5

SRV(P)130_170_210 1.1.8 - 2017

Planning and important precautions

EN

Prior to installation, it is important that the installer reads this guide to ensure necessary acquaintance with this product.

The thruster must NOT be installed in compartments that require ignition proof electric equipment. If necessary, make a separate

compartment.

The electromotor will generate some carbon dust so that any storage compartment must be separated from the thruster to prevent the stored

items from becoming dusty/dirty.

If you are installing the Sidepower in a small room /compartment, it should be ventilated to ensure cooling of the electromotor.

If the height in the room you are installing the Sidepower is limited, the Sidepower can be installed horizontally or at any angle in between.

- The electromotor must be handled carefully. Do not lift it by the internal connections/main terminals or put it down on the driveshaft.

- Beware to keep installation within advised measurements. No part of the propeller or gearhouse must be outside the tunnel.

The electromotor, its components, contacts / plugs or other joints in the control cables must be mounted so that they will keep dry at all times.

We advice to paint the gearhouse and propellers with antifouling. PS! Do not paint the anodes, sealings or propellershafts.

Do not nish the inside of the tunnel with a layer of gelcoat / topcoat or similar. It is only room for a thin layer of primer and two layers of

anti-fouling between the tunnel and the props.

With the boat on land, only run the thruster for a fraction of a second, as without resistance it will accelerate very fast to a damaging rpm.

Also, while the thruster is in air, make sure that the propellers have come to a complete stop before performing a directions change of the

thruster, as it might cause damage to the thruster.

This manual is intended to support educated/experienced sta and is therefore not sucient in all details for the correct installation.

Don’t install the electromotor at close range to easily ammable objects as it will reach over 100°C before the temperature switch is

activated.

Do not store items close to the thruster motor as it gets hot as well as any loose items near the thruster motor can cause problems with electrical

wiring coming loose and short-circuiting.

When installed in boats approved or classied according to international or special national rules, the installer is responsible for following the

demands in accordance with these regulations / classication rules. The instructions in this guide can not be guaranteed to comply with all

dierent regulations/classication rules.

These instructions are only general instruction. If you are not skilled to do this work, please contact professional installers for assistance.

NB! Faulty installation of the tunnel/case, thruster or panel will render all warranty given by Sleipner Motor AS void.

Nature de la Modification

---

---

Ce document est la propriété de BJ Technologie

Il ne pourra être reproduit ou communiqué sans son autorisation.

Ech 1:1 Matière :

Masse(kg) : 0kg

Parc d'activité de l'Eraudière

85170 DOMPIERRE SUR YON

Tol. ± 0.5

english designation

BJ

TECHNOLOGIE

G

D

E

C

F

G

H

IMPLANTATION

PROPULSEUR DE

POUPE

Vue auxiliaire B

Section C-C

1

1

2

2

3

3

4

4

5

5

6

6

A A

BB

C C

DD

olekr 14.01.2015

Designed by Checked by Approved by Date

1 / 1

Edition Sheet

Date

Present issues:

1. Aproximately 5mm of the tunnel end covers have been cut, due to

adjustments. This causes incorrect angel and alignment.

2. Actuator support brackets have been moved to adjust. This also

causes incorrect angel and alignment.

Actions to be done:

3. Place and mould in an wedge between the upper and lower flanges

to adjust to correct angel and alignment.

4. Replace retract mechanism (without engine.)

Nature de la Modification

---

---

Ce document est la propriété de BJ Technologie

Il ne pourra être reproduit ou communiqué sans son autorisation.

Ech 1:1 Matière :

Masse(kg) : 0kg

Parc d'activité de l'Eraudière

85170 DOMPIERRE SUR YON

Tol. ± 0.5

english designation

BJ

TECHNOLOGIE

H G

IMPLANTATION

PROPULSEUR DE

POUPE

B

Vue auxiliaire B

Section C-C

IMPORTANT!

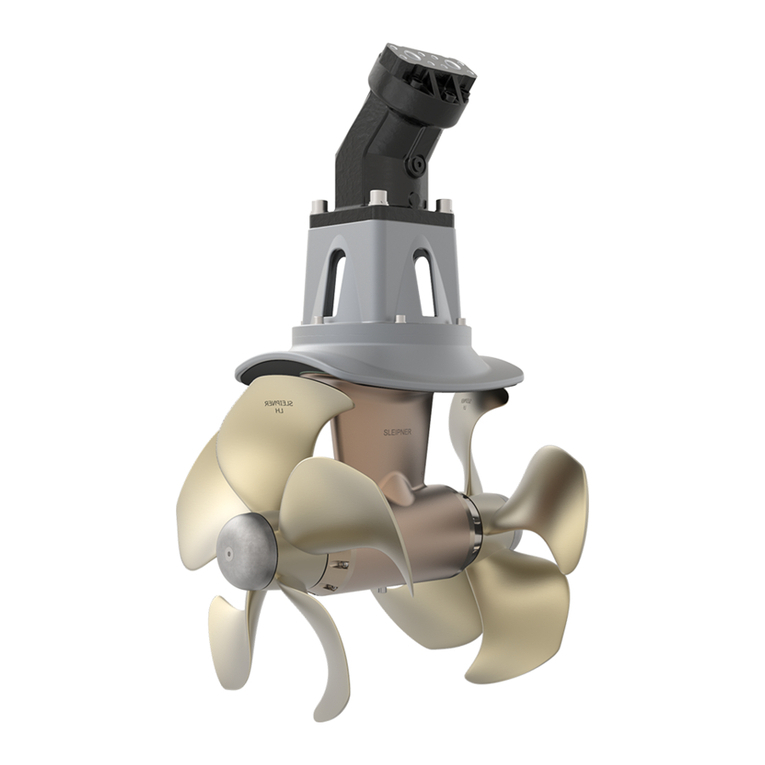

If thruster will be stern mounted, propeller/water stream and thruster posi-

tion must be considered by a Naval Architect regarding exact position-

ing of the thruster. This to avoid conicts that will cause extra wear on

thruster mechanics and reduced power on the vessels propeller.

IMPORTANT!

Fig1b is just an example of

thruster positioned outside

of conict area. Detailed

measurements must be done

by boatbuilder. Propeller size

and shaft angle will aect

positioning the thruster.

Precautions with Stern installation

Nature de la Modification

---

---

Ce document est la propriété de BJ Technologie

Il ne pourra être reproduit ou communiqué sans son autorisation.

Ech 1:1 Matière :

Masse(kg) : 0kg

Parc d'activité de l'Eraudière

85170 DOMPIERRE SUR YON

Tol. ± 0.5

english designation

BJ

TECHNOLOGIE

G

D

E

C

F

G

H

IMPLANTATION

PROPULSEUR DE

POUPE

B

Vue auxiliaire B

Section C-C

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

olekr 14.01.2015

Designed by Checked by Approved by Date

1 / 1

Edition Sheet

Date

Present issues:

1. Aproximately 5mm of the tunnel end covers have been cut, due to

adjustments. This causes incorrect angel and alignment.

2. Actuator support brackets have been moved to adjust. This also

causes incorrect angel and alignment.

Actions to be done:

3. Place and mould in an wedge between the upper and lower flanges

to adjust to correct angel and alignment.

4. Replace retract mechanism (without engine.)

Nature de la Modification

---

---

Ce document est la propriété de BJ Technologie

Il ne pourra être reproduit ou communiqué sans son autorisation.

Ech 1:1

Masse(kg) : 0kg

Parc d'activité de l'Eraudière

85170 DOMPIERRE SUR YON

Tol. ± 0.5

BJ

TECHNOLOGIE

H G

321

Vue auxiliaire B

Ver.

Date

Nature de la Modification Nom

---

---

---

---

---

---

---

---

Ech 1:1 Tol.

D

E

C

F

B

G

A

H

3

2

4

4

2 8 5

A

A

C

C

DO NOT connect any other control equipment to the S-link controlled products except Side-Power original S-link products

or via a Side-Power supplied interface product made for interfacing with other controls. Any attempt to directly control or at

all connect into the S-link control system without the designated and approved interface, will render all warranties and re-

sponsibilities for the complete line of Side-Power products connected void and null. If you are interfacing by agreement with

Sleipner and through a designated Side-Power supplied interface, you are still required to also install at least one original

Side-Power control panel to enable ecient troubleshooting if necessary.