55-VPA-SMX85EN-A

Page 1 of 2

Instruction Manual

Air operated 3 port valves

55-VPA(-1) 300/500/700 Series

The intended use of this product is to provide directional control to

pneumatic actuators (or similar industrial pneumatic equipment).

1 Safety Instructions

1.1 General safety instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety. etc.

•Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

•Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and

standards.

•All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

1.2 Special conditions of use Warning

• Protect from impacts using an ATEX compliant enclosure.

• To avoid the build-up of electrostatic charge, do not mount in areas

subject to electrostatic charging mechanisms and clean only with a

damp cloth and allow to dry naturally.

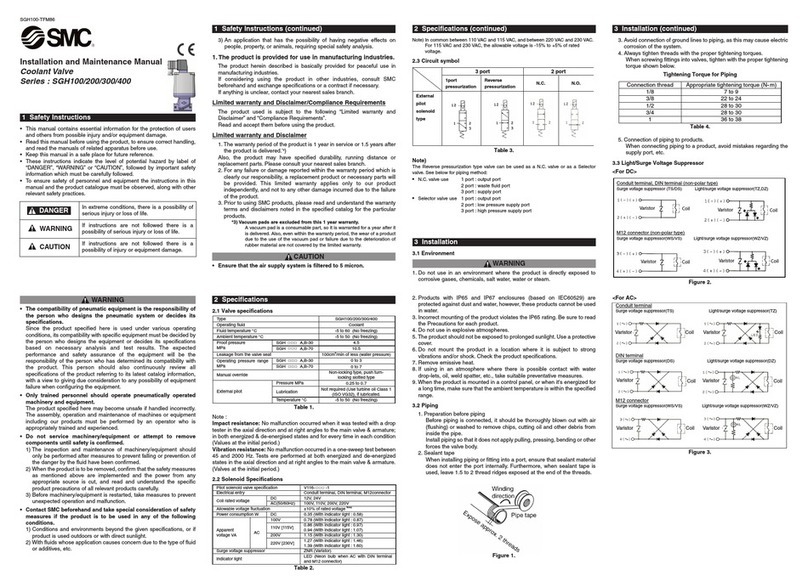

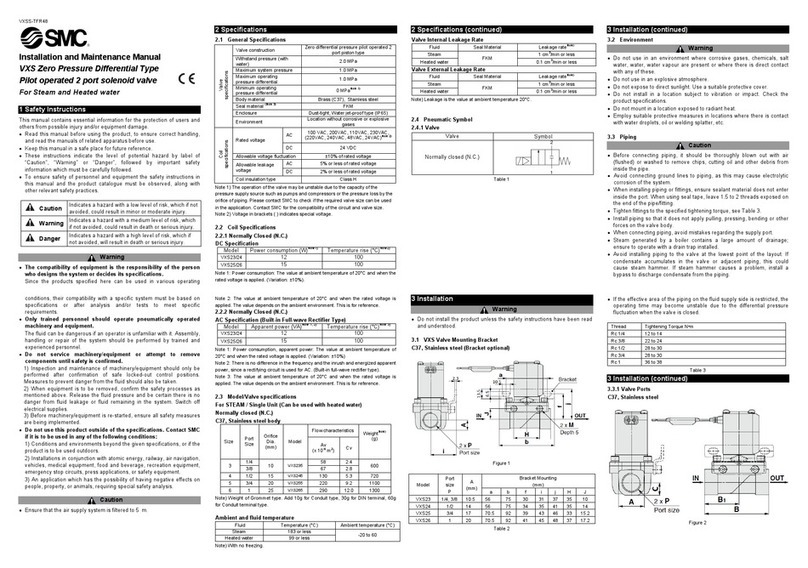

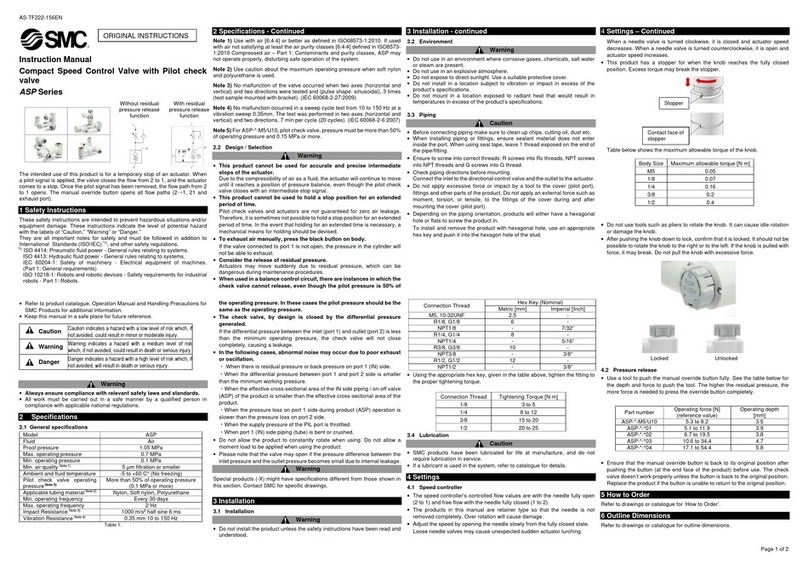

2 Specifications

2.1 Valve specifications

N.C or N.O. (Convertible)

