Installation & Maintenance Manual

Compact Pressure Sensor

Series PSE530

NOTE

Follow the instructions given below when handling the

pressure sensor. Otherwise, the sensor may be damaged or

may fail, thereby resulting in malfunction.

•Do not drop, bring into collision with other objects or apply excessive

shock to the unit (980m/s2or more).

•Do not pull the lead wire with force or lift the main unit by holding the

lead wire. (Pulling strength less than 23N)

•Do not insert wire or other articles into the pressure port.

•Connect wires and cables correctly.

•Do not perform wiring while power is on.

•Do not wire with power cable or high-voltage cable in the same wire

route.

•Connect Terminal FG to ground when using a switching regulator

obtained on the commercial market.

•Install the air tube correctly in a safe area away from water and dust.

Indicates a potentially hazardous situation that

could result in death or serious injury if you do

not follow instructions.

Read this manual and follow its instructions. Signal words such as

WARNING and NOTE will be followed by important safety

information that must be carefully reviewed.

Gives you helpful information.

IMPORTANT MESSAGES

The Pressure Sensor and this manual contain essential information for

the protection of users and others from possible injury and property

damage and to ensure correct handling.

Please check that you fully understand the definition of the following

messages (signs) before going on to read the text, and always follow the

instructions.

Do not disassemble, modify (including change of printed

circuit board) or repair.

An injury or failure can result.

Do not operate outside of the specification range.

Fire, malfunction or sensor damage can result.

Please use after confirming the specification.

Do not operate in atmosphere of an inflammable, explosive

or corrosive gas.

Fire, an explosion and corrosion can result.

This pressure sensor is not an explosion proof type.

