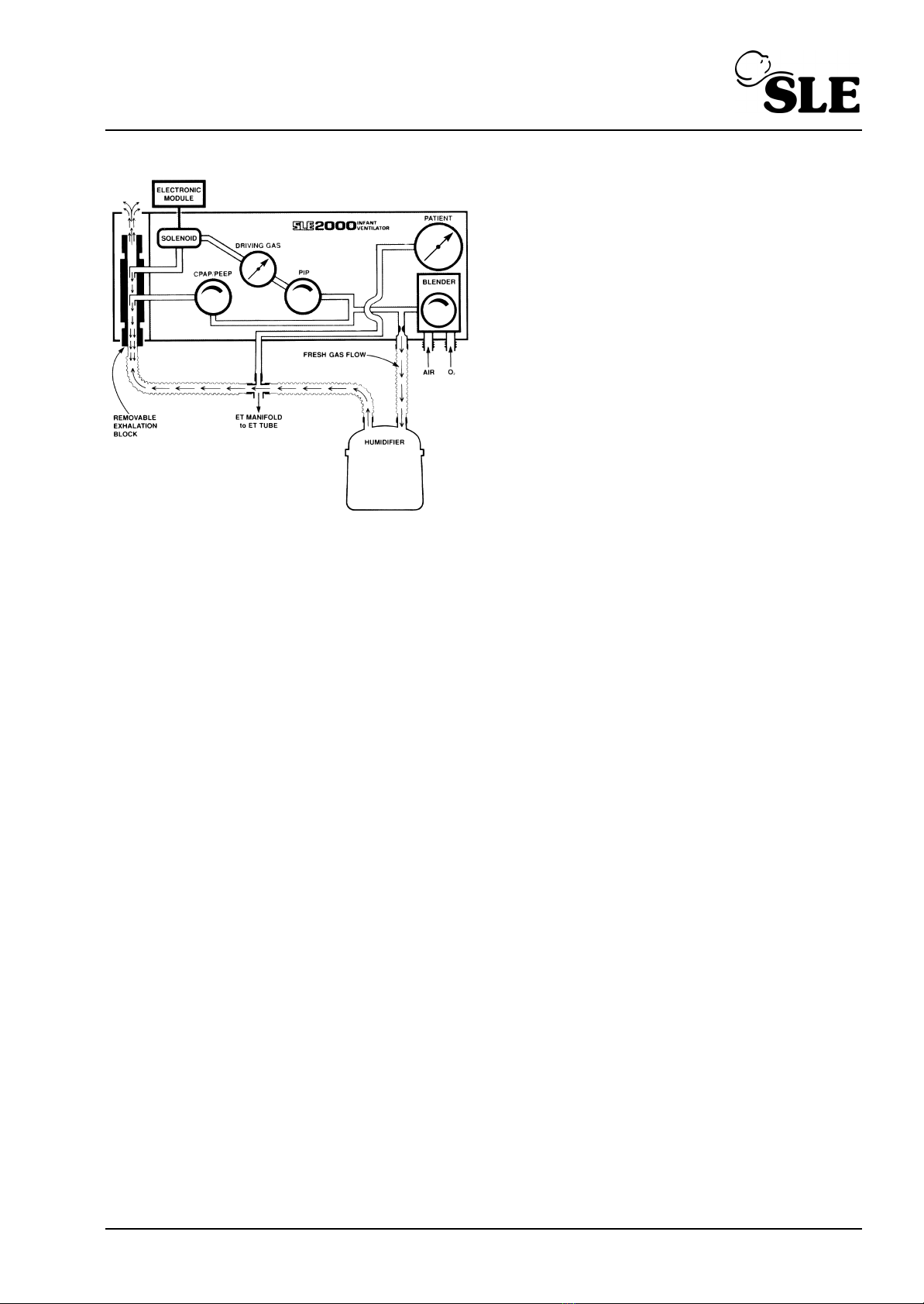

2. Principles of operation SLE2000 valveless system*

The patient circuit is supplied with a constant fixed flow of 5LPM fresh gas. This gas comes

from the internally mounted oxygen blender and its concentration is also monitored by a fuel

cell and displayed on the FlO2 digital display. This fresh gas supply is then passed through a

humidifier to the inspiratory port of the patient ET connector. Built into the ventilator are

circuits to detect either a gas flow failure or a tubing blockage. The patient circuit requires a

restrictor fitted into the inspiritory port. Therefore, only SLE approved patient circuits must

be used.

