SLE SLE2000 HFO User manual

SLE2000 HFO

User manual

Page 2

Contact Information:

All rights reserved. No part of this publication may be

reproduced, stored in any retrieval system, or

transmitted in any form or by any means, electronic,

mechanical, photocopy, recording or otherwise,

without prior permission of SLE. © Copyright SLE

08/11/2013.

Manual : UM8 Issue 17

SLE Part Nº: N2006/00

SLE Limited

Twin Bridges Business Park

232 Selsdon Road

South Croydon

Surrey CR2 6PL

Telephone: +44 (0)20 8681 1414

Fax: +44 (0)20 8649 8570

Web site: www.sle.co.uk

Page 3

Contents

1. Introduction ..................................................8

1.1. intended use ................................................8

1.2. Principles of Operation SLE 2000 HFO .......8

2. User/Owner Responsibility. ........................9

3. Warnings ......................................................10

3.1. Operational Warnings ..................................10

3.2. Clinical Warnings .........................................11

3.3. Monitoring ....................................................11

3.4. Clinical considerations .................................11

4. Operation ......................................................14

4.1. Functional Tests ..........................................14

4.2. Pressure Regulators and Gauges ...............14

4.3. Automatic Power On Test............................14

4.4. Setting Alarm Limits.....................................14

4.5. CPAP Mode .................................................14

4.6. CMV Mode...................................................15

4.7. PTV Mode....................................................15

4.8. SIMV Mode ..................................................15

4.9. HFO Modes .................................................15

4.10. Alarm Test .................................................16

4.10.1. To Verify Alarms ....................................16

4.10.2. High Alarm .............................................16

4.10.3. Cycle Fail Alarm.....................................16

4.10.4. Low Alarm..............................................17

4.10.5. Leak/block Alarm ...................................17

4.10.6. Mains Failure Alarm...............................17

4.10.7. O2Blender Alarm...................................17

4.10.8. Oxygen Concentration Alarm.................17

4.11. O2Cell .......................................................17

4.11.1. Condition Of O2Cell. .............................17

5. Basic Set Up for the SLE 2000 HFO ...........18

5.1. To Use the SLE 2000 HFO in CPAP Mode .19

5.2. To Use the SLE 2000 HFO in CMV Mode ...19

5.3. Patient Trigger Modes .................................20

5.3.1. To Use SLE 2000 In PTV or SIMV Mode20

5.4. To Use the SLE 2000 HFO in the Oscillator

Mode...................................................................20

5.4.1. EXP..........................................................20

5.4.2. INSP ........................................................21

5.4.3. CONT. (combined)...................................21

5.4.4. CONT. (oscillation only)...........................21

6. Technical Information .................................24

6.1. Electronic Module Controls..........................24

6.1.1. Mode Switch (5 positions)........................24

6.1.2. System Fail LED ......................................24

6.1.3. CPAP Mode .............................................24

6.1.4. CMV Mode ...............................................24

6.1.5. PTV Mode ................................................24

6.1.6. SIMV Mode ..............................................25

6.1.7. BPM .........................................................25

6.1.8. Inspiration Time .......................................25

6.1.9. I:E Ratio ...................................................25

6.1.10. Oxygen (FlO2)........................................26

6.1.11. Pressure Display....................................26

6.1.12. Three Position Switch. ...........................26

6.1.13. Pressure Display Bargraph. ...................26

6.1.14. Pressure Wave Switch...........................26

6.1.15. Manual Breath........................................26

6.1.16. HFO Controls .........................................26

6.1.17. Time Control Switch...............................26

6.1.18. Screen Switch ........................................27

6.1.19. Freeze....................................................27

6.2. Pneumatic Module Controls.........................27

6.2.1. Proximal Airway .......................................27

6.2.2. Removable Exhalation Block ...................27

6.2.3. Fresh Gas Port.........................................27

6.2.4. Regulator and Pressure Gauges .............27

6.2.5. O2Blender (% FlO2) ................................27

7. Alarms ...........................................................28

7.1. Microprocessor ............................................28

7.2. Mains Failure Audible Alarm ........................28

7.3. Gas Supply Failure Alarm ............................28

7.4. Fresh Gas Fail Alarm (Block & Leak)...........28

7.5. HFO Fail.......................................................28

7.6. Fan Fail ........................................................28

7.7. Adjustable Alarm..........................................28

7.8. High Alarm ...................................................28

7.9. Cycle Fail Alarm...........................................28

7.10. Low Alarm ..................................................28

7.11. Delta P Alarm .............................................29

7.12. O2BLender Alarm......................................29

7.13. Oxygen Alarm ............................................29

7.14. Alarm Mute.................................................29

7.15. Alarm Volume ............................................29

7.16. Alarm Verification.......................................29

8. Auxiliary Output ...........................................29

9. Rear Panel ....................................................30

Page 4

10. Filter Systems ............................................ 31

10.1. Bacterial filter, SLE Part Nº:N2029

(Autoclavable) .................................................... 31

10.2. Bacterial filter, SLE Part Nº:N2587/000/001

(Single use) ........................................................ 31

10.2.1. Precautions when using bacterial filter

N2587/000/001................................................... 31

11. Cleaning, Disinfection and Sterilization .. 32

11.1. Preparation of a new ventilator.................. 32

11.2. Cleaning and disinfection of an

in-service ventilator ............................................ 32

11.2.1. Cleaning, Disinfection & Sterilization

chart ................................................................... 32

11.3. Cleaning method ....................................... 33

11.4. Disinfection method................................... 33

11.5. Sterilization method................................... 33

12. SLE 2000 HFO Trouble Shooting Chart ... 34

13. User Operational Checks .......................... 37

14. Service and Maintenance Programmes .. 37

14.1. Maintenance.............................................. 37

14.2. Overhaul at 10,000 hours.......................... 37

14.3. 10,000 Hrs Overhaul ................................. 38

15. Glossary of Abbreviations Used in This

Manual .............................................................. 39

16. Symbols ....................................................... 40

17. Pressure Unit Conversion Constants ...... 41

18. Technical Specification ............................ 42

18.1. Conventional Ventilation............................ 42

18.2. HFO Ventilation ......................................... 42

18.2.1. Spontaneous breathing during power

failure.................................................................. 42

18.3. Displays..................................................... 42

18.4. Controls ..................................................... 42

18.5. Alarms ....................................................... 43

18.6. Air and Oxygen Supplies........................... 43

18.6.1. Oxygen supply....................................... 43

18.6.2. Air supply............................................... 43

18.6.3. Flow rates.............................................. 43

18.7. Power , Dimensions etc............................. 43

18.8. Environmental Storage Conditions............ 44

19. EMC compliance ........................................ 45

19.1. Electromagnetic immunity ......................... 46

19.2. Recommended separation distances between

portable and mobile RF communications equipment

and the SLE2000 HFO ....................................... 48

20. Pneumatic Diagram ................................... 49

21. Consumables and Accessories ............... 52

Page 5

How to use the SLE2000 HFO

NOTE: The warnings (page 10) must be read and understood before using the

SLE2000 HFO ventilator. Failure to do so could lead to injury or death.

