7

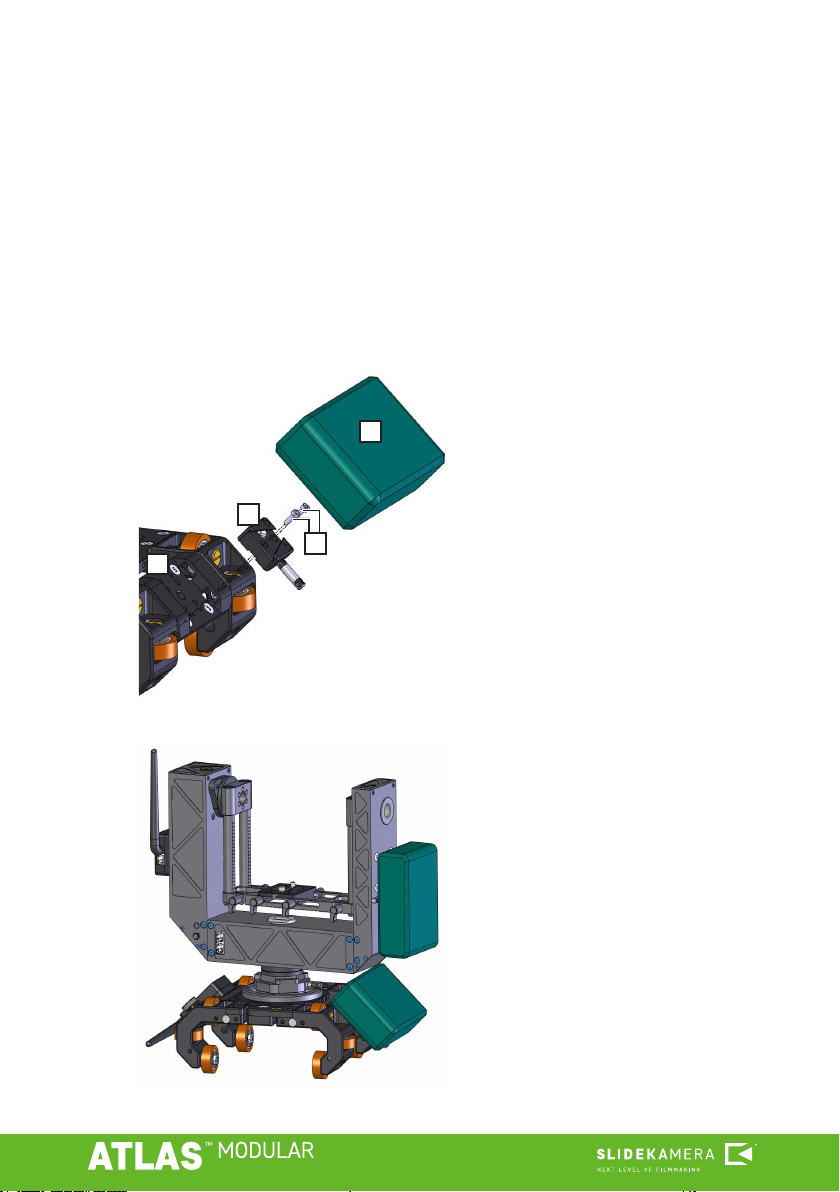

• With 4 Allen screws [1] tighten the

centering adapter [2] to the chosen

port of the slider’s rail [3],

• if the slider consists of one section

only, tighten the adapter to the mid-

dle port,

• if the slider consists of several sec-

tions, choose the mounting points

carefully to attain stable support,

• note that each section should be

supported at least in one point,

• to mount the slider on the tripod

place the adapter underneath the tripod’s socket; tighten the adapter as an

ordinary head; use a universal 3/8” screw.

2

2

3

3

4

4

3.3. Motion end blocks

3.4. Adjustable feet

3.5. Centering adapters

To secure the slider’s dolly put the motion end

blocks [1] in the slider’s end sections.

• Fit the end blocks into appropriate centering

holes [2].

• Tighten them with knobs [3], located on the

outer side of the end blocks.

The end blocks also have clamps for mounting

the timing belt of the slider’s drive [4].

• attach the foot’s mounting element

[2] with 4 Allen screws [1] to the

slider’ rail’s end port [3]

• place the regulated feet [4] in the

sockets

• adjust their height and tighten the

clamps [5]

Each section has 4 regulated feet which adjust to the ground. When the set

is standing on the ground, it can be quickly leveled.

The producer provided centering adapters for correct and quick mounting of the

slider to the tripods. The adapters are t for tripod sockets with a diameter of 75

and 100mm. Each section has one 75/100mm centering adapter.

2

2

33

1

TIP

The feet are necessary for the prop-

er functioning of the slider, when it

is standing directly on the ground.

They can be removed to make work

easier when the slider is mounted,

e.g. on a tripod.

TIP

As the feet and the slider’s rails’

ports are equipped with 3/8” sockets

[4] it is possible to mount the tripod

directly to the port.

Such installation is not recommend-

ed for tripods with bowls for mount-

ing 75/100mm half-balls due to the

lack of precision of mounting and a

potential lack of connection stability.

4

5

5

1

1

4