The Expiratory limb of the patient circuit is connected to the Exhalation port on the ventilator.

This consists of a removable block mounted on a manifold, accessed by lowering the left

hand side cover. The expiratory manifold has two nozzles. The front one to generate CPAP/

PEEP and is supplied via the CPAP regulator on the front panel of the Pneumatic Module.

The rear one to generate peak inspiratory pressure(PIP).

To avoid the possibility of gas dilution these regulators are supplied with the same oxygen

concentration as the Fresh Gas supply . The front nozzle is used to generate an opposing

flow to the Fresh Gas in the exhalation block and thus create CPAP The rear nozzle is used

to generate the peak inspiratory pressure in the same way, supplying constant pressures at

all breathing rates.

(SLE2000) Page 9

The PIP regulator and gauge on the front

panel set the pressure that is supplied to a

solenoid valve which is connected to the rear

nozzle.

The Electronic Module controls the rate and

duration of the flow of Driving Gas into the

Exhalation block in opposition to the Fresh

Gas flow. This opposing flow acts as a

pneumatic piston and creates a pressure

wave at the ET manifold. The lung inflation

pressure and hence the tidal volume are

controlled by the PIP regulator.

NOTE: The ventilator should be set to a

square waveform for breathing rates above 60 BPM

* The Valveless Ventilation Principle was designed and patented by Prof. J G Whitwam and Mr. M. K.

Chakrabarti of the R.P.G.M.S Hammersmith Hospital.

This patent is exclusively licensed to SLE

Page 10 (SLE2000)

3. User/owner responsibility

This SLE 2000 INFANT VENTILATOR equipment and the authorised accessories for it are

designed to function as specified in the relevant instruction manual only when operated,

maintained and repaired in accordance with supplied manuals and instructions. This

equipment must be periodically checked, recalibrated, maintained and components repaired

and replaced when necessary for the equipment to operate safely and reliably. Parts that

have failed, in whole or in part, or exhibit excessive wear, or are contaminated, or are

otherwise at the end of their useful life should not be used and should be replaced

immediately with parts supplied by SLE or parts which are otherwise approved by SLE.

Equipment which is not functioning correctly or is otherwise in need of repair or maintenance

must not be used until all necessary repairs and/or maintenance have been completed and

a factory authorised service representative has certified that the equipment is fit and ready

for use. This equipment and any of its accessories or component parts should not be

modified.

The owner/user of this equipment shall have the sole responsibility and liability for any

damage or injury to persons or property (including the equipment itself) resulting from

operation not in accordance with the operating instructions, or from faulty maintenance not

in accordance with the authorised maintenance instructions, or from repair by anyone other

than a factory authorised service representative, or from unauthorised modification of the

equipment or accessories, or from the use of components or accessories that have either

been damaged or not authorised for use with this equipment by the factory.

(SLE2000) Page 11

4. Warnings

1 Oxygen - Clinical use. Oxygen is a drug and should be prescribed as such.

2 Oxygen - Fire Hazard. Oxygen vigorously supports combustion and its use requires

special precaution to avoid fire hazards. Keep all sources of ignition away when

oxygen is in use. Do Not use oil or grease on oxygen fittings or where oxygen is used.

3 The ventilator functional tests must be carried out each time the SLE 2000 is used on

patients. If any of these tests do not function as described then there is a problem and

the ventilator must not be used until it is rectified.

4 The humidifier used in the patient circuit must be operated and maintained in

accordance with its manufacturer’s instructions. It is the owners responsibility to

ensure that the equipment is regularly maintained.

5 Failure to comply with the recommended service programs could lead to injury to the

patient, operator or damage to the ventilator. It is the owners responsibility to ensure

that the equipment is regularly maintained.

