50-VFE-SMY62EN

Page 1 of 4

Instruction Manual

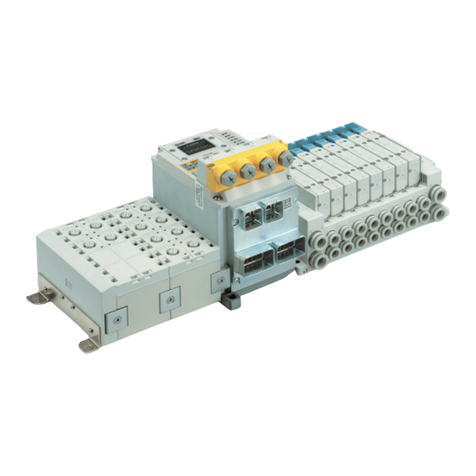

Solenoid operated 3 and 5 port valves

50-VFE/VPE-X60, 50-VFE3#90-X60 NAMUR

For ISO symbols see section 3.4.

The intended use of this product is to provide directional control to

pneumatic actuators (or similar industrial pneumatic equipment).

1 Safety Instructions

1.1 General safety instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety. etc.

Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

Always ensure compliance with relevant safety laws and

standards.

All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

The product is only suitable for use in Zones 1 and 2.

Do not open when energised.

Do not energise both solenoids at the same time, as this can cause

higher surface temperatures than under normal operating conditions.

Do not refurbish the flameproof joints.

1 Safety Instructions - continued

Electrostatic charge may cause an explosion hazard.

Avoid any actions that cause the generation of electrostatic charge,

such as rubbing with a dry cloth on coating face of product.

Electrostatic charges on the non-metallic parts of the equipment shall

be avoided.

This product has components made of aluminium alloy. When

mounting this product, it must be installed such that, even in the event

of rare incidents, ignition sources due to impact and friction sparks are

excluded.

Use of 50-VFE3000/5000-X60 5-port valve as a 3-port valve

Series 50-VFE3000/5000-X60 valves can be used as normally closed

(N.C.) or normally open (N.O.) 3 port valves by closing one of the

cylinder ports (A or B) with a plug (see Table 1).

Note: Do not exceed the maximum specified operating frequency.

Table 1

1.2 Special conditions for safe use

Warning

The solenoid valves are provided with special fasteners of property

class A2-50.

The manufacturer shall be contacted for information regarding the

flameproof joints.