Operating pressure range (MPa)

0.2 to 1.0 (Equivalent to the

operating pressure or more)

Maximum operating frequency (Hz)

Ambient and fluid temperature (°C)

Impact/Vibration resistance (m/s) Note

1)

Note 1) Impact resistance: No malfunction to axis and right angle

directions of main valve, each one time when pilot signal ON and OFF

(Values at the initial period).

Vibration resistance: No malfunction from test with 45 to 2000

Hz one sweep, to axis and right angle direction of main valve, each one

time when pilot signal ON and OFF (Values at the initial period).

Note 2) For general specifications (materials, flow rate, dimensions,

weight) please refer to the catalogue for the standard VPA(-1) Series.

2.2 Production batch codes

Note: The batch code is included on the product label.

3 Installation

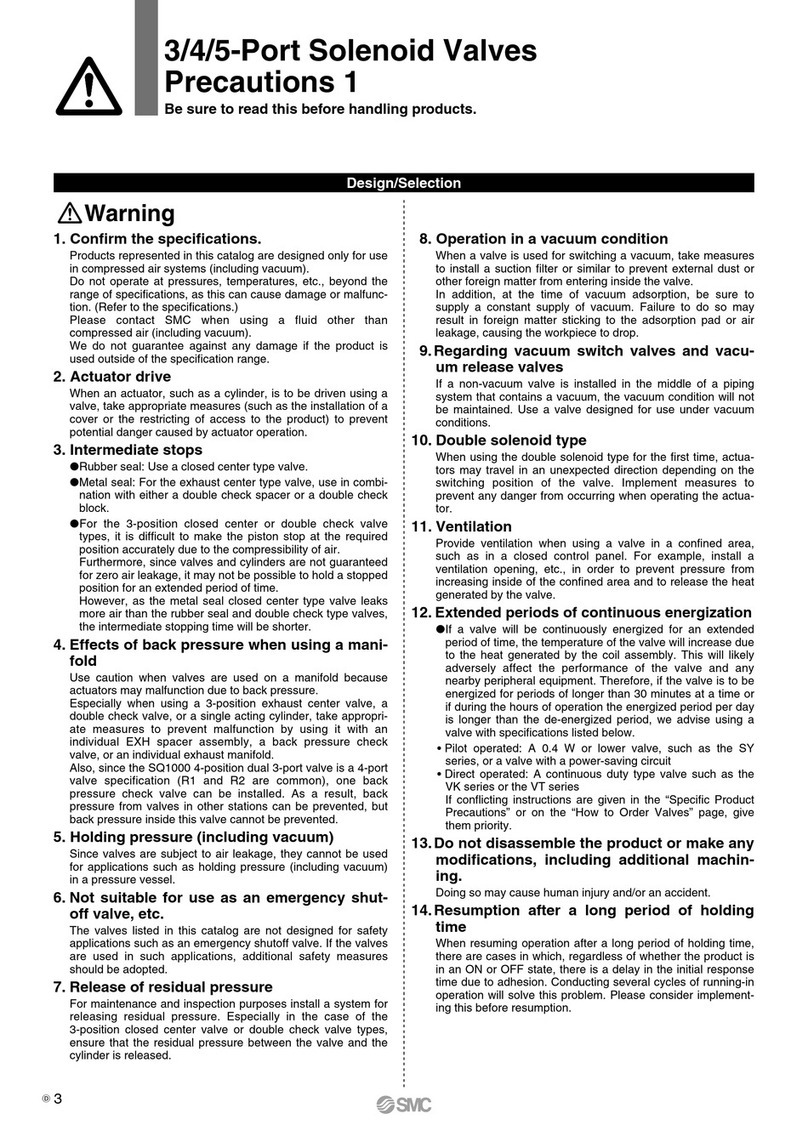

3.1 General Warning

•Do not install the product unless the safety instructions have been read

and understood.

•Protect from impacts using an ATEX compliant enclosure.

3.2 Vacuum type valves: Caution

•When using vacuum type valves, please note that the Ex atmosphere

could be drawn into the pneumatic circuit via the pilot exhaust port

(breathing hole) of the valve. This port is threaded, allowing it to be

piped outside of the Ex zone if necessary. See fig.1 for location of

breathing hole (55-VPA3*-1 shown as an example).

3.3 Torque values for valves mounted on sub-base and manifold.

Caution

Valves are attached to the manifold/sub-base with 2 mounting screws.

Tighten the mounting screws to the appropriate tightening torque.

3 Installation (continued)

3.4 Environment Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product’s specifications.

•Do not mount in areas subject to electrostatic charging mechanisms.