1 PERFORM THE FUNCTIONAL TESTS : PAGE 14.

(This should take no more than 20 minutes)

2 SETUP THE SLE2000 HFO IN THE CHOSEN MODE: PAGE 18.

3 THE SLE2000 HFO IS READY FOR USE

For more information see technical section page 24.

For trouble shooting see troubleshooting chart page 34.

Page 6

This page is intentionally blank.

Page 7

Introduction

Page 8

1. Introduction

The SLE2000 HFO ventilator is designed for use on

neonates/infants. Its principle of operation is time

cycled, pressure limited ventilation using a constant

fresh gas flow.

Main features are that it has no expiratory valve but

uses a reverse flow of mixed gas that is injected into

the expiratory limb of the patient circuit from the

exhaust manifold. This flow of gas has the effect of

compressing 5 l/min humidified gas into the patient

ET tube.

The advantage of this system is that there is no

expiratory resistance due to valves or diaphragms,

therefore no inadvertent PEEP is generated. Also

the fresh gas flow does not require adjusting for

various rates. Another advantage is that the driving

flow in the exhaust manifold is controlled by a

regulator and therefore provides constant pressure

at all breathing rates.

The oscillatory feature is provided by a rotating jet,

driven by a motor, situated at the rear of the exhaust

block. From this jet a stream of driving gas is rotated

into the exhalation manifold which provides both, an

active inspiratory and active expiratory flow. It can

also be combined with a conventional mode such

that we can have oscillation superimposed on the

inspiratory pressure plateau, or during the expiration

phase, or a combination of both. Finally with the

ventilator operating in the CPAP mode, the

SLE2000 HFO can act as a pure oscillator where

the mean airway pressure is adjusted via the CPAP

control, and the differential pressure can be set by

the oscillation regulator.

Another main feature of the ventilator is its patient

trigger system. This functions without any

transducer in the patient circuit, on the principle of

monitoring the rate of change of pressure during the

onset of inspiratory effort. In fact it measures

inspiratory flow by this means and not a pressure

plateau.

Additionally the SLE2000 HFO has a built in oxygen

monitoring cell, fresh gas and leak alarms.

1.1 intended use

The ventilator is designed for use on neonatal and

paediatric patients from 300g to 10 kg in the

following invasive modes: CPAP, CMV, PTV, SIMV

& HFO.

The ventilator is designed to be used in a clinical

environment (example a hospital NICU or similar)

where medical grade gas and power supplies are

present.