6 Functioning of this ventilator may be adversely affected by high frequency surgical

(Diathermy) , defibrillators, mobile phones, short-wave therapy or equipment producing

strong magnetic fields, operating the in vicinity.

7 The Ventilator must be plugged into a suitably rated and grounded electrical power

source.

8 There is no special protection provided against ingress of water or liquids.

9 The equipment is not suitable for use with, or in the presence of flammable anaesthetic

mixtures.

10 Use only SLE approved patient circuits. On no account should antistatic or electrically

conductive tubing be used in the patient circuit.

11 No external voltage should be applied to the auxiliary socket. Any connections to this

socket must be approved by SLE and screened to comply with EMC regulations.

Ensure protection cap is fitted when socket is not in use.

12 The electronic module of the ventilator contains a primary battery for mains failure

alarm, if the ventilator is not to be used for 3 months or more, then the battery should

be removed.

13 Care should be taken when attaching other equipment as this may affect stability.

14 If the SLE 2000 Infant Ventilator is adversely affected by equipment emitting

electromagnetic interference then that equipment should be switched off or removed

from the vicinity of the 2000. Conversely, if the 2000 is the source of such interference

to neighbouring equipment then it should be switched off or taken to another location.

Page 12 (SLE2000)

5. Symbols used on or in the equipment

Protective Earth

Attention, Consult accompanying documents.

B.S.I. and I.E.C. symbol for equipment with type B (non isolated parts).

Do not dispose of as general waste (WEEE directive).

(Appears on serial number label).

WARNING : - No external voltage should be applied to the auxiliary socket.

WARNING : - The electronic module contains a primary battery. If the unit is

not to be used for a period exceeding 3 months, it is recommended that the

battery be removed.

Mains

Fuses

Two externally accessible fuses are;

Type T 0.2 amps. For 200 - 250V

Type T 0.5 amps. For 100 - 120V

(SLE2000) Page 13

6. Glossary of abbreviations

amp ........................ Ampere

BPM ....................... Breaths Per Minute

cm .......................... Centimetre

cmH2O ................... Centimetres of Water Pressure

CMV ....................... Continuous Mandatory Ventilation

CPAP ..................... Continuous Positive Airway Pressure

°C........................... Degrees Centigrade

°F ........................... Degrees Fahrenheit

DISS....................... Diameter Index Safety System

ETO........................ Ethylene Oxide

ET .......................... Endotracheal

Exp......................... Expiration Time

FIO2....................... Fractional concentration of Inspired Oxygen

Hz........................... Hertz

ID ........................... Internal Diameter

I:E........................... Inspiratory : Expiratory ratio

Insp ........................ Inspiration Time

IMV......................... Intermittent Mandatory Ventilation

MAP ....................... Mean Airway Pressure

IPPB....................... Intermittent Positive Pressure Breathing

IPPV....................... Intermittent Positive Pressure Ventilation

kg ........................... Kilogram

lb ............................ Pound

LPM........................ Litres per Minute

Peak....................... Peak Airway Pressure

ml ........................... Millilitre

O2........................... Oxygen

PEEP ..................... Positive End Expiratory Pressure

PSI ......................... Pounds per Squire Inch

psig ........................ Pounds per Squire Inch Gauge

SIMV ...................... Synchronous Intermittent Mandatory Ventilation

VAC........................ Volts, Alternating Current

Vt............................ Tidal Volume

Nist......................... Non interchangable Standard Terminal

PTV ........................ Patient Triggered Ventilation

PIP ......................... Peak Inspiratory Pressure

ms .......................... Millisecond

Page 14 (SLE2000)

This page is intentionally blank.

(SLE2000) Page 15

Ventilator Control Description

Page 16 (SLE2000)

7. Ventilator control description

The SLE 2000 consists of two linked modules, Electronic and Pneumatic.

