SmartLine SL1600 User manual

• Align the three retainers on back of the controller housing onto the

mounting bracket and lower it into place.

• For additional security, install a bottom cen-

ter mounting screw from the inside of the

controller. Drive the provided screw through

the mounting notch located just below the

zone modules to secure the controller to the

bracket.

2B. Installing Without Quick Mount Bracket

• Determine mounting height for easy viewing and be sure to mount low

enough for field wires to reach controller wiring terminals and test post

at top of controller.

• Install a wall anchor in the desired location.

This will be for the top/center hanger hole of

the controller.

• Install one of the mounting screws provided

into the wall anchor.

Hang the controller on the mounting screw by

positioning the controller on the head of the

mounting screw. Check the controller for level,

then drive a 2nd screw into the “notch” inside

the bottom/center location to mark position for second anchor. Remove

controller from top keyhole and install second anchor and then remount

controller and tighten both screws to secure unit.

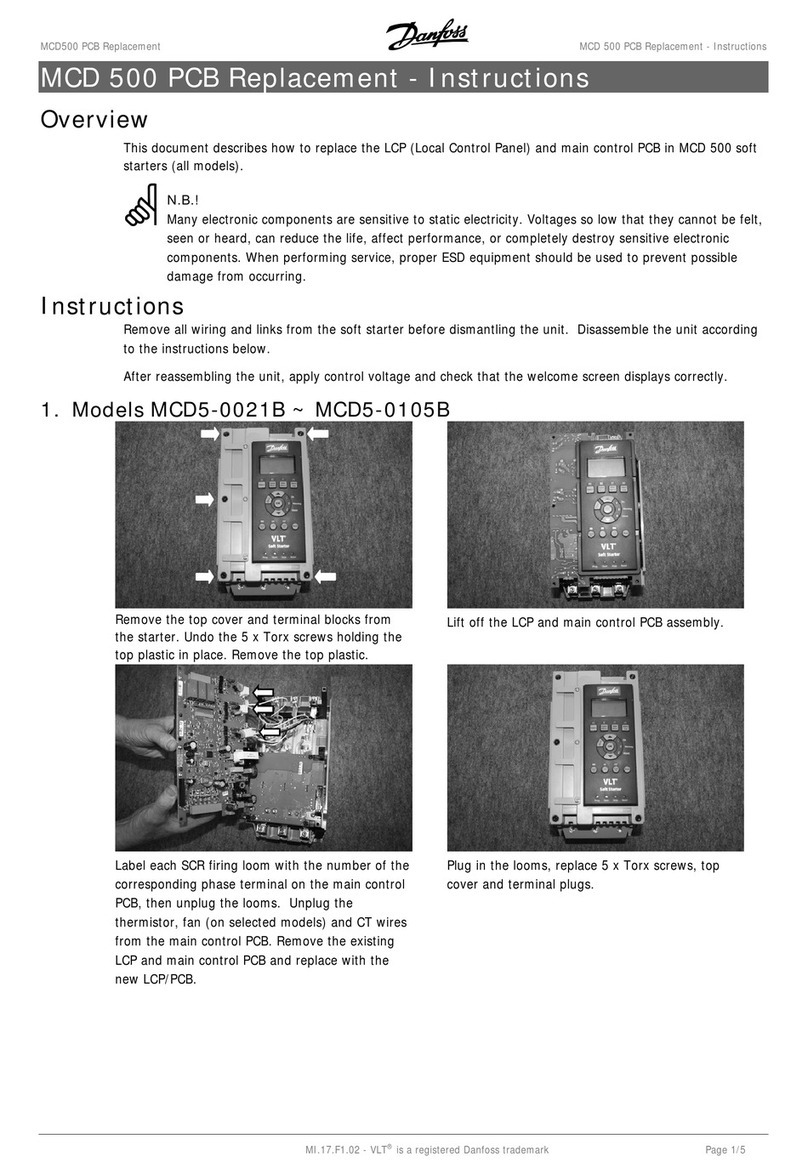

3. SLM4 Module Installation

• The SL1600 controller is equipped with one 4-zone module (SLM4).

Additional SLM4 modules may be added to expand capacity to 16

zones. The SL1620 has 20 fixed zones; the SL1624 has 24 fixed zones.

The SLM4 module is useable only on the SL1600.

• The SL1600 controller will automatically recog-

nize the additional zones as they are installed.

No special programming or resetting is

required to initialize the modules.

• You can insert or remove a module without

removing power from the controller.

• To install a module, push the module into

the channels until you feel it lock in place. To

remove a module, push DOWN on the center release panel on the top

of the module and use the top tab to pull it out.

4. AC Power Wiring

• Plug the included 6-foot line cord into a 120VAC outlet. (E-SL1600

units for international use are prewired for 230VAC.)

• Do NOT use a switch controlled wall outlet for operating an irrigation

controller.

TEST

AC1

SEN

SEN

COM

P/MV

RED

BLACK

SILVER

Note: Modules must be inserted in the sequence of numbered

zones. Do not leave any gaps in module positions.

TEST

AC1

SEN

SEN

COM

P/MV

RED

BLACK

SILVER

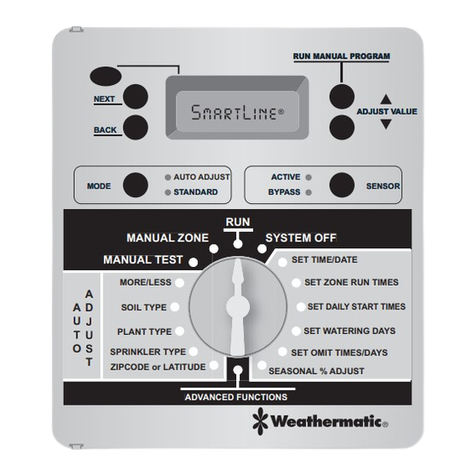

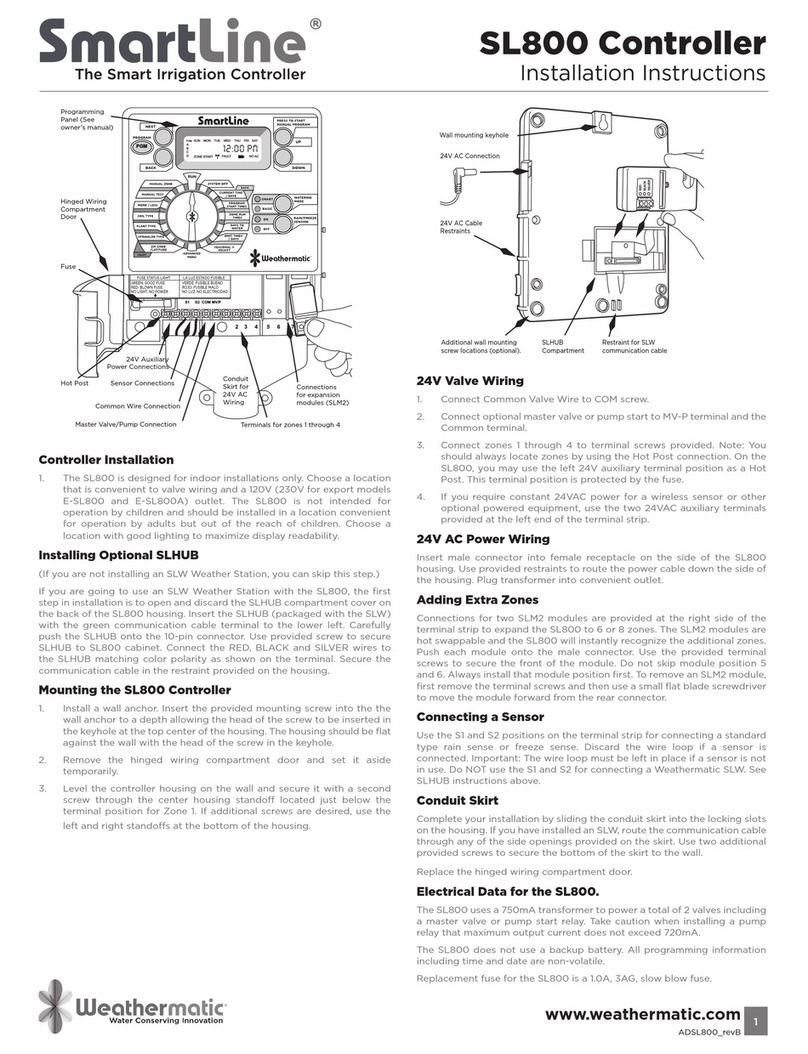

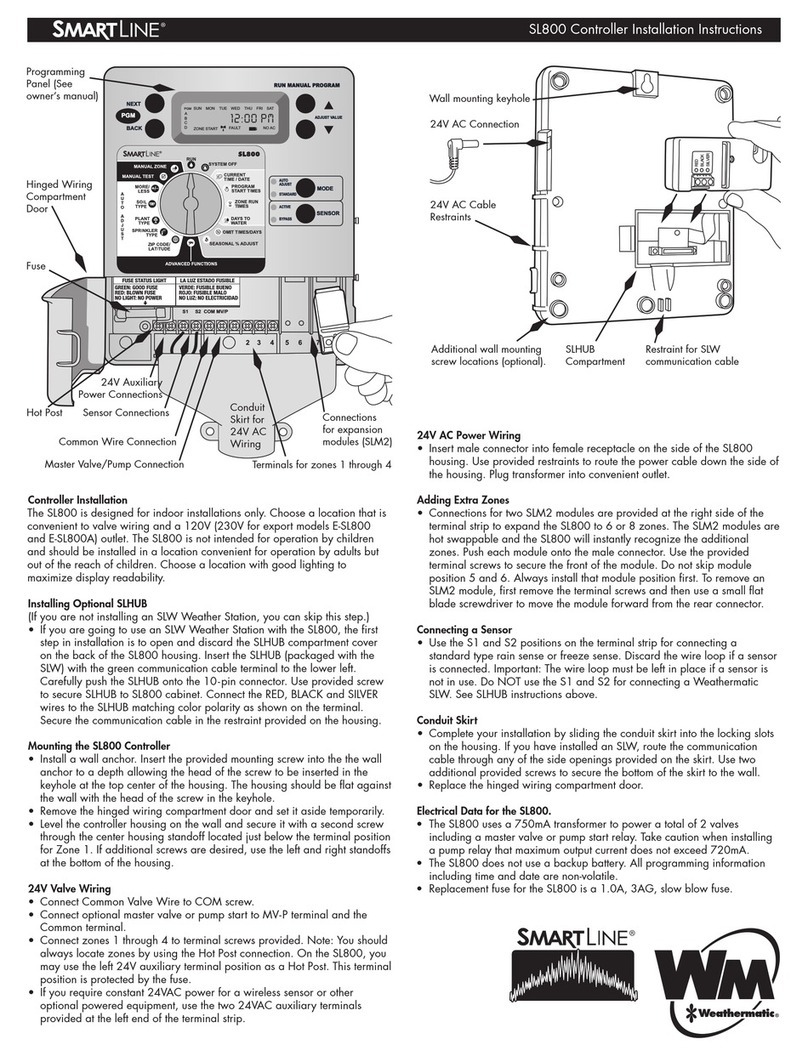

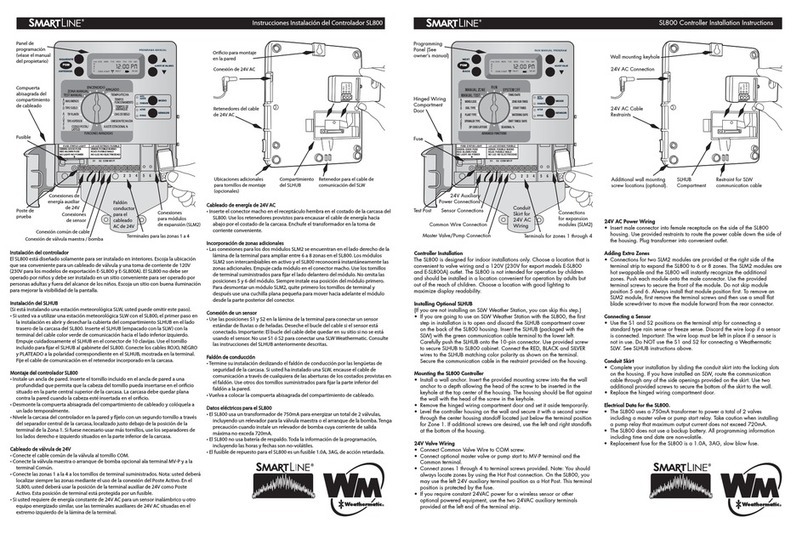

1. Controller Installation

All SL1600 controller housings are designed for indoor or outdoor instal-

lation. Your SL1600 controller can be located in any convenient spot such

as inside the garage or on an outside wall. It is recommended that you

choose a location where the irrigation system will not be spraying directly

on the controller, in the event the housing door is left open.

• Open the

controller’s

front door,

then open the

control panel

of your SL1600

controller.

• Remove the

control panel

from the

SL1600 con-

troller housing

by pushing

upward and outward to remove from the hinges, then set the control

panel aside in a safe place.

• Mount the SL1600 controller with or without the SL1600 controller Quick

Mount bracket.

2A. Installing With Quick Mount Bracket (recommended)

• Determine mounting height for easy viewing and be sure to mount low

enough for field wires to reach all controller wiring terminals and test

post at top of controller.

• Place the mounting bracket against the

wall so that the word “CONTROLLER

SIDE” is visible and the open ends of the

housing retainers are pointing upward.

• Using one of the mounting screws (or a

pencil) mark the location onto the wall of

the top/center hole (see photo).

• Install a wall anchor in the marked

position then install the bracket onto

the anchor using one of the mounting screws provided (do not tighten

screw fully yet). The center screw will automatically level the bracket on

the wall. After level is set, mark the other mounting holes and install the

remaining wall anchors.

• Install other screws through bracket into anchors (except for bottom cen-

ter screw) and tighten all screws.

TEST

AC1

SEN

SEN

COM

MV/P

RED

BLACK

SILVER

TEST

AC1

SEN

SEN

COM

MV/P

RED

BLACK

SILVER

A

C Wiring Cavity

with panel removed

MOV (Metal

Oxide Varistor)

Installed SLM4 Modules

AC Wiring

Cavity panel

Optional SLHUB

Communication Hub

Transformer Test

Post

SL1600 Interior Layout

SL1600 Controller Installation Instructions

®

Optional

SLHUB

CONTROLL

THIS

™

Alternate Wiring

If you are mounting your SL1600 controller outdoors or local electrical

codes require hard wiring, proceed with the following steps.

Warning: Connecting the SL1600 controller to the primary power

should be done by a licensed electrician following all local codes.

To prevent electrical shock, make sure all supply power is turned

OFF at the breaker before connecting these wires. Electrical shock

can cause severe injury or death. This controller is not intended for

use by children. Do not allow children to play with the controller.

• Remove the screws that secure the AC Wiring Cavity Panel. This will

allow access to the transformer wiring.

• Disconnect the existing line cord connected to the transformer wires.

• For use with conduit, simply remove the line cord knockout. To do this,

use a small, flat screwdriver blade in the slot of the knockout on the

underside of the controller housing. Tap out the knockout with a ham-

mer. Install the conduit and wiring. Discard the line cord.

• For 120VAC operation, using wire nuts, make the wire connections indi-

cated in the chart below.

• For 230VAC operation, using wire nuts, make the wire connections indi-

cated in the chart below.

• Replace the AC Wire Cavity Panel and secure with the screws.

• Return to the breaker box and turn on the circuit breaker. Verify that

the controller no longer displays “no AC.” This indicates that the AC

power is on.

5. 24VAC Valve Wiring

WARNING: Never mix 24VAC and high voltage wiring in the same

conduit.

• For solid wires, simply push to

insert the stripped end of valve wire

into the module connector.

• For stranded wires, use a small

screwdriver blade to push back the

orange slide lock trigger first, then insert the stranded wire while holding

the trigger in the open position. When you release the orange slide trig-

ger, the wire will lock in place.

• Knockouts: The SL1600 controller

provides several convenient knock-

outs for your choice of routing for

valve and accessory 24VAC wiring.

The knockouts should be removed

by striking with a hammer and

screwdriver inwards, toward the

inside of the housing.

•

COM (Valve Common): Connect the Valve Common wire to the COM ter-

minal.

Wire connections TRANSFORMER

for 120VAC WIRE COLOR AC INPUT WIRE NOTE

BLACK NEUTRAL

WHITE 120VAC HOT

RED DO NOT USE-230VAC (cover with wire nut)

GREEN/

YELLOW EARTH GROUND (typically green wire)

Wire connections TRANSFORMER

for 230VAC WIRE COLOR AC INPUT WIRE NOTE

BLACK NEUTRAL

WHITE DO NOT USE-120VAC (cover with wire nut)

RED 230VAC HOT

GREEN/

YELLOW EARTH GROUND

Note: Your SL1600

controller utilizes

screwless terminals

for fast installation.

Note: To remove

wires, push back

the orange slide trig-

ger using a small screwdriver

and then pull out the wire to

remove.

• MV/P (Master Valve/Pump

Terminal): Connect one wire to

the COM position and the second

wire to the MV/P position. Polarity

is not important. Note that the

total current of the activated Pump

Start Relay AND valve(s) cannot

exceed the maximum output current

(default is 1.0A).

• SEN (Rain/Freeze/Wind Sensor):

If you are using an optional rain,

freeze, or wind sensor, use the SEN

terminals for these devices. There is

no polarity required for these wires.

Remove and discard the factory

installed wire jumper.

• Zone Wires: Connect a zone wire

to a terminal on the SLM4 Module.

Your SL1600 controller can power

a total of 3 valves concurrently or

a total of 2 valves with one master

valve. Take caution when running a

pump start relay so maximum out-

put current does not exceed 1.0A.

To locate a zone, touch zone wire

to the TEST POST and determine

which zone valve is ON. Note that

the TEST POST is HOT even when

the control panel is not in the hous-

ing.

9V Battery Installation (optional)

SL1600 controllers with firmware

versions later than 1.10 do

not require a battery for

clock time retention. A 9-volt

battery may be installed for

operating the display when

the panel is open or for pro-

gramming while the panel is

outside the housing.

6. Control Panel Installation

• With the controller and

optional SLW On-Site

Weather Station installation

complete, re-insert the con-

trol panel into the housing. To do this, hold the operating panel at a 90

degree angle from the housing (see photo at right) and position the top

of the panel slightly toward the housing and slip the top post into the

top hinge, then push the bottom post into the lower hinge. The panel

should now swing open and close freely on the hinges.

• The SL1600 controller will automatically restore power and communica-

tion to the control panel as soon as it is firmly closed. No ribbon cable

is required.

Installation is complete! Proceed to your Owner’s Manual to program your

SL1600 controller.

RESET

VDC

Battery

Compartment

Back of Control Panel

9V Battery installed

TEST

AC1

RED

BLACK

SILVER

SEN

SEN

COM

P/MV

TEST

AC1

Note: If you are NOT

using an optional

rain or freeze sensor,

the wire jumper must be in

place for your valves to turn

ON. The jumper must also

be in place if you are using

the SLW weather station. SLW

WEATHER STATION DOES

NOT ATTACH TO THESE

TERMINALS.

TEST

AC1

SEN

SEN

COM

P/MV

RED

BLACK

SILVER

Test Pos

t

Typical

W iring

ADSL1600 REV E

SL1600 Controller Installation Instructions

®

™

Other manuals for SL1600

1

Other SmartLine Controllers manuals

Popular Controllers manuals by other brands

Consort

Consort CRX2 Installation and user guide

McIntosh

McIntosh VJ1001 manual

Danfoss

Danfoss AK-CC55 user guide

Danfoss

Danfoss DEVI DEVIreg Hotwater Installation and user guide

Nidec

Nidec Leroy-Somer D510 C Installation and Maintenance

Johnson Controls

Johnson Controls LN Series installation instructions