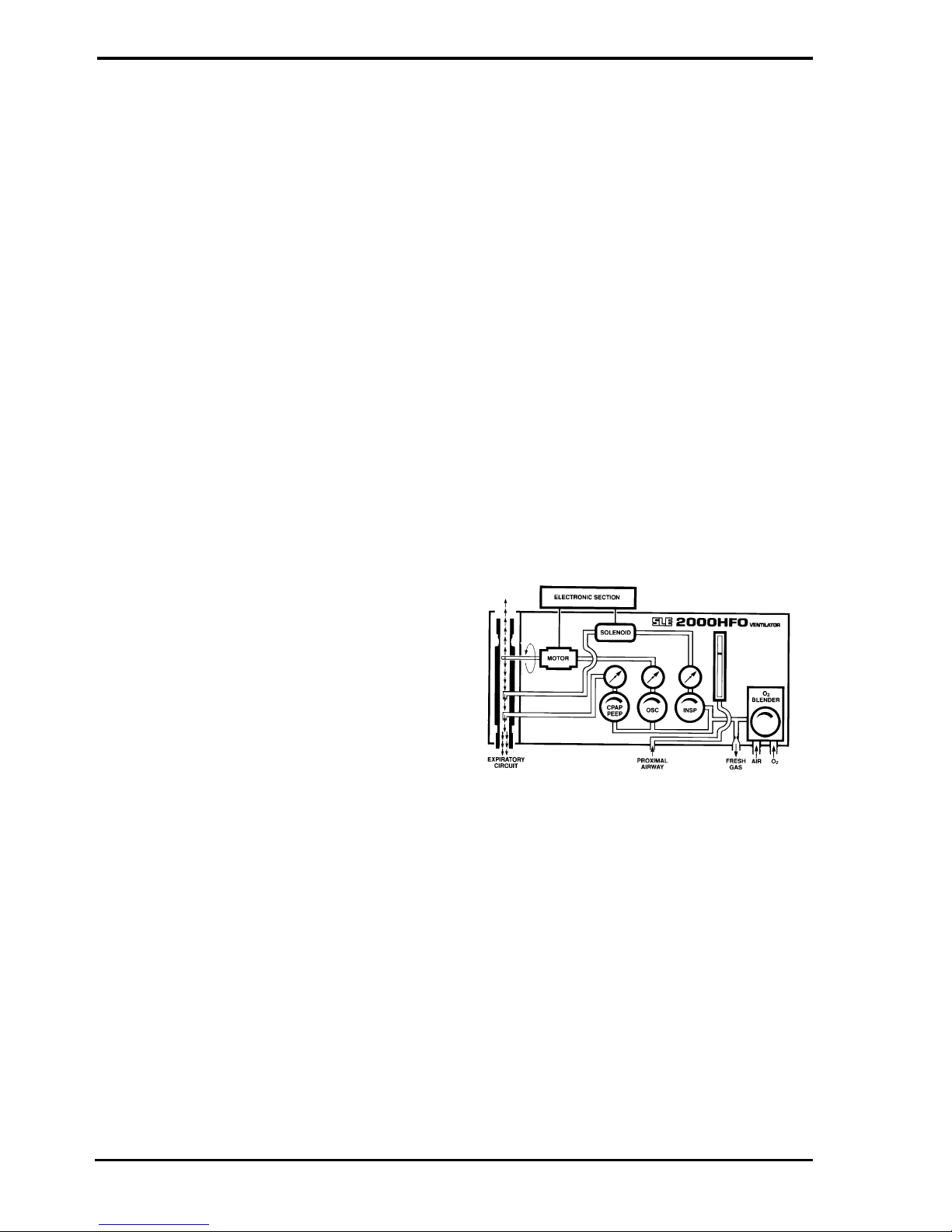

1.2 Principles of Operation SLE 2000

HFO

The patient circuit is supplied with a constant fixed

flow of fresh gas at 5 litres per minute. This gas

comes from the internally mounted Oxygen Blender

and its concentration is monitored by a fuel cell and

displayed on the FlO2digital display. This Fresh

Gas Supply is then passed through a humidifier to

the Inspiratory port of the patient ET connector. Built

into the ventilator are circuits to detect either a gas

flow failure or a tubing blockage. This circuitry

requires a restrictor fitted into the Inspiratory port of

the patient circuit. Therefore, only SLE2000

approved patient circuit must be used with this

equipment.

The Exhalation block mounts onto two pressure

manifold blocks. The front block has two nozzles.

The first is used to generate CPAP/PEEP via the

CPAP/PEEP regulator, by generating an opposing

flow to the fresh gas in the exhalation tube thus

creating CPAP/PEEP. The second is used to

generate the peak Inspiratory pressure. The

Inspiratory regulator sets the pressure that is

supplied to a solenoid valve which is connected to

the rear nozzle.

The Electronic Section controls the rate and

duration of opening of the solenoid valve.

When the valve is open the Driving Gas enters the

expiratory tube in opposition to the Fresh Gas flow.

This opposing flow acts as a pneumatic piston and

creates a pressure plateau at the ET connector

The lung inflation pressure and hence the tidal

volume are controlled by the Inspiratory regulator in

conventional ventilation.

The same gas mixture from the Oxygen Blender is

used to supply the patient Fresh Gas, CPAP,

Inspiratory and Oscillation driving gas pressure.

This avoids any possibility of dilution of the Fresh

Gas mixture.

There is a wave shape switch. This modifies the

Driving Gas flow rate from the Solenoid valve

through the nozzle and is used to slow down the rise

time of the pressure waveform. In the taper position

The rise time is approximately 250 ms.

Page 9

The second or rear manifold block is the High

Frequency Oscillator pressure generator. Creating a

pressure by means of a spinning jet of gas thus

providing an active positive and negative waveform

(Sinusoidal). Pressure is controlled via the oscillator

regulator and frequency via the Frequency or Rate

control.

When operating the HFO in Inspiratory or expiratory

mode, gas release is controlled via a solenoid

synchronised with the Inspiratory time and BPM.

2. User/Owner Responsibility.

This SLE 2000 HFO INFANT VENTILATOR and the

authorised accessories for it are designed to be

used in accordance with supplied manuals and

instructions. This equipment must be periodically

checked, recalibrated, maintained and components

repaired and replaced when necessary for the

equipment to operate safely and reliably.

Parts that have failed, in whole or in part, or exhibit

excessive wear, or are contaminated, or are

otherwise at the end of their useful life, should not

be used and must be replaced immediately with

parts supplied by SLE, or parts which are otherwise

approved by SLE. Equipment which is not

functioning correctly or is otherwise in need of repair

or maintenance must not be used until all necessary

repairs and/or maintenance have been completed

and a factory authorised service representative has

certified that the equipment is fit and ready for use.

This equipment, its accessories or component parts

should not be modified. The use of non-approved

parts or accessories will invalidate the warranty.

The owner/user of this equipment shall have the

sole responsibility and liability for any damage or

injury to persons or property (including the

equipment itself) resulting from operation not in

accordance with the operating instructions, or from

faulty maintenance not in accordance with the

authorised maintenance instructions, or from repair

by anyone other than the factory authorised service

representative, or from unauthorised modification of

the equipment or accessories, or from the use of

components or accessories that have been either

damaged or not authorised for use with this

equipment by the manufacturer.

Page 10

3. Warnings

3.1 Operational Warnings

The following warnings must be read and

understood before using the SLE2000 HFO

ventilator. Failure to do so could lead to injury or

death.

1 The whole of this manual should be read and

understood before using the SLE2000 HFO

Operators must be suitably trained and

clinically authorised for using the SLE2000

HFO with patients. Particular care should be

taken to check the ventilator pressures prior to

changing modes.

2 Oxygen - Clinical use. Oxygen is a drug and

should be prescribed as such.

3 Oxygen - Fire Hazard. Oxygen vigorously

supports combustion and its use requires

special precaution to avoid fire hazards. Keep

all sources of ignition away when oxygen is in

use. Do Not use oil or grease on oxygen

fittings or where oxygen is used.

4 Audible and Visual warning alarms indicate a

potentially harmful condition to the patient.

However when ventilating a patient with a

3mm or smaller size endotracheal tubes, in

case of patient extubation or the ET tube

disconnecting from its ET connector, only the

monitoring of flow (module SLE 2100), or of

SpO2, or Pt02/PtCO2will dependably alert the

medical team to an alarm situation, not the

monitoring of pressures.

5 When the ventilator is being used on a patient,

a suitably trained person must be in

attendance at all times to take prompt action

should an alarm or other indication of a

problem occur.

6 The ventilator functional tests must be carried

out each time the SLE 2000 HFO is used on

patients. If any of these tests do not function as

described then there is a problem and the

ventilator must not be used until it is rectified.

7 The humidifier used in the patient circuit must

be operated and maintained in accordance

with its manufacturer’s instructions.

8 An alternative form of ventilation should be

available whenever the ventilator is in use.

9 Any water trap used in the patient circuit must

be drained regularly before it is full.