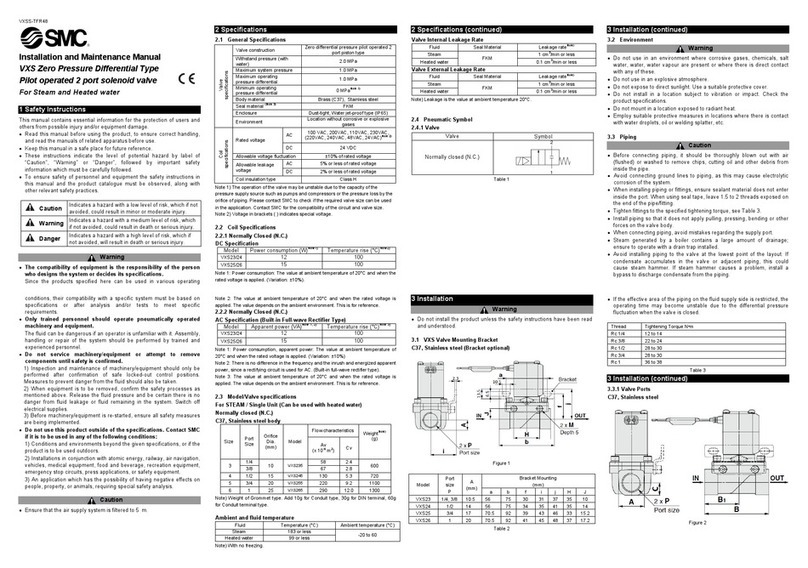

2 Specifications

2.1 General specifications

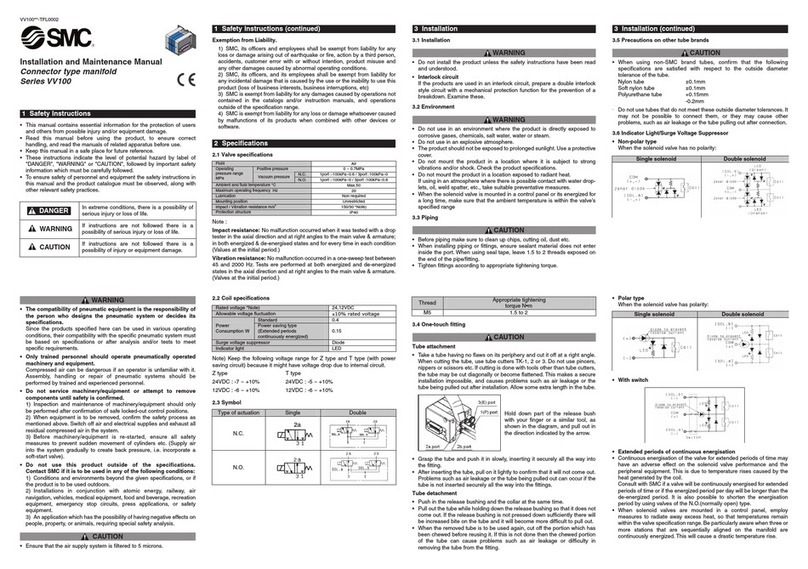

SERIES 50-VFE3000/5000-X60 SOLENOID VALVE

Ambient and fluid temperature

(No freezing)

Max. operating

frequency(1)

Impact/Vibration resistance (2)

SERIES 50-VPE500/700-X60 SOLENOID VALVE

N.C or N.O. (convertible)

Ambient and fluid temperature

(No freezing)

-10 to 50°C (T5)

-10 to 40°C (T6)

Max. operating frequency(1)

Impact/Vibration resistance (2)

2 Specifications - continued

SERIES 50-VFE3#90-X60 NAMUR SOLENOID VALVE

N.C or N.O. (convertible)

Ambient and fluid temperature

(No freezing)

-10 to 50°C (T5)

-10 to 40°C (T6)

Max. operating frequency(1)

Impact/Vibration resistance (2)

Note 1) Do not exceed the maximum specified operating frequency.

Note 2) Impact resistance: There should be no malfunction of the valve after testing

along the valve axis and at right angles to the valve and armature. Carry out each

test with the valve energised and de-energised (value at initial stage).

Vibration resistance: There should be no malfunction of the valve after testing using

a 8.3 to 2000Hz sweep along the valve axis and at right angles to the valve and

armature. Carry out each test with the valve energised and de-energised (value at

initial stage).

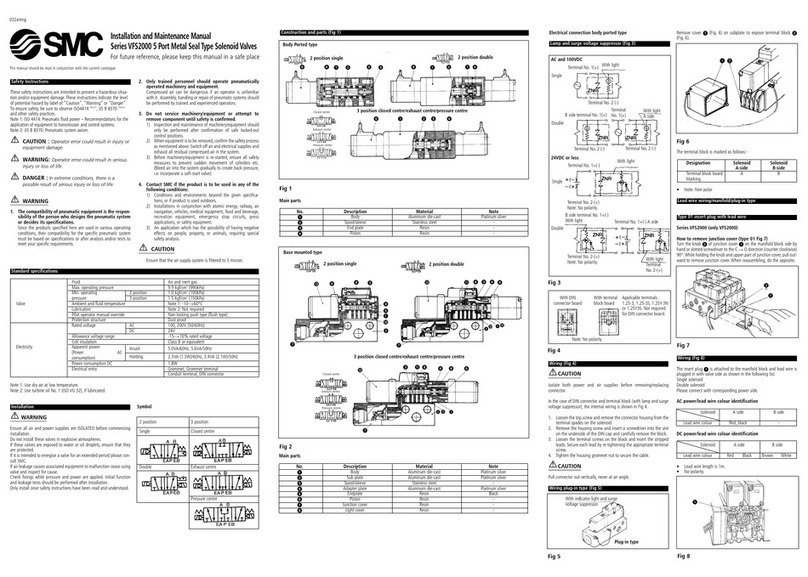

SERIES 50-VF3-#-X60 PILOT VALVE

External connection method

Metal conduit type/ (Cable gland type)

100, 200, 12, 24,

48, 110, 220, 240V

Allowable voltage fluctuation

-15% to +10% of rated voltage

9.1VA (50Hz) 7.8VA (60Hz)

6.2VA (50Hz) 4.6VA (60Hz)

Batch codes and Construction month:

The product control number is shown by two characters and two figures.