7.1 Front Panel

Electronic

Module

Pneumatic

Module

28

1

23457912

13

14

17

18

19

20

21

22

24

25

26

10

27

6811

15

23

16

(SLE2000) Page 17

7.2 Function of front panel controls and indicators

Nº Item Description

1 POWER and

OPERATIONAL

MODE Switch

Selects Power OFF, ALARM TEST/CPAP, CMV,

PTV, SIMV modes.

2 POWER LED Indicates power is ‘ON’.

3 SYSTEM FAIL LED When this LED lights and the alarm sounds, it

indicates failure of the main processor. If this

happens, the ventilator must be removed from

service.

4 BPM digital display

with adjustment

knob

Displays between 1-250 BPM.

Available in two ranges: 1-125 BPM& 126-250

BPM, selectable by rear security key switch

5INSP.TIMEdigital

display with

adjustment knob

Inspiratory Time

Displays 0.1-3.0 seconds in 1-125 BPM range

or 0.01-0.3 seconds in 126-250 BPM range.

6 FRESH GAS

BLOCK audible

alarm.

Indicates problems within the patient circuit line.

7 I:E RATIO digital

display

Displays from 9.9:1 to 1:9.9 calculated from BPM

and insp. time

8 LEAK LED’s

audible alarm.

Indicates problems within the patient circuit line.

9 MAX MEAN MIN

switch with digital

PRESSURE display

Selects and displays Max., Mean or Min airway

pressures.

10 FIO2digital display Accurately displays the % O2as set by the Air-

Oxygen Blender.

11 TRIGGER BACK-

UP LED

Indicates a machine-delivered breath due to patient

failure to trigger ventilate or during back-up time

window.

12 MANUAL BREATH

Pushbutton

Causes delivery of a single breath in CPAP, CMV

and PTV modes to preset inspiration times and

pressures.

13 Pressure Gauge -6

to +60 cmH2O.

Proximal Airway Pressure. This pressure is

displayed more accurately by the independent

digital display.

14 PTV SENSITIVITY

control

Variable patient trigger level setting.

Sensitivity between 1(least sensitive to patient

effort) and 5 (most sensitive to patient effort).

Page 18 (SLE2000)

15 PRESSURE WAVE

switch

Permits change of leading edge of pressure wave

from square to taper in 1-125 BPM range only.

16 ALARM MUTE

Pushbutton and

LED

Mutes audible alarms for one minute.

17 AIR OXYGEN

BLENDER control

Sets air/oxygen mix between 21 and 100% 02±

3%

with digital indication from independent monitoring

circuits.

18 O2inlet O2 hose connector.

19 Medical air inlet Medical air hose connector.

20 Inspiratory

Pressure

Regulator

Adjusts driving pressure to set circuit inspiratory

pressure.

Range 0-60 cmH2O.

21 SYSTEM DRIVING

PRESSURE gauge

Approximate indication of the pressure above

PEEP which will be delivered to the patient in CMV,

PTV, SIMV or manual breath modes.

22 CPAP/PEEP

regulator

Sets CPAP level in the circuit, range is 0 to 15

cmH2O (nominal).

23 ALARM RESET

Pushbutton

Resets audible and visual alarms.

24 Fresh Gas Port 5LPM blended gas supply to patient (ventilator

powered up).

1LPM blended gas supply to patient (ventilator

OFF)

25 Proximal airway Proximal airway tube connector.

26 Exhalation block Connection for expiratory limb of patient circuit.

27 PIP, CYCLE FAIL

and HIGH alarm

LED’s with control

Sets visual and audible alarm level for inspiratory

pressure between 0 and 60 cmH2O.

28 CPAP Alarm LED

and control

Sets visual and audible alarm level for CPAP

pressure.