10 Failure to comply with the recommended

service programs could lead to injury to the

patient, operator or damage to the ventilator. It

is the owners responsibility to ensure that the

equipment is regularly maintained.

11 Functioning of this ventilator may be adversely

affected by high frequency surgical

(Diathermy) defibrillators, short-wave therapy

or equipment producing strong magnetic fields,

operating in the vicinity.

12 The Ventilator must be connected to a suitably

rated and grounded electrical power source.

13 There is no special protection provided against

ingress of water or liquids.

14 The equipment is not suitable for use with, or

in the presence of flammable anaesthetic

mixtures.

15 Do not cover the ventilator during use or allow

the ventilator to become covered by any fabric

or curtain. Do not allow the exhaust ports or

inlet vents to become obstructed or blocked by

positioning the ventilator near curtains or

fabric.

16 No external voltage should be applied to the

auxiliary socket. Any connections to this socket

must be approved by SLE and screened to

comply with EMC regulations. Ensure

protection cap is fitted when socket is not in

use.

17 The electronic module of the ventilator

contains a primary battery, if the ventilator is

not to be used for 3 months or more, then the

battery should be removed.

18 Care should be taken when attaching other

equipment as this may affect stability.

19 Use only SLE approved patient circuits. On no

account should antistatic or electrically

conductive tubing be used in the patient circuit.

20 The patient circuit should not be modified.

Modified patient circuits or circuits with

additional sections or components may

produce too high a circuit resistance and circuit

compliance for effective ventilation.

21 Use of non approved patient circuits may

cause inadvertent block or leaks alarms.

Page 11

3.2 Clinical Warnings

Failure to take corrective action when the alarms

are activated could result in injury or death to the

patient.

3.3 Monitoring

The minimum patient monitoring requirements are:

1 ECG/heart rate.

2 Blood pressure (either by invasive or non

invasive means).

3 Oxygen saturation.

4 Transcutaneous carbon dioxide arterial /

capillary blood sampling.

5 Standard nursing care for Intensive Care

patients.

3.4 Clinical considerations

1 When switching from conventional to high-

frequency ventilation, or vice-versa, alterations in

ventilator settings and inspired oxygen

concentrations may be required.

2 All ventilation should only be instituted by fully

trained and experienced medical personnel.

3 Incorrect humidification.

4 Intra-ventricular haemorrhage, cerebral

ischaemia;

5 Volutrauma resulting in (bronchopulmonary

dysplasia in the newborn);

6 The use of an uncuffed ET tube.

7 Maintenance of an adequate airway is of

paramount importance.

Page 12

This page is intentionally blank.

Page 13

Operation

Page 14

4. Operation

4.1 Functional Tests

With HFO and Mode switches set to OFF, High

alarm set to maximum and all other variable controls

set to minimum.

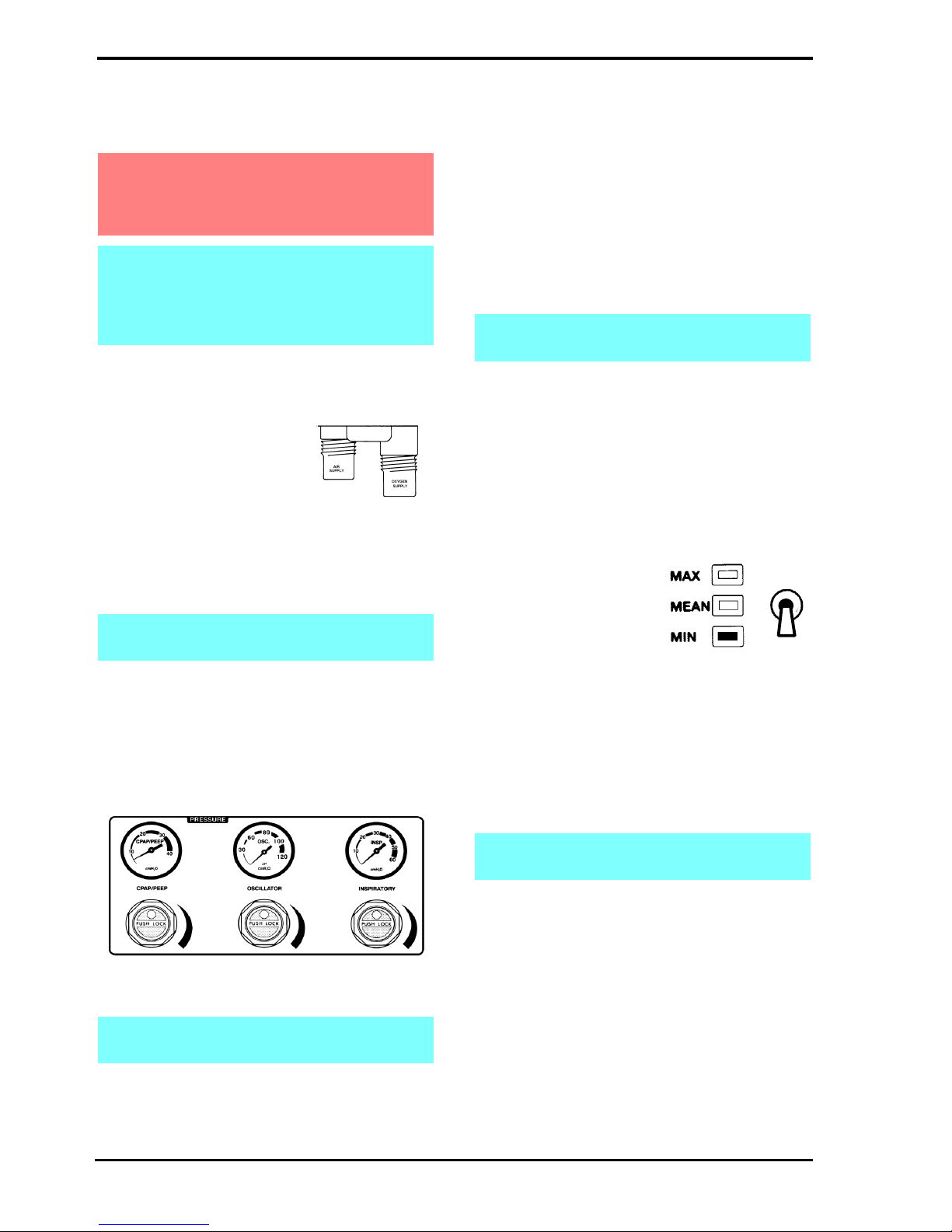

Step 1. Connect AIR,

OXYGEN Hoses to

ventilator and plug

into gas supplies, at

a gas pressure of

about 4 bar.

Connect mains cable to a suitably rated

and grounded electrical power source.

Step 2. Connect SLE approved patient circuit with

test lung to the ventilator.

4.2 Pressure Regulators and Gauges

Check in turn the CPAP/PEEP, OSCILLATOR and

INSPIRATORY regulators and gauges by turning

the regulator controls from minimum to maximum

and making sure that the gauges read between

minimum and maximum. Return regulators to

minimum.

Regulator Controls are lockable. Push to lock,

Pull to unlock.

4.3 Automatic Power On Test

Select ventilator mode to CPAP.

The ventilator will now carry out a self test as

follows.

Power LED shows green and an automatic test of

functions & alarms is initialised. Firstly the displays

and audible alarms are turned on for approximately

two seconds to demonstrate that they are operable,

then for a further three seconds all the digital

displays show a sequence of numbers from O to 9

before returning to their normal state.

4.4 Setting Alarm Limits

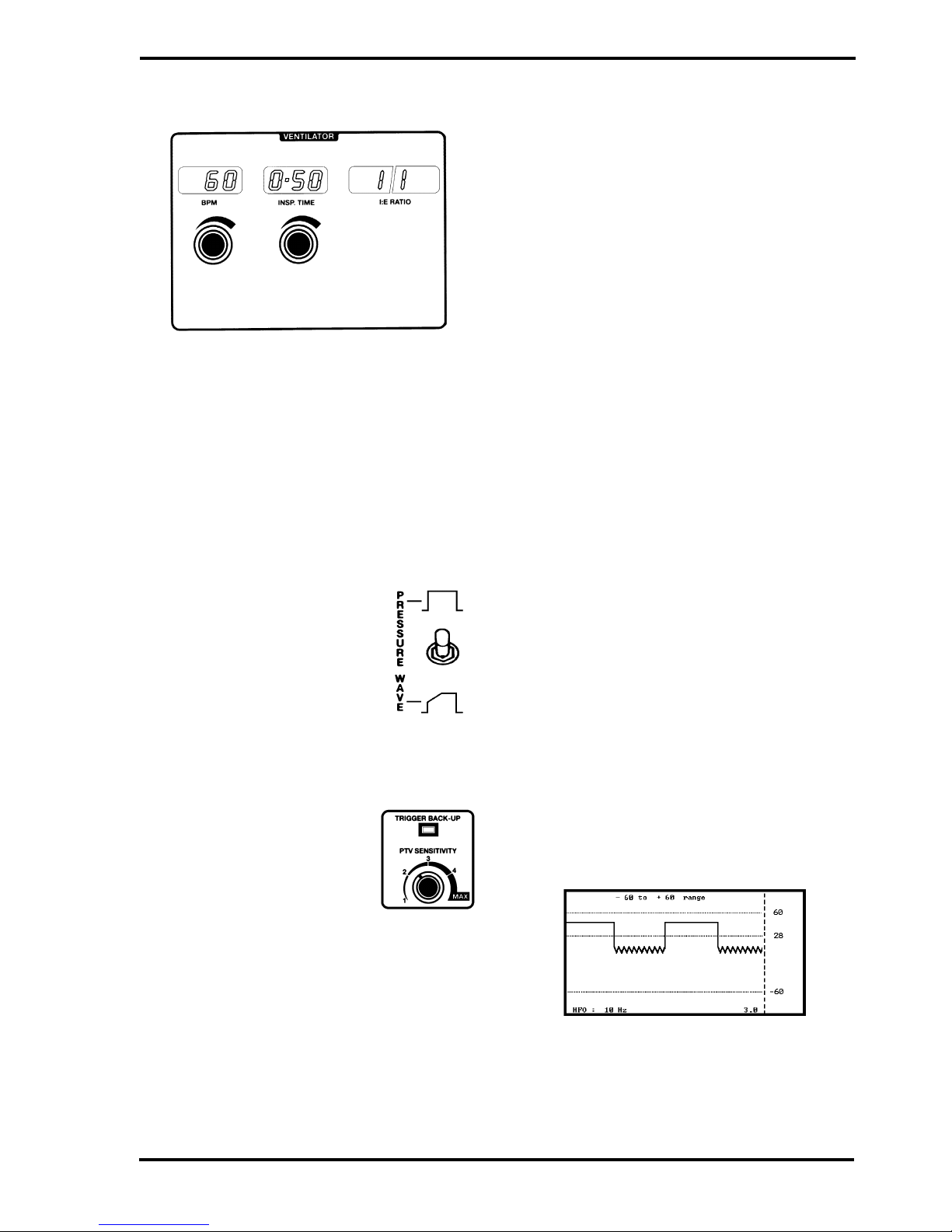

•Set the High Alarm to maximum 60 cmH2O

•Set the Cycle Fail Alarm to approximately 28

cmH2O

•Set the Low Alarm to minimum -60 cmH2O

4.5 CPAP Mode

Set CPAP/PEEP Regulator

to give 30 cmH2O on the

pressure display with the

pressure display selector

switch in the MIN position.

Set Inspiratory Regulator to 20 cmH2O

Ensure that:-

•Bargraph display reads 30 cmH2O ± 2 cmH2O

•CPAP/PEEP gauge reads 30 cmH2O

•An Inspiratory cycle is initiated when manual

breath button is pressed

Warning: The following functional tests must

be carried out to ensure that this equipment

is working correctly before connection to a

patient.

Note: If any of these tests do not function as

described, there is a problem and the unit

should not be used until it has been repaired.

please contact an sle approved engineer, or

SLE.

Note: See instructions supplied with patient

circuit.

Note: These gauges are for indication only

and not for measuring operating pressures.

Note: HFO Fail and Block LEDs do not come

on during this sequence.

Note: Alarm limits will also be shown on the

bargraph display.

Page 15

4.6 CMV Mode

Set the following ventilator conditions :

•CPAP/PEEP regulator to 0 cmH2O

•Inspiratory regulator to 30 cmH2O

•Mode switch to CMV

•BPM Rate to 60

•INSP TIME to 0.50

•Cycle Fail Alarm to mid waveform

•Press Reset to cancel all alarms

Ensure that :-

•The ventilator is cycling

•I:E Ratio display reading 1:1

•Pressure waveform is shown on

graphics display

•Pressure waveform shape

changes with operation of

PRESSURE WAVE SWITCH.

(Return the switch to the square

wave setting.)

4.7 PTV Mode

Set BPM rate to 20

•Set the CPAP/PEEP regulator

to 10 cmH2O on the gauge

•Set the PTV Sensitivity to 3

•Select PTV with mode switch.

Ensure that :-

•Ventilator should continue to cycle

•BPM display reading is initially 0

•TRIGGER BACK-UP LED is “ON”

Apply slight pressure to test lung and release to

simulate patient inspiratory effort.

Ensure that with each operation :-

•The ventilator cycles once.

•The TRIGGER BACK-UP LED is “OFF”.

4.8 SIMV Mode

Select SIMV with mode switch.

Ensure that:-

•The ventilator continues to cycle.

•The BPM display shows set rate.

•The TRIGGER BACK-UP LED illuminates on

each inspiration.

Apply a varying pressure to test lung to simulate

patient breathing.

Ensure that:-

•The ventilator continues to cycle at the set rate

but synchronised with the pressure from test

lung.

•The TRIGGER BACK-UP LED is “OFF”.

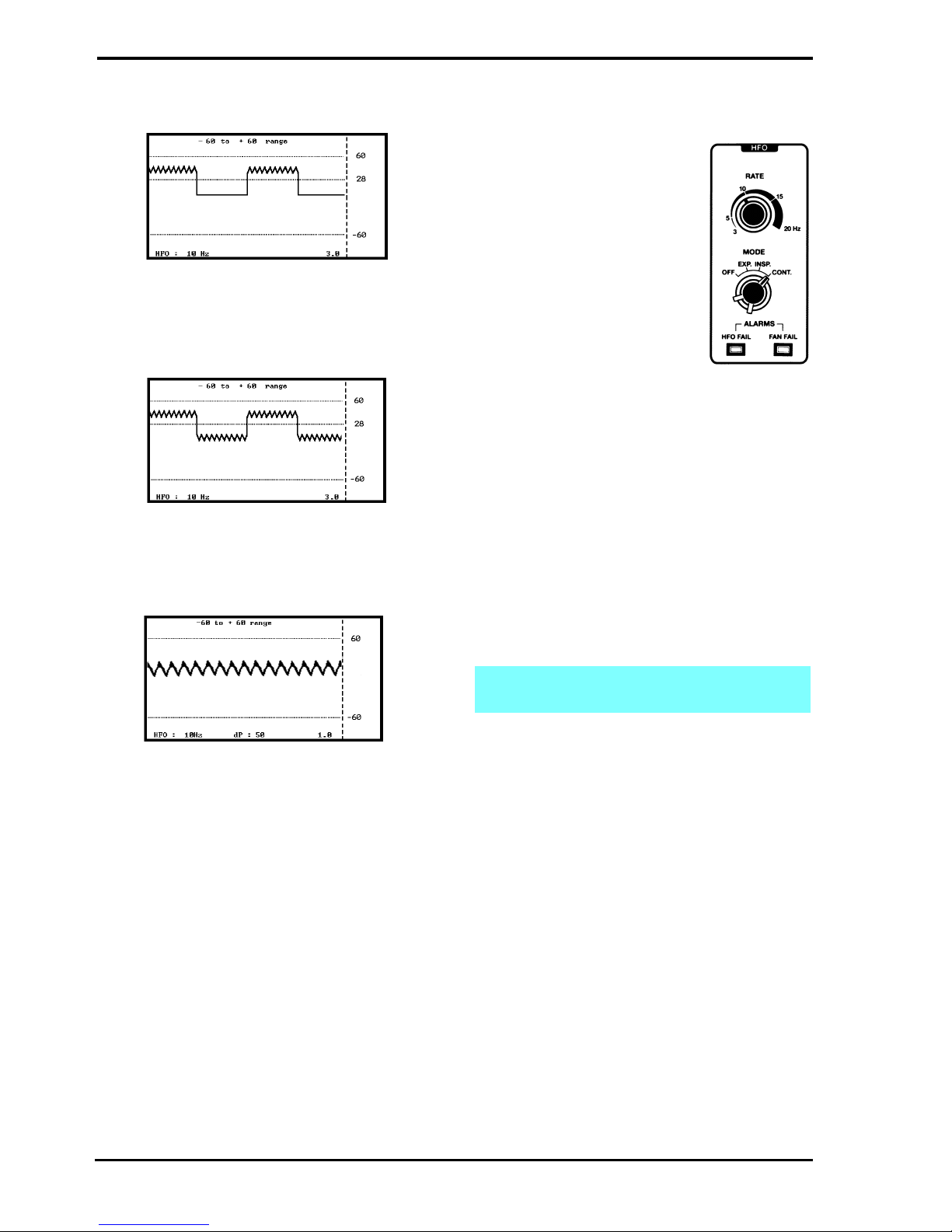

4.9 HFO Modes

Set the following conditions:-

•CMV Mode

•BPM rate to 30

•INSP Time to 1.00

•Oscillator Regulator to » 30 cmH2O

•Inspiratory Regulator to » 20 cmH2O

•HFO Mode to EXP

•HFO Rate to 10 Hz

•Display Switch to 3 seconds

•Screen Switch to ±60 cms

•Press Alarm Mute Button

Ensure that :

•The ventilator is cycling.

•10 Hz oscillation shown on expiratory cycle of

waveform.

Page 16

Set HFO mode to INSP

Ensure that :

•10 Hz oscillation shown on inspiratory cycle of

waveform.

Set HFO mode to CONT

Ensure that :

•10 Hz oscillation shown on both inspiratory and

expiratory cycles of waveform.

Set mode switch to CPAP.

Ensure that :-

•Continuous 10 Hz waveform is seen on the

screen.

Press the reset button to autoset the alarms.

4.10 Alarm Test

4.10.1 To Verify Alarms

Set the following ventilator

conditions :-

•HFO mode OFF.

•CPAP/PEEP regulator to 10

cmH2O.

•Inspiratory regulator to30

cmH2O.

•Oscillator Regulator to 0

cmH2O

•Mode switch to CMV

•Rate to 60 BPM

•INSP. TIME to 0.50

•Ensure ventilator is cycling and check the

following alarms

•Set Cycle fail alarm to mid waveform

•Reset all alarms

4.10.2 High Alarm

Reduce high alarm setting so that alarm cursor line

is below the peak pressure wave on the screen.

This should initiate an audible alarm and a HIGH

and LEAK visual indication. Return alarm setting to

maximum position. Reset alarm by the reset button.

4.10.3 Cycle Fail Alarm

Increase the alarm setting so that alarm cursor line

is above peak pressure wave on the screen. This

will initiate an audible and CYCLE FAIL visual alarm

indication. Return alarm setting to within the

pressure wave, audible alarm should self cancel.

Reset visual alarm by the reset button

Decrease the alarm setting so that alarm cursor line

is below pressure wave on the screen. This should

initiate an audible and CYCLE FAIL visual alarm

indication. Return alarm setting to within the

pressure wave, audible alarm should self cancel.

Reset visual alarm by the reset button.

Note: The Fresh Gas flow is reduced from 5

l/min to 1 l/min in the High Alarm condition.

Page 17

4.10.4 Low Alarm

Increase low alarm setting so that alarm cursor line

is above the minimum pressure wave on the screen.

This should initiate an audible and LOW visual

alarm indication. Visual alarms once set can only be

cancelled by pressing the reset button. Return

alarm setting to required position. Reset visual

alarm by the reset button.

4.10.5 Leak/block Alarm

Disconnect the fresh gas tubing from the ventilator.

This should initiate an audible and LEAK visual

alarm indication. Occlude the fresh gas outlet. This

should initiate an audible and BLOCK visual alarm

indication. Reconnect tubing, audible and visual

alarms should self reset.

4.10.6 Mains Failure Alarm

DO NOT TURN MODE SWITCH TO OFF.

Disconnect mains power by switching off or

removing mains plug from power socket.

This should initiate an audible alarm. Reconnect

mains power supply, ventilator should carry out self

test and resume previous mode of operation.

4.10.7 O2Blender Alarm

Set Blender to 60%. Disconnect Air supply from

wall outlet, an audible alarm should be heard from

Blender. Reconnect Air Supply, alarm should self

cancel. Disconnect O2supply, an audible alarm

should be heard from blender. Reconnect O2

supply, alarm should self cancel.

4.10.8 Oxygen Concentration Alarm

Set the Oxygen concentration to 60% and press the

reset button. Wait 1minute for the reading to

stabilise. Increase the Oxygen concentration to

100%, the alarm should sound. Decrease the

Oxygen concentration to 21%, the alarm should

cancel as the Oxygen concentration crosses the

alarm threshold and then sound again as the

Oxygen concentration gets too low. Press Reset.

4.11 O2Cell

4.11.1 Condition Of O2Cell.

Set blender to 100% and observe that displayed

FIO2is 100%. Set blender to 21% and observe that

displayed FIO2is 21%. To adjust, set blender

control to 100%. Remove Air Supply Hose and

allow 3 minutes before adjusting control on rear

panel. If unable to set 100%, O2Cell must be

replaced. Ignore any blender alarms during this

adjustment.

Page 18

5. Basic Set Up for the SLE 2000

HFO

Step 1. Connect AIR and

OXYGEN hoses to

ventilator and plug

into gas supplies, at a

gas pressure of about

4 bar. Connect

mains cable to a suitably rated and

grounded electrical power source.

Step 2. Connect SLE approved patient circuit to

the Ventilator and Humidifier.

• For further information see instructions

supplied with patient circuit.

• To test the system the patient manifold must

be occluded or a Test Lung fitted.

