- 5 -

No.SYJ300-OMO0002-A

Piping

1. Refer to the Fittings and Tubing

Precautions for handling one-touch

fittings.

2. Preparation before piping

Before piping is connected, it should be thoroughly

blown out with air (flushing) or washed to remove chips,

cutting oil and other debris from inside the pipe.

3. Wrapping of pipe tape

When screwing piping or fittings into ports, ensure that

chips from the pipe threads or sealing material do not

enter the piping. Also, if pipe tape is used, leave 1

thread ridges exposed at the end of the threads.

4. Connection of fittings

When screwing fittings into valves, tighten as follows.

(1) Follow the procedures below when installing an

SMC fitting, etc.

1) M3

After tightening the fitting by hand, use a wrench to

tighten the fitting an additional approximately 1/4

turn. As a reference valve, tightening torque is 0.4

to 0.5N・m.

2) M5

After tightening the fitting by hand, use a wrench to

tighten the fitting an additional approximately 1/6 to

1/4 turn. As a reference value, tightening torque is 1

to 1.5 N・m.

Note) If tightened excessively, the thread of the

product may break or the gasket may deform. If

tightened insufficiently, the thread of the product

may become loose. In either case, air leakage

can occur.

(2) Follow the procedure of the manufacture when

fittings other than SMC is used.

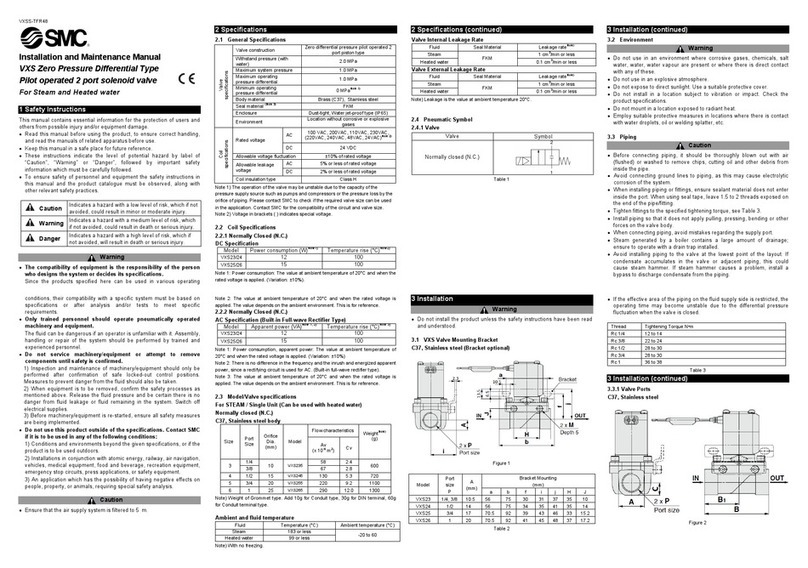

3) Rc type

Tighten with the proper torque shown below.

Tightening Torque for Piping Applicable

Connection

thread Proper tightening torque

(N・

・・

・m)

Rc1/8 7 to 9

5. Piping to products

When piping to a product, avoid mistakes regarding the

supply port, etc.

Lubrication

1. Lubrication

1) The valve has been lubricated for life by the factory

and does not require any further.

2) If a lubricant is used in the system, use class 1

turbine oil (no additive), ISO VG32.

Once a lubricant is used in the system, lubrication

must be continued because the original lubricant

applied during manufacturing will be washed away.

If turbine oil is used, refer to the Material Safety Data

Sheet (MSDS) of the oil.

Air Supply

1.

Type of fluids

Please consult with SMC when using the product in

applications other than compressed air.

2.

When there is a large amount of drainage.

Compressed air containing a large amount of drainage

can cause malfunction of pneumatic equipment. An air

dryer or water separator should be installed upstream

from filters.

3.

Drain flushing

If condensation in the drain bowl is not emptied on a

regular basis, the bowl will overflow and allow the

condensation to enter the compressed air lines. It

causes malfunction of pneumatic equipment. If the

drain bowl is difficult to check and remove, installation

of a drain bowl with an auto drain option is

recommended.

For compressed air quality, refer to SMC’s Best

Pneumatics catalog.

4. Use clean air

Do not use compressed air that contains chemicals.

Synthetic oils including organic solvents, salt or

corrosive gases, etc., as it can cause damage or

malfunction.

1. When extremely dry air is used as the

fluid, degradation of the lubrication

properties in side the equipment may

occur, resulting in reduced reliability (or

reduced service life) of the equipment.

Please consult with SMC.

2. Install an air filter.

Install an air filter upstream near the valve. Select an

air filter with a filtration size of 5 µm or smaller.

3. Take measures to ensure air quality,

such as by installing an aftercooler, air

dryer, or water separator.

Compressed air that contains a large amount of

drainage can cause malfunction of pneumatic

equipment such as valves. Therefore, take

appropriate measures to ensure air quality, such as by

providing an aftercooler, air dryer, or water separator.

Caution Warning

Warning

Caution

SYJA300/3000 Series

Precautions for 5 Port Solenoid Valve ②

②②

②

Be sure to read before handling. Refer to main text for detailed precautions on every series.