LV Series

High Purity Chemical Liquid Valve

Precautions 2

Be sure to read this before handling the products.

Refer to the back cover for Safety Instructions.

1. Maintenance should be performed in accordance with

the procedures in the Operation Manual.

Incorrect handling can cause damage or malfunction of machin-

ery and equipment, etc.

2. Before removing equipment or compressed air supply/

exhaust devices, shut off the air and power supplies,

and exhaust compressed air from the system.

Further, when restarting equipment after remounting

or replacement, first confirm safety and then check

the equipment for normal operation.

3.

Perform work after removing residual chemicals and careful-

ly replacing them with DI water (Deionized water) or air, etc.

4. Do not disassemble the product. Products which have

been disassembled cannot be guaranteed.

If disassembly is necessary, please contact SMC.

5. In order to obtain optimum performance from valves,

perform periodic inspections to confirm that there are

no leaks from valves or fittings, etc.

Maintenance

Warning

Handling

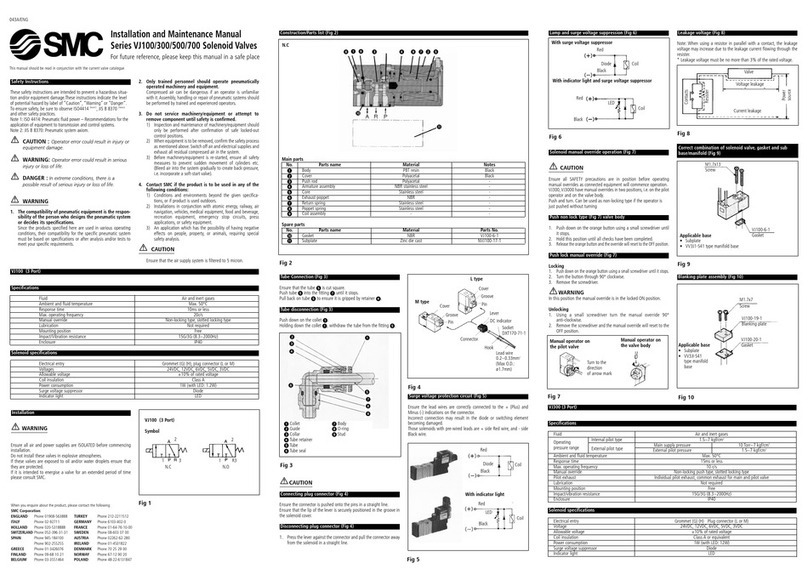

1. When the diaphragm is made of PTFE

Please note that when the product is shipped from the factory,

gases such as N2and air may leak from the valve at a rate of

1 cm3/min (when pressurized).

2.

When operated at a very low flow rate, the LVmseries with

flow rate adjustment may vibrate, etc. depending on the

operating conditions. Therefore, operate it after careful

examination of the flow rate, pressure and piping conditions.

3.

In the LVmseries, water hammering may occur

depending on the fluid pressure conditions. In most

cases, improvement is possible by adjusting the pilot

pressure with a speed controller, etc., but the flow rate,

pressure and piping conditions should be reviewed.

4.

To adjust the flow rate for the LVmseries with flow rate

adjustment, open gradually starting from the fully closed

state.

Opening is accomplished by turning the adjustment knob

counterclockwise. Additionally, do not apply excessive

force to the adjustment knob when nearing a fully open or

closed state. This may result in deformation of the orifice

sheet surface or damage to the threaded portion of the

adjustment knob. It is in the fully closed state when the

product is shipped from the factory.

5. After a long period of nonuse, perform a test run

before beginning regular operation.

1. Removal of drainage

Flush drainage from filters regularly.

Caution

1. Do not use in a location having an explosive atmo-

sphere.

2. Do not operate in locations where vibration or im-

pact occurs.

3. Do not use in locations where radiated heat will be

received from nearby heat sources.

4. Do not use in environments which exceed the ambi-

ent temperature specifications of the product.

Operating Environment

Warning

1. Use clean air.

Do not use compressed air which includes chemicals, syn-

thetic oils containing organic solvents, salt, or corrosive gases,

etc., as this may cause damage or malfunction.

Operating Air Supply

Warning Caution

1. Operate within the ranges of the maximum operat-

ing pressure and back pressure.

Handling

Warning

-5-

Warning

If the product to be returned is contaminated or is

possibly contaminated with substances that are harm-

ful to humans, for safety reasons, please contact SMC

beforehand and then employ a specialist cleaning

company to decontaminate the product. After the de-

contamination prescribed above has been carried out,

submit a Product Return Request Sheet or the Detoxi-

fication/Decontamination Certificate to SMC and await

SMC’s approval and further instructions before at-

tempting to return the item.

Please refer to the International Chemical Safety

Cards (ICSC) for a list of harmful substances.

If you have any further questions, please don’t hesi-

tate to contact your SMC sales representative.

Return of Product