Nº Item Description

(SLE2000) Page 19

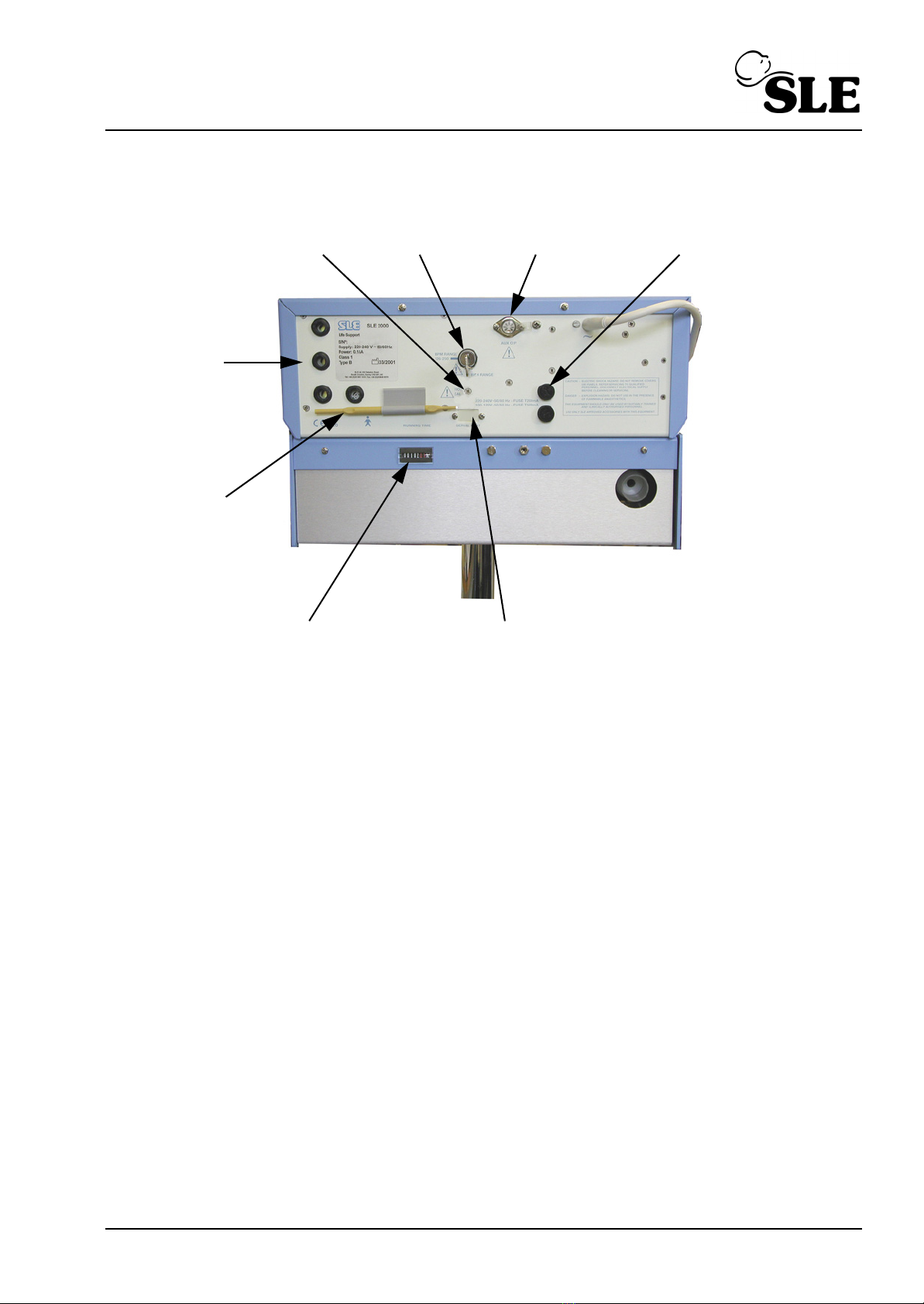

7.3 Rear panel

Nº Item

1FIO

2calibration adjustment.

2 125 - 250 BPM range switch

3 Aux. Output socket.

4 Fuse Holders

5 Optional serial port

6 Running Time Indicator

7FIO

2adjustment tool.

8 Alarm sounder

7

3

6

2

5

4

1

8

Page 20 (SLE2000)

7.4 Side panel

Nº Item

1 Side flap latching mechanism.

2 Fixed jet.

3 Expiratory tube guide.

3

2

1

Other manuals for SLE2000 HFO

2

Table of contents

Other SLE Medical Equipment manuals