3.5 Piping Warning

•When using the vacuum type valves, consideration must be given to

the piping of the pilot exhaust, see section 3.2 for details.

•The function of body ported valves can be changed by rotating the end

plate, see section 4.2 for details.

Caution

•Before connecting piping make sure to clean up chips, cutting oil, dust

etc.

•When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

•For details regarding pipe sizes, please refer to the catalogue for the

standard VPA(-1) Series.

•Tighten fittings to the specified tightening torque.

Note: For connection thread M5, first tighten by hand then use a suitable

wrench to tighten the fitting an additional 1/6 to 1/4 turn. The reference

value for the tightening torque is 1 to 1.5 N•m.

3.6 Lubrication Caution

•SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

•If a lubricant is used in the system, refer to the catalogue for the

standard VPA(-1) Series for information.

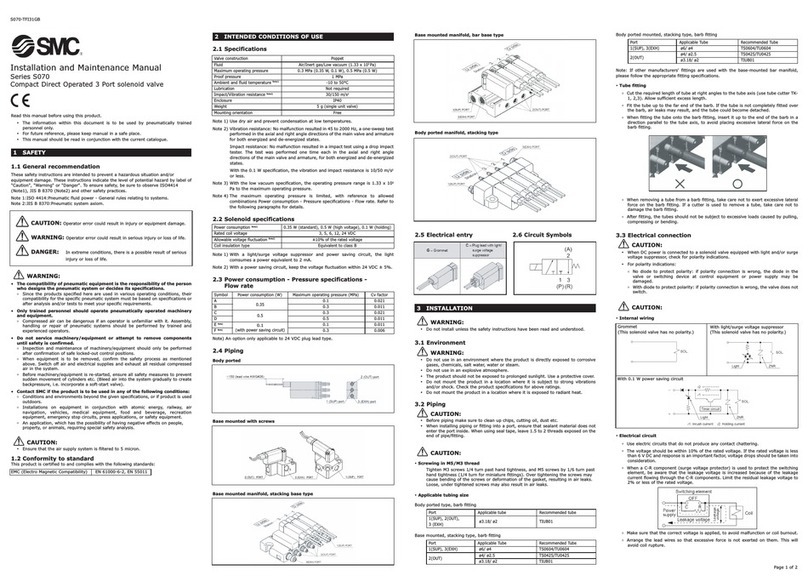

4 Settings

4.1 Change of Base Mount valve function

The function of base mount type valves can be switched between

normally closed (N.C.) and normally open (N.O.).

•Sub-base mounted

Example showing change from N.C. to N.O. See fig.2.

Remove the valve body from the sub-base and reset the “” mark on

the body corresponding to the “N.O.” mark on the sub-base.

Then remove the end plate from the valve body and rotate it 180° so

that the “N.O.” mark is at the top of the valve.

Note: It is not necessary to remove the sub-base piping when

performing this change.

4 Settings (continued)

•Manifold mounted

When 55-VPA(-1) valves are mounted on a manifold the orientation of

the valve determines the function (NC or NO). Fig.3 shows valves A

and B configured as NC and valves C and D configured as NO.

4.2 Change of Body port valve function

•The function (NO and NC) of the body ported valves is indicated by the

mark on the top of the end plate, see fig.4.

•To change the function from NC to NO, remove the end plate from the

body and rotate it 180°so that the NO mark is now at the top, see fig.5.

•Change the piping as shown below.

5 How to order

5.1 Valves

Body port: 55-VPA#42#-1-###-#(-X505)

Base mount: 55-VPA#44#-1-###

Please contact SMC for details.

5.2 Sub-plates and Manifolds.

Standard VP#00* sub-bases and VV3PA#* manifolds (including

blanking plates) are used for 55-VPA(-1) valves. Please refer to the

catalogue for the standard VPA(-1) Series.

6 Outline Dimensions

The 55-VPA(-1) Series has the same dimensions as the standard VPA(-

1) Series please refer to the catalogue for the standard VPA(-1) Series.

7 Maintenance

7.1 General Maintenance Caution

•Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

•If handled improperly, compressed air can be dangerous.

Maintenance of pneumatic systems should be performed only by

qualified personnel.

•Before performing maintenance, turn off the power supply and besure

to cut off the supply pressure. Confirm that the air is released to

atmosphere.

Construction

Year / M onth Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

2019 Xo XP XQ XR XS XT XU XV XW XX Xy XZ

2020 yo yP yQ yR yS yT yU yV yW yX yy yZ

… … … … … … … … … … … … …

2024 Co CP CQ CR CS CT CU CV CW CX Cy CZ

Connection thread size (R, NPT)

ATEX classification: II 2 G Ex h IIB T6 Gb -10°C ≤ Ta ≤ +50°C

II 2 D Ex h IIIB T70°C Db

Certificate reference: SMC 19.0052 X

For special conditions of use see section 1.2.

Refer to Declaration of

Conformity for relevant

Directives