NOTE

Follow the instruction given below when designing, selection and handling your pressure sensor.

♦

♦♦

♦The instructions on design and selection

Installation, wiring, environment of use, adjustment, operation and maintenance described belo

must also be followed.

∗

∗∗

∗Product specifications

•Operate the pressure sensor with the specified voltage.

Operation with a voltage beyond specifications can cause malfunction or damage of the pressure sensor.

Insufficient supply voltage may not drive a load due to a voltage drop inside the pressure sensor.

Verify the operating voltage of the load before use.

•Use at pressure within the specified range.

Otherwise it can cause damage to the pressure sensor and an abnormal measurement.

•Do not exceed the specified maximum allowable load.

Otherwise it can cause damage or shorten the lifetime of the pressure sensor.

•Reserve a space for maintenance.

Remember to leave space for maintenance when designing the piping plan.

♦

♦♦

♦Product handling

∗

∗∗

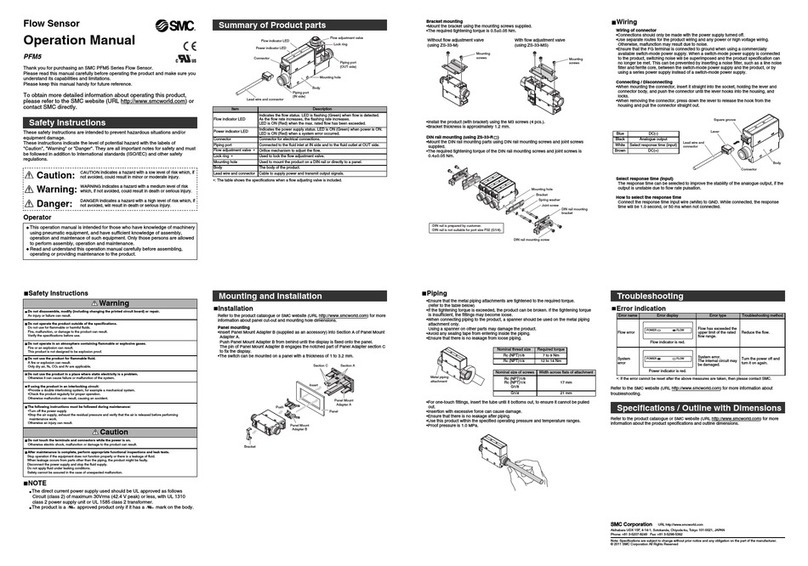

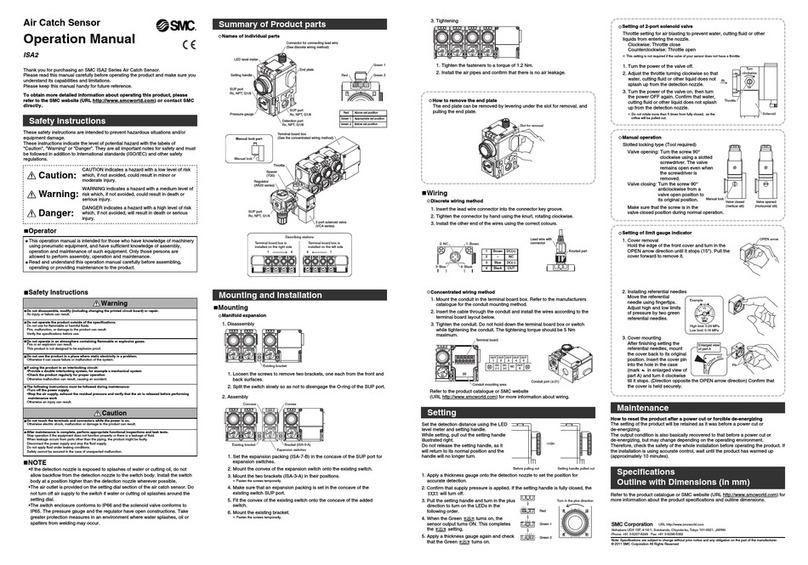

∗Installation

•Do no drop, hit or apply excessive shock (300m/s2) to the pressure sensor.

Otherwise it can result in damage to the pressure sensor causing failure or malfunction.

•Do not pull lead wires or lift the body with lead wires. (The pulling force is 50N)

Hold the body when handing. Otherwise it can result in damage of the pressure sensor causing failure o

malfunction.

•Follow the specified tightening torque. (Appropriate tightening torque 0.5 to 0.7N.m)

Excessive tightening torque can break the pressure sensor. Insufficient tightening torque can displace the

pressure sensor from the original position or loosen the mounting screws.

•Do not insert wires or other foreign matter into the pressure measurement port.

It can damage the pressure sensor causing failure or malfunction.

•Connect frame-ground terminal (FG terminal) to the ground when using a switching power supply.

•Insert a noise filter (power line noise filter, ferrite core, etc.) between the switching power suppl

and this pressure sensor.

•Extend connection of air tube to safety place without exposure to splashing water and dust.

•Do not apply unnecessary forces such as twisting, pulling, moment loads, etc. on fittings or tubing.

•When the tube of other company is used, ensure the tube has the accuracy of inside diamete

within ±0.3mm.

•Insert into pipe precisely so that air tube won’t come off. (Tensile strength is approx.25N at 8mm

inserted.)

∗

∗∗

∗Wiring

•Do not bend or apply tensile stress to lead wires repeatedly.

Wiring with repetitive bending stress or tensile stress can cause breakage of the lead wires.

Replace the product when damage to a lead wire is observed.

•Connect wires and cables correctly.

Miswiring can break the pressure sensor depending on a miswired circuit.

•Do not connect wires while the power is on.

Otherwise it can break the circuit inside the pressure sensor causing malfunction.

•Do not lay wires or cables with power cable or high-voltage cable in the same wiring route.

Otherwise the wires to the pressure sensor can be contaminated with noise or induced surge voltage from

power lines or high voltage lines causing malfunction. Lay the wires to the controller to a wire duct or in a

protective tube other than those for power lines or high voltage lines.

•Verify the insulation of wiring.

Poor insulation (interference with other circuit, poor insulation between terminals and etc.) can introduce

excess voltage or current to the controller causing damage.

•Keep wiring as short as possible to prevent noise and surge voltage from being induced.

Do not use a cable longer than 10m. Consult with SMC for the use with a cable longer than 10m. Connect the

0V DC wire (blue line) directly or as close as possible to the 0V DC terminal of the DC power supply.

- 4 - PS##-OMG0009