• Only an SLE approved patient circuit should

be used with this equipment

Step 3. Set up humidifier to manufacturer’s

instructions

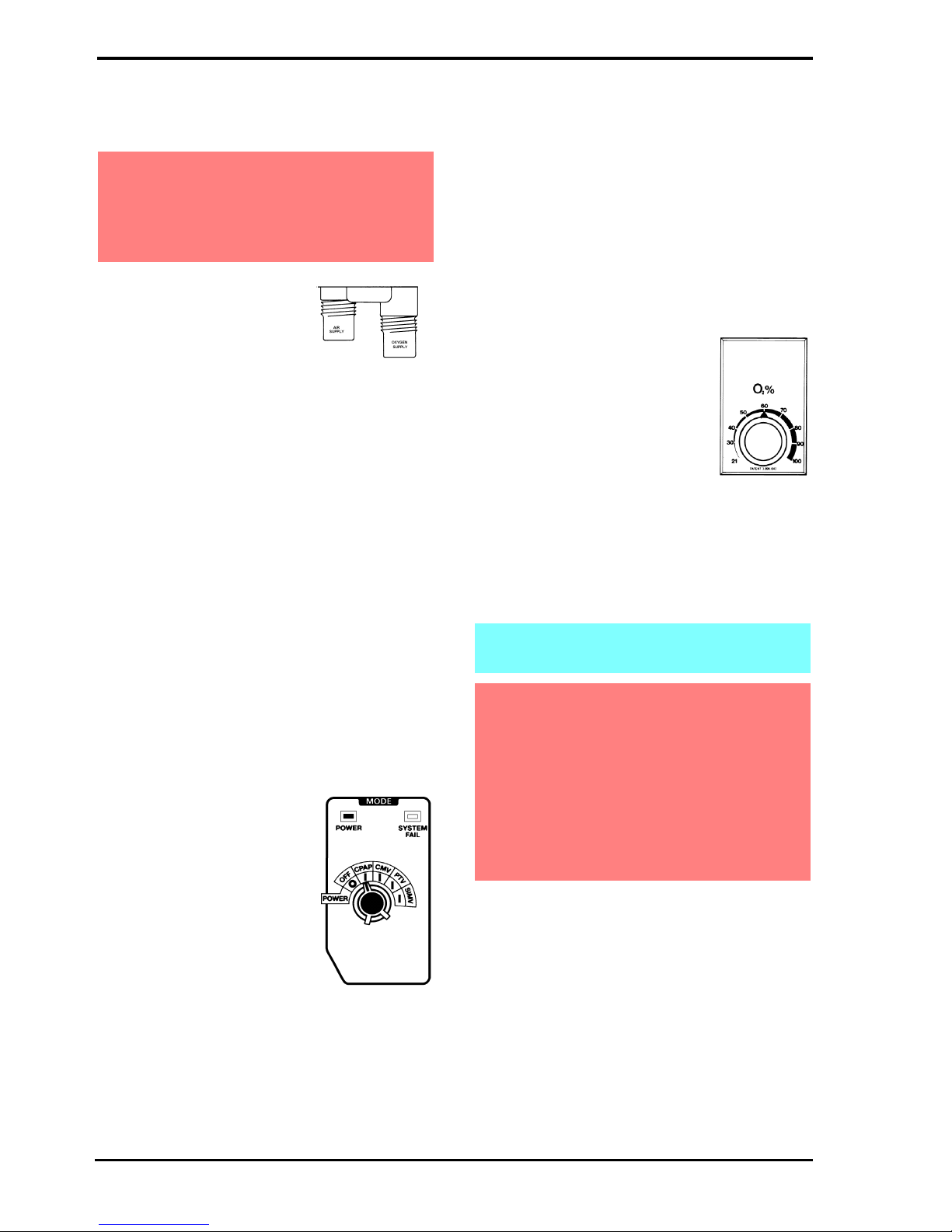

Step 4. Set the following ventilator conditions :-

•High alarm to maximum

•Low alarm to minimum

•HFO mode OFF

•Three pressure regulators to minimum

Step 5. Select mode of

ventilation to CPAP

The ventilator will now carry out

a self test as described on

page 14. Ensure that this test is

completed satisfactorily before

continuing.

If after completion of the above self test an alarm

continues, a red light might indicate either BLOCK

or LEAK in the fresh gas tubing of the patient circuit.

Ensure that all patient fittings are correctly made

and secure.

Do not continue until alarms are cleared

•The ranges of the graphic display can be set

using the display controls. A Freeze button

allows the waveform to be held. Press to freeze,

press again to un-freeze.

•Do not carry out any adjustments with the

display in the freeze mode.

Step 6. (a) Set required O2

concentration by means of

O2Blender Control. %O2

Oxygen will be monitored

and displayed in FlO2

Digital Display.

The oxygen monitor will

alarm if the oxygen

concentration rises or falls

by more than 5% and a

warning message will be

displayed on the LCD.

The ventilator should now be ready to connect to a

patient.

Warning:It is the operator’s responsibility to

check the ventilator pressures prior to

changing modes.

The ventilator must not be connected to the

patient during this set up procedure.

Changes will take 30 seconds to stabilise on

the FlO2display.

Oxygen - Clinical use. Oxygen is a drug and

should be prescribed as such.

Exposing a baby to elevated concentrations

may lead to Retrolental Fibroplasia.

Oxygen - Fire Hazard. Oxygen vigorously

supports combustion and its use requires

special precaution to avoid fire hazards. Keep

all sources of ignition away when oxygen is in

use. Do Not use oil or grease on oxygen

fittings or where oxygen is used.

Page 19

5.1 To Use the SLE 2000 HFO in CPAP

Mode

As steps 1 to 6 in basic setup

Step 7. (a) Set pressure

display switch to

minimum

(b) Increase CPAP/

PEEP pressure to required level

Pressure will be indicated on the digital display, the

graphic display and bargraph.

(c) Set Low alarm to the required level.

The alarm levels are digitally and pictorially

displayed on the graphic display.

A manual breath can be delivered, of the set

inspiratory time, by pressing the Manual Breath

Button.

5.2 To Use the SLE 2000 HFO in CMV

Mode

As steps 1 to 7 basic set-up and CPAP then:

Step 8. (a) Set INSP. TIME to required rate

(displayed in seconds)

(b) Select Pressure Wave

Shape SQUARE or TAPER

(c) Switch mode switch

from CPAP to CMV

(d) Adjust the BPM to required rate.

(e) Set the pressure display switch to MAX and

increase the INSP pressure to the desired level.

This is indicated on the digital pressure display, the

graphic display and the bargraph.

(f) Set the CYCLE FAIL and HIGH alarms to

required levels. Press RESET to clear the alarms

lights.

These Controls are lockable. Push to lock,

Pull to unlock.

Note: Ventilator will start to cycle and the

alarms will probably sound - press MUTE to

silence them.

Page 20

HIGH will activate if setting is exceeded and also

open a pressure relief valve and activate LEAK

alarm

CYCLE FAIL will activate if pressure wave fails to

pass through threshold on inspiration and expiration

LOW is activated if pressure falls below setting

5.3 Patient Trigger Modes

5.3.1 To Use SLE 2000 In PTV or SIMV Mode

As steps 1 to 7 then:-

Step 9. (a) Set PTV sensitivity to min

(b) Set the BPM control to provide either:-

The desired back-up rate for

PTV

or

The desired number of

mandatory breaths per minute

for SIMV

(c) Switch mode from CMV to PTV or SIMV

Once connected to a patient, increase the PTV

sensitivity towards Max until patient effort triggers

the ventilator. This is indicated by the TRIGGER

BACK-UP light extinguishing.

•The weaker the patient the higher the sensitivity

required.

After 60 seconds with an update every 60 seconds,

the BPM LED display will indicate the number of

patient initiated breaths that were delivered in the

preceding minute.

Care should be taken not to set the PTV sensitivity

too high as it will self trigger.

5.4 To Use the SLE 2000 HFO in the

Oscillator Mode

THERE ARE 4 OSCILLATORY

MODES

5.4.1 EXP.

Expiratory oscillation combined with conventional

ventilation.

(a) Set ventilator mode to CMV (see page 19)

(b) Set HFO mode to EXP

(c) Set HFO frequency using rate control.

(d) Set amplitude using oscillation pressure

regulator

Oscillation is added to the conventional pressure

waveform. The frequency of oscillation will be

shown on the screen.

Other manuals for SLE2000 HFO

2

Table of contents

Other SLE Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual