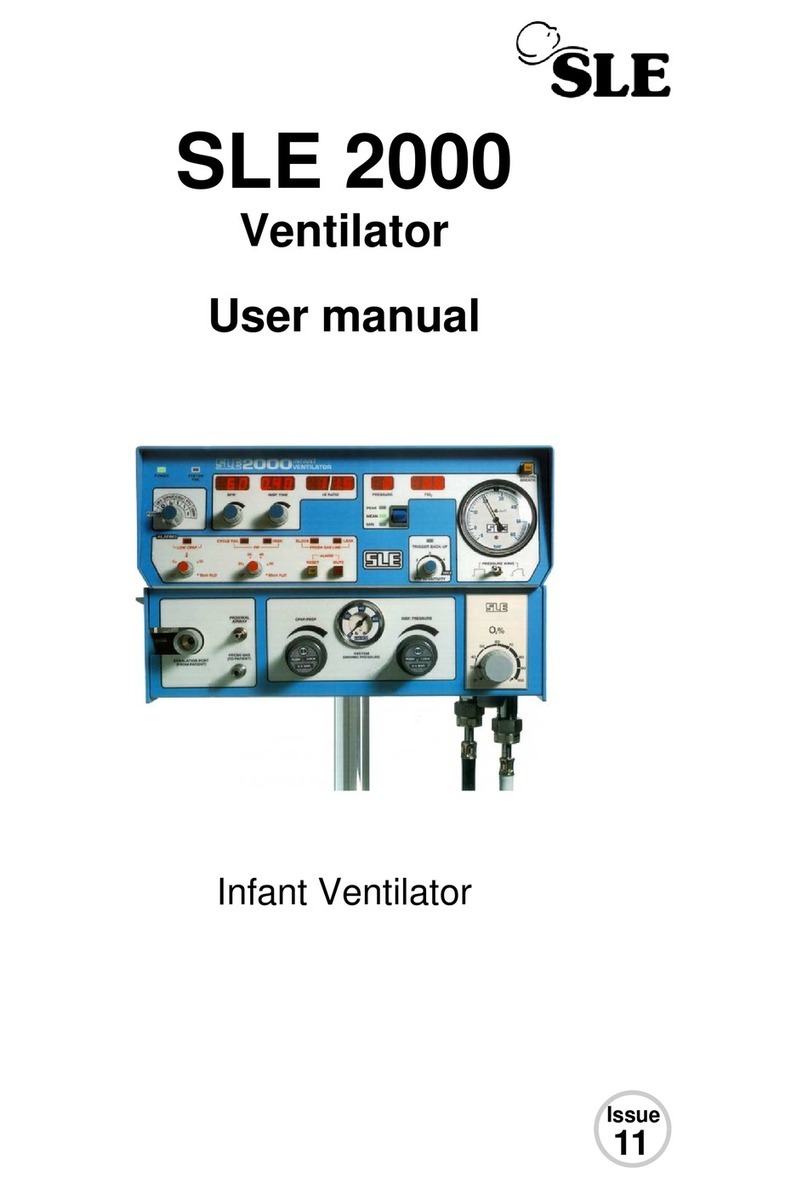

SLE SLE5000 Model J User manual

SLE5000

Model J service manual

Version 4.3.1 & 4.3.2 software

Page 2 (Model J)

Software/Manual application Information:

Contact Information:

All rights reserved. No part of this publication may be reproduced, stored in any retrieval system, or transmitted

in any form or by any means, electronic, mechanical, photocopy, recording or otherwise, without prior

permission of SLE. © Copyright SLE 30/09/2016.

Manual: SM31 Issue 3

SLE Part Nº: N6645/J

Note: This manual is to be used only with models J ventilators using the following

software version:

Version 4.3.1 & 4.3.2

SLE Limited

Twin Bridges Business Park

232 Selsdon Road

South Croydon

Surrey CR2 6PL

Telephone: +44 (0)20 8681 1414

Service Fax: +44 (0)20 8649 4517

Web site: www.sle.co.uk

Revision history.

Issue 3: CR 371, 451 & 586. ECN167.

(Model J) Page 3

Contents

1. Warnings and Cautions .............................................................................................10

1.1. Warnings ........................................................................................................10

1.2. Cautions .........................................................................................................11

2. Principles of Operation ..............................................................................................14

2.1. Electronic System...........................................................................................14

2.2. Pneumatic System .........................................................................................15

3. Description of Symbols .............................................................................................18

4. Equipment list ...........................................................................................................22

5. ENGMODE ...............................................................................................................24

5.1. Accessing the Calibration Programs ..............................................................24

5.2. Ventilator Calibration Program .......................................................................26

5.3. O2 & Flow System Calibration........................................................................27

5.4. Reset Elapsed Time.......................................................................................28

5.5. Language Selection........................................................................................28

5.6. Activation of Language Selection Program form User Interface.....................29

5.7. Exit .................................................................................................................29

5.8. Touch Screen Calibration Program................................................................30

6. Component Replacement Procedure ........................................................................32

7. Preparing the SLE5000 .............................................................................................33

8. Component Replacement (Electronic unit) ...............................................................35

8.1. N6631/21/CF/50 Compact Flash Card...........................................................35

8.2. N6631/LX800 PC Board.................................................................................35

8.3. N6634/OEM2 CAN Card ................................................................................36

8.4. N6631/2216 Serial controller (Touch screen).................................................36

8.5. L0275/OEM2 Computer/Display Control assembly........................................37

8.6. A0763/02/M Control/Monitor Board................................................................38

8.7. M0915 Power Supply Unit..............................................................................39

8.8. M0901 Batteries .............................................................................................40

8.9. A0761 Transducer PCB Assembly.................................................................41

8.10. N6631/13 Inverter PCB ................................................................................42

8.11. N6631/02 LCD & N6631/05 Touch Screen ..................................................43

9. Component Replacement (Pneumatic unit) ..............................................................45

9.1. Duckbill and conical filters..............................................................................45

10. A0763/02/M Monitor and control board ...................................................................56

10.1. A0763/02/M board programmable devices...................................................56

10.2. A0763/02/M Board Hardware Identifier........................................................57

11. Electrical Safety Testing of the SLE5000 ................................................................61

12. PSU Testing ............................................................................................................65

13. Ventilator Power up and Power down. ....................................................................68

14. Back-up Battery Charging .......................................................................................69

Page 4 (Model J)

14.1. Battery indicator............................................................................................69

15. Extended storage ....................................................................................................71

16. Maintenance and Overhaul .....................................................................................74

16.1. Preventative Maintenance Kit.......................................................................74

16.2. 12 & 36 month preventative maintenance procedure...................................76

16.3. 24 month and 48 month overhaul procedures ..............................................84

16.4. 24 month / 10,000 hour overhaul procedure.................................................86

16.5. 48 month / 20,000 hour overhaul procedure.................................................94

16.6. 48 month overhaul procedure using N9410/48/G overhaul kit......................96

17. Calibration Procedure for V4.3.1 & V4.3.2 software ................................................108

17.1. Equipment required for calibration................................................................108

17.2. Preliminary Inspection before calibration......................................................109

17.3. Pneumatic set up..........................................................................................110

17.4. Calibration of Controller and Monitor subsystems........................................113

17.5. Controller “Block and Leak” pressure sensor calibration ..............................115

17.6. Controller Blender Pressure Sensor zeroing and Input pressure reg. trim ...116

17.7. Mean Jet Pressure Regulator Calibration.....................................................117

17.8. Forward Jet Pressure Regulator Calibration.................................................119

17.9. Reverse Jet Pressure Regulator Calibration.................................................120

17.10. Time Constant for pressure measurement waveform.................................121

17.11. Wave shaping for leading and trailing edge of insp. phase ........................121

17.12. O2 System Calibration................................................................................123

17.13. Flow System Calibration .............................................................................123

17.14. Pressure Triggering Verification..................................................................123

17.15. Gas Fail Detection Verification....................................................................123

17.16. Blender and Oxygen Monitoring Verification...............................................124

17.17. Soak Test....................................................................................................125

17.18. Battery Charge Verification.........................................................................126

17.19. Total Power Fail Alarm Test........................................................................126

17.20. Pressure Calibration Verification.................................................................127

18. Functional Testing ...................................................................................................130

18.1. Ventilator setup.............................................................................................130

19. Trouble Shooting Chart ...........................................................................................162

20. Software Version History .........................................................................................172

21. Oxygen Calibration Routines ...................................................................................174

21.1. One point or 100% Oxygen system calibration.............................................174

21.2. Two point or 21% & 100% Oxygen system calibration.................................174

22. Alarms .....................................................................................................................176

22.1. Alarm Protocols.............................................................................................176

22.2. Alarm Sounds ...............................................................................................176

22.3. Alarm Descriptions and actions to be taken..................................................177

22.4. Software and System Fail Protocols.............................................................196

(Model J) Page 5

23. Cleaning, disinfection and sterilization ....................................................................197

23.1. Preparation of a new ventilator.....................................................................197

23.2. Cleaning and disinfection of an in-service ventilator ....................................197

23.3. Cleaning method ..........................................................................................198

23.4. Disinfection method......................................................................................199

23.5. Sterilization method......................................................................................200

24. Technical Specification ...........................................................................................201

24.1. Operating Modes Conventional Ventilation..................................................201

24.2. HFO Ventilation............................................................................................203

24.3. Measurement ...............................................................................................207

24.4. Exhalation Block Port Jet Sizes....................................................................208

24.5. Alarms ..........................................................................................................209

24.6. Patient circuits..............................................................................................210

24.7. Outputs.........................................................................................................211

24.8. Gas supplies.................................................................................................212

24.9. Power, Dimensions, Classification etc..........................................................213

24.10. Classification ..............................................................................................213

24.11. Environmental Storage Conditions.............................................................213

25. EMC compliance .....................................................................................................214

25.1. Electromagnetic immunity ............................................................................215

25.2. Recommended separation distances between portable and mobile RF

communications equipment and the SLE5000......................................................217

26. Ventilator labelling ...................................................................................................218

27. Electrical Block Diagram .........................................................................................220

28. L0280/KV Pneumatic Unit Layout & Schematic ......................................................221

28.1. Layout ..........................................................................................................221

28.2. Schematic ....................................................................................................222

29. Main Loom Circuit Diagram ....................................................................................223

30. L0275/OEM2 Assembly Schematic ........................................................................224

31. A0761 circuit diagram .............................................................................................226

31.1. Transducer PCB Assembly ..........................................................................226

32. A0763/02 circuit diagrams ......................................................................................228

32.1. Micro Controller............................................................................................228

32.2. Conventional Valve Drive.............................................................................229

32.3. Power Distribution And Hardware Identifier..................................................230

32.4. Analogue Valve Drive / Non Volatile Memory / Interboard Comms..............231

32.5. High Speed Valve Drive ...............................................................................232

32.6. Analogue Data acquisition/Monitor port........................................................233

32.7. Control & Monitor, PCB PSU Circuit.............................................................234

32.8. Control & Monitor, Micro Non-isolated..........................................................235

32.9. Control & Monitor, Micro Isolated.................................................................236

32.10. Control & Monitor, Analog Isolated.............................................................237

32.11. Control & Monitor, Alarm Controller............................................................238

Other manuals for SLE5000 Model J

1

Table of contents

Other SLE Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual