D-MP-SMX03EN

Page 1 of 3

Instruction Manual

Actuator Position Sensor

D-MP# series

The intended use of theactuator position sensoris tomonitor theposition

of the actuator while connected to the IO-Link communication protocol.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)

*1)

, and other safety regulations.

*1)

ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety. etc.

•Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

•Keep this manual in a safe place for future reference.

•This product is class A equipment intended for use in an industrial

environment. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments due to conducted

or radiated disturbances.

Caution

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and

standards.

•All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

•Do not disassemble, modify (including changing the printed

circuit board) or repair.

An injury or failure can result.

•Do not operate the product outside of the specifications.

Fire, malfunction or damage to the product can result.

•Do not operate in an atmosphere containing flammable, explosive

or corrosive gas.

Fire or an explosion can result.

•Do not use the product for flammable or harmful fluids.

Fire, explosion, damage or corrosion can result.

•If using the product in an interlocking circuit:

Provide a double interlocking system, for example a mechanical

system.

•Check the product for correct operation.

Otherwise malfunction can result, causing an accident.

•Do not use the product in a place where static electricity is a

problem.

Product failure or system malfunction may result.

Otherwise electric shock, malfunction or product damage can result.

•Refer to the operation manual on the SMC website

(URL: https://www.smcworld.com) for more safety instructions.

2 Specifications

2.1 General specifications

2.2 IO-Link specifications

Model D-MP

025∗D-MP

050∗D-MP

100∗D-MP

200∗

IO-Link type Device

IO-Link version V1.1

Communication

speed COM3 (230.4 kbps)

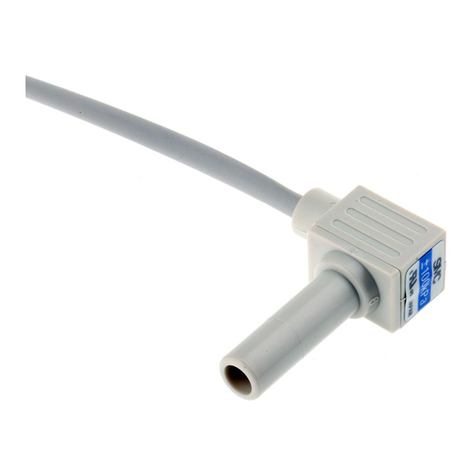

3 Names of Individual parts

3.1 D-MP#

3.2 Operation Display

Operation Light Colours

Category

Mode Indicator

light 2 Indicator

light 1 Description

System

status

Analogue

Current

B Analogue current

output active

Analogue

Voltage

G Analogue voltage

output active

IO-Link G IO-Link connection

Error

O Sensor not ready for

operation /

Detectable magnetic

field is decrease.

LED flashing at 4 Hz

Switch

output

High B Switch output High

Low B Switch output Low

Over current

error B Overload of the switch

output (over current)

Magnetic

field

In measuring

range O Magnetic field

registered in

measuring range

Outside of

measuring

O Magnetic field is not

registered in

= LED ON, = LED flashing, = LED OFF

B = Blue, O = Orange, G = Green

4 Installation

4.1 Installation

Warning

•Do not install the product unless the safety instructions have been read

and understood.

•Use the product within the specified operating pressure and

temperature range.

•When mounting an actuator position sensor, use a mounting bracket

appropriate for the cylinder/actuator.

•The mounting method differs according to the type of actuator and the

inner diameter of the tube.

•When mounting a sensor for the first time, check that the

cylinder/actuator has a built-in magnet and use an appropriate bracket

for the cylinder/actuator. There are also cases when a bracket is not

needed.

•Use the correct tightening torque

When tightening mounting screws, use a suitable hexagon wrench

(size 1.5). Recommended torque should be 0.2 to 0.4 Nm.

Over-tightening can damage the cylinder/actuator and sensor.

Loose screws can cause misalignment or a reduction in accuracy

during operation. Tightening below the specified tightening torque will

allow the position sensor to move out of position.

•Do not carry an actuator by the position sensor lead wire.

•This may cause a broken lead wires or damage to the auto switch

internal elements.

•Use only the screws installed in the position sensor body for mounting

the position sensor.

If other screws are used, the position sensor may be damaged.

•Check and adjust the actual product operation during installation.

The auto switch may not operate in the correct actuator mounting

position due to the installation environment. Also check and adjust the

auto switch operation when used in intermediate stroke positions,

according to the operating environment.

•Press the switch down into the cylinder/actuator switch mounting

groove as shown.

•Tighten the mounting screws evenly.

4.2 Environment

Warning

•Do not use in an environment where corrosive gases, condensation,

chemicals, salt water or steam are present.

•Do not use in an explosive atmosphere.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product’s specifications.

•Do not use in a location where magnetic fields are generated.

Orange

Green

BlueBlue

Refer to Declaration of

Conformity for relevant

Model D-MP

025∗D-MP

050∗D-MP

100∗D-MP

200∗

Length determination

25 mm

50 mm

100 mm

200 mm

Power supply voltage 15 to 30 VDC, ripple (p-p) 10% or below

(with power supply polarity protection)

(when no load is applied)

o

Resolution 0.05 mm

Linearity ±0.3 mm (@25

o

C)

Switch

output NPN or PNP 1 output (push-pull)

Max. load

40 mA

Internal

voltage

2 V or less

Leakage

current

NPN: 0.5 mA or less at load resistance 3 kΩ,

1.5 mA or less at load resistance 750 Ω

Short

circuit

Yes

Analogue

current

output

Output

4 to 20 mA

Max. load

500 Ω

Analogue

voltage

output

Output

0 to 10 V

Min. load

resistance 2 kΩ

PUR 4 core φ2.6 0.08 mm

2

2

50 MΩor more with 500 VDC Ohmmeter

Withstand voltage 1000 VAC 1 minute

Ambient temperature -10 to 60

o

C

Lead wire

Mounting screw

Operation display

Mounting screw

Teach pad