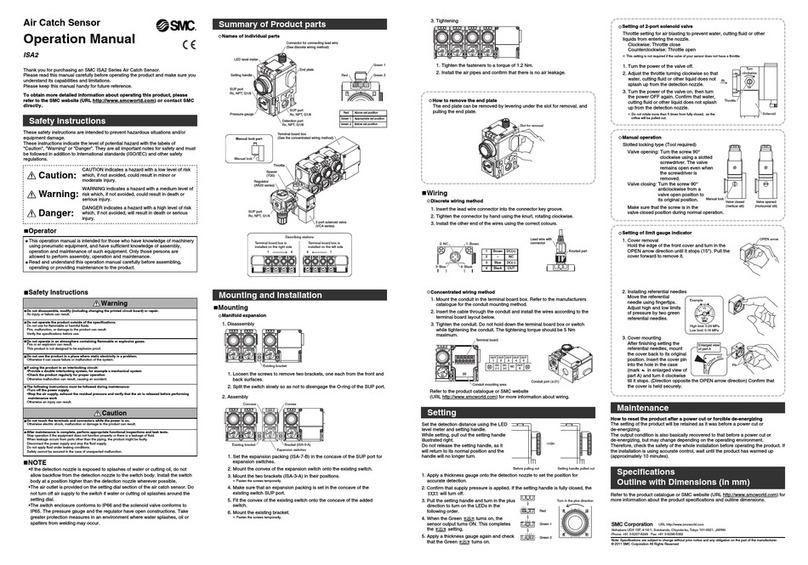

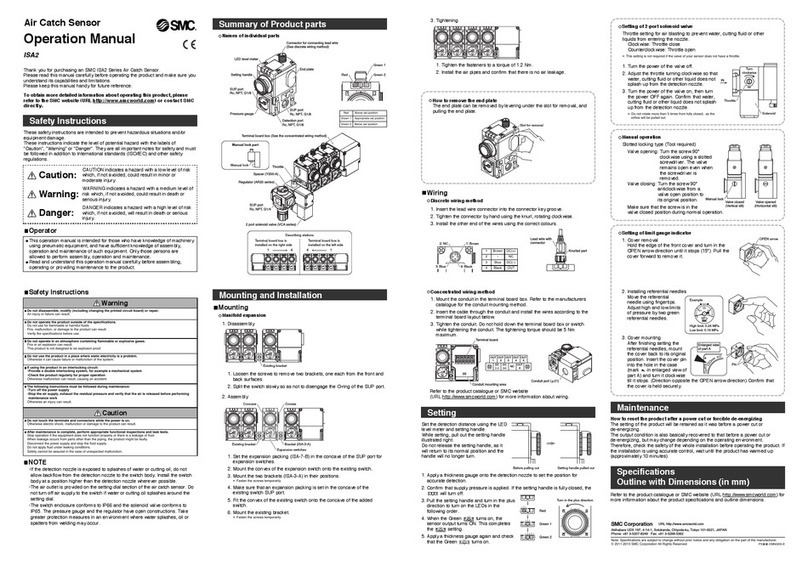

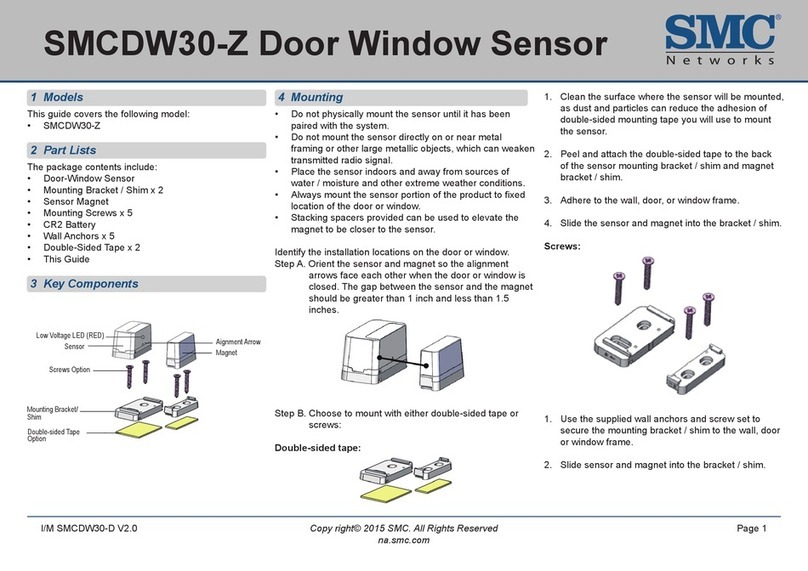

Model Indication Method

PSE53 0 M5

Nil

L

C2L

Option

Without cable

0

1

2

3

Pressure sensing range

High pressure[0 to 1MPa]

Vacuum [0 to -101kPa]

Low pressure [0 to 101kPa]

Compound pressure [-101 to 101kPa]

M5

R06

R07

Pipe Specification

M5 0.8

6 reducer

1/4inch reducer

Sensor cable (3m), ZS-26-F

Connector for sensor controller (1pc)

+Sensor cable (3m), ZS-26-J

Note) At the factory, the connector (ZS-28-C) is not connected

to the cable, but packed together with it for shipment.

3.4

5.4

5 5.5

4

3

29.4

27.2

M5 0.8

Pressure port

7.2

12

12

2.5

13

PSE53 -M5

5.4

3.4 Pressure port

7.2

12

D

45.5

43.3

PSE53 - R06

R07

Applicable port size(D)

6mm

1/4inch

Model No.

PSE53 -R06

PSE53 -R07

With sensor cable fitted

9.8

2.7

10.4

Outline with Dimensions

(

in mm

)

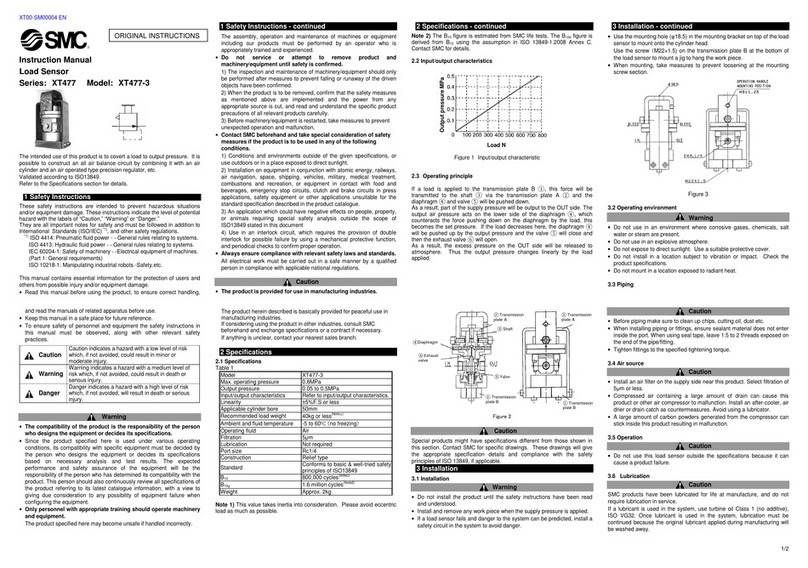

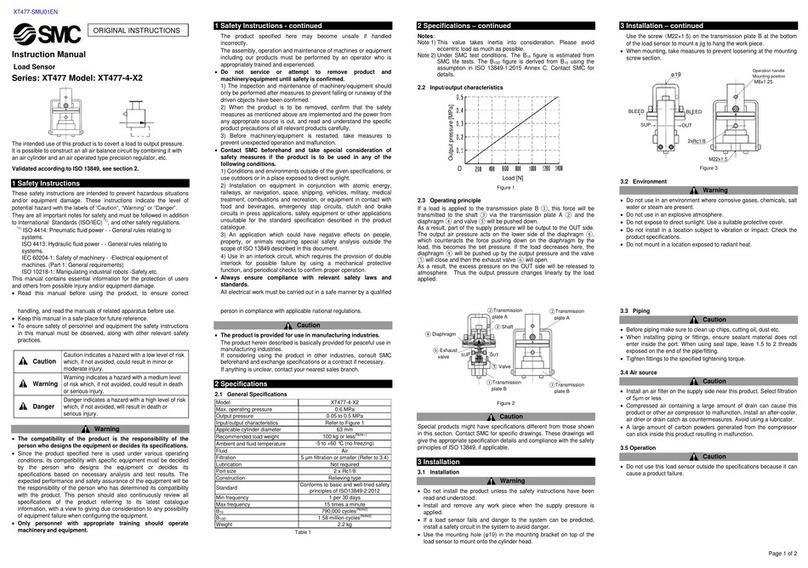

Installation

Model No.

Rated Pressure Range

Withstand Pressure

Fluid

Power Supply

Current Consumption

Repeatability

Power Supply Effect

Temperature Characteristic

Standard

Cable

PSE530-

0 to 1MPa

1.5MPa

Air, Non-corrosive gases, Non-flammable gases

12 to 24VDC, ripple(p-p)10% or less (Protection against inverse connection)

15mA or less

Voltage: 1 to 5V 2%F.S. or less (Rated pressure range)

Linearity : 1%F.S. or less Output impedance : Approx.1k

1%F.S. or less

1%F.S. or less based on analog output at 18V in the range of 12 to 24VDC

2%F.S. or less (25 reference)

IP40 (IEC 60529)

Operation : 0 to 50 ,Storage :-10 to 70 (No condensation, No freezing)

1000VAC, 50/60Hz, 1minute (Between wires and case)

5M or more 500VDC (Between wires and case)

10 to 500Hz 1.5mm or 98m/s

2

acceleration, 2 hours each direction

of X, Y and Z

980m/s23times each in directions of X ,Y and Z respectively

CE MARKING

Halogen free heavy insulation cable, 2.7, 0.15mm

2

, 3wire, 3m

500kPa

PSE531-

0 to -101kPa

PSE532-

0 to 101kPa

PSE533-

-101 to 101kPa

Analog

Output

Voltage

Output

Enclosure

Ambient Temperature

Withstand Voltage

Insulation Resistance

Vibration Proof

Impact Proof

Environment

Model No.

Port Size

Material Specification

Material

M5

M5 0.8

Body : SUS303

41g

7g

Body : PBT

38g

3.8g

Pressure sensor : Silicon O-ring : NBR

R06

6 Reducer

R07

1/4inch Reducer

Weight With cable(3m)

Excluding cable

1

Pressure or Vacuum

Analog output [ V ]

5

1 to 5VDC

AB

Model No.

Rated pressure

range

A

B

PSE530-

0 to 1MPa

0kPa

1MPa

PSE531-

0 to -101kPa

0kPa

-101kPa

PSE532-

0 to 101kPa

0kPa

101kPa

PSE533-

-101 to 101kPa

-101kPa

101kPa

Analog output

Observe the specified tightening torque when connecting pipes.

Refer to the following table for the appropriate torque values.

When connecting pipeline to the

sensor, apply a spanner vertically

to the piping section of the sensor.

Install the air piping correctly in a

safe area away from water and

dust.

Nominal size of Thread Tightening torque N • m

M5 1/6 rotations after tightening by hand

Hold the sensor and insert it into the

one-touch fitting carefully and securely

all the way to the bottom.

PSE##-TFI52GB

Safety Instructions

EMC Directive 89/336/EEC

EN61000-6-2:2001 Electromagnetic Compatibility (EMC). Generic

standards - lmmunity for industrial environments.

EN55011+A1:1998 Limits and methods of measurement of radio

disturbance characteristics of industrial, scientific

and medical radio-frequency equipment and light

industrial environments.