- 6 -

2.Specific Product Precautions (3)

Caution

(1)Install an air filter.

Install an air filter at the upstream side of valve.

Select an air filter with a filtration degree of 5μm

or finer.

(2)Install an aftercooler, air dryer or water

droplet separator, etc.

Compressed air that contains a large amount of

drainage can cause malfunction of pneumatic

equipment. Therefore, take appropriate

measures to ensure air quality, such as by

providing an aftercooler, air dryer, or water

droplet separator.

(3)Ensure that the fluid and ambient

temperature are within the specified range.

If the fluid temperature is 5℃or less, the

moisture in the circuit could freeze, causing

damage to the seals and leading to equipment

malfunction. Therefore, take appropriate

measures to prevent freezing.

For details on the above compressed air quality,

refer to SMC's Best Pneumatics catalog.

Warning

(1)Do not use in an atmosphere having

corrosive gases, chemicals, sea water, water,

water steam, or where there is direct contact

with any of these.

Refer to each construction drawing on the fittings

and tubing material.

(2)Do not expose the product to direct sunlight

for an extended period of time.

(3)Do not use in a place subject to heavy

vibration and/or shock.

(4)Do not mount the product in locations where

it is exposed to radiant heat.

(5)Do not use the ordinary fittings and tubing in

locations where static electricity would be

problematic.

It may result in the system failure and trouble. In

such places, use of antistatic fittings (Series KA)

and antistatic tubing (Series TA) are

recommended.

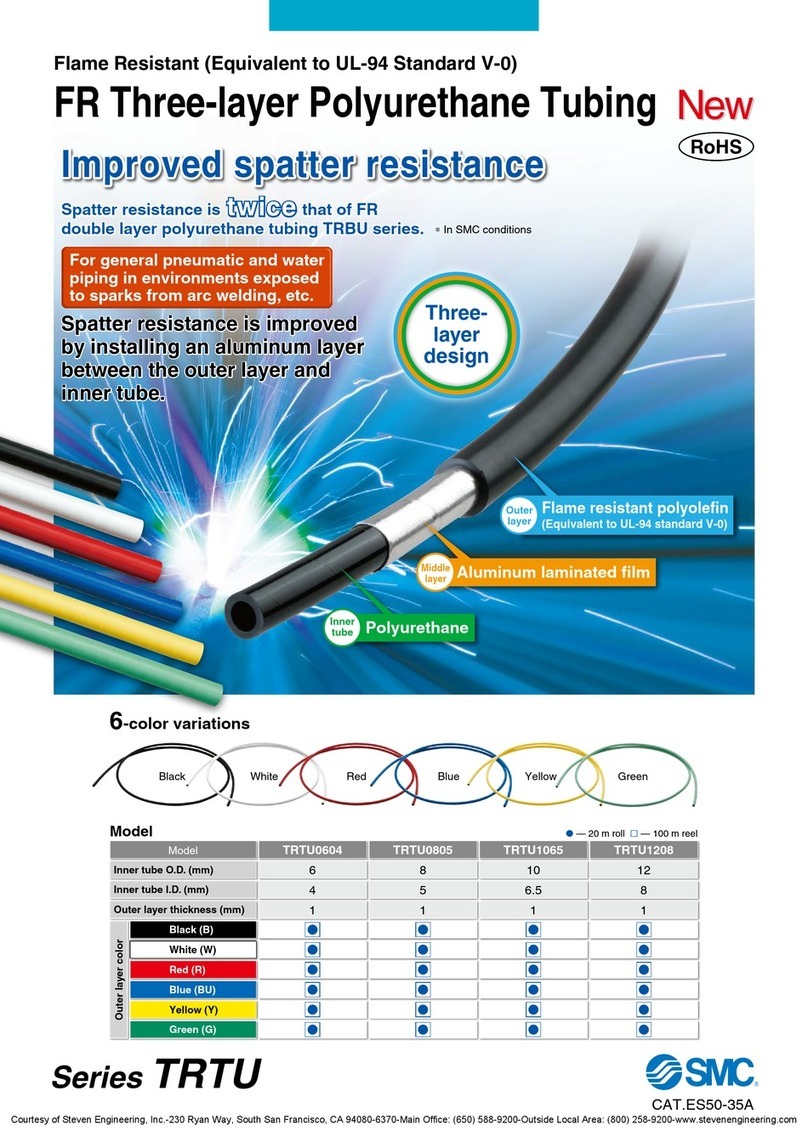

(6)Do not use the ordinary fittings and tubing in

locations where spatter is generated.

Spattering may result in a fire hazard. In such a

place, use of flame resistant fittings (Series

KR/KRM) and flame resistant tubing (Series

TRS/TRB) are recommended.

(7)Do not use in an environment where the

product is directly exposed to cutting oil,

lubricant, coolant oil, etc.

Please contact SMC if using for an environment

exposed to cutting oil, lubricant or coolant oil,

etc.

(8)Take note that if nylon tubing and soft nylon

tubing are used in a clean room.

The antioxidant on the surface of the soft nylon

tubing may come off, thereby lowering the

cleanness level.

(9)Do not use in environment where foreign

matter may stick to the product or get mixed in

the product's interior.

This may cause leakage or disconnection of the

tubing.

(10)Avoid installing and using fittings inside a

food zone.

・Not installable

Food zone---An environment where food which

will be sold as merchandise,

directly touches the fitting

components.

・Installable

Splash zone---An environment where food which

will not be sold as merchandise,

directly touches the fitting

components.

Non-food zone---An environment where there is

no contact with food.

Warning

(1)Perform maintenance inspection according to

the procedures indicated in the operation

manual.

If handled improperly malfunction and damage of

machinery or equipment may occur.

(2)Maintenance work

If handled improperly, compressed air can be

dangerous. Assembly, handling, repair and

element replacement of pneumatic systems

should be performed by a knowledgeable and

experienced person.

(3)Drain flushing

Remove drainage from air filters regularly.

(4)Removal of equipment, and supply/exhaust

of compressed air

When components are removed, first confirm that

measures are in place to prevent workpieces

from dropping, run-away equipment, etc. Then,

cut off the supply pressure and electric power,

and exhaust all compressed air from the system

using the residual pressure release function.

When machinery is restarted, proceed with

caution after confirming that appropriate

measures are in place to prevent cylinders from

sudden movement.

Caution

(1)Be certain to wear safety glasses at all times

during periodical inspections.

(2)Replace fittings or tubing having the

following problems.

a)Cracks, gouges, wearing, corrosion

b)Air leakage

c)Twists or crushing of tubing

d)Hardening, deterioration, softening of tubing

(3)When replacing tubes or fittings, do not try

to mend or repair and then reuse them.

Air Supply

Operating Environment

Maintenance