The character shows Year and Month of manufacturing.

The figures show a serial number stamp.

This stamp indicates the year and month of production, the month of the

production request and the order in which work order has been

processed.

3 Installation

3.1 Installation Warning

Do not install the product unless the safety instructions have been read

and understood.

3.2 Environment Warning

The product is only suitable for use in Zones 1 and 2.

Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

Do not expose to direct sunlight. Use a suitable protective cover.

Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product’s specifications.

When the solenoid valve is mounted in a control panel or is energised

for a long time, make sure the ambient temperature is within the valve

specification range.

3 Installation - continued

3.3 Piping Caution

Before connecting piping make sure to clean up chips, cutting oil, dust

etc.

When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

Tighten fittings to the specified tightening torque, see Table 2.

Table 2

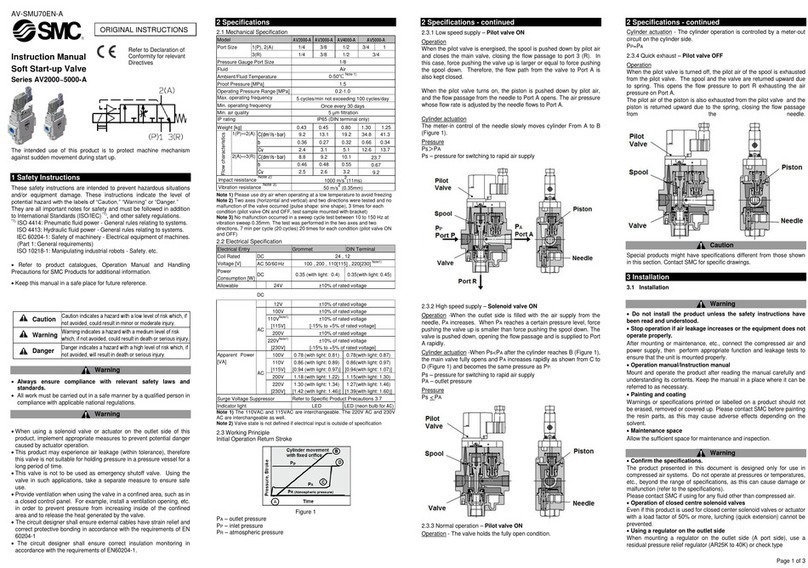

3.4 ISO symbols

50-VPE5(7)42(R)

N.C.

N.O.

C.O.

50-VFE3/5000

5/2 Single

5/2 Double

5/3 Closed

centre

5/3 Exhaust

centre

5/3 Pressure

centre

3.5 Electrical entry (see Figure 1)

The terminal box can be rotated 300° about plane ‘A’.

Loosen screw ‘C’ and rotate the terminal box to the desired position.

Re-tighten screw to lock the terminal box in position.

The cover can be rotated 360° about plane ‘B’.

Undo screw ‘D’ and rotate the cover to the desired position – there are

4 positions –in increments of 90°.

Re-assemble screw to lock the cover in place.

Construction

Year / M onth Jan Feb M ar Apr M ay Jun Jul Aug Sep Oct Nov Dec

2019 Xo XP XQ XR XS XT XU XV XW XX Xy XZ

2020 yo yP yQ yR yS yT yU yV yW yX yy yZ

… … … … … … … … … … … … …

2024 Co CP CQ CR CS CT CU CV CW CX Cy CZ

ATEX Classification:

II 2G Ex db IIC T6..(T5) Gb -10°C ≤ Ta ≤ +40°C(+50°C)

Certificate reference: KEMA 09ATEX0024 X

‘X’ Special conditions of safe use apply, see section 1.2.

Refer to Declaration of

Conformity for relevant

Directives