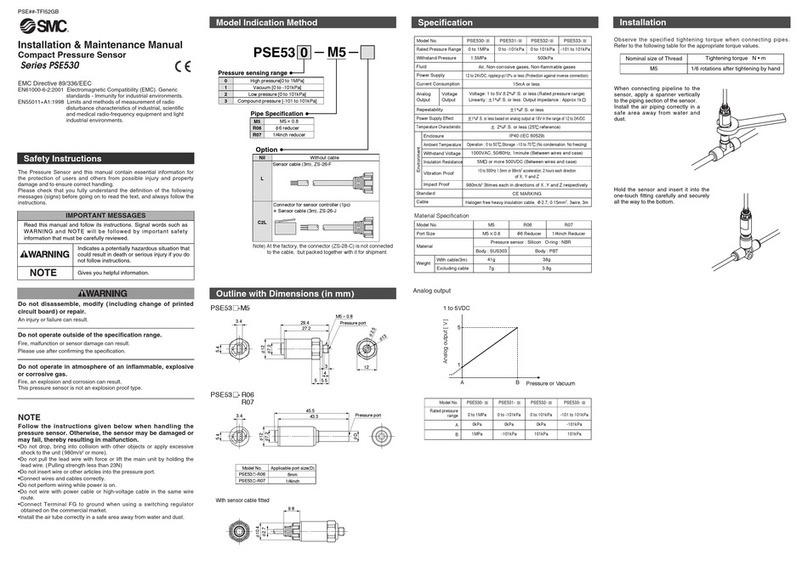

⋅Keep wiring as short as possible to prevent contamination from noise and induced surge voltage.

Do not use a cable longer than 10m. Consult with SMC for the use with a cable longer than 10 m.

Connect the 0V DC wire (blue line) directly or as close as possible to the 0V DC terminal of the DC power supply.

⋅The direct-current power supply to combine should use UL authorization power supply which is the class 2

power supply based on UL 1310 or the power supply is using the transformer of a class 2 based on UL 1585.

•Environment

⋅Do not use the product in an atmosphere containing corrosive gas, chemicals, sea water, water or vapor, or in

a place where there is a possibility of adhesion of those substances to the product.

It can cause failure or malfunction.

⋅Avoid exposure of this product to direct sunlight.

Use sunshades if the product is exposed to direct sunlight. Otherwise it can cause failure or malfunction.

⋅Do not use in a place where water, oil or chemicals splashes.

Otherwise it can cause failure or malfunction.

⋅Do not use a pressure sensor nearby a place where electric surges are generated.

Internal circuit elements of the pressure sensor can deteriorate or break when equipment generating a large surge

(electromagnetic lifter, high frequency induction furnace, motor, etc.) is located near the pressure sensor. Provide surge

preventives, and avoid interference.

⋅Do not apply the pressure sensor to the load that generates electric surge voltage.

Relays or solenoid values generate electric surge voltage. When applying the pressure sensor to drive these loads

directly, use the product equipped with surge absorber.

⋅The product is not resistive to a lightning surge defined in CE marking. Take measures to protect against a

lightning surge at the load side.

⋅Prevent foreign matter such as remnant of wires from entering this product.

Take proper measures for the remnant not to enter the pressure sensor in order to prevent failure or malfunction.

⋅Do not expose the pressure sensor to vibration (less than 98 m/s2), and impact (less than 980 m/s2).

Otherwise it can cause damage or malfunction.

⋅Follow the specified ranges of the operating fluid and maintain ambient temperatures.

The operating fluid and ambient temperatures should be in the range of 0 to 50 °C. When operating at low temperature

of 5°C or below, breakage or malfunction can occur to the pressure sensor due to freezing of condensed water in the

pressurized air. Take preventive measures against freezing. Do not use the pressure sensor in a place where

temperature suddenly changes even if it stays within the specified range.

⋅Do not expose the pressure sensor to heat radiation from a heat source located nearby.

It can cause malfunction.

•Adjustment and Operation

⋅Do not short-circuit the load.

Excess current can damage the pressure sensor.

⋅A warm-up time of 20 to 30 minutes is needed for detection of low pressure.

The indication drifts about ±1% soon after the power is on.

•Maintenance

⋅Before performing maintenance, make sure to turn off the power supply.

Otherwise an unexpected operation of the system component can occur.

⋅Perform maintenance and check regularly.

Otherwise an unexpected malfunction of the system can occur due to a malfunction of the pressure sensor.

⋅Perform a proper functional check after maintenance.

Stop operation when an abnormality is observed such that the device does not work properly. Otherwise an unexpected

malfunction of the system component can occur.

Do not use solvents such as benzene or thinner to clean the pressure sensor body.

It can damage the surface of the body and erase the indication on the body.

Use a soft cloth to remove stains. For heavy stains, use a cloth soaked with diluted neutral detergent and fully squeezed

then wipe up the stains again with a dry cloth.

- 5 -

PS